Abstract

The nanostructured materials offer various advantages as they provide more flexible space for ease reconstruction, as their nanosize expands the limits and results in confinement effect, enhanced mechanical stability, and large surface area, and make them suitable for photocatalytic activities. The advancement in synthesis techniques provides the freedom to alter its physical properties as per the demand. This article provides a 360° view point on the nanomaterials which are used for solar energy harnessing with respect to environmental and energy application. The discussion emphasizes on various synthesis methods of nanostructured materials, their mechanistic features, usage in demanding applications such as photosplitting of water for hydrogen production, artificial photosynthesis, and water and wastewater treatment with an endnote highlighting the future scope of nanomaterials for real-world applications.

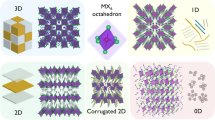

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The drastic increment in global population has led to a large increase in energy and water demand. In most cases, the classical energy resources, i.e., fossil fuel, are widely deployed; however, they are prone to release large amount of greenhouse gases as their end product. Being a classical route of combustion, it is impossible to avoid these unwanted gaseous products but prolong release of these gases on the Earth’s atmosphere leads to long term effects like global warming and climate change [1, 2]. Moreover, the non-replenishable nature, limited availability, and environmental deterioration caused by processing these fossil fuels urged to search new source of sustainable energy. The natural resources like solar, wind, hydrothermal, and geothermal are some of the well known as they are replenishable and emission free. Among them, solar energy is most preferred, because, besides generating electricity, it can also benefit in water and wastewater treatment, hydrogen production, and driving artificial photosynthesis [1,2,3,4].

“Photocatalysis” is a general term which is used for all the catalysis processes which are light driven in nature that uses special category of materials called “Photocatalysts” [5]. Semiconductor is the major category of materials which are chosen for this owing to its electronic structure and intrinsic nature which makes them suitable for this purpose. When the incident light possesses energy greater than bandgap, it excites the electrons of the photocatalyst from the valence band (VB) to the conduction band (CB) leading to the generation of holes in VB. During the aqueous phase reaction, the generated holes oxidize water molecule, thus leading to the production of O2 in the VB, whereas electrons in the CB reduce the H + ion producing hydrogen. Furthermore, the aquatic phase reaction of electron hole pair results in the production of reactive oxygen species (ROS), a strong oxidant for the degradation of recalcitrant pollutants [2, 4, 5]. Similarly, CO2 can also be directly photoreduced to methane, methanol, ethanol, acetate, etc., mimicking photosynthesis process. Mineralizing several complex aquatic organic contaminants is one of the unique properties of light-driven materials. Major categories of pollutants that have been successfully removed include textile dyes, phenolic compounds, pesticides, insecticides, aldehydes, pharmaceuticals, health care products, etc. It has been observed that intrinsic modifications such as doping, co-catalyst loading, as well as extrinsic modification such as addition of external electron acceptor can significantly enhance the mineralisation rate of these pollutants under diverse light sources [6,7,8,9,10,11,12,13].

The photocatalytic activity is measured in terms of apparent quantum yield (AQY) which is given by the following equation [14]:

The quantum yield increases if the photocatalyst is active in visible or near infrared (NIR) region or combination of both, since the amount of solar light reaching the earth surface comprises of ~ 45% visible light and ~ 50% NIR as compared to ~ 5% of ultraviolet light [2, 15].

It is evident that the focus of researchers in the current days is leaning towards nanomaterials as compared to bulk. These nanomaterials possess size range between 1 and 100 nm. Some of the well-known advantages of these nanomaterials are the high surface area-to-volume ratio, improved physical properties (melting point and hardness), and tunable electronic properties [16]. The greater surface area of these nanomaterials allows more space either for storage or reaction. Nanomaterials are harder as compared to that of bulk, because the nanosize prevents the particle from further bending and thus results in increased hardness of the particle. On the other hand, increased hardness results in modification of other physical properties such as malleability, brittleness, ductility, and toughness of the materials. Further reduction of particle size to < 10 nm results in quantum confinement effect and increases the bandgap of the materials, thereby enhancing the charge separation [16, 17]. Moreover, these nanomaterials can be synthesized into morphologies like tubes, rods, flowers, sphere, and many more, while the properties of the specific morphology vary accordingly [18, 19].

Hence, the present review deals with various types of nanostructured photocatalyst to harness solar energy for environmental and energy applications. In specific, the review details the significance of the synthesis, mechanistic feature, application, and future prospect of nanostructured materials.

Type of nanostructure photocatalysts

Classical photocatalysts

In general, the classical photocatalysts refers to inorganic one and includes metal oxides and sulphides. Examples for metal oxide include TiO2, ZnO, WO3, V2O5, etc., in which TiO2 is the most widely studied because of its low cost, abundance, non-toxicity, and stability. One of its major disadvantages is the existence of wider bandgap allowing the excitation only in the ultraviolet light range (< 380 nm). However, numerous modifications have been carried out to narrow its bandgap for visible light application [2]. Dopants like N, S, C, Cr3+, Fe3+, V5+, Cu2+, and Ce2+ have been used for achieving it [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42,43,44]. In the metal oxide-based semiconductors, the O2p orbital acts as VB maxima, whereas the cationic part acts as CB minima. Moving down to sulphide semiconductors like ZnS, CdS, and SnS2 have been predominantly studied [45,46,47,48]. In this category, the 3p orbital of sulphur that lies at less positive than O2p orbital of metal oxides acts as VB maxima resulting in a narrower bandgap of metal sulphides [2, 15, 45]. Though the metal sulphides are active in visible light, their poor photostability restricts their usage. For an instance, the positive charge carrier in metal sulphide oxidizes their own S2− anion instead of water molecule resulting in photocorrosion [15]. Besides, semiconductors of phosphides (e.g., InP and Ni2P), selenides (e.g., CdSe, CuSe, ZnSe, etc.), oxynitrides (e.g., TaON), nitrides (e.g., GaN, Ge3N4, etc.), phosphates (e.g., Ag3PO4), and halides (AgCl and AgBr) origin have been explored [49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65]. The priority on the selection of semiconductors relies on the nature of application. For example, GaN and AgBr are known for their higher photostability, whereas InP for narrow bandgap, i.e., 1.25 eV [49, 59, 65].

Apart from these categories, perovskites have also been widely studied. These photocatalysts possess ABO3-based crystal structure, which contain two cations A and B, and three oxygen atoms in one molecule. Almost any cations in the periodic table can substitute A and B in the ABO3 structure, and therefore, their band structure can be easily tuned for desirable photoactivity. These perovskite are highly stable and can be easily synthesized. Some of the well studied in this category includes SrTiO3, AgNbO3, NaNbO3, etc. All these metal oxides, sulphides, and perovskite semiconductors have been widely investigated and applied for water and wastewater treatments in environmental, while for H2 production and direct CO2 photoreduction in energy sector [66,67,68]. Band-gap (Eg) values (in eV) and the edge potential of CB and VB for above-mentioned photocatalysts at pH 0 vs NHE are shown in Fig. 1 [14].

Carbon-based nanomaterials

The predominant electrical, mechanical, and thermal properties of carbon had gained its attraction in various sectors. The widely used carbon-based nanomaterials employed in various energy and environment applications include fullerene and carbon dots of 0D configuration; single and multiwalled carbon nanotubes (CNT) of 1D configuration; graphene, graphene oxide (GO), and reduced graphene oxide (rGO) of 2D configuration [69]. Addition of small percent (~ 1 wt.%) of carbon nanomaterial to semiconductor photocatalysts can enhance their photoactive nature [70]. Materials like CNT, rGO, and fullerene in composite with TiO2 have shown enhanced photocatalytic activity by increasing the recombination time of charge carriers [70]. This is generally achieved by the preeminent electron capturing and transportation properties contributed by the carbon [70]. Fullerene that is made up of 12 fixed penta rings and varies in number of hexa rings possesses high electron affinity and, hence, is preferred as an electron acceptor [71,72,73]. Moreover, it is an n-type semiconductor allowing high utilisation of UV light rather than visible [74]. Being an n type, it compliments for the increment of charge carriers and hence used in photocatalysis application [74, 75]. Carbon nanomaterials having size less than 10 nm are categorised as carbon dots (CD) which can be further subclassified as graphene quantum dots (GCD) and carbon nanodots (CND) [76]. The carbon dots possess excellent chemical stability, high specific capacitance, and enhanced luminescence behavior promoting them as excellent photocatalyst with wide applications in energy and environment [77,78,79]. Their low cost and non-toxic nature along with excellent electron transfer efficacy further substantiate its application [76]. The CNTs have been used in almost every field of energy and environment, either as a catalyst or composite due to its superior electrical conductivity and surface area [80,81,82]. The physical and chemical properties of CNT enhance the chemical resistance, elasticity, and strength of materials in composite [83]. In general, the low cost and ease availability of graphite has promoted it as an attractive carbon material [84]. It has been widely used in composite with TiO2 for enhancing its photocatalytic activity. It contributes for the suppression of the charge-carrier recombination and increases the visible photon absorption rate [84]. Graphene, the honeycomb atomic scale lattice of carbon, having properties like high specific surface area and high electrical conductivity is also an alternative active carbon compound to increase the photocatalytic activity of semiconductor photocatalysts [85]. This specific compound in combination with metal oxides has been widely applied in photocatalytic CO2 reduction, water split reaction, and organic degradation [86,87,88,89,90,91]. It is also used to synthesize GO which can further synthesize rGO possessing different physical and chemical properties [92]. High surface area and ionisable functional groups of GO craft it as a preferable scaffold in photocatalysis [93]. It would be an ideal support material for photocatalytic water splitting under visible light illumination [94]. Similarly, the layered structure of rGO provides superior site for nucleation and anchors the growth of semiconductor [95]. In specific, it is used in photocatalytic CH4 production by CO2 reduction, in Z-scheme water splitting, and water treatment [95,96,97].

