Abstract

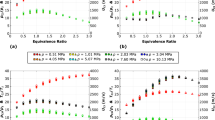

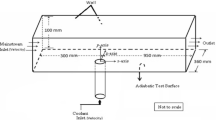

One of the world’s efforts is to mitigate the greenhouse effect, and the increase in thermal efficiency is a way to reduce the CO2 emissions. Models of simulation of thermodynamic nature are useful to predict the performance of internal combustion engines. Once set up with operational characteristics, the simulation is relatively fast and does not need complex and expansive experimental apparatus to set the engine’s best parameters. The aim of this study is to build a phenomenological model to predict the performance of diesel engines, to evaluate its characteristics with experimental results, and propose thermal improvements by testing new operation parameters. In addition, this simulation model contains a blowby routine, unusual in thermodynamic models. First, a direct-injection diesel engine equipped with turbocharger and aftercooler was simulated under four operating test conditions: (1) max load and speed; (2) max speed and partial load; (3) max load and partial speed; (4) partial load and speed. The results show the experimental heat-release profile by the combustion is essential for the good agreement between the simulation and the experimental results, whose relative errors were −0.766, −0.148, −1.126, and 1.371% to the indicated shaft power for the Tests 1–4, respectively. In a second investigation, the engine simulation was made by varying the start of injection (SOI) of the Test (1). Advancing the SOI from 4.8° to 28° BTDC, the specific fuel consumption decreased 18.26%, and the indicated shaft power increased 22.37%. This article shows that a regular commercial diesel engine has a large field to improve the thermal performance, and the thermodynamic simulation fits well to support the decision of an engine project.

Similar content being viewed by others

Notes

There is resistance of the squeezed oil only when the ring is settling on the piston-groove surface.

Abbreviations

- A :

-

Total cylinder area, (m2)

- A0:

-

Cylinder head area, (m2)

- β :

-

Valve seat angle, (°)

- CN:

-

Cetane number

- D :

-

Piston diameter, valve inner seat diameter (m)

- D v :

-

Head valve diameter, (m)

- D s :

-

Stem valve diameter, (m)

- E a :

-

Activation energy, (J/mol)

- \(\epsilon\) :

-

Compression ratio

- h :

-

Heat-tranfer coefficient, (m)

- L :

-

Piston stroke, (m)

- L v :

-

Valve lift, (m)

- l :

-

Connecting rod length, (m)

- m :

-

Mass, (kg)

- N :

-

Crank velocity, (rpm)

- n c :

-

Polytropic exponent of compression

- p :

-

Pressure, (bar)

- Q :

-

Heat, (J)

- \(R_{0}\) :

-

Universal gas constant, (8.31434 J/mol)

- r :

-

Crank radius, (m)

- S :

-

Position, (m)

- \(\theta\) :

-

Crank angle, (°)

- T :

-

Temperature (K)

- T w :

-

Surface temperature (K)

- t id :

-

Ignition delay, (ms)

- V :

-

Volume, (m3)

- Vcc:

-

Combustion chamber volume, (m3)

- U :

-

Internal energy, (J)

- W :

-

Work, (J)

- w :

-

Valve seat width, (m)

- V :

-

Cylinder volume, (m3)

- Vp :

-

Mean piston velocity, [m / s]

- (A/F):

-

Air/fuel rate, (kg/kg)

- CA:

-

Crank angle (°)

- CI:

-

Compression-ignition engines

- DI:

-

Direct injection

- DOI:

-

Duration of Injection

- IDI:

-

Indirect diesel injection

- SOI:

-

Start of Injection

- RPM:

-

Revolutions per minute

- Sfc:

-

Specific fuel consumption (g/kW h)

References

Alkidas AC (1987) Combustion characteristics of a single-cylinder open-chamber diesel engine. J Eng Gas Turbines Power 109(4):419–425

