Abstract

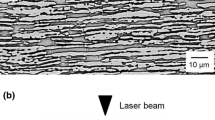

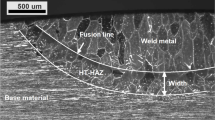

Duplex stainless steels generally solidify with a ferritic microstructure, followed by a partial transformation to austenite during cooling. Rapid cooling may render the transformation incomplete. The too-low or too-high cooling rate can also result in the formation of intermetallic phases and precipitates which can have a detrimental effect on the pitting corrosion resistance. The possibilities of achieving a microstructure with 30–70% ferrite in duplex stainless steel (1.4462, DX 2205) autogenously welded with a novel plasma welding equipment were investigated. Welding was performed as a square butt joint, with a 0-mm nominal gap size, on a 6-mm plate thickness, without the use of filler metal. The plasma torch uses a focus gas that allows it to constrict the arc in addition to the conventional constriction by the plasma nozzle. The three separated gas flows (plasma, focus and shielding gas) allow the gas composition to be tailored in the different gas flows. The effect of argon, nitrogen and helium content on the phase balance related to the gas flow channels was studied. The presence of nitrides as well as the sigma phase was investigated, and the joint quality was evaluated. The microstructure of the welded samples, investigated by image analysis, was correlated to pitting corrosion resistance. It was shown that high joint quality, quality level B, with favourable ferrite/austenite phase balance can be achieved through autogenous single-pass welding of duplex stainless steel 1.4462, DX 2205 (6.0 mm) using the novel plasma torch. With N2 additions in, most notably, the plasma gas and the shielding gas, it was possible to get a ferrite phase fraction in the weld metal close to 50%.

Similar content being viewed by others

Data availability

Not available.

References

Stainless Steel Advisory Service (2001) Stainless steel advisory service British stainless steel association welding of stainless steel

Ureña A, Otero E, Utrilla MV, Múnez CJ (2007) Weldability of a 2205 duplex stainless steel using plasma arc welding. J Mater Process Technol 182:624–631. https://doi.org/10.1016/j.jmatprotec.2006.08.030

Mohammed GR, Ishak M, Aqida SN, Abdulhadi HA (2017) Effects of heat input on microstructure, corrosion and mechanical characteristics of welded austenitic and duplex stainless steels: a review. Metals (Basel) 7

International Molybdenum Association (IMOA) (2014) Practical guidelines for the fabrication of duplex stainless steels 2, 3rd ed. Int Molybdenum A (IMOA)

International Organization for Standardization (2017) ISO 17781:2017 Petroleum, petrochemical and natural gas industries — test methods for quality control of microstructure of ferritic/austenitic (duplex) stainless steels. 7–13

International Organization for Standardization (2019) International Standard ISO 15156–3:2015 Technical circular 3-petroleum and natural gas industries-materials for use in h2s-containing environments in oil and gas production, part 3: cracking-resistant CRAs (corrosion-resistant alloys) and other alloys. 6

NORSOK (2016) Welding and inspection of piping M-601:2016. 14–21

European committee for standardization (2021) EN 13445–4:2021 Unfired pressure vessels – part 4: fabrication. 33

Det Norske Veritas (2021) DNV-ST-F101 Submarine pipeline systems. 166

Outokumpu Stainless AB (2010) Plasma arc welding (PAW). In: Welding Handbook, 1st ed. Outokumpu Oyj. Avesta 29

Pekkarinen J, Kujanpää V (2010) The effects of laser welding parameters on the microstructure of ferritic and duplex stainless steels welds. In: Physics Procedia. Elsevier B.V 517–523

Outokumpu Stainless AB (2010) Plasma arc welding (PAW). In: Welding Handbook, 1st ed. Outokumpu Oyj. Avetsta 29–30

Westin EM, Serrander D (2012) Experience in welding stainless steels for water heater applications. Weld World 56:14–28. https://doi.org/10.1007/BF03321346

Ramesh Singh (2016) Physics of welding. In: Applied Welding Engineering, 2nd ed. Elsevier 131–162

Outokumpu Stainless AB (2010) Shielding and backing gases. In: Welding Handbook , 1st ed. Outokumpu Oyj. Avesta 46–47

Outokumpu Stainless AB (2009) Delivery testing and acceptance testing. In: Corrosion Handbook 75th Anniversary Edition, 75th ed. Outokumpu Oyj I:40

European Committee for Standardization (2015) SS-EN ISO 5817:2014 Welding – fusion-welded joints in steel, nickel, titanium and their alloys (beam welding excluded) – quality levels for imperfections

Chan KW, Tjong SC (2014) Effect of secondary phase precipitation on the corrosion behavior of duplex stainless steels. Materials 7:5268–5304

