Abstract

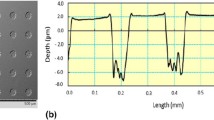

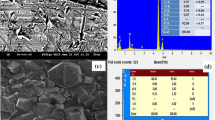

In this study, the influence of soft substrate surface finishing (5 distinct conditions) on tribological properties of hydrogenated amorphous carbon (a-C:H) films is investigated. Low carbon steel substrates were plasma-nitrided and DLC-coated in a single PECVD batch. Topographical evolution was investigated through white light interferometry (WLI) and scanning electron microscopy (SEM). The substrate topography leads to a negligible impact on bonding structure and mechanical properties of a-C:H films, which were analyzed by Raman spectroscopy (RS) and nano-indentation. The nitriding and deposition process resulted in two groups of samples regarding the topographic features: (A) Rough—Sq coated ≈ 0.17–0.23 µm; (B) Smooth—Sq coated ≈ 0.08–0.11 µm. Tribological performance of multifunctional coatings under incremental normal load reciprocating dry sliding tests in ambient air revealed friction coefficients of 0.09 (Rough) and 0.05 (Smooth). Wear scars were analyzed by WLI, SEM and RS. The results suggest that rougher substrates inhibit tribolayer formation and stability, leading to higher friction coefficients.

Similar content being viewed by others

References

Robertson J (2002) Diamond-like amorphous carbon. Mater Sci Eng R Rep 37(4–6):129–281. https://doi.org/10.1016/S0927-796X(02)00005-0

Donnet C, Erdemir A. (2008) Tribology of diamond-like carbon films. Edited by Christophe Donnet and Ali Erdemir. Boston, MA: Springer US. https://doi.org/10.1007/978-0-387-49891-1

Vetter J (2014) 60 years of DLC coatings: historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications. Surf Coat Technol 257:213–240. https://doi.org/10.1016/j.surfcoat.2014.08.017

Sanchez-Lopez JC, Erdemir A, Donnet C, Rojas TC (2003) Friction-induced structural transformations of a diamondlike carbon coatings under various atmospheres. Surf Coat Technol 163–164:444–450. https://doi.org/10.1016/S0257-8972(02)00641-2

Podgornik B, Vizintin J, Ronkainen H, Holmberg K (2000) Friction and wear properties of DLC-coated plasma nitrided steel in unidirectional and reciprocating sliding. Thin Solid Films 377–378:254–260. https://doi.org/10.1016/S0040-6090(00)01302-X

Holmberg K, Mathews A (1994) Coatings tribology: a concept, critical aspects and future directions. Thin Solid Films 253(1–2):173–178. https://doi.org/10.1016/0040-6090(94)90315-8

Jiaren J, Arnell RD (2000) The effect of substrate surface roughness on the wear of DLC coatings. Wear 239(1):1–9. https://doi.org/10.1016/S0043-1648(99)00351-8

Tsuguyori O, Suzuki M, Nakamura T, Tanaka A, Koga Y (2004) Tribological properties of DLC films deposited on steel substrate with various surface roughness. Diam Relat Mater 13(11–12):2211–2215. https://doi.org/10.1016/j.diamond.2004.06.037

Chouquet C, Gerbaud G, Bardet M, Barrat S, Billard A, Sanchette F, Ducros C (2010) Structural and mechanical properties of a-C: H and Si doped a-C: H thin films grown by LF-PECVD. Surf Coat Technol 204(9–10):1339–1346. https://doi.org/10.1016/j.surfcoat.2009.09.016

Andujar JL, Vives M, Corbella C, Bertran E (2003) Growth of hydrogenated amorphous carbon films in pulsed DC methane discharges. Diam Relat Mater 12(2):98–104. https://doi.org/10.1016/S0925-9635(03)00009-8

Michler T, Grischke M, Traus I, Bewilogua K, Dimigen H (1998) DLC films deposited by bipolar pulsed DC PACVD. Diam Relat Mater 7(2–5):459–462. https://doi.org/10.1016/S0925-9635(97)00236-7

Corbella C, Vives M, Oncins G, Canal C, Andújar JL, Bertran E (2004) Characterization of DLC films obtained at room temperature by pulsed-Dc PECVD. Diam Relat Mater 13(4–8):1494–1499. https://doi.org/10.1016/j.diamond.2003.10.079

Nakanishi K, Mori H, Tachikawa H, Itou K, Fujioka M, Funaki Y (2006) Investigation of DLC-Si coatings in large-scale production using DC-PACVD equipment. Surf Coat Technol 200(14–15):4277–4281. https://doi.org/10.1016/j.surfcoat.2005.02.167

Ebrahimi M, Mahboubi F, Naimi-Jamal RM (2015) Wear behavior of DLC film on plasma nitrocarburized AISI 4140 steel by pulsed DC PACVD: Effect of nitrocarburizing temperature. Diam Relat Mater 52(9):32–37. https://doi.org/10.1016/j.diamond.2014.12.004

