Abstract

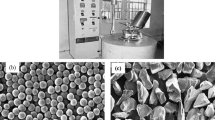

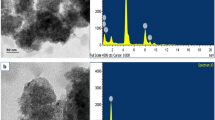

Due to the advancement in the material technology to produce desired materials for various industrial applications and fast changing scenario in the production of lighter and stronger materials, composite materials are gaining wide acceptance because of their unusual characteristics of behaviour with their high strength to weight ratios. The most widely used material in the current industrial sectors is aluminium and its alloys because of their light weight. To make use of the advantages of the alloys of aluminium for further versatile and flexible varieties of application, such materials are expected to behave as highly resistant to the various loading conditions for a long duration under different environments. Aluminium Alloy 356 has been chosen for the proposed study. AA356 alloy material has been mixed with Zirconium Silicate particles (ZiSO4) with different fractions like 0 wt%, 3 wt%, 5 wt% and 8 wt%. The test samples have been prepared by means of stir casting process. SEM images have been taken on the ZrSiO4 particles for noting down the size and shape of the particles. Three specimens for each composition have been prepared with ASTM standards in order to carry out the tensile test, compression test and hardness test. The tensile test results revealed that AA356 + 5 wt% of ZrSiO4 composition yielded better tensile strength value (169.29 MPa) than the other three compositions. The micro images taken on the fractured samples of the tensile test specimens have been analyzed. It has also been noted that adding ZrSiO4 particles beyond 5 wt% decreased the tensile strength of the proposed composite material. Similarly compression strength and hardness values also have been noted as better upto 5 wt% inclusion of ZrSiO4 particles.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this submitted article.

References

Hariharasakthisudhan P, Moshi AAM, Bharathi SRS, Logesh K (2019) Regression and Grey relational analysis on friction and wear behavior of AA6061/Al2O3/Si3N4/graphite hybrid nano composites. Mater Res Express 6:085017

Logesh K, Hariharasakthisudhan P, Moshi AAM, Rajan BS, Sathickbasha K (2020) Mechanical properties and microstructure of A356 alloy reinforced AlN/MWCNT/graphite/Al composites fabricated by stir casting. Mater Res Express 7:015004

Granesan S, Ganesh SD, Moshi AAM (2020) Characterization of Metal Matrix Composites reinforced with suitable reinforcement agents – A comprehensive review. IOP Conf Ser: Mater Sci Eng 988:012029

Mohanavel V, Vijay K, Vigneswaran A, Srinath S, Gokulnath S (2021) Mechanical and tribological behaviour of AZ91/ZrSiO4 composites. Mater Today Proc 37:1529–1534

Choi DH, Kim YH, Ahn BW, Kim YI, Jung SB (2013) Microstructure and mechanical property of A356 based composite by friction stir processing. T Nonferr Metal Soc 23:335–340

Akbari M, Shojaeefard MH, Asadi P, Khalkhali A (2017) Hybrid multi-objective optimization of microstructural and mechanical properties of B4C/A356 composites fabricated by FSP using TOPSIS and modified NSGA-II. T Nonferr Metal Soc 27:2317–2333

Zadeh MH, Mirzaee O, Semnani HM (2018) Evaluation of microstructural and mechanical properties of A356 composite strengthened by nanocrystalline V8C7-Al2O3 particles synthesized through mechanically activated sintering. J Alloy Compd 782:995–1007

Xu T, Li G, Xie M, Liu M, Zhang D, Zhao Y, Chen G, Kai X (2019) Microstructure and mechanical properties of in-situ nano γ-Al2O3p/A356 aluminum matrix composite. J Alloy Compd 787:72–85

Ma X, Wang X (2019) Mechanical properties and fracture of in-situ Al3Ti particulate reinforced A356 composites. Mat Sci Eng A-Struct 754:46–56

Liu Z, Wang X, Han Q, Li J (2014) Effects of the addition of Ti powders on the microstructure and mechanical properties of A356 alloy. Powder Technol 253:751–756

Cetin A, Kalkanli A (2008) Effect of solidification rate on spatial distribution of SiC particles in A356 alloy composites. J Mater Process Tech 205:1–8

Ghandvar H, Idris MH, Ahmad N, Moslemi N (2017) Microstructure development, mechanical and tribological properties of a semisolid A356/xSiCp composite. J Appl Res Technol 15:533–544

Kim HH, Babu JSS, Kang CG (2013) Fabrication of A356 aluminum alloy matrix composite with CNTs/Al2O3 hybrid reinforcements. Mat Sci Eng A-Struct 573:92–99

Shayan M, Niroumand B (2013) Synthesis of A356–MWCNT nanocomposites through a novel two stage casting process. Mat Sci Eng A-Struct 582:262–269

Miskovic Z, Bobic I, Tripkovic S, Rac A, Vencl A (2006) The structure and mechanical properties of an aluminium A356 alloy base composite with Al2O3 particle additions (MMC). Tribol Ind 28:23–27

Acknowledgements

The authors are thankful to the management of National Engineering College, Kovilpatti for the facility availed for performing stir casting process and conducting the mechanical characterization study on the prepared metal matrix composites.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation was performed by B.Surya Rajan. Data collection and the experimental analysis were carried out by M.Dhurva Maharishi and P.Hariharasakthisudhan. A.Arul Marcel Moshi acted as the supervisor for the work, and wrote the first draft of the manuscript. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

The authors approve that the works reported in this research article are original, did not copied from any other’s work. And the authors assure that the presented research work was carried out by them and written without committing any unethical practice.

Research Involving Human Participants and/or Animals

Not applicable.

Informed Consent

All authors agreed with the content of the manuscript; and that all gave explicit consent to submit and that they obtained consent from the responsible authorities at the institute/organization where the work has been carried out.

Conflict of Interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

M., D.M., A., A.M.M., P., H. et al. Investigation on the Mechanical Behaviour of Aluminium Alloy 356 – Zirconium Silicate Metal Matrix Composites (AA356-ZrSiO4 MMCs). Silicon 14, 11731–11739 (2022). https://doi.org/10.1007/s12633-022-01896-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-01896-0