Polymer-based nanomaterials

The conductive polymers have found immense potential to form composites with the various nanomaterials. Polymers like graphitic carbon nitride (g-C3N4), polypyrrole (PPy), polyaniline (PANI), polythiophene (PT), polyvinylidene fluoride (PVDF), polyethersulfone (PES), and cellulose have been used in composite with TiO2 for water purification [98]. In recent years, g-C3N4 has been widely used as photocatalyst due to its controllable bandgap, high stability, and low cost [99, 100]. Its bandgap (2.6–2.7 eV) and properties like biocompatibility, chemical stability, and photo resistivity promoted it as a significant visible light photocatalyst [101]. Doping with selected metals or non-metals suppresses the recombination of the charge carriers and further promotes the visible light utilisation [101]. It has been widely employed for H2 production, CO2 reduction, and organic pollutant removal [98,99,100,101,102]. It was also found that the conjugated polymers like PPy, PANI, and PT addition enhanced the photocatalytic activity, environmental stability, and photocorrosion resistance [98]. PT incorporation increased the photocatalytic activity by reducing the recombination rate and improving the electron mobility [98]. Having good light absorption property, its composite has been used for H2 generation [103]. PANI incorporation extended the absorption in the visible light region; similarly, PPy showed good catalytic activity and narrowed the bandgap of the composite [98]. PANI under light irradiation behave as an efficient electron donor and hole transporter, and, hence, used in combination with limited metal oxides [104]. In a study, boron nitride was supported with PANI and thereby applied to remove carcinogenic dyes [104]. The vinylidene fluoride monomers enhance the light contact area of the partnering photocatalyst [105]. Furthermore, the porous structure of the PVDF helps in steady catalyst deposition for improving the photodegradation potential. Moreover, the strong adhering property of PVDF prevents photocatalyst leaching [105]. On the other hand, the ether sulfone network of PES favors photodegradation owing to its robust photostability and high porosity [106,107,108]. In some recent studies, cellulose, a renewable natural polymer possessing precised structural network with high porosity, is also used as a support for photocatalysts [109, 110]. The presence of hydroxyl group and features like biocompatibility and hydrophilicity favors photocatalysis-mediated water treatment [110].

Modifications in photocatalysts

The modifications in photocatalysts are performed to increase the quantum efficiency of the material. Doping with metals and non-metals, functionalizing with co-catalysts, and formulating binary composites with heterojunction and ternary with an additional co-catalyst are some of the methods adopted to achieve this. These modification techniques are discussed in detail below.

Metal or non-metal doping

This is one of the most familiar and classical techniques to narrow the bandgap of photocatalysts. The narrowing allows the photocatalyst to be active in visible light, thereby enhancing its quantum efficiency. D block metal cations including Nickel, Chromium, Copper, Ruthenium, Ferrous, and Rhodium ions are most commonly considered under metal category, while Carbon, Sulphur, Fluorine, Nitrogen, etc. are considered under non-metal category. Doping with metal ions reduces the bandgap by introducing a new acceptor or donor level within their band structure. The non-metal ions, however, rarely introduce any new impurity level, but they change the valence band potential by shifting it upwards [2, 14]. Figure 2 shows band modification that takes place in photocatalyst when doped with metal or non-metal [2].

Schematic showing the impurity level introduced in semiconductors by metal doping (a), and upshifting of valence band through non-metal doping (b) (the figure is adopted and reproduced with permission from Ref. [2])

Co-catalyst loading

This technique is usually performed for increasing the number of active sites on the surface of the photocatalysts. Most common co-catalysts used are noble metals or metal oxides such as Au, Ag, Pt, Pd, Ru, NiOx, RuOx, etc. [2, 4, 111]. Sometimes, these noble metals are covered with a protective coating of chromia (Cr2O3) which forms a shell around the co-catalyst for specific reasons. At first, they prevent backward reactions on the surface of the photocatalyst when the noble metals are used as core (i.e., reaction between H2 and O2 to form water in the water split reaction). Second, they prevent the metal oxide degradation in the reactant solution when the metal oxides are used as core [112, 113]. Figure 3 illustrates a schematic of the aforesaid mentioned mechanism of shell and core concept [111].

Schematic showing chromia shell preventing O2 molecule photoreduction on both noble metal and metal oxide core (the figure is adopted and reproduced with permission from Ref. [111])

Heterojunction structure

These structures are synthesized by coupling two semiconductors whose band structures are aligned in such a way that they allow for enhanced charge separation compared to the single system. Maximum of two alignments are feasible with this binary combination, viz., type I and typeII [3, 114]. A schematic of the band alignment of the nanocomposites for both heterostructures is shown in Fig. 4 [114].

Band alignment of nanocomposites in type I and II heterostructure (the figure is adopted and reproduced with permission from Ref. [114])

In the type I alignment, both the VB and CB edge potential of either of the semiconductor lies within the bandgap of the other semiconductor as the latter possesses wider bandgap. Since one is having lower VB and CB potentials than the other, therefore, both the bands act as hole and electron collecting sites and are evident from Fig. 5.

Schematic showing electron transfer pathway in type I nanocomposite (the figure is adopted and reproduced with permission from Ref. [3])

Examples of some of the successfully employed type I heterostructure includes CdS/ZnS, BiOCl/BiOI BiOI/TiO2 heterostructure and few more [115,116,117]. Considering CdS/ZnS heterostructure, it is a core–shell assembly in which ZnS with wider bandgap forms the shell, while CdS forms the core. The BiOCl/BiOI and BiOI/TiO2 were of non core–shell assembly in which BiOI was having narrow bandgap, and thus, its edge potential lies within the wider bandgap of BiOCl and TiO2, respectively.

In the type II heterostructure, CB position of the first semiconductor lies above that of the second, whereas its VB lies within the bandgap of the second. Thus, the photogenerated holes have a tendency to migrate to the VB of first one, whereas the excited electrons have a tendency to migrate to the CB of the second. The first and second implies to the position either of the photocatalyst occupy. The mentioned band position and migration of the charge carriers is depicted in Fig. 6a [4]. In general, the type II heterostructure is widely preferred, because it allows the migration of electrons and holes in opposite direction [3]. On the other hand, an alternative pathway that the electrons can follow is Z-pathway. In this scheme, the electrons after photoexcitation in VB of one semiconductor jump to higher potential CB of the second. The oxidation reaction takes place in the VB of the first semiconductor that is located at higher potential than that of the second [3, 4]. This Z-scheme interaction is pictorially represented in Fig. 6b [4]. Since both the redox reactions are occurring at higher potentials, therefore, the Z-scheme pathway results in higher redox efficiency as compared to the redox efficiency of type II. g-C3N4/SnS2, g-C3N4/NaNbO3, Ag3PO4/AgI, CdS/WO3, WO3/g-C3N4, etc. are some successfully synthesized heterostructures that follow either type II or Z-pathway. These have shown good photocatalysis performance for driving direct reduction of CO2, water split reaction, and wastewater treatment [118,119,120,121,122].

Heterostructure formed by semiconductors and their electron mobilisation in type II (a) and Z scheme (b) [4]

Quantum dots (QDs)

QDs are zero-dimensional semiconductor nanomaterials having particle size close to Bohr radius. QDs possess comparatively enhanced material properties than usual nanomaterial owing to the confinement of electrons and associated holes. The energy emitted by excited photons in QDs varies according to the semiconductor used and could be adjusted by varying the particle sizes through quantization or quantum size confinement [123, 124]. It appreciably enhances the photostability of the adjoining photocatalyst, increases electron hole separation, and, thus, helps in improving the overall quantum efficiency of the photocatalyst [77]. The carbon QDs (CQDs) in combination with Ag3PO4 and Ag showed enhanced visible light photocatalysis with a clear quantum confinement [77]. Therefore, the QDs or CQDs in standalone or in combination with noble metal and photocatalyst of any origin act as an efficient energy material for photocatalysis applications.