Baghdadchi A, Hosseini VA, Hurtig K, Karlsson L (2021) Promoting austenite formation in laser welding of duplex stainless steel-impact of shielding gas and laser reheating. Weld World 65:499–511. https://doi.org/10.1007/s40194-020-01026-7/Published

Taban E, Kaluc E (2011) Welding behaviour of duplex and superduplex stainless steels using laser and plasma arc welding processes. Weld World 55:48–57. https://doi.org/10.1007/BF03321307

Cui S, Pang S, Pang D et al (2021) Numerical simulation and experimental investigation on 2205 duplex stainless steel K-TIG welded joint. Metals (Basel) 11. https://doi.org/10.3390/met11081323

Hosseini V (2016) Influence of multiple welding cycles on microstructure and corrosion resistance of a super duplex stainless steel. Licentiate Thesis, University West

Cui S, Yu Y, Tian F, Pang S (2022) Morphology, microstructure, and mechanical properties of S32101 duplex stainless-steel joints in K-TIG welding. Materials 15. https://doi.org/10.3390/ma15155432

Cui S, Shi Y, Cui Y, Zhu T (2018) The impact toughness of novel keyhole TIG welded duplex stainless steel joints. Eng Fail Anal 94:226–231. https://doi.org/10.1016/j.engfailanal.2018.08.009

Karlsson L, Arcini H (2012) Low energy input welding of duplex stainless steels. Weld World 56

Omura T, Kushida T, Komizo Y (2000) Microstructural features and corrosion properties in laser welded duplex stainless steels. Weld Int 14:257–260. https://doi.org/10.1080/09507110009549176

Asuncion M, Bermejo V, Pandian KT et al (2021) Microstructure of laser metal deposited duplex stainless steel: influence of shielding gas and heat treatment. Weld World. https://doi.org/10.1007/s40194-020-01036-5/Published

Kotecki DJ (2010) Some pitfalls in welding of duplex stainless steels (Algumas Armadilhas na Soldagem de Aços Inoxidáveis Duplex). Soldag insp 15:336–343

Sales AM, Westin EM, Jarvis BL (2017) Effect of nitrogen in shielding gas of keyhole GTAW on properties of duplex and superduplex welds. Weld World 61:1133–1140. https://doi.org/10.1007/s40194-017-0486-1

Hosseini V (2018) Super duplex stainless steels-microstructure and properties of physically simulated base and weld metal

Varbai B, Adonyi UY, Baumer R et al (2019) Weldability of duplex stainless steels-thermal cycle and nitrogen effects. Weld J 98:78–87. https://doi.org/10.29391/2019.98.006

Karlsson L, Rigdal S, Bergquist EL, Arcini H (2007) Int. Conf. Duplex 2007. In: Effects of alloying elements on properties of duplex Weld Metal

Holländer Pettersson N, Lindell D, Lindberg F, Borgenstam A (2019) Formation of chromium nitride and intragranular austenite in a super duplex stainless steel. Metall Mater Trans A Phys Metall Mater Sci 50:5594–5601. https://doi.org/10.1007/s11661-019-05489-2

Varbai B, Pickle T, Májlinger K (2019) Effect of heat input and role of nitrogen on the phase evolution of 2205 duplex stainless steel weldment. Int J Press Vessel Pip 176. https://doi.org/10.1016/j.ijpvp.2019.103952

Outokumpu Stainless AB (2010) Duplex (austenitic-ferritic) stainless steels. In: Welding Handbook , 1st ed. Outokumpu Oyj. Avesta 20

Hosseini AV, Karlsson L (2019) Physical and kinetic simulation of nitrogen loss in high temperature heat affected zone of duplex stainless steels. Materialia 6. https://doi.org/10.1016/j.mtla.2019.100325

Acknowledgements

Outokumpu provided the material. Rickard Aldén (currently AFRY, formerly Swerim AB) design and interpretation of DoE. Oskar Karlsson (Swerim AB) SEM analysis. Jesper Flyg (Swerim AB) design and analysis of corrosion testing.

Funding

The investigation was financed by the Centre for Joining and Structures (CJS) at Swerim AB.

This research was partially sponsored by XPRES (Centre of Excellence in Production Research) – a strategic research area in Sweden.

Author information

Authors and Affiliations

Contributions

Conceptualisation: all authors; methodology: all authors; welding: Erwan Siewert, Nakhleh Hussary, Michael Pfreuntner; analysis and investigation: Klara Trydell, Kjell-Arne Persson; writing—original draft preparation: Klara Trydell; writing—review and editing: Klara Trydell, Kjell-Arne Persson, Nuria Fuertes.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Trydell, K., Persson, KA., Fuertes, N. et al. Ferrite fraction in duplex stainless steel welded with a novel plasma arc torch. Weld World 67, 805–817 (2023). https://doi.org/10.1007/s40194-022-01447-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01447-6