Asmus TW (1982) Valve events and engine operation. Tech. rep, SAE Technical Paper No, p 820749

Borman G, Nishiwaki K (1987) Internal combustion engine heat transfer. Prog Energy Combust Sci 13(1):1–46

Carden P, Pisani C, Lainé E, Field I, Devine M, Schoeni A, Beyer P (2013) Calculation of crank train friction in a heavy duty truck engine and comparison with measured data. Proc Inst Mech Eng Part J J Eng Tribol 227(2):168–184

Furuhama S, Tada T (1961) On the flow of gas through the piston-rings: 1st report, the discharge coefficient and temperature of leakage gas. Bull JSME 4(16):684–690

Gallo WLR (1990) Análise exergética de motores a gasolina e Álcool. PhD thesis, Universidade Estadual de Campinas, Unicamp

Ghojel J (2010) Review of the development and applications of the wiebe function: a tribute to the contribution of ivan wiebe to engine research. Int J Engine Res 11(4):297–312

Hardenberg H, Hase F (1979) An empirical formula for computing the pressure rise delay of a fuel from its cetane number and from the relevant parameters of direct-injection diesel engines. Tech. rep, SAE Technical Paper No, p 790493

Heywood JB et al (1988) Internal combustion engines fundamentals, vol 930. Mcgraw-Hill, New York

Hohenberg GF (1980) Advanced approaches for heat transfer calculations. Society of automotive enginners–SAE Technical Paper No, Tech. rep., p 790825

Jayashankara B, Ganesan V (2010) Effect of fuel injection timing and intake pressure on the performance of a di diesel engine-a parametric study using cfd. Energy Convers Manag 51(10):1835–1848

Kastner L, Williams T, White J et al (1963) Poppet inlet valve characteristics and their influence on the induction process. ProcInst MechEng 178(1):955–975

Lyford-Pike EJ, Heywood JB (1984) Thermal boundary layer thickness in the cylinder of a spark-ignition engine. Int J Heat Mass Trans 27(10):1873–1878

Miyamoto N, Chikahisa T, Murayama T, Sawyer R (1985) Description and analysis of diesel engine rate of combustion and performance using wiebe’s functions. Tech. rep, SAE Technical Paper No, p 850107

Nakonieczny K (2002) Entropy generation in a diesel engine turbocharging system. Energy 27(11):1027–1056

Namazian M, Heywood JB (1982) Flow in the piston-cylinder-ring crevices of a spark-ignition engine: effect on hydrocarbon emissions, efficiency and power. Tech. rep, SAE Technical Paper No, p 820088

Nishiwaki K, Shimamoto Y, Miyake K (1979) Average heat transfer coefficients on a cylinder wall in the intake and exhaust processes of motoring test. Bull JSME 22(174):1796–1809

Uchida N, Daisho Y, Saito T (1992) The control of diesel emissions by supercharging and varying fuel-injection parameters. In: Tech. rep., SAE Technical Paper No. 920117

Uchida N, Daisho Y, Saito T, Sugano H (1993) Combined effects of egr and supercharging on diesel combustion and emissions. In: Tech. rep., SAE Technical Paper No. 930601

Van Gerpen JH, Cw Huang, Borman GL (1985) The effects of swirl and injection parameters on diesel combustion and heat transfer. Tech. rep, SAE Technical Paper No, p 850265

Woschni G (1967) A universally applicable equation for the instantaneous heat transfer coefficient in the internal combustion engine. Tech. rep, SAE Technical Paper No, p 670931

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Fernando Marcelo Pereira.

Rights and permissions

About this article

Cite this article

Nunes, P.G.K., Gallo, W.L.R. Validation of a phenomenological model and investigations of effects of injection timing in four-stroke direct-injection diesel engine performance. J Braz. Soc. Mech. Sci. Eng. 39, 3707–3719 (2017). https://doi.org/10.1007/s40430-017-0857-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40430-017-0857-y