Abstract

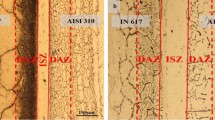

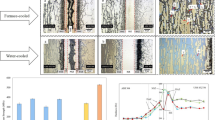

In the present work, transient liquid phase bonding (TLP) of stainless steel 316 L to Ti-6Al-4 V using simultaneously both Cu and Ni interlayers was performed and effect of bonding temperature (950 to 1050 °C) on microstructure and mechanical properties of the joints was studied. The joint zones were analyzed using scanning electron microscopy (SEM) equipped with energy dispersive spectroscopy (EDS). Microhardness and shear strength tests were also applied to evaluate the mechanical properties of the joints. The results showed that various eutectic phases and intermetallic compounds were formed at the interface; however, diversity of intermetallics was different in the joint zone for each specimen which can be due to the bonding temperature and type of eutectic phase transformation. The more increase of bonding temperature to higher than 1000 °C, the more deterioration in mechanical properties of the bonded joints is led so that the shear strength decreased from 385 MPa (maximum value) to 257 MPa.

Similar content being viewed by others

References

Lee JG, Lee M-K (2017) Microstructure and mechanical behavior of a titanium-to-stainless steel dissimilar joint brazed with Ag-Cu alloy filler and an Ag interlayer. Mater Charact 129:98–103

Guo S, Zhou Q, Xu P, Gao Q, Luo T, Peng Y, Kong J, Wang K, Zhu J (2017) Study on lightweight design and connection of dissimilar metals of titanium alloy TC4/T2 copper/304 stainless steel. International Conference on Intelligent Computing for Sustainable Energy and Environment pp 229–237

Sahasrabudhe H, Harrison R, Carpenter C, Bandyopadhyay A (2015) Stainless steel to titanium bimetallic structure using LENS™. Addit Manuf 5:1–8

Pardal G, Ganguly S, Williams S, Vaja J (2016) Dissimilar metal joining of stainless steel and titanium using copper as transition metal. Int J Adv Manuf Technol 86(5):1139–1150

Yang D, Luo Z, Xie G, Misra R (2018) Effect of interfacial compounds on mechanical properties of titanium–steel vacuum roll-cladding plates. Mater Sci Technol 34(14):1–10

Tomashchuk I, Grevey D, Sallamand P (2015) Dissimilar laser welding of AISI 316L stainless steel to Ti6–Al4–6V alloy via pure vanadium interlayer. Mater Sci Eng A 622:37–45

Muralimohan CH, Ashfaq M, Ashiri R, Muthupandi V, Sivaprasad K (2016) Analysis and characterization of the role of Ni interlayer in the friction welding of titanium and 304 austenitic stainless steel. Metall Mater Trans A 47(1):347–359

Chen H-C, Bi G, Lee BY, Cheng CK (2016) Laser welding of CP Ti to stainless steel with different temporal pulse shapes. J Mater Process Technol 231:58–65

Wang T, Zhang B, Feng J (2014) Influences of different filler metals on electron beam welding of titanium alloy to stainless steel. Trans Nonferrous Met Soc China 24(1):108–114

Velmurugan C, Senthilkumar V, Sarala S, Arivarasan J (2016) Low temperature diffusion bonding of Ti-6Al-4V and duplex stainless steel. J Mater Process Technol 234:272–279

Kaya M, Kılıç M, Kırık İ, Karakurt EM, Gülenç B (2017) Diffusion bonding between Ti-6Al-4V alloy and interstitial free steel. Mater Werkst 48(7):661–665

Li P, Li J, Xiong J, Zhang F, Raza SH (2012) Diffusion bonding titanium to stainless steel using Nb/Cu/Ni multi-interlayer. Mater Charact 68:82–87

Yıldız A, Kaya Y, Kahraman N (2016) Joint properties and microstructure of diffusion-bonded grade 2 titanium to AISI 430 ferritic stainless steel using pure Ni interlayer. Int J Adv Manuf Technol 86(5):1287–1298

Balasubramanian M (2016) Characterization of diffusion-bonded titanium alloy and 304 stainless steel with Ag as an interlayer. Int J Adv Manuf Technol 82(1):153–162

Balasubramanian M (2015) Development of processing windows for diffusion bonding of Ti–6Al–4V titanium alloy and 304 stainless steel with silver as intermediate layer. Trans Nonferrous Met Soc China 25(9):2932–2938

Balasubramanian M (2015) Application of Box–Behnken design for fabrication of titanium alloy and 304 stainless steel joints with silver interlayer by diffusion bonding. Mater Des 77:161–169

Mukherjee AB, Laik A, Kain V, Chakravartty JK (2016) Shrinkage-stress assisted diffusion bonds between titanium and stainless steel: a novel technique. J Mater Eng Perform 25(10):4425–4436

Wang F-L, Sheng G-M, Deng Y-Q (2016) Impulse pressuring diffusion bonding of titanium to 304 stainless steel using pure Ni interlayer. Rare Metals 35(4):331–336

Jalali A, Atapour M, Shamanian M, Vahman M (2018) Transient liquid phase (TLP) bonding of Ti-6Al-4V/UNS 32750 super duplex stainless steel. J Manuf Process 33:194–202

Norouzi E, Atapour M, Shamanian M (2017) Effect of bonding time on the joint properties of transient liquid phase bonding between Ti--6Al--4V and AISI 304. J Alloys Compd 701:335–341

Kundu S, Thirunavukarasu G, Chatterjee S, Mishra B (2015) Effect of bonding temperature on phase transformation of diffusion-bonded joints of duplex stainless steel and Ti-6Al-4V using nickel and copper as composite intermediate metals. Metall Mater Trans A 46(12):5756–5771

Kundu S, Chatterjee S (2008) Characterization of diffusion bonded joint between titanium and 304 stainless steel using a Ni interlayer. Mater Charact 59(5):631–637

Gupta KP (2002) The Cu-Ni-Ti (copper-nickel-titanium) system. J Phase Equilibria 23(6):541–547

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Surendar, A., Lucas, A., Abbas, M. et al. Transient liquid phase bonding of stainless steel 316 L to Ti-6Al-4 V using Cu/Ni multi-interlayer: microstructure, mechanical properties, and fractography. Weld World 63, 1025–1032 (2019). https://doi.org/10.1007/s40194-019-00742-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00742-z