Each of the modifications mentioned above are having their own advantages and disadvantages. Doping by the metals or non-metals internally changes the band structure of the photocatalyst which makes them active in the visible region and thus aid in increasing the quantum efficiency, whereas co-catalyst loading increases, the number of active site present on the surface of photocatalyst thus is helpful in increasing the product yield. QDs are quite new in this area and are responsible for the quantum confinement effect which results in changes in several properties of the nanomaterial as well as a better charge separation and stability of the photocatalyst. Furthermore, the application of heterostructures is revolutionizing, since it allows composite consisting of two photocatalysts to be present in a system. Their appropriate band alignment results in better absorption of visible light and charge separation than the single [125, 126].

Synthesis of nanostructure materials

There is a wide variety of synthesis technique available for the synthesis of aforementioned nanostructure materials. However, the selection depends on the need and availability of the method and material for the application. The most commonly adopted synthesis method for some specified energy and environmental applications are discussed below, and their respective schematic representation is shown in Fig. 7.

Schematic representation of various synthesis methods. a Arc discharge (the figure is adopted and reproduced with permission from Ref. [269]). b Sonochemical (the figure is adopted and reproduced with permission from Ref. [270]). c Exfoliation (the figure is adopted and reproduced with permission from Ref. [271]). d Hydrothermal (the figure is adopted and reproduced with permission from Ref. [272]). e Solvothermal (the figure is adopted and reproduced with permission from Ref. [273]). f Microwave-assisted synthesis (the figure is adopted and reproduced with permission from Ref. [274]). g Polyol synthesis (the figure is adopted and reproduced with permission from Ref. [275]). h Chemical vapor deposition (the figure is adopted and reproduced with permission from Ref. [276]). i Ball milling (the figure is adopted and reproduced with permission from Ref. [177]). j Flame spray pyrolysis (the figure is adopted and reproduced with permission from Ref. [277]). k Microemulsion (the figure is adopted and reproduced with permission from Ref. [278]). l Sol–gel method (the figure is adopted and reproduced with permission from Ref. [279]). m Electrodeposition (the figure is adopted and reproduced with permission from Ref. [280])

Chemical vapor deposition

Chemical vapor deposition (CVD) is a multidirectional conformal deposition technique in which a substrate surface is coated with the desired nanomaterial. The deposition is facilitated by a heat treatment followed by a chemical reaction with precursor gases. The sequence of steps is as follows: (1) reactant advent inside the reactor; (2) reaction of reactor gas; (3) diffusion of the reactant gas on substrate surface; (4) adsorption of the gaseous molecules on substrate surface; (5) surface reaction; finally, (6) by-product desorption and removal. Material of construction of substrate, reactant gas applied, and temperature and pressure exerted in the reactor chamber are essential factors on which the CVD process depends. The temperature and reaction time are crucial that influences the product formation. For example in a study involving MWCNT formation in the range of 590 and 850 °C, it was found that the higher temperature disrupted the alignment of the nanotubes. The diameter of the tubes increased from 16 nm to 45 nm with increment in temperature. Furthermore, increasing the reaction time resulted in longer tube formation [127]. The CVD can be further classified depending upon energy source, substrate, pressure, etc. as rapid thermal, laser-induced, plasma-enhanced, non-porous, atmospheric pressure, ultrahigh vacuum, direct liquid ejection, and many more. The major drawback of this method is its high cost and unsuitability for fabricating certain materials. It is widely employed technique for CNT, CNF synthesis, and synthesis of metal oxides posing specified morphology. These include granular, broccoli-like, crystallite facetted texture, semi-hexagonal shape, high crystallinity and hexagonal structure, triangles, etc. [128,129,130,131,132].

Apart from the above-mentioned CVD, aerosol assisted is recently developed technique and gains attention owing to its low atmospheric pressure operation [133]. It is an easily scalable single-step technique in which the solution containing the substrate is atomised and transported with the help of a carrier gas in the deposition chamber [134]. It finds applications in synthesizing photocatalysts with mixed phase deposition. In one such typical synthesis with SnO2/TiO2, the surface morphology changed from cassiterite SnO2 to anatase TiO2, while synthesizing ZrO2/TiO2 results in dense array of facets [133, 134]. Similar synthesis for a pure SnO2 resulted in flattened and uniform morphology possessing round-shaped crystals and flattened grains [135].

Sol–gel

Sol–gel is one among the synthesis methods that can yield high-purity nanomaterials at room temperature. It adopts colloidal with transitional solution and gel-phase formation. In general, metal alkoxides are used as precursors and these precursors serve as monomers for polymerisation which is followed by hydrolysis, condensation, and crosslinking to yield the desired gel. It is widely used flexible technique to form ceramics and composite materials with high surface area. Its limitation includes the use of costly precursors and development of unwanted cracks on drying. pH and temperature are the factors upon which the sol–gel process depends; for instance, in PbO–TiO2 formation, lower temperature (~ 30 °C) and acidic pH resulted in anatase structured TiO2, while incremental (~ 70 °C, Alkaline) resulted in tetragonal structure of PbTiO3 [136]. Materials like spherical-shaped C-TiO2, 3D ordered macroporous 3DOM PW11Co–APS–TiO2 with interconnected honeycomb pore structure, spherical crystal ZnO, shapeless Fe2O3-TiO2, metal ion-doped TiO2, irregular Bi2WO6Porphyrin/SiO2/Cp*Rh(bpy)Cl Hybrid to mimic chloroplast, etc. [137,138,139,140,141,142,143].

Pyrolysis

Pyrolysis is a vapor phase synthesis technique occurring at high temperature. It is further classified as follows:

Flame spray pyrolysis

A high-energy flame is produced in this technique using a laser employing carbon dioxide in a closed chamber. The precursors are first passed into the reaction chamber in the form of aerosol where they undergo flame treatment followed by rapid cooling to achieve the desired product. Thus, temperature is only the governing factor that can influence this technique. This can be substantiated by the BiVO4 synthesis, where, at relatively low temperature, scheelite-monoclinic phase was observed, while, at higher temperature, the phase changed to tetragonal [144]. It is generally used for synthesizing crystal-modified CuS, classical non-metal-doped photocatalysts, and heterojunction composite with higher surface area [145,146,147,148].

Laser pyrolysis

It is a technique in which the substrates are decomposed in an anaerobic environment using infrared laser source. Aerosol precursor formation occurs when the reactant molecules are dissolved in a solvent followed by ultrasonic spraying. These aerosols are subjected to laser treatment resulting in final desired product [149]. The nanomaterial possesses small diameter without any agglomeration of particles [150]. Nanomaterials formed by this method include spherical-shaped N-doped and Au-loaded TiO2 arranged in chain geometry and partially facetted TiO2/SnO2 [151, 152].

Hydrothermal

The hydrothermal technique employs autoclave for heating the precursors in water solvent at elevated temperature and pressure. In general, the temperature used for heating is above 100 °C and less than 300 °C. This high temperature of the closed system generates high-pressure environment aiding solubility of reactants. This hydrothermal method is a crystallisation process that involves nucleation and crystal growth as predominant steps. Due to its ease and simple operation, this method is most widely used for various nanomaterial preparations. Since temperature is the only direct controlling parameter, it has a significant influence on the product. For example, in a typical ZnO nanorod synthesis, dimensions of the nanorods were directly proportional to the temperature [153]. Moreover, the residence time could also play an effective role, as the nanorod diameter increases with increase in reaction time [153]. In the same study, pH also influenced the ZnO synthesis by changing its structural morphology, i.e., acidic pH favored nanorod morphology, whereas alkaline favored flower-like structure [153]. A variety of nanomaterials were produced by this method including heterostructures like g-C3N4/Bi2WO6 [154]. The obtained g-C3N4 showed aggregated laminar structure, while Bi2WO6 exhibited flake-like morphology. Similarly, photocatalyst possessing irregular sheet morphology, irregular particles, flower-like spheres, spherical-shaped nanoparticles, and hexagonal morphology was also synthesized by this method [155,156,157,158,159].

Solvothermal

The solvothermal method is similar to the hydrothermal method; only difference is that the solvent used in this technique is non-aqueous. This process depends on factors like solvent, temperature, and pressure. Organic solvents like 1, 4-butanediol produce thermally stable nanomaterials as compared to toluene [160]. In some instance, increase in temperature directly influenced the synthesis by significantly decreasing the particle size of the nanomaterial [161]. This method can be considered if the researchers are looking for a photocatalyst with defined morphology as listed: Gd-doped TiO2 bearing hollow flower morphology, hierarchical TiO2 of chrysanthemum flower morphology, Bi2WO6 with flower morphology, and many more [162,163,164,165,166]. In recent years, microwave-assisted solvothermal synthesis method has gained attention and deployed for synthesizing materials with more uniform structure with tunable intrinsic properties. This is due to uniform and even temperature induced by the microwave throughout the reaction [167, 168]. Few cases include synthesis of α-Fe2O3 nanosheet consisting of uniform hierarchical hollow mesoporous with microspheres structure and Bi4O5I2 having uniform microsphere geometry [167, 168].

