Abstract

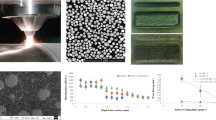

Spherical Nb–20Si–24Ti–2Cr–2Al pre-alloyed powders were processed by selective laser melting (SLM) on Ti6Al4V substrates with different energy densities. A series of single tracks and single layers were produced using different processing parameters, including powder size, laser power, scanning speed and hatch distance. Results showed that the pre-alloyed powders ranging from 45 to 75 μm were more applicable to SLM with less balling tendency, in comparison with those between 75 and 180 μm. The increase in linear energy density (LED) resulted in the decrease in contact angle and the increase in the width of single track as well as its penetration depth into the substrate. Smaller hatch distance leaded to a larger remelted part of the former track and a higher volumetric laser energy density. With a thickness of 75.6 μm, an interfacial intermediate layer, enriched in Ti and depleted in Nb, Si, Cr and Al, was formed between the SLM part and the Ti6Al4V substrate. The mechanisms of the elimination of balling phenomenon by employing a higher LED and the interfacial bonding characteristics between Nb–Si-based alloys via SLM and the Ti6Al4V substrate were discussed.

Similar content being viewed by others

References

T.M. Pollock, Nat. Mater. 15, 809 (2016)

W. Liu, H. Xiong, N. Li, S. Guo, R. Qin, Qin, Acta Metall. Sin. (Engl. Lett.) (2017). https://doi.org/10.1007/s40195-017-0619-y. (in press)

Y.X. Tian, J.T. Guo, L.Y. Sheng, G.M. Cheng, L.Z. Zhou, L.L. He, H.Q. Ye, Intermetallics 16, 807 (2008)

B.P. Bewlay, M.R. Jackson, P.R. Subramanian, J. Zhao, Metall. Mater. Trans. A 34, 2043 (2003)

Y. Guo, L. Jia, B. Kong, H. Zhang, H. Zhang, Mater. Sci. Eng. A 701, 149 (2017)

T. Fei, Y. Yu, C. Zhou, J. Sha, Mater. Des. 116, 92 (2017)

S. Dadbakhsh, M. Speirs, J. Van Humbeeck, J. Kruth, MRS Bull. 41, 765 (2016)

L.C. Zhang, H. Attar, Adv. Eng. Mater. 18, 463 (2016)

H. Attar, M. Bönisch, M. Calin, L. Zhang, S. Scudino, J. Eckert, Acta Mater. 76, 13 (2014)

D. Gu, H. Wang, D. Dai, P. Yuan, W. Meiners, R. Poprawe, Scr. Mater. 96, 25 (2015)

Y. Zhou, S.F. Wen, B. Song, X. Zhou, Q. Teng, Q.S. Wei, Y.S. Shi, Mater. Des. 89, 1199 (2016)

J. Sander, J. Hufenbach, L. Giebeler, H. Wendrock, U. Kühn, J. Eckert, Mater. Des. 89, 335 (2016)

H. Attar, K.G. Prashanth, L. Zhang, M. Calin, I.V. Okulov, S. Scudino, C. Yang, J. Eckert, J. Mater. Sci. Technol. 31, 1001 (2015)

I. Yadroitsev, I. Smurov, Phys. Proc. 5, 551 (2010)

H. Gong, K. Rafi, H. Gu, G.D.J. Ram, T. Starr, B. Stucker, Mater. Des. 86, 545 (2015)

Y.J. Liu, S.J. Li, H.L. Wang, W.T. Hou, Y.L. Hao, R. Yang, T.B. Sercombe, L.C. Zhang, Acta Mater. 113, 56 (2016)

Y.J. Liu, X.P. Li, L.C. Zhang, T.B. Sercombe, Mater. Sci. Eng. A 642, 268 (2015)

X.P. Li, C.W. Kang, H. Huang, L.C. Zhang, T.B. Sercombe, Mater. Sci. Eng. A 606, 370 (2014)

N.J. Harrison, I. Todd, K. Mumtaz, Acta Mater. 94, 59 (2015)

D. Gu, Y. Shen, Mater. Des. 30, 2903 (2009)

X. Zhou, X. Liu, D. Zhang, Z. Shen, W. Liu, J. Mater. Process. Technol. 222, 33 (2015)

D. Wang, Y. Liu, Y. Yang, D. Xiao, R.I. Campbell, I. Gibson, Rapid Prototyping J. 22 (2016)

H. Schwab, F. Palm, U. Kühn, J. Eckert, Mater. Des. 105, 75 (2016)

X.P. Li, M. Roberts, Y.J. Liu, C.W. Kang, H. Huang, T.B. Sercombe, Mater. Des. 65, 1 (2015)

A. Pérez Del Pino, P. Serra, J.L. Morenza, Appl. Surf. Sci. 197–198, 887 (2002)

D.D. Gu, W. Meiners, K. Wissenbach, R. Poprawe, Int. Mater. Rev. 57, 133 (2012)

D. Dai, D. Gu, Mater. Des. 55, 482 (2014)

Y. Guo, L. Jia, S. Sun, B. Kong, J. Liu, H. Zhang, Mater. Des. 109, 37 (2016)

N.K. Tolochko, S.E. Mozzharov, I.A. Yadroitsev, T. Laoui, L. Froyen, V.I. Titov, M.B. Ignatiev, Rapid Prototyp. J. 10, 78 (2004)

R. Mead-Hunter, A.J. King, B.J. Mullins, Langmuir 28, 6731 (2012)

I. Yadroitsev, A. Gusarov, I. Yadroitsava, I. Smurov, J. Mater. Process. Technol. 210, 1624 (2010)

A. Simchi, Mater. Sci. Eng. A 428, 148 (2006)

E.J.R. Parteli, T. Pöschel, Powder Technol. 288, 96 (2016)

I. Yadroitsev, P. Bertrand, I. Smurov, Appl. Surf. Sci. 253, 8064 (2007)

A.V. Gusarov, I. Yadroitsev, P. Bertrand, I. Smurov, Appl. Surf. Sci. 254, 975 (2007)

D. Dai, D. Gu, Int. J. Mach. Tool Manuf. 100, 14 (2016)

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China (Nos. 51471013 and 51571004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195.

Rights and permissions

About this article

Cite this article

Guo, YL., Jia, LN., Kong, B. et al. Energy Density Dependence of Bonding Characteristics of Selective Laser-Melted Nb–Si-Based Alloy on Titanium Substrate. Acta Metall. Sin. (Engl. Lett.) 31, 477–486 (2018). https://doi.org/10.1007/s40195-017-0670-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-017-0670-8