Abstract

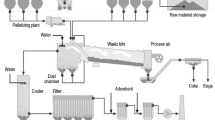

In iron ore sinter plants, the process off-gas is de-dusted by electrostatic precipitators which are installed upstream of the fan. For further reduction of emissions, a second cleaning stage can be installed. This stage usually comprises a sorption process for removal of acid gases and polychlorinated dibenzo(p)dioxins and furans, followed by a fabric filter. The residue from the first de-dusting stage can be recirculated to the sintering process. The residue from the second cleaning stage has to be disposed of in landfill sites. A new single-stage off-gas cleaning concept for sinter plants comprises an entrained flow sorption process and a fabric filter, installed upstream of the fan. In this way, the investment costs for the off-gas cleaning system can be reduced significantly. However, it would become necessary to dispose of most of the residue. In this work, air classification of a residue equivalent to that of a single-stage off-gas cleaning unit was investigated with the aim of producing a fraction of this residue with reduced sulphur and chloride concentrations which can then be recycled. The results confirm that air classification is a suitable process. In order to maintain raw mixture targets for chlorine or to avoid chlorine enrichment in the raw feed, the recommended dust recycling rate is 66 % with air classification which is an improvement over the allowed rates without air classification of 42 %.

Similar content being viewed by others

References

Bastürk S, Delwig C, Ehler W, Hartig W, Hillmann C, Lüngen HB, Richter J, Schneider H, Zirngast J (2009) Technologien und Trends zur Abgasreinigung an Sinteranlagen. Stahl Eisen 129(5):51–59

Bonte L, Buttiens K, Fournelle R, Merchiers G, Pieters M (2003) New coal injection plant for dioxin reduction at the Sidmar sinter plants. Stahl Eisen 123(1):47–50

Buchwalder J, Hensel M, Richter J, Lychatz B (2008) Verminderung der Staubemissionen an der Sinteranlage von ArcelorMittal Eisenhüttenstadt. Stahl Eisen 128(9):111–117

Delwig C, Hartig W, Hoffmann M, Lüngen HB (2007) Developments in sinter technology. Stahl Eisen 127(6/7):S51–S66

EC (ed) (2012) Institute for Prospective Technological Studies, European IPPC Bureau best available techniques (BAT) Reference document for iron and steel production, industrial emissions directive 2010/75/EU, European Commission, Sevillia

Eisen HP, Groß J, Hüsig K-R, Kersting K, Stedem K-H (1996) Reduction of dust emissions in German sinter plants. In: Proceedings of 3rd Int. ironmaking congress, Gent, pp 165–169

Fleischanderl A, Neuhold R, Meierhofer G, Lanzerstorfer C (2006) MEROS®—improved dry-type gas-cleaning process for the treatment of sinter offgas. In: Proceedings of Iron&Steelmaking Conference 2006, Linz, 11.4, pp 1–6

Gebert W (1996) Abgasreinigungssysteme für Sinteranlagen, Dissertation, Universität Kaiserslautern

Guerriero E, Guarnieri A, Mosca S, Rosetti G, Rotatori M (2009) PCDD/F removal efficiency by electrostatic precipitator and wetfine scrubber in an iron ore sintering plant. J Hazard Mater 172:1498–1504. doi:10.1016/j.jhazmat.2009.08.019

Hosokawa (2014, July 16) Classifiers and air classifiers, Retrieved from the Hosokawa Alpine AG website https://www.hosokawa-alpine.com/powder-particle-processing/machines/classifiers-and-air-classifiers/

Kazyuta VI, Mantula VD, Shvets MN (2004) Ecology and resource conservation: bag filters for cleaning sintering gases. Steel Transl 34(11):68–73

Kim JR, Lee KJ, Hur NS (1997) Reduction of dust emission in sinter plant at Kwangyang works. Curr Adv Mater Process 10:799

Lanzerstorfer C, Fleischanderl A, Plattner T, Ehler W, Zwittag E (2008) Emissionsminderung bei Eisenerz-Sinteranlagen. In: VDI Wissensforum GmbH (ed), Emissionsminderung 2008 Stand-Konzepte-Fortschritte, VDI-Bericht 2035, VDI Verlag, Düsseldorf, pp 161–170

Leroy J, Ravier E, Wajs A (2007) New abatement technique of the atmospheric emissions of large sinter plant. First results of industrial pilot in Arcelor´s Fos-sur-mer. In: Proceedings DustConf2007, April 23–24, Maastricht, S2/2, pp 1–2

Menad N, Tayibi H, Carcedo FG, Hernández A (2006) Minimization methods for emissions generated from sinter strands: a review. J Clean Product 14:740–747

Peng C, Zhang F-L, Guo Z-C (2009) Separation and recovery of potassium chloride from sintering dust of ironmaking works. ISIJ Int 49:735–742

Reidetschläger J, Stiasny H, Hötzinger S, Aichinger C, Fulgenico A (2012) Selective waste gas recirculation system for sintering plants. Stahl Eisen 132(1):25–30

Schuster E, Zirngast J, Zahn M (2005) Experiences with flue-gas cleaning by bag filter at the sinter strand of voestalpine stahl Donawitz. In: Proceedings of international conference on clean technologies in the steel industry, Balatonfüred, pp 292–300

Smit A, Leuwerink THP, van der Panne ALJ, Gebert W, Lanzerstorfer C, Riepl H, Hofstadler K (2000) Reduction of dioxin emissions from Hoogovens Sinter plant with the AIRFINE® system. BHM 145:183–185

Weiss W (1998) Maßnahmen zur Verbesserung der Entstaubung einer Eisenerzsinteranlage mit nachfolgenden Untersuchungen zur Minderung der PADD/PCDF-Emissionen, Stahlwerke Bremen

Xu S, Liu J, Song M (2012) Water-washing of iron-ore sintering gas cleaning residue for beneficial reutilization as secondary construction material. Procedia Environ Sci 16:244–252. doi:10.1016/j.proenv.2012.10.034

Yu Z, Li Q, Xu H, Lin C (2009) Design and Application of the Dry-FGD Process in Sanming Steel No. 2 Sintering Plant. In: Yan K (ed) Electrostatic Precipitation—11th Int. conf. on electrostatic Precipitation, Hangzhou 2008, Springer-Verlag, Berlin, pp 620–623

Acknowledgments

The financial support of K1-MET is acknowledged. K1-MET is member of COMET—Competence Centers for Excellent Technologies and is financially supported by the BMVIT (Federal Ministry for Transport, Innovation and Technology), BMWFJ (Federal Ministry of Economy, Family and Youth), the federal states of Upper Austria, Styria and Tyrol, SFG and Tiroler Zukunftsstiftung. COMET is managed by FFG (Austrian research promotion agency). The RFA analyses were done by Treibacher Industrie AG. The laboratory work of Mr. B. Benque is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lanzerstorfer, C., Neuhold, R. Residues from single-stage dry de-dusting and desulphurization of sinter plant off-gas: enabling partial recirculation by air classification. Int. J. Environ. Sci. Technol. 12, 2939–2946 (2015). https://doi.org/10.1007/s13762-014-0709-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-014-0709-6