Abstract

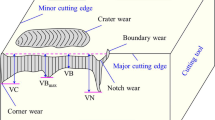

Hard turning is becoming an usual way to replace grinding operations and is performed with ceramics and cubic boron nitride tools. However, tool inserts are brittle and may be subjected to wear and damage mechanisms like chipping and breakage. The damages are intensified in internal turning operations, where the tool holder presents lower rigidity than in external turning, making it subjected to higher vibrations. Most works analyze chatter (unstable cut) conditions, and a gap remains over the effects of stable cut vibrations. Therefore, this work conducted internal turning tests of hardened AISI 4340 steel in a 24 full factor design (tool holder material, overhang, cutting speed and feed) in order to verify the effects of these factors on tool vibration, tool life and wear mechanisms. Under stable cut, tool accelerations were 2 times higher for steel bars, when compared to carbide bar. Tool life (in terms of volume of material removed) was not affected by tool vibration and remained around 120,000 mm3 of material removed. The main conclusion of this work was that tool vibration, in the levels obtained in this work, did not influence tool life, but its growth made tool wear mechanism to change from diffusion to abrasion.

Similar content being viewed by others

References

Klocke F, Brinksmeier E, Weinert K (2005) Capability profile of hard cutting and grinding processes. CIRP Ann 54(2):22. https://doi.org/10.1016/S0007-8506(07)60018-3

Mallick R, Kumar R, Panda A, Sahoo AK (2020) Performance characteristics of hardened AISI D2 steel turning: a review. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.02.565

Astakhov V (2011) Definitions and industrial applications. In: Davim J (ed) Machining of hard materials, vol 1, pp 1–32. https://doi.org/10.1007/978-1-84996-450-0_2

König W, Berktold A, Koch K-F (1993) Turning versus grinding—a comparison of surface integrity aspects and attainable accuracies. CIRP Ann 42(1):39. https://doi.org/10.1016/S0007-8506(07)62387-7

Tönshoff HK, Arendt C, Ben Amor R (2000) Cutting of hardened steel. CIRP Ann 49(2):547. https://doi.org/10.1016/s0007-8506(07)63455-6

Abrão AM, Aspinwall DK (1996) The surface integrity of turned and ground hardened bearing steel. Wear 196:279. https://doi.org/10.1016/0043-1648(96)06927-X

Majerik J, Barényi I, Eckert M (2019) Investigation of mechanical properties of hard finish turned and grinded surfaces. Procedia Struct Integr 23:541–546. https://doi.org/10.1016/j.prostr.2020.01.142

Patel VD, Gandhi AH (2019) Analysis and modeling of surface roughness based on cutting parameters and tool nose radius in turning of AISI D2 steel using CBN tool. Measurement 138:34–38. https://doi.org/10.1016/j.measurement.2019.01.077

Anand A, Behera AK, Das SR (2019) Economic machining of hardened steels by hard turning and its process variables. Manuf Rev 6:1–9. https://doi.org/10.1051/mfreview/2019002

Das SR, Panda A, Dhupal D (2018) Hard turning of AISI 4340 steel using coated carbide insert: surface roughness, tool wear, chip morphology and cost estimation. Mater Today Proc 5:6560–6569. https://doi.org/10.1016/j.matpr.2017.11.311

Machado ÁR, Abrão AM, Coelho RT, Silva MB (2009) Materiais para ferramentas de corte. Teoria da Usinagem dos Materiais 1:176

Godoy VAA, Diniz AE (2011) Turning of interrupted and continuous hardened steel surfaces using ceramic and CBN cutting tools. J Mater Process Technol 211(6):1014. https://doi.org/10.1016/j.jmatprotec.2011.01.002

López de Lacalle LN, Lamikiz A, Fernández de Larrinoa J, Azkona I (2011) Advanced cutting tools. In: Davim J (ed) Machining of hard materials, vol 1, pp 33–86. https://doi.org/10.1007/978-1-84996-450-0_2

Lahiff C, Gordon S, Phelan P (2007) PCBN tool wear modes and mechanisms in finish hard turning. Robot Comput Integr Manuf 23:638. https://doi.org/10.1016/j.rcim.2007.02.008

Matsuda Y, Okamura K, Uesaka S, Fukaya T (2012) Development of new grade “SUMIBORON BN7000” for cast iron and ferrous powder metal machining. SEI Tech Rev 75:13

Coromant S (2012) Hard part turning with CBN, pp 1–44. https://www.sandvik.coromant.com/sitecollectiondocuments/downloads/global/catalogues/en-gb/c-2940-137.pdf

Gordon S, Phelan P, Lahiff C (2019) The effect of high speed machining on the crater wear behaviour of PCBN tools in hard turning. Procedia Manuf 38:1833–1848. https://doi.org/10.1016/j.promfg.2020.01.076