Microwave-assisted synthesis

This method employs microwave for heating of reaction mixture to synthesize nanomaterial. The rapid attainment of high temperature and pressure by microwave heating enhances the reaction rate and homogeneous mixing. It has also made remarkable use in combination with other synthesis methods like solvothermal, sol–gel, CVD, polyol synthesis, etc. The faster reaction product with a better yield by implementing microwave with other techniques is the key factor for its application. Some of the nanomaterials obtained by synergistic effect of this method are Ag/g-C3N4 having crystalline Ag nanoparticle and CdS having smaller particles with enhanced monodispersity, etc. [169, 170].

Sonochemical

In sonochemical synthesis method for nanomaterials, an indirect interaction between the precursor and ultrasound via “acoustic cavitation” takes place. In this process, the ultrasound wave leads to the formation of bubbles in the sample which oscillate with collecting ultrasonic energy and grew in size. The excessive growth in size ultimately leads to its implosive collapsing leading to the release of stored energy which promotes the formation of nanomaterials. It is a preferred technique as the reaction takes place at ambient temperature. The pH is the major factor that affects the nanomaterials formed in sonochemical synthesis. When BiPO4 is prepared at very low pH (~ 1), it forms irregular cluster; upon increasing (~ 5) results in rod-shaped structure, and at highly alkaline condition (~ 12), irregular particles were obtained [171]. The nanomaterials like N, Cl-co-doped TiO2, Graphene-Ce-TiO2, and Graphene-Fe-TiO2, Ag-modified Bi4Ti3O12, and rGO decorated with zinc sulphide, SrMnO3, etc. are formed by sonochemical method [172,173,174,175,176].

Microemulsion

Microemulsion is a type of liquid-phase synthesis method in which reverse micelle serves as reaction unit. Oil in water or water in oil microemulsion depending on the surfactant used reactants collides with each other to nucleate and form the desired nanoparticle. Microemulsion is a facile and efficient synthesis technique providing control over the structure, shape, and porosity of the resulting nanomaterial [177]. The concentration of aqueous solution and reaction temperature are the major parameters that influence the product. In a particular TiO2 synthesis, increasing the concentration of aqueous solution increased the particle size of the TiO2. Moreover, by increasing the reaction temperature from 20 to 50 °C favored the increment of particle size [178]. The pH also influenced the product, as increase in pH from 8 to 10 decreased the particle size [178]. It is employed for the synthesis of a wide range of nanomaterials with defined shaped and some of them are Zn-doped TiO2 with globular shape, BiOCl possessing hollow hemispherical shells with sheet-like structure, 2D and 3D Bi4O5Br2, ZnO/ZnWO4 heterojunction, etc. [179,180,181,182].

Arc discharge

In this technique, an arc is produced between two electrodes kept in an inert environment which leads to the deposition of nanomaterial on the electrode surface. A direct current is supplied to the electrode chamber which sublimates the anode and deposits it as nanomaterial on the cathode. The method is predominately employed for the production of fullerene and CNT. The precursors used along with its concentration are the factors upon which the product formation by arc discharge depends. A study of Wang et al. using polyvinyl alcohol (PVA) and iron as catalyst for CNT formation showed that higher PVA concentration produced entangled MWCNT with 60–190 nm diameter; however, when the concentration of iron was higher, no MWCNT formation occurred. Moreover, using PVA alone yielded MWCNT of diameter range of 30–60 nm [183]. Apart from that, it is also used in synthesizing materials like ZnO-graphene hybrid nanostructure, TiO2/C having spherical morphology, multiwalled carbon nanotubes (MWCNTs), single-walled carbon nanohorns (SWCNHs), and multiwalled carbon nanohorns (MWCNHs) having fine well defined and straight walls, hexagonal wurtzite ZnO, and rutile TiO2 consisting of nanorods and nanospherical structures, etc. [184,185,186,187].

Electrodeposition

Electrodeposition is a flexible, low cost, and widely used method for coating a substrate surface with nanomaterials with the aid of current. In general, it is a surface technique to improve its characteristics performed at room temperature. The electrodeposition process employs an anode and a cathode (substrate) dipped in electrolyte solution. Whenever the electricity (in the form of direct current) is passed through the electrolyte solution, the cations in the solution gets reduced and attached to the cathode surface forming a thin layer of desired nanomaterial. The thickness of the deposited nanomaterial depends on the time and intensity of current passed. Apart from them, the electrolyte temperature is a major factor influencing electrodeposition. Cu2O thin-film formation was highly influenced by electrolyte temperature and exhibited different phase and structure at different temperature [188]. The only drawback of electrodeposition is its uneven plating thickness at the substrate surface. However, this technique can synthesize varieties of nanomaterials with specified structure and composition. Some of this includes spherical-shaped Bi2WO6/graphene with hierarchical structure, uniform well-aligned MnO2/TiO2 nanotube arrays, granular and densely agglomerated multiphase CuInSe2 with spherical structure, WO3 consisting of irregular nanocrystalline particle, and Cu/FTO possessing hexagonal nanoslice structure [189,190,191,192,193].

Polyol synthesis

It is a liquid-phase synthesis method in which multivalent alcohols called polyol with precursors and capping agents are subjected to high boiling. Mostly ethylene glycol, diethylene glycol, glycerol, and butanediol are used as solvent and simple metal salts like sulphates, nitrates, halides, etc. are used as precursors. The high boiling point (200–320 °C) of polyol facilitates crystalline nanomaterial formation. The pH of the solution influences the product formed by polyol synthesis as in reduces the particle size with an increase in pH and the case was observed in Sn synthesis [194]. This method was also adopted for synthesizing materials of specified shape. Some of the reported shapes include rose flower resembled Cu2O, highly dispersed SnO2/TiO2, and hierarchical spherical nanoflower-structured CuS [170, 195,196,197,198].

Exfoliation

Exfoliation is mainly used to prepare “ultrathin 2D nanomaterials”. The exfoliation method can be further divided into two types.

Mechanical exfoliation

The nanomaterials are obtained by peeling of substrate surface with a scotch tape. It is a time-consuming and low yielding method, and is mostly preferred to synthesize graphene from graphite rather than any other materials.

Chemical exfoliation

The exfoliation or peel off of substrate surface takes place in chemicals. The oxidation of substrate takes place either by ultrasonication or mechanical stirring that weakens the bonding of substrate layer to yield desired nanomaterial. As like mechanical, this method is mainly employed to synthesize graphite oxide from graphite. In some instance, it is used for synthesizing photocatalyst like hexagonal SnS2 of plate morphology, TiO2-MoS2 hybrid-bearing dense TiO2 crumpled on MoS2 nanosheet, and irregular g-C3N4 of tissue-like 2D nanosheet [199,200,201].

Ball milling

In ball milling, the samples are in powder form and are subjected to mechanical treatment for obtaining finer homogeneous nanoparticles. The sample is charged in a milling chamber-containing balls which perform the grinding operation. The chamber along with the balls is then rotated, causing collision to break the samples into smaller fragments. It is used for synthesizing selective nanomaterials and some of them are as follows: MoS2–TiO2 having layered MoS2 dispersed on TiO2, C3N4/TiO2 consisting of irregularly agglomerated elliptic particles, CoFe2O4–rGO having evenly fixed CoFe2O4 nanoparticles on the stacked and wrinkled rGO sheets, CoO micropowder having nanocrystal structure, Ag/ZnO possessing aggregated crystalline structure, etc. [202,203,204,205,206]. High-energy ball milling is the recently preferred ball-milling technique used to synthesize several nanomaterials like Ag/BiVO4, Cu5FeS4, etc. [207, 208].

Mechanistic features

The behavior of nanostructured material mostly depends upon the origin of material, its composites, method adopted, and various governing parameters of synthesis. The physical morphology of a particle significantly impacts the behavior of energy harnessing materials. It is a known fact that nanostructured materials possess distinct properties as compared to bulk. Equivalently, the surface characteristics also play a vital role, and moreover, the centric of the review is focused on the structure-defined mechanistic features. Over a period of years, significant efforts have been made on developing materials using various synthesis methods for achieving several morphological features. These unique features of nanostructured materials can be further tailored and engineered specifically to tackle the current challenge. The different type of nanostructures that we would be concentrating on are quantum dots, thin films, sheets, tubes, rods, fibers, wires, and various other 0-D, 1-D, and multidimensional structures. Hereon, we would discuss on the relationship between mechanistic features of the materials and the methods used for synthesis followed by its photocatalytic performance.