Agarwal K, Shivpuri R, Vincent J, Rolinski E, Sharp G (2013) DC pulsed plasma deposition of nanocomposite coatings for improved tribology of gray cast iron stamping dies. Process Technol 213(9):864–876. https://doi.org/10.1016/j.jmatprotec.2013.01.00

Dalibon EL, Charadia R, Cabo A, Trava-Airoldi V, Brühl S (2013) Evaluation of the mechanical behaviour of a DLC film on plasma nitrided AISI 420 with different surface finishing. Surf Coat Technol 235:735–740. https://doi.org/10.1016/j.surfcoat.2013.08.059

Shioga PH, Binder C, Hammes G, Klein AN, de Mello JDB (2016) Effects of different plasma nitrided layers on the tribological performance of DLC coatings. Mater Res 19:1180–1188. https://doi.org/10.1590/1980-5373-MR-2015-0455

Giacomelli RO, Salvaro DB, Bendo T, Binder C, Klein AN, de Mello JDB (2017) Topography evolution and friction coefficient of gray and nodular cast irons with duplex plasma nitrided + DLC coating. Surf Coat Technol 314:18–27. https://doi.org/10.1016/j.surfcoat.2016.09.035

Holmberg K, Ronkainen H, Laukkanen A, Kim Wallin (2007) Friction and wear of coated surfaces—scales, modelling and simulation of tribomechanisms. Surf Coat Technol 202:1034–1049. https://doi.org/10.1016/j.surfcoat.2007.07.105

Erdemir A (2001) The role of hydrogen in tribological properties of diamond-like carbon films. Surf Coat Technol 146–147:292–297. https://doi.org/10.1016/S0257-8972(01)01417-7

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation. Experiments. J Mater Res 7(6):1564–1583

Miyoshi K (2001) Solid lubrication, fundamentals and applications, vol 1. Marcel Dekker Inc., Cleveland

De Mello JDB, Binder R (2006) A methodology to determine surface durability in multifunctional coatings applied to soft substrates. Tribol Int 39(8):769–773. https://doi.org/10.1016/j.triboint.2005.07.015

Casiraghi C, Piazza F, Ferrari AC, Grambole D, Robertson J (2005) Bonding in hydrogenated diamond-like carbon by Raman spectroscopy. Diam Relat Mater 14:1098–1102. https://doi.org/10.1016/j.diamond.2004.10.030

Casiraghi C, Ferrari AC, Robertson J (2005) Raman spectroscopy of hydrogenated amorphous carbons. Phys Rev B Condens Matter Mater Phys 72(8):1–14. https://doi.org/10.1103/PhysRevB.72.085401

Holmberg K, Ronkainen H, Laukkanen A, Wallin K, Hogmark S, Jacobson S, Wiklund U, Souza RM, Ståhle P (2009) Residual stresses in TiN, DLC and MoS2 coated surfaces with regard to their tribological fracture behaviour. Wear 267(12):2142–2156. https://doi.org/10.1016/j.wear.2009.01.004

Kaufmann H (1995) Industrial Applications of plasma and ion surface engineering. Surf Coat Technol 74–75:23–28. https://doi.org/10.1016/0257-8972(95)08295-6

Klein AN, Cardoso RP, Pavanati HC, Binder C, Maliska AM, Hammes G, Fusao D, Seeber A, Brunatto SF, Muzart JLR (2013) DC plasma technology applied to powder metallurgy: an overview. Plasma Sci Technol 15(1):70–81. https://doi.org/10.1088/1009-0630/15/1/12

Maliska AM, Pavanati HC, Klein AN, Muzart JLR (2003) The influence of ion energy bombardment on the surface porosity of plasma sintered iron. Mater Sci Eng A 352(1–2):273–278. https://doi.org/10.1016/S0921-5093(02)00914-0

De Mello JDB, Binder R, Demas NG, Polycarpou AA (2009) Effect of the actual environment present in hermetic compressors on the tribological behaviour of a Si-rich multifunctional DLC Coating. Wear 267(5–8):907–915. https://doi.org/10.1016/j.wear.2008.12.070

Ferrari A, Robertson J (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61(20):14095–14107. https://doi.org/10.1103/PhysRevB.61.14095

Acknowledgements

The authors would like to thank the following Brazilian agencies for funding this research: CNPq, Capes, BNDES, as well as Whirpool/Embraco and the LCME-UFSC for their technical support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Soprano, P.B., Salvaro, D.B., Giacomelli, R.O. et al. Effect of soft substrate topography on tribological behavior of multifunctional DLC coatings. J Braz. Soc. Mech. Sci. Eng. 40, 371 (2018). https://doi.org/10.1007/s40430-018-1290-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1290-6