Abstract

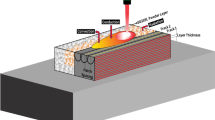

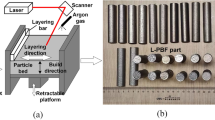

Low pressure cold gas dynamic spray (LPCGDS) is a coating process that utilize low pressure gas (5–10 bars instead of 25–30 bars) and the radial injection of powder instead of axial injection with the particle range (1–50 μm). In the LPCGDS process, pressurized compressed gas is accelerated to the critical velocity, which depends on length of the divergent section of nozzle, the propellant gas and particle characteristics, and the diameters ratio of the inlet and outer diameters. This paper presents finite element modeling (FEM) of powder stream in supersonic nozzle wherein adiabatic gas flow and expansion of gas occurs in uniform manner and the same is used to evaluate the resultant temperature and velocity contours during coating process. FEM analyses were performed using commercial finite volume package, ANSYS CFD FLUENT. The results are helpful to predict the characteristics of powder stream at the exit of the supersonic nozzle.

Similar content being viewed by others

Abbreviations

- LPGDS:

-

Low pressure gas dynamic spray

- FEM:

-

Finite element modeling

- CGDS:

-

Cold gas dynamic spray

- CFD:

-

Computational fluid dynamics

- Di :

-

Inlet diameter

- De :

-

Outlet diameter

- Dt :

-

Throat diameter

- Lu :

-

Convergent length

- Ld :

-

Divergent section length

- A, B, C, D, E, F, G, H:

-

Key points for nozzle

- Ωf :

-

Fluid region

- Ωe :

-

Typical element

- ρ g :

-

Density of the gas

- δij :

-

Components of the identity tensor (Kronecker delta)

- v j :

-

Velocity vector in the jth direction

- τ ij :

-

The stress

- g i :

-

The gravitational acceleration

- μ t :

-

The turbulent viscosity

- μ :

-

The molecular viscosity

- k t :

-

The kinetic energy of turbulence

- ε :

-

The dissipation of kinetic energy of turbulence

- ωi :

-

The weight function

- Pi :

-

Pressure applied at the inlet of the nozzle MPa

- x1, x2 :

-

Variable functions of the position at the axis

- χ, α, Ψ :

-

(Column) vectors of interpolation (shape) functions

References

A.O. Tokarev, Structure of aluminum powder coatings prepared by cold gas dynamic spraying. Met. Sci. Heat Treat. 38(3), 136–139 (1996)

R.C. McCune, A.N. Papyrin, J.N. Hall, W.L. Riggs, P.H. Zajchowski, C.C. Berndt, S. Sampath, An exploration of the cold gas-dynamic spray method for several material systems”, Thermal Spray Science and Technology; ASM International, pp. 1–5 1995

J. Vlcek, A systematic approach to material eligibility for the cold spray process, International Thermal Spray Conference and Exhibition, Orlando, Florida, 5–8 May 2003

D.G. McCartney, Particle-substrate interactions in cold gas dynamic spraying, International Thermal Spray Conference and Exhibition, Orlando, Florida, 5–8 May 2003

H. Assadi, F. Gärtner, T. Stoltenhoff, H. Kreye, Bonding mechanism in cold gas spraying. Acta Mater. 51, 4379–4394 (2003)

F. Gärtner Numerical and microstructural investigations of the bonding mechanisms in cold spraying, International Thermal Spray Conference and Exhibition, Orlando, Florida, 5–8 May 2003

R.G.R. Maev, V. Leshchynsky, Introduction to Low Pressure Gas Dynamic Spray Physics and Technology (Wiley2VCH, Weinheim, 2008)

A.P. Alkhimov, A.N. Papyrin, V.F. Dosarev, N.I. Nestorovich, M.M. Shuspanov, Gas dynamic spraying method for applying a coating, U.S Patent 5, 302,414-12, April 1994

R.C. Dykhuizen, M.F. Smith, Gas dynamic principles of cold spray. J. Therm. Spray Technol. 7(2), 205–212 (1998)

A.P. Alkhimov, V.F. Kosarev, S.V. Klinkov, The features of cold spray nozzle design. J. Therm. Spray Technol. 10(2), 375–381 (2001)

M. Grujicic, W.S. DeRosset, D. Helfritch, Flow analysis and nozzle-shape optimization for the cold-gas dynamic-spray process, in Proceedings of Institution of Mechanical Engineers Vol. 217 Part B: J. Engineering Manufacture

W.-Y. Li, C.J. Li, Optimal design of a novel cold spray gun nozzle at a limited space. J. Therm. Spray Technol. 14(3), 391–396 (2005)

T.-C. Jen, L. Li, W. Cui, Q. Chen, X. Zhang, Numerical investigations on cold gas dynamic spray process with nano and micro size particles. Int. J. Heat Mass Trans. 48, 4384–4396 (2005)

F. Raletz, M. Vardelle, G. Ezo’o, Critical particle velocity under cold spray conditions. J. Surf. Coat. Technol. 201, 1942–1947 (2006)

W.-Y. Li, Optimal design of a convergent-barrel cold spray nozzle by numerical method. Appl. Surf. Sci. 253, 708–713 (2006)

B. Jodoin, F. Raletz, M. Vardelle, Cold spray modeling and validation using an optical diagnostic method. Surf. Coat. Technol. 200(14–15), 4424–4432 (2006)

Wen-Ya. Li, Optimal design of a cold spray nozzle by numerical analysis of particle velocity. Mater. Des. 28, 2129–2137 (2007)

S.P. Pardhasaradhi, V. Venkatachalapathy, S.V. Joshi, S. Govindan, Optical diagnostics study of gas particle transport phenomena in cold gas dynamic spraying and comparison with model predictions. J. Therm. Spray Technol. 17(4), 551–563 (2008)

R. Lupoi, W.O’Neill, An investigation on powder stream in Cold Gas Spray (CGS) nozzles, V. European Conference on Computational Fluid Dynamics ECCOMAS CFD 2010, J.C.F.Pereira and A. Sequeira (Eds), Lisbon, Portugal, 14–17 June 2010

N. Rajaratnam, Turbulent Jets (Elsevier, Amsterdam, 1976)

J.N. Reddy, D.K. Gartling, The Finite Element Method in Heat Transfer and Fluid Dynamics (CRC Press, London, 1994)

H.C. Huang, Z.H. Li, A.S. Usmani, Finite Element Analysis of Non-Newtonian Flow Theory and Software (Springer, London, 1999)

FLUENT 12.0

ANSYS 12.0 software

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goyal, T., Walia, R.S., Sharma, P. et al. Finite Element Modeling and Analysis of Powder Stream in Low Pressure Cold Spray Process. J. Inst. Eng. India Ser. C 97, 331–344 (2016). https://doi.org/10.1007/s40032-016-0234-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0234-0