Zero-dimensional materials

QDs

QDs are achieved by decreasing the size of bulk semiconductor to nanometer level and the behavior of the atomic and subatomic particles impacts photon upconversion, thereby shifting the absorption towards a shorter wavelength. In a study by Zhao et al., higher charge separation leading to extended lifetime of photoinduced charges and lower recombination rate was obtained by depositing MoS2 quantum dots on the surface of TiO2 nanotubes. This achievement is attributed to quantum confinement effect [209]. In a similar study, CdSe quantum dot over WS2 composite prepared by Hao and team showed efficient separation of electron hole pairs, thereby decreasing photoluminescence and enhancing photocatalytic performance [210]. Thus, the synergism of all these properties makes it an efficient material for light-driven applications. Although quantum dots are very attractive dimensionless material, it has drawbacks such as cytotoxicity, poor photostability, and material recovery, and hence, further research is required before it is considered for real-world applications [211].

Thin films

One of the most common and easy ways of synthesizing nanostructured materials is thin films coated on various substrates. Nanosheets and nanomembranes have similar structure as like thin films but without the support of a substrate. Dimensionally, such materials can be classified as 2-D, but most of their light-driven mechanism takes place in the third nanodimension, classifying it as a 0-D material. Light-driven application of thin films were first investigated by Fujishima’s group in the early 1990s, wherein TiO2 thin films were prepared over a silica substrate sintered at 450 °C yielding exceptional photocatalytic property as compared to classical P-25Degussa [212].

CVD and electrodeposition are the most popular and well-practised techniques for depositing desirable materials onto a substrate [128, 129, 131, 133,134,135, 192]. On the other hand, mechanical or chemical exfoliation can deliver photoefficient materials in the form of plate and sheet geometry [199,200,201]. Thin films provide excellent support systems for introducing various micro- and nanostructures onto the planar films and membranes. For example, as shown in Fig. 8(a), Zhang et al. grew rod-shaped grass-resembling monoclinic W18O49 through solvothermal route and bundled it onto g-C3N4 sheets by exfoliation through sonication. The obtained defined structures of the composite exhibited heterojunction through Z-scheme mechanism, resulting in enhanced visible light photocatalytic activity [213]. In similar work as shown in Fig. 8b, c, Leong and co-workers wrapped the classical perovskite (SrTiO3) onto amorphous g-C3N4 nanosheets by a facile thermal method giving symbiotic interaction resulting in enhanced solar photocatalytic behavior [214]. Likewise, BiOBr@graphene oxide was synthesized through solvothermal approach and wrapped around melamine foam by Huo et al.. The final ternary ends up with a structure, wherein the pollutants are transferred through channels provided by the melamine foam leading to enhanced mass transfer and visible light photocatalysis [215]. The schematics of the above-discussed materials morphologies are presented in Fig. 9.

SEM images of different samples of melamine foam (the figure is adopted and reproduced with permission from Ref. [215])

To further enhance the photocatalytic activity of a desired material, doping of transition metals is widely practised and provides synergetic change in behavior of excitons. The controlled composition of precursors makes it easy to dope metals or elements during synthesis. Imani et al., adopted sol–gel approach for doping Cr into titania thin films forming cubic, hexagonal, and worm-like morphologies due to varied dopant concentration. The Cr doping increased the lattice mismatch, resulting in microstructural coarsening [216]. Sayikan and team approached hydrothermally to synthesize Sn-doped TiO2 nanoparticles and further developed a thin film by spin coating. As a result, the doped material showed a better photocatalytic degradation than that of undoped TiO2 [217]. The use of non-metals is also practised for doping various semiconductors to improve the efficiency of energy materials [146, 147, 172]. This is achieved through a more favorable flame and laser pyrolysis route [146, 147, 151]. Using this technique, Smirniotis’s team synthesized N-doped and S-doped TiO2 thin films, while a team led by Ahmad prepared C- and S-doped and mixture of C- and S-doped TiO2 thin films via the traditional sol–gel technique [146, 147, 218]. Ultimately, all the developed doped materials exhibited good visible light photocatalytic activity.

The above-discussed zero-dimension nanostructures owing to its unique properties obtained from quantum confinement effect have demonstrated appreciable photocatalytic activity. Furthermore, the appreciation should also be attributed to high surface area with uniform pore size distribution, thereby effectively moving the activated electron–hole pairs to the surface consequently increasing the availability of active sites for reaction.

One-dimensional materials

The basic category of one-dimensional semiconductor comprises of solid nanostructures that grow in a single direction and some classical examples are wires, rods, and simple 1-D hollow tubes. These structures have their own set of unique properties which are further reviewed and discussed in Table 1. Therefore, just by introducing various structures with unique properties has improved the photocatalytic activities of semiconductors. A schematic illustrating synthesis of 1-D nanotube arrays utilizing multiple light reflection phenomena is presented in Fig. 10 [219].

Multidimensional hierarchical hybrid materials

The advancement in the development of sophisticated instruments significantly improved and modified the synthesis approach. As a result, fabrications of multidimensional hierarchical structures were realistic. These multidimensional structured materials were economically obtained with the support of hydrothermal, solvothermal, and sol–gel methods. Such multidimensional semiconductor nanomaterials usually bear composite structures, which further tends to improve the surface area and other photocatalysis governing intrinsic properties. Recently, the focus has shifted on the formation of multidimensional semiconductors with hierarchical structures for the purpose. The most significant among those were presented in Table 2 with their salient features.

It is evident that, in most cases, the surface chemistry of a concentric core shell structure is restricted to the outer shell only, thereby urging the need to introduce a new-generation hybrid structure of non-centrosymmetric nature. The pictorial representation of such non-centrosymmetric nanostructures as described by Weng et al. is presented in Fig. 11 [220].

Schematic showing development of non-centrosymmetric nanostructures (the figure is adopted and reproduced with permission from Ref. [220])

It is clear from the figure that the structure holds series of multiple functional units where each subunit is independently capable of functionalisation, leading to its synergisation, resulting in commanding photocatalytic activities. Although a rudimentary study was conducted by Weng et al., a further detailed investigation is required to understand its complete mechanism [220].

Noble metal deposition

Noble metal deposition onto desired metal surface is a common approach practised over decades. This is generally achieved by chemical and photo reduction or by direct deposition of chosen noble metal on to desired material [221, 222]. Interfacial contact between support and noble metal is one among the important factors on which the photocatalytic activity depends. Hence, for better interfacial contact, researchers used a direct defect-mediated growth for depositing noble metal [222]. On the other hand, the size of noble metals also has a significant effect on light-harvesting activities. This was very well revealed by a team led by Kamat, where they demonstrated the intrinsic inherent feature, i.e., shift in Fermi energy level attained by varying the Au size onto TiO2. A greater shift in Fermi energy level was observed in smaller Au particles than the larger one. The study also showed the influence of the same on the recombination of the charge carriers, concluding the contribution of Au for visible light shift in TiO2 and improved quantum efficiency [223].

In most cases, silver is opted by the researchers owing to its cost and delivery of better mechanistic features for light harvesting. However, a detrimental report was observed by Barakat and co-workers in which they utilised TiO2 as a desired semiconductor. This unusual contradiction was attributed to the change in structure from fibers to rods with an increase in the silver content and the same was revealed by the team [224]. Ma and team embedded Pt on molybdenum carbide through an in situ route. This embedment allowed for better interface properties, thereby enhancing the photocatalytic activity of molybdenum carbide [225]. Though many such reports were available in the scientific database most of them were critically reviewed and reported elsewhere [226].

Application of nanostructured materials

In energy conservation and generation, photocatalysis can aid in two particular ways: (1) water splitting reactions for H2 production and (2) direct photoreduction of CO2. Photocatalysis in a sequence can be described as follows. The first step in photocatalysis involves absorption of suitable wavelength of solar energy, such that its energy exceeds the band-gap energy. In the second step, thus, the photoexcited electron moves from valence band to conduction band forming an electron–hole pair favoring redox reaction at the valence and conduction band. Hence, an effective photocatalyst is one which possesses low band-gap energy, resisting ability to prevent recombination of electron–hole pairs, and high redox potential. This section discusses various operation parameters, its interplay with the performance, some challenges and strategies adopted in the application of nanostructured materials in energy, environmental safety, and remediation. Table 3 presents various photocatalysts that have been used for water splitting reaction, CO2 photoreduction and degradation pesticides, and other persistent organic pollutants (POPs). This section emphasizes on the modifications that have been performed for the light-driven energy applications.

Water split application of the nanostructure photocatalyst

Titanium oxide is one of the most widely studied photocatalysts as it has low toxicity, high chemical and biological inertness, and high photocatalytic reactivity [227]. Its limitation is that it is naturally activated by UV radiations which form a very low percent of solar spectrum [228]. However, doping with transitional metals such as Pt, V, Cr, or Fe have enabled the absorption spectrum towards visible. In a similar effort, hierarchal porous structure (HPT-500) TiO2 was deposited with Pt and Zinc phthalocyanine (PCH-001) to form a composite. The results showed that Pt-HPT nanocomposite with 0.25 µmol/15 mg of nanocomposite (HPT-0.25) exhibited maximum H2 evolution. The H2 yield was found to be 2260 µmol at λ ≥ 450 nm (300 W xenon arc lamp) and the turn over number was found to be 18,080. Highest apparent quantum yield (AQY) of 11.97% was achieved at 690 nm for HPT-0.25 [229].

