Abstract

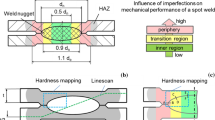

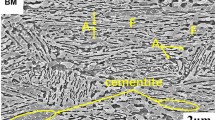

Press-hardened steels (PHS) are widely used in the safety cage of vehicle body-in-white structures owing to their high strength which is attained from phase transformation during hot stamping. Resistance spot welding of PHS produces a martensitic microstructure in the fusion zone (FZ) exhibiting brittle failures with low energy absorption capacity in the case of a vehicle crash event. Typically, the martensitic microstructure impairs the toughness of the fusion zone leading to interfacial failure (IF) which is perceived to be undesirable for crashworthiness. Tempering of the martensite in the FZ has been adopted as a means to improve weld toughness; however, differential tempering was observed across the nugget diameter in this study. The differential tempering was attributed to the presence of pre-existing irregular voids formed during the welding cycle which altered the current flow at the weld center and periphery. Findings revealed that reducing the voids in the nugget leads to effective tempering and improved mechanical properties of the joint when performed under the right temperature and time regime. The optimal tempering condition showed an improved cross tension peak load of 36% and 33% in the energy absorption capacity. The improved cross-tension performance was attributed to the tempered martensitic structure in the FZ which promoted crack deflection leading to a pull-out failure mode.

Similar content being viewed by others

References

Demeri MY (2013) Advanced high-strength steels—science, technology, and application. In: Advanced steels, 1st Editio. ASM International, Ohio, pp 1–22

Shojaee M, Midawi ARH, Barber B et al (2021) Mechanical properties and failure behavior of resistance spot welded third-generation advanced high strength steels. J Manuf Process 65:364–372. https://doi.org/10.1016/j.jmapro.2021.03.047

Soomro IA, Pedapati SR, Awang M (2022) A review of advances in resistance spot welding of automotive sheet steels: emerging methods to improve joint mechanical performance. Int J Adv Manuf Technol 118:1335–1366. https://doi.org/10.1007/s00170-021-08002-5

Ramachandran DC, Figueredo B, Sherepenko O et al (2022) A study on improving the mechanical performance by controlling the halo ring in the Q&P 980 steel resistance spot welds. J Manuf Process 75:320–330. https://doi.org/10.1016/j.jmapro.2022.01.019

Shojaee M, Tolton C, Midawi ARH, et al (2022) Influence of loading orientation on mechanical properties of spot welds. Int J Mech Sci 107327. https://doi.org/10.1016/J.IJMECSCI.2022.107327

Samadian P, O’Keeffe C, Butcher C, Worswick MJ (2021) Fracture response in hot-stamped tailor-welded blanks of Ductibor® 500-AS and Usibor® 1500-AS: experiments and modelling. Eng Fract Mech 253:107864. https://doi.org/10.1016/j.engfracmech.2021.107864

Chen RM, Zhang CQ, Lou M et al (2020) Effect of Al-Si coating on weldability of press-hardened steels. J Mater Eng Perform 29:626–636. https://doi.org/10.1007/s11665-020-04555-w

Khan MS, Razmpoosh MH, Biro E, Zhou Y (2020) A review on the laser welding of coated 22MnB5 press-hardened steel and its impact on the production of tailor-welded blanks. Sci Technol Weld Join 25:447–467. https://doi.org/10.1080/13621718.2020.1742472

Pouranvari M, Marashi SPH (2013) Critical review of automotive steels spot welding: Process, structure and properties. Sci Technol Weld Join 18:361–403. https://doi.org/10.1179/1362171813Y.0000000120

Pouranvari M (2012) Susceptibility to interfacial failure mode in similar and dissimilar resistance spot welds of DP600 dual phase steel and low carbon steel during cross-tension and tensile-shear loading conditions. Mater Sci Eng A 546:129–138. https://doi.org/10.1016/j.msea.2012.03.040