Zhang S, Zhu W (1993) TiN coating of tool steels: a review. J Mater Process Technol 39(1–2):165. https://doi.org/10.1016/0924-0136(93)90016-Y

Rickerby DS, Newbery RB (1988) Structure, properties and applications of TiN coatings produced by sputter ion plating. Vacuum 38(3):161. https://doi.org/10.1016/0042-207X(88)90172-8

Shaw MC (2005) Wear and tool life. Met Cutt Princ 2:170

Poulachon G, Bandyopadhyay BP, Jawahir IS, Pheulpin S, Seguin E (2004) Wear behavior of CBN tools while turning various hardened steels. Wear 256:302. https://doi.org/10.1016/S0043-1648(03)00414-9

Luo SY, Liao YS, Tsai YY (1999) Wear characteristics in turning high hardness alloy steel by ceramic and CBN tools. J Mater Process Technol 88(1–3):114. https://doi.org/10.1016/S0924-0136(98)00376-8

Machado ÁR, Diniz AE (2017) Tool wear analysis in the machining of hardened steels. Int J Adv Manuf Technol 92(9–12):4095. https://doi.org/10.1007/s00170-017-0455-2

Diniz AE, Marcondes FC, Coppini NL (2013) Avarias e desgastes da ferramenta. Tecnologia da Usinagem dos Materiais 8:107

Uhlmann E, Riemer H, Schröter D, Henze S, Sammler F, Barthelmä F, Frank H (2018) Investigation of wear resistance of coated PcBN turning tools for hard machining. Int J Refract Metal Hard Mater 72:270. https://doi.org/10.1016/j.ijrmhm.2017.12.011

Panda A, Das SR, Dhupal D (2018) Hard turning of HSLA steel with coated ceramic inserts: an assessment, modelling, optimisation and cost analysis. Int J Autom Mech Eng 15:5890–5913. https://doi.org/10.15282/ijame.15.4.2018.13.0450

Boing D, Schroeter RB, Oliveira AJ (2018) Three-dimensional wear parameters and wear mechanisms in turning hardened steels with PCBN tools. Wear 398–399:69. https://doi.org/10.1016/j.wear.2017.11.017

Tang L, Sun Y, Li B, Shen J, Meng G (2019) Wear performance and mechanisms of PCBN tool in dry hard turning of AISI D2 hardened steel. Tribol Int 132:228–236. https://doi.org/10.1016/j.triboint.2018.12.026

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Huo D, Cheng K (2009) Basics concepts and theory. In: Cheng K (ed) Machining dynamics - fundamentals, applications and practices, vol 1, pp 7–20. https://doi.org/10.1007/978-1-84628-368-0

Chou YK, Evans CJ (1999) Cubic boron nitride tool wear in interrupted hard cutting. Wear 225–229:234. https://doi.org/10.1016/S0043-1648(99)00012-5

Oliveira AJ, Diniz AE, Ursolino DJ (2009) Hard turning in continuous and interrupted cut with PCBN and whisker-reinforced cutting tools. J Mater Process Technol 209:5262. https://doi.org/10.1016/j.jmatprotec.2009.03.012

Siddhpura M, Paurobally R (2012) A review of chatter vibration research in turning. Int J Mach Tools Manuf 61:27. https://doi.org/10.1016/j.ijmachtools.2012.05.007

Coromant S (ed) (2015) Turning tools. In: Main catalogue A1-A284

Suyama DI, Diniz AE, Pederiva R (2017) Tool vibration in internal turning of hardened steel using cBN tool. Int J Adv Manuf Technol 88:2485–2495. https://doi.org/10.1007/s00170-016-8964-y

Thomas W, Diniz AE, Pederiva R, Suyama DI, de Albuquerque MV (2019) A new type of impact damper with long overhangs in the internal turning of hardened materials. Procedia CIRP 82:255–260. https://doi.org/10.1016/j.procir.2019.04.147

de Aguiar HCG, Hassui A, Suyama DI, Magri A (2020) Reduction of internal turning surface roughness by using particle damping aided by airflow. Int J Adv Manuf Technol 106:125–131. https://doi.org/10.1007/s00170-019-04566-5

Acknowledgements

The authors would like to thank São Paulo Research Foundation (FAPESP Grant 2010/08457-1) and Sandvik Coromant for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Adriano Fagali de Souza.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Suyama, D.I., Diniz, A.E. Influence of tool vibrations on tool wear mechanisms in internal turning of hardened steel. J Braz. Soc. Mech. Sci. Eng. 42, 370 (2020). https://doi.org/10.1007/s40430-020-02452-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02452-w