Exfoliation is a technique that can either modify or reduce the size of the photocatalysts. One major advantage of using exfoliation is that it does not alter the crystal structure. Due to reduction in size, the migration distance of charge carriers is reduced and the surface area of the catalyst is increased [230]. In spite of this, one challenge faced in the exfoliation is excessive time consumption and low-scale production. To address this issue, Yuchao and Liejin engineered a new ultrasonic method for rapid and high yield of (TBA/H)Pb2Nb3O10 by exfoliation. The obtained (TBA/H)Pb2Nb3O10 was loaded with Pt and used as visible light photocatalyst for production of hydrogen (λ > 415 nm), thereby making it as a first and foremost visible light-driven AB2Nb3O10. The perovskite yielded 50 mmol/h and 17 mmol/h of H2 under full-arc and visible light irradiation, respectively. The study concluded that, due to smaller migration distance of charge carriers, efficiency of electrons for hydrogen production improved [231]. Perovskite nanosheets can also improve the photocatalytic activity. In one such study, experiment with HCa2Nb2TaO10 was performed. This particular perovskite displayed a quantum yield of 80% at 300 nm for H2 evolution. This study concluded that the composition of metal oxides played a key role in determining the photocatalytic activity [232].

CQDs along with graphene QDs have become very popular in photocatalytic energy applications. The desired feature of the CQDs is broad optical absorption accounting for photoluminescence [233, 234]. In addition, the optical absorption is in the range of UV–Vis and up to near IR [235]. Hence, the core carbon nanoparticle can use the visible light to generate necessary charge carriers for catalytic energy conversion. Similar property is also exhibited by graphene QDs and other carbon-based QDs [236]. However, in present scenario, many reported catalysts suffer low quantum efficiency with solar-to-hydrogen (STH) ratio less than 0.1%, high cost, and poor stability [237]. To combat this issue, Carbon nanodot-carbon nitride (C3N4) has been reported with high performance for water splitting reactions using solar energy. Carbon nitride is found in high quantity on the earth crust, and thus, it lowers the cost of production. This composite exhibited a decreased bandgap of 2.77 eV with increased visible light absorption and quantum efficiency of 16%. The overall solar energy conversion efficiency was reported to be 2.0% [238].

Shinde et al. reported improvement in photocatalytic activity of g-C3N4 under visible light irradiation by doping it with carbon dots and TiN nanoparticles. The prepared composite showed sixfold increases in photocatalytic activity as compared to pure g-C3N4. Doping with carbon dots eliminated the problem of C3N4 poisoning by H2O2 [238]. Utilizing the broadband plasmonic resonance of TiN nanoparticles increased the absorption spectrum from UV–Vis to NIR (320–700 nm), thereby convalescing the performance of photoelectrochemical water splitting. The calculated incident photon-to-current efficiency for pure C3N4 was found to be in the range of 0.089–0.00077% and that for TiN-C3N4-C dots was 1.143 to 0.0056% for 400–700 nm [239].

Graphene has some distinct properties like high work function, intrinsic electron mobility, and optical transmittance which make it highly suitable for photocatalytic activity [240]. Thus, it rapidly accepts, transfers electrons, and decreases the recombination rate. Graphene has been used as a co-catalyst in a study by Mateo et al., where a few layers of graphene were used to support Cu2O nanoplates bearing 2.0.0 facet. The prepared Cu2O strongly interacted with graphene and improved hydrogen yield to 19.5 mmol/g in the presence of 300 W Xe lamp [241].

Nanostructure photocatalyst for driving artificial photosynthesis

Photocatalytic conversion of carbon dioxide into methane (fuel) has been considered as an efficient and viable technique for dealing with the global environment challenge of carbon sequestration. TiO2 and CdS are popular semiconductor nanomaterials employed for this purpose; however, the problem with most is that they get excited only in the UV region [242]. Lin et al. created a photosystem with g-C3N4 as a photocatalyst with triethanolamine (TEOA) as hydrogen and electron source. Here, Co2+ ion when coordinated with bipyridine ligand activated the electron transfer process. g-C3N4 was coated with cobalt oxides (oxidative catalyst) which aided in transfer of light generated electron–hole pair with a turnover number of 4.3. The reduction of CO2 resulted in 3.7 µmol of CO and 0.6 µmol of H2. It was also noted that low Co2+ concentration was beneficial for selective reduction of CO2, whereas an increase in Co2+ favored the H2 production [243].

In a recent path breaking study, strontium titanium nanorods were used as UV light-harvesting photocatalyst along with CuxO nanocluster and cobalt phosphate as co-catalyst to enhance the selectivity of CO2 using water as the donor molecule. The team constructed an artificial, wireless leaf like plate using SrTiO3 film deposited with CuxO by simple impregnation method. As a co-catalyst, cobalt and phosphate nanoparticles were later deposited on the film using photoelectrochemical method. TEM reports showed that the deposited co-catalyst was highly dispersed onto the porous structure of STO, enhancing electron–hole pairs. The result was first of its kind as it displayed 80% selectivity for CO generation over H2 production using Hg–Xe lamp. The reported co-catalyst-loaded SrTiO3 film showed 2.5 times more CO formation than bare SrTiO3 film [244].

Fabrication of noble metal-free polyoxometalates (POM) reduces the cost of photocatalysts to a great extent. One such effort is seen in a study by Zhou et al. while synthesizing Co4 doped g-C3N4. Modification with Co4 increased the oxidative capacity of g-C3N4 and led to increased reduction of CO2 and enabled ease charge transfer. This hybrid displayed higher yield of CO from CO2 in the order of 107 µmol g−1 h−1 (43% wt. of CoO4) at λ ≤ 420 nm with 94% selectivity. Prolonging the irradiation up to 10 h, CO yield surged to a maximum of 896 µmol g−1 h−1 [245]. Rhenium has been widely explored for reducing CO2 due to desirable photocatalytic properties of the former. In a study Re3(5-dmb)3+/fac-[Re(bpy)(CO)3(MeCN)]+ was used as photocatalyst for conversion of CO2 to CO. Trinuclear Re ring were used as a redox photosensitizer and fac-[Re(bpy)(CO)3(MeCN)] as a catalyst. The π–π interaction in the Re ring increased the lifetime of the electrons in excited state. This combination reduced the CO2 to CO with the highest quantum yield of 82% at λ = 436 nm [246].

Wang et al. obviated the use of expensive noble metals by replacing with CuO-ZnO. Both ZnO and CuO was synthesized in the wire form where ZnO was deposited on CuO using atomic layer deposition technique. ZnO grew epitaxially, demonstrating island growth mechanism that favored recombination free transfer of electrons. The defects created by ZnO increased the life time of the electrons. The maximum CO yield under UV–visible–NIR (250 nm ≤ λ ≤ 810 nm) was 1.98 mmol g-cat−1 h−1 for eight cycles of atomic layer deposition of ZnO with lower quantum yield [247]. Tungsten selenide in composite with graphene was attempted for direct CO2 reduction. The photocatalytic efficiency was increased for WSe2 by efficient reduction in recombination of electron–hole pairs with increase in electron transport facilitated by graphene. The study utilized an additional sacrificial agent in the form of Na2S/Na2SO3. The CO2 was reduced to methanol with a maximum yield of 4.3257 µmol g−1 h−1 under visible light and 5.0278 µmol g−1 h−1 under UV light [248].

Nanostructure photocatalysts for water and wastewater treatment

Nanostructured photocatalytic materials are widely used to purify both water, wastewater and they are known for degrading the recalcitrant organics. The most common materials widely used include TiO2, ZnO, WO3, g-C3N4, etc. [6,7,8,9,10,11,12, 249,250,251,252,253,254,255,256]. Photocatalysts have proven to be helpful in degrading several categories of organic contaminants including POPs and endocrine disrupting compounds (EDCs). Various parameters that affect the photocatalysis include pH, availability of solar light, band structure of the photocatalyst, concentration of the photocatalyst, concentration of pollutant, etc. pH of the reaction mixture exhibits profound effect on the degradation of pollutants, for instance, in an experiment performed by Yosefi and Haghighi [249], it was found that the photocatalyst heterojunction (p-BiOI/p-NiO) was able to degrade acid orange 7 more effectively at strong acidic condition as compared to neutral. The acidic condition modified the surface charge of the photocatalyst and thus enhanced the degradation process. Other important parameters that can affect the degradation process are photocatalyst dosage and pollutant concentration. Higher concentration of photocatalyst can lead to agglomeration, while pollutant can prevent sunlight from reaching the surface of photocatalyst [249].