Mohamadizadeh A, Biro E, Worswick M (2020) Shear band formation at the fusion boundary and failure behaviour of resistance spot welds in ultra-high-strength hot-stamped steel. Sci Technol Weld Join 25:556–563. https://doi.org/10.1080/13621718.2020.1773057

Soomro IA, Pedapati SR, Awang M (2021) Optimization of postweld tempering pulse parameters for maximum load bearing and failure energy absorption in dual phase (DP590) steel resistance spot welds. Mater Sci Eng A 803:https://doi.org/10.1016/j.msea.2020.140713

Chen T, Ling Z, Wang M, Kong L (2022) Effect of post-weld tempering pulse on microstructure and mechanical properties of resistance spot welding of Q&P1180 steel. Mater Sci Eng A 831:142164. https://doi.org/10.1016/J.MSEA.2021.142164

Baltazar Hernandez VH, Nayak SS, Zhou Y (2011) Tempering of martensite in dual-phase steels and its effects on softening behavior. Metall Mater Trans A Phys Metall Mater Sci 42:3115–3129. https://doi.org/10.1007/s11661-011-0739-3

Pouranvari M, Aghajani H, Ghasemi A (2020) Enhanced mechanical properties of martensitic stainless steels resistance spot welds enabled by in situ rapid tempering. Sci Technol Weld Join 25:119–126. https://doi.org/10.1080/13621718.2019.1641962

Saha DC, Nayak SS, Biro E et al (2014) Mechanism of secondary hardening in rapid tempering of dual-phase steel. Metall Mater Trans A Phys Metall Mater Sci 45:6153–6162. https://doi.org/10.1007/s11661-014-2591-8

Chuko WL, Gould JE (2002) Development of appropriate resistance spot welding practice for transformation-hardened steels. Weld J 81:1–7

Sajjadi-Nikoo S, Pouranvari M, Abedi A, Ghaderi AA (2018) In situ postweld heat treatment of transformation induced plasticity steel resistance spot welds. Sci Technol Weld Join 23:71–78. https://doi.org/10.1080/13621718.2017.1323174

Eftekharimilani P, van der Aa EM, Hermans MJM, Richardson IM (2017) The microstructural evolution and elemental distribution of a 3rd generation 1 GPa advanced high strength steel during double pulse resistance spot welding. Weld World 61:691–701. https://doi.org/10.1007/s40194-017-0459-4

Stadler M, Schnitzer R, Gruber M, Hofer C (2021) Improving the mechanical performance of a resistance spot welded 1200 MPa TBF steel. Int J Mater Res 112:262–270. https://doi.org/10.1111/j.1444-0938.1971.tb00039.x

Stadler M, Gruber M, Schnitzer R, Hofer C (2020) Microstructural characterization of a double pulse resistance spot welded 1200 MPa TBF steel. Weld World 64:335–343. https://doi.org/10.1007/s40194-019-00835-9

Saha DC, Biro E, Gerlich AP, Zhou Y (2016) Effects of tempering mode on the structural changes of martensite. Mater Sci Eng A 673:467–475. https://doi.org/10.1016/j.msea.2016.07.092

Matsuda H, Mizuno R, Funakawa Y et al (2013) Effects of auto-tempering behaviour of martensite on mechanical properties of ultra high strength steel sheets. J Alloys Compd 577:661–667. https://doi.org/10.1016/j.jallcom.2012.04.108

Cavusoglu O, Cavusoglu O, Yilmazoglu AG et al (2020) Microstructural features and mechanical properties of 22MnB5 hot stamping steel in different heat treatment conditions. J Mater Res Technol 9:10901–10908. https://doi.org/10.1016/j.jmrt.2020.07.043

I. Diallo, T. Dupuy, C. Kaczynski (2014) High strength steel spot weld strength improvement through in situ post weld heat treatment. In: AWS sheet metal welding Conference XVI. 1–13

Chen R, Lou M, Li Y, Carlson BE (2022) A critical nugget size prediction model for Al–Si-Coated press hardened steel resistance spot welds. J ManufSci Eng 144:https://doi.org/10.1115/1.4051680

Hou J, Chan K, Scotchmer N, et al (2014) In-situ tempering of hot stamped martensitic steel. Sheet Met Weld Conf XVI 1–9

Vijayan V, Murugan SP, Son SG, Do PY (2019) Shrinkage void formation in resistance spot welds: its effect on advanced high-strength-steel weld strength and failure modes. J Mater Eng Perform 28:7514–7526. https://doi.org/10.1007/s11665-019-04465-6

Yurioka N, Suzuki H, Ohshita S, Saito S (1983) Determination of necessary preheating temperature in steel welding. Weld J 62:147–153

Sherepenko O, Schreiber V, Schischin I et al (2020) Influence of surface layers on resistance spot joinability of partially hardened steel 22MnB5 with aluminum-silicon and zinc coatings. Weld World 64:755–771. https://doi.org/10.1007/s40194-020-00864-9

AWS D8.9M:2012 A test methods for evaluating the resistance spot welding behavior of automotive sheet steel materials, 3rd Editio. American Welding Society

Aghajani H, Pouranvari M (2019) Influence of In situ thermal processing strategies on the weldability of martensitic stainless steel resistance spot welds effect of second pulse current on the weld microstructure and mechanical properties. Metall Mater Trans A 50(5191):5209. https://doi.org/10.1007/s11661-019-05443-2

Chertov AM, Maev RG, Severin FM (2007) Acoustic microscopy of internal structure of resistance spot welds. IEEE Trans Ultrason Ferroelectr Freq Control 54:1521–1529. https://doi.org/10.1109/TUFFC.2007.422

Peterson W, Gould J (2004) Development of spike temper diagraoms for a range of advanced high strength steels. In: Sheet Metal Welding Conference XI. AWS Detroit, MI, pp 1–25

Vijayan V, Murugan S, Son SG, Do PY (2020) Microstructural analysis of cavity formed in advanced high-strength steel resistance spot welds. J Mater Eng Perform 29:6372–6377. https://doi.org/10.1007/s11665-020-05139-4

Lin HJ, Kim WJ, Chang HS, Choi DY (2018) Effect of profile force on toughness of resistance spot weld joints for ultra high strength steel. Weld World 62:481–496. https://doi.org/10.1007/s40194-018-0571-0

Marya M, Gayden XQ (2005) Development of requirements for resistance spot welding Dual-Phase (DP600) steels part 1 - The causes of interfacial fracture. Weld J 84:172–182

Sherepenko O, Jüttner S (2019) Transient softening at the fusion boundary in resistance spot welded ultra-high strengths steel 22MnB5 and its impact on fracture processes. Weld World 63:151–159. https://doi.org/10.1007/s40194-018-0633-3

AWS 8.1M:2007 Specification for automotive weld quality-resistance spot welding of steel, 1st Editio, American Welding Society

Liu XD, Xu YB, Misra RDK et al (2019) Mechanical properties in double pulse resistance spot welding of Q&P 980 steel. J Mater Process Technol 263:186–197. https://doi.org/10.1016/j.jmatprotec.2018.08.018

Park G, Kim K, Uhm S, Lee C (2019) Remarkable improvement in resistance spot weldability of medium-Mn TRIP steel by paint-baking heat treatment. Mater Sci Eng A 766:138401. https://doi.org/10.1016/j.msea.2019.138401

Furuhara T, Kobayashi K, Maki T (2004) Control of cementite precipitation in lath martensite by rapid heating and tempering. ISIJ Int 44:1937–1944. https://doi.org/10.2355/isijinternational.44.1937

Acknowledgements

The authors would like to acknowledge the Auto/Steel Partnership for their financial support and providing materials used for the study, and the Canadian Standards Association (CSA) group for their support.

Funding

Auto/Steel Partnership,Canadian Standards Association (CSA) group

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Betiku, O.T., Shojaee, M., Sherepenko, O. et al. Optimizing post-weld performance of press-hardened steel resistance spot welds by controlling fusion zone porosity. Weld World 66, 1733–1746 (2022). https://doi.org/10.1007/s40194-022-01332-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01332-2