A major challenge observed by the researchers was separation of nanoparticles after the completion of the treatment. This was overcome by decorating TiO2 with ferromagnetic (N-TiO2@SiO2@Fe3O4), which imparts magnetic properties leading to easy separation [250]. Another approach adopted by researchers to solve this problem is immobilisation of nanoparticles. This strategy prevents the photocatalyst from washing out as well as increases its reusability. However, a major problem associated with immobilisation was the poor degradation rate of pollutant because of its decreased surface area-to-volume ratio. Furthermore, to resolve this problem, Tototzintle and group used H2O2 as an external electron acceptor. The usage of H2O2 increased the production of hydroxyl radicals, thereby enhancing the photocatalysis [251]. A usual problem faced by most researchers with metal sulphide was their instability caused by the self-oxidation of sulphide ions. The conjugation of chitosan with metal sulphide (ZnS) eliminated the self-oxidation issue where the chitosan acted as a capping ligand. [252].

Synergizing photocatalysis with processes like adsorption can show a greater impact. In a similar approach, a Fe3O4/BiVO4 heterojunction was synergised with Pinus roxburghii-derived biochar and studied for the degradation of methyl paraben. It was found that the photocatalyst was able to degrade only 74.98% of methyl paraben, whereas the photocatalysis adsorption synergised was able to degrade 95.64%. The presence of biochar clearly acted as adsorbent which accumulated larger amount of methyl paraben molecules on its surface and thus allowed its easier degradation. Furthermore, the presence of Fe3O4 allowed easy separation of the composite after treatment [253]. Several other challenges faced by the researchers and the respective strategies chosen to solve the issue are presented in Table 3.

Future prospect

Environmental challenges and energy crisis are the biggest concern of this era; however, its solution is hidden in an outskirt domain of “nanotechnology”. It refers to the exploitation of the incredible physiochemical properties of materials which have been attained by manipulating the size and structure of the material. After the discovery of light-assisted catalysis, engineered nanostructured material has become more popular tool to harvest photon energy from solar spectrum [254, 255]. Later, this technology was extended to develop more efficient nanostructured assemblies with captivating designs for enhancing surface plasmonic, since the manipulation in morphology and topography of materials can modify the intrinsic properties of nanomaterials. Therefore, architecting of nanomaterials in varying fashion to enhance the efficacy and surface plasmonic performance has piqued the global attention and becomes a fascinating approach [255, 256].

These reviewed designs and approach are attractive in the arena of nanotechnology. Yet, biomimicking is emerging as a pioneer technology to revolutionize the scientific world with a modern notion to light-assisted designs. Bio-inspired duplicating of hierarchical structures demonstrates great design that instigated the distinctive architectures of biological world. A few such reports include replicate of photosynthetic pigment of cyanobacteria, scale of butterfly wings and snake, plant leaves, and spine of some marine polychaete worms [226, 257, 258]. For example, absorbance of wide range of solar light (300–800 nm) has been inferred in the wings of Paysandisia archon moth owing to the nanostructured fabrication of wing scale. The hierarchical assembling of various pigmentary nanostructures of 3D photonic crystals in the upper lamella of wing scale is finely tuned with light absorption to perform the photocoloration. A highest visible and NIR light utilisation was observed for dark black-colored spotted areas of wings, while the lowest for white-colored spots [259]. Therefore, this nanostructured fabrication of wing scale can be a good alternative to develop energy materials [260, 261]. Similarly, biomimicking of natural photosynthesis phenomenon to construct the artificial novel photosynthetic antenna is another promising green approach to maximise the harnessing of the photons [141]. The metabolic and photosynthetic activities of floral pigments of biological world were emulated for enhancing the photon utilisation and CO2 transformation. However, in some cases, the characteristics of chlorophyll stacks were tailored for effective electron transfer [262, 263]. In a typical study, graphitic nitride nanopaper has been employed to synthesize the biomimicked photosynthetic nanostructured leaf along with zeolitic imidazolate frameworks (ZIF-9 metal organic framework) and Au stacked like thylakoids. The ZIF-9 in the composite performed electron transport and redox reaction to reduce the CO2, while Au enhanced the light-harvesting capacity of the material. The coupling of graphene-nitride nanolayer with ZIF-9 MOF created interferences at the junctions and modified the band structure. This ternary was successfully tested for water splitting and CO2 reduction [257]. The design and mechanistic utility of the fabricated materials is illustrated in Fig. 12 [257]. Similar mechanism of marine diatoms for mimicking the photosynthetic properties of Photosystem I (PSI) was imitated to architect the artificial diatom frustules with graphitic nitride material (C3N4 (DE-g-C3N4). Here, the reduction of nicotinamide adenine dinucleotide phosphate (NADP) to NADPH acts as an electron transporter and helps to convert the photon energy into chemical energy [264,265,266].

Design and mechanistic of artificial photosynthetic utility [257]

In another study, artificial moth eye structure was fabricated through the impregnation of perovskite on the glass frame which was coated with a layer of polydimethylsiloxane (PDMS) and phenyl-C61-butyric acid methyl ester (PCBM), while Ag was introduced as co-catalyst to enhance the trapping and scattering of low-energy photons. This moth eye framework provided a dramatic enhancement in the external quantum efficiency. Meanwhile, free absorption of electromagnetic spectrum was obtained which improved the surface plasmon resonance activity [267, 268]. Thus, above-discussed nature inspired nanostructure harbored with carbonaceous materials, surface modified semiconductors, and noble metal would be a new future perspective to devise intelligent energy materials.

Conclusion

The review has emphasized the distinct mechanistic features of nanostructure materials that lend them unique properties with potential benefits towards energy and environment. Though all nanostructure materials are potent for the purpose, the metal oxides established its excellent photostability after being modified through doping. The doping has expanded the absorption of the solar light that promoted water splitting and CO2 reduction. It was clearly seen that the hydrothermal synthesis method can encompass the synthesis of various nanostructure materials such as zero-D, one-D, two-D, and three-D, and bring down the synthesis cost. Thus, the nanostructured materials have offered an economically feasible route for upgrading the technological approach. Meanwhile, biomimicking of nanostructure materials on the principle of nature’s design also provided a pathway to solve the critical challenges of engineering and technology to develop highly intelligent and smart designs.

References

Sagadevan, S.: Recent trends on nanostructures based solar energy applications: a review. Rev. Adv. Mater. Sci. 34, 44–61 (2013)

Martha, S., Sahoo, P.C., Parida, K.M.: An overview on visible light responsive metal oxide based photocatalysts for hydrogen energy production. Rsc Adv. 5, 61535–61553 (2015)

Li, H., Zhou, Y., Tu, W., Ye, J., Zou, Z.: State-of-the-art progress in diverse heterostructured photocatalysts toward promoting photocatalytic performance. Adv. Funct. Mater. 25, 998–1013 (2015)

Li, H., Tu, W., Zhou, Y., Zou, Z.: Z‐Scheme photocatalytic systems for promoting photocatalytic performance: recent progress and future challenges. Adv. Sci. 3, Article ID:1500389, (2016)

Ohtani, B.: Photocatalysis A to Z—what we know and what we do not know in a scientific sense. J. Photochem. Photobiol. C: Photochem. Rev. 11, 157–178 (2010)

Pallavi, N., Shivaraju, H.P.: A feasibility study on photocatalytic degradation of methyl benzene using N doped TiO2 nanoparticles. Int. J. Nanotechnol. 14, 762–774 (2017)

Satheesh, R., Vignesh, K., Suganthi, A., Rajarajan, M.: Visible light responsive photocatalytic applications of transition metal (M = Cu, Ni and Co) doped α-Fe2O3 nanoparticles. J. Environ. Chem. Eng. 2, 1956–1968 (2014)

Ahmad, J., Majid, K.: In-situ synthesis of visible-light responsive Ag2O/graphene oxide nanocomposites and effect of graphene oxide content on its photocatalytic activity. Adv. Compos. Hyb. Mater. 1, 374–388 (2018)

Rajabi, H.R., Khani, O., Shamsipur, M., Vatanpour, V.: High-performance pure and Fe3+-ion doped ZnS quantum dots as green nanophotocatalysts for the removal of malachite green under UV-light irradiation. J. Hazard. Mater. 250, 370–378 (2013)

Sathishkumar, P., Sweena, R., Wu, J.J., Anandan, S.: Synthesis of CuO-ZnO nanophotocatalyst for visible light assisted degradation of a textile dye in aqueous solution. Chem. Eng. J. 171, 136–140 (2011)

Sim, L.C., Wong, J.L., Hak, C.H., Tai, J.Y., Leong, K.H., Saravanan, P.: Sugarcane juice derived carbon dot–graphitic carbon nitride composites for bisphenol A degradation under sunlight irradiation. Beilstein J. Nanotechnol. 9, 353–363 (2018)

Dionysiou, D.D., Khodadoust, A.P., Kern, A.M., Suidan, M.T., Baudin, I., Laîné, J.M.: Continuous-mode photocatalytic degradation of chlorinated phenols and pesticides in water using a bench-scale TiO2 rotating disk reactor. Appl. Catal. B: Environ. 24, 139–155 (2000)

Ayodhya, D., Veerabhadram, G.: A review on recent advances in photodegradation of dyes using doped and heterojunction based semiconductor metal sulfide nanostructures for environmental protection. Mater. Today Energy 9, 83–113 (2018)

Chen, X., Shen, S., Guo, L., Mao, S.S.: Semiconductor-based photocatalytic hydrogen generation. Chem. Rev. 110, 6503–6570 (2010)

Maida, K.: Z-scheme water splitting using two different semiconductor photocatalysts. ACS Catal. 3, 1486–1503 (2013)

Valiev, R.: Materials science: nanomaterial advantage. Nature 419, 887–889 (2002)

Guo, D., Xie, G., Luo, J.: Mechanical properties of nanoparticles: basics and applications. J. Phys. D. 47, Article ID:013001, 25 (2014)

Gleiter, H.: Nanostructured materials: basic concepts and microstructure. Acta Mater. 48, 1–29 (2000)

Gentile, A., Ruffino, F., Grimaldi, M. G.: Complex-morphology metal-based nanostructures: fabrication, characterization, and applications. Nanomaterials. 6, Article ID:110, 33 (2016)

Burda, C., Lou, Y., Chen, X., Samia, A.C., Stout, J., Gole, J.L.: Enhanced nitrogen doping in TiO2 nanoparticles. Nano Lett. 3, 1049–1051 (2003)

Hensel, J., Wang, G., Li, Y., Zhang, J.Z.: Synergistic effect of CdSe quantum dot sensitization and nitrogen doping of TiO2 nanostructures for photoelectrochemical solar hydrogen generation. Nano Lett. 10, 478–483 (2010)

Yoshida, T., Niimi, S., Yamamoto, M., Nomoto, T., Yagi, S.: Effective nitrogen doping into TiO2 (N-TiO2) for visible light response photocatalysis. J. Colloid Interface Sci. 447, 278–281 (2015)

Shi, R., Li, Z., Yu, H., Shang, L., Zhou, C., Waterhouse, G.I., Wu, L., Zhang, T.: Effect of nitrogen doping level on the performance of N-doped carbon quantum dot/TiO2 composites for photocatalytic hydrogen evolution. Chem Sus Chem. 10, 4650–4656 (2017)

Shin, S.W., Lee, J.Y., Ahn, K.S., Kang, S.H., Kim, J.H.: Visible light absorbing TiO2 nanotube arrays by sulfur treatment for photoelectrochemical water splitting. J. Phys. Chem. C 119, 13375–13383 (2015)

Lei, X.F., Xue, X.X., Yang, H., Chen, C., Li, X., Niu, M.C., Gao, X.Y., Yang, Y.T.: Effect of calcination temperature on the structure and visible-light photocatalytic activities of (N, S and C) co-doped TiO2 nano-materials. Appl. Surf. Sci. 332, 172–180 (2015)

Yan, X., Yuan, K., Lu, N., Xu, H., Zhang, S., Takeuchi, N., Kobayashi, H., Li, R.: The interplay of sulfur doping and surface hydroxyl in band gap engineering: mesoporous sulfur-doped TiO2 coupled with magnetite as a recyclable, efficient, visible light active photocatalyst for water purification. Appl Catal B: Environ. 218, 20–31 (2017)

Bakar, S.A., Ribeiro, C.: A comparative run for visible-light-driven photocatalytic activity of anionic and cationic S-doped TiO2 photocatalysts: a case study of possible sulfur doping through chemical protocol. J. Mol. Catal. A: Chem. A: Chem. 421, 1–15 (2016)

El-Sheikh, S.M., Zhang, G., El-Hosainy, H.M., Ismail, A.A., O’Shea, K.E., Falaras, P., Kontos, A.G., Dionysiou, D.D.: High performance sulfur, nitrogen and carbon doped mesoporous anatase–brookite TiO2 photocatalyst for the removal of microcystin-LR under visible light irradiation. J. Hazard. Mater. 280, 723–733 (2014)

Mollavali, M., Falamaki, C., Rohani, S.: Preparation of multiple-doped TiO2 nanotube arrays with nitrogen, carbon and nickel with enhanced visible light photoelectrochemical activity via single-step anodization. Int. J. Hydrogen Energy 40, 12239–12252 (2015)

Lu, Z., Zeng, L., Song, W., Qin, Z., Zeng, D., Xie, C.: In situ synthesis of C-TiO2/g-C3N4 heterojunction nanocomposite as highly visible light active photocatalyst originated from effective interfacial charge transfer. Appl. Catal. B: Environ. 202, 489–499 (2017)

Zhang, Y., Zhao, Z., Chen, J., Cheng, L., Chang, J., Sheng, W., Hu, C., Cao, S.: C-doped hollow TiO2 spheres: in situ synthesis, controlled shell thickness, and superior visible-light photocatalytic activity. Appl. Catal. B: Environ. 165, 715–722 (2015)

Ji, L., Zhang, Y., Miao, S., Gong, M., Liu, X.: In situ synthesis of carbon doped TiO2 nanotubes with an enhanced photocatalytic performance under UV and visible light. Carbon 125, 544–550 (2017)

Kerkez-Kuyumcu, Ö., Kibar, E., Dayıoğlu, K., Gedik, F., Akın, A.N., Özkara-Aydınoğlu, Ş.: A comparative study for removal of different dyes over M/TiO2 (M = Cu, Ni Co, Fe, Mn and Cr) photocatalysts under visible light irradiation. J. Photochem. Photobiol. A Chem. 311, 176–185 (2015)

Inturi, S.N.R., Boningari, T., Suidan, M., Smirniotis, P.G.: Visible-light-induced photodegradation of gas phase acetonitrile using aerosol-made transition metal (V, Cr, Fe Co, Mn, Mo, Ni, Cu, Y, Ce, and Zr) doped TiO2. Appl. Catal. B: Environ. 144, 333–342 (2014)

Yan, X., Xue, C., Yang, B., Yang, G.: Novel three-dimensionally ordered macroporous Fe3+-doped TiO2 photocatalysts for H2 production and degradation applications. Appl. Surf. Sci. 394, 248–257 (2017)

Wang, G., Ma, X., Wei, S., Li, S., Qiao, J., Wang, J., Song, Y.: Highly efficient visible-light driven photocatalytic hydrogen production from a novel Z-scheme Er3+: yAlO3/Ta2O5-V5+|| Fe3+-TiO2/Au coated composite. J Power Sour. 373, 161–171 (2018)

Xiang, G., Yu, Z., Hou, Y., Chen, Y., Peng, Z., Sun, L., Sun, L.: Simulated solar-light induced photoelectrocatalytic degradation of bisphenol-A using Fe3+-doped TiO2 nanotube arrays as a photoanode with simultaneous aeration. Sep. Purif. Technol. 161, 144–151 (2016)

Arellano, U., Wang, J.A., Asomoza, M., Chen, L.F., González, J., Manzo, A., Solis, S., Lara, V.H.: Crystalline structure, surface chemistry and catalytic properties of Fe3+ doped TiO2 sol–gel catalysts for photooxidation of 2, 4–dichlorophenoxyacetic acid. Mater. Chem. Phys. 214, 247–259 (2018)

Devi, L.G., Murthy, B.N., Kumar, S.G.: Photocatalytic activity of V5+, Mo6+ and Th4+ doped polycrystalline TiO2 for the degradation of chlorpyrifos under UV/solar light. J. Mol. Catal. A: Chem. 308, 174–181 (2009)

Ren, F., Li, H., Wang, Y., Yang, J.: Enhanced photocatalytic oxidation of propylene over V-doped TiO2 photocatalyst: reaction mechanism between V5+ and single-electron-trapped oxygen vacancy. Appl. Catal. B Enviro. 176, 160–172 (2015)

Chen, R.F., Zhang, C.X., Deng, J., Song, G.Q.: Preparation and photocatalytic activity of Cu2+-doped TiO2/SiO2. Int. J. Miner. Metall. Mater. 16, 220–225 (2009)

Zhang, M., Yuan, S., Wang, Z., Zhao, Y., Shi, L.: Photoelectrocatalytic properties of Cu2+-doped TiO2 film under visible light. Appl. Catal. B Environl. 134, 185–192 (2013)

Wu, Z., Jin, R., Wang, H., Liu, Y.: Effect of ceria doping on SO2 resistance of Mn/TiO2 for selective catalytic reduction of NO with NH3 at low temperature. Catal. Commun. 10, 935–939 (2009)

Silva, A.M., Silva, C.G., Dražić, G., Faria, J.L.: Ce-doped TiO2 for photocatalytic degradation of chlorophenol. Catal. Today 144, 13–18 (2009)