Abstract

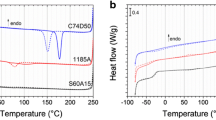

Polyurethane elastomers are widely utilized in various engineering applications due to their favorable properties. However, their high surface energy and internal heat generation limit their potential use under high dynamic or temperature conditions. To overcome these limitations, we prepared polyurethane elastomer (PUE) composites and blended them to reinforce with polytetrafluoroethylene (PTFE), polyethylene wax (PEW), or melamine cyanurate (MCA). The composites were characterized using several techniques, including electronic universal material testing machine, scanning electron microscope, differential scanning calorimetry, and thermal gravimetric analyzer. Our results indicated that the optimal mass ratio of curing agent to polyurethane prepolymer was 12.5%, which yielded a PUE with a shore hardness of 92 HA, tensile strength of 17.2 MPa, and elongation-at-break of 329%. In addition, we observed that the incorporation of 0.5% (by wt) multifunctional friction reducer into the composite produced an excellent antistatic performance. The MCA-reinforced PUE composite exhibited remarkable tensile and thermal behavior, with an 11.6% increase in tensile strength and a 101.2% increase in elongation-at-break compared to pristine PUE. Moreover, the glass transition temperature and thermal stability of MCA/PUE composite were enhanced to − 26.7℃ and 280℃, respectively, compared to the unmodified counterpart. However, the incorporation of PTFE or PEW only marginally influenced the tensile and thermal behavior of the PUE composites. These findings indicated that the improved tensile and thermal properties of the polyurethane composite reinforced with MCA can be attributed to the superior interface compatibility between MCA and the polyurethane matrix as well as the increased cross-linking density. Therefore, this work demonstrates the potential for expanding the use of PUE in high-performance automobile tires or rubber-covered rollers.

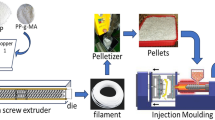

Graphical Abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

PetrovićZS FJ (1991) Polyurethane elastomers. Prog Polym Sci 16:695–836

Haji M, Haddadi-Asl V, Jouibari IS (2022) Carbon nanotube/polyurethane nanocomposites with surface-modified nanostructures. Iran Polym J 31:1173–1182

Bhandari S, Nayak S, Artiaga R, Guchhait PK (2023) Time derivative of DSC and dielectric analysis of elastomeric poly(thiourethane–urethane)/Cloisite 30B clay nanocomposites. Iran Polym J 32:151–163

El-Zahed MM, Kiwaan HA, Farhat AAM, Moawed EA, El-Sonbati MA (2023) Anticandidal action of polyurethane foam: a new modifier with functionalized isothiouronium group. Iran Polym J 32:71–79

Burelo M, Gutiérrez S, Treviño-Quintanilla CD, Cruz-Morales JA, Martínez A, López-Morales S (2022) Synthesis of biobasedhydroxyl-terminated oligomers by metathesis degradation of industrial rubbers SBS and PB: tailor-made unsaturated diols and polyols. Polymers 14:4973

Burelo M, Gaytán I, Loza-Tavera H, Cruz-Morales JA, Zárate-Saldaña D, Cruz-Gómez MJ, Gutiérrez S (2022) Synthesis, characterization and biodegradation studies of polyurethanes: effect of unsaturation on biodegradability. Chemosphere 307:136136

Khatoon H, Ahmad S (2017) A review on conducting polymer reinforced polyurethane composites. J IndEngChem 53:1–22

Nishiyama Y, Kumagai S, Motokucho S, Kameda T, Saito Y, Watanabe A, Nakatani H, Yoshioka T (2020) Temperature-dependent pyrolysis behavior of polyurethane elastomers with different hard- and soft-segment compositions. J Anal ApplPyrol 145:104754

HuSK HSY, Wang YM, Wu YW, Shou T, Yin DX, Mu GY, Zhao XY, Gao YY, Liu J, Li FZ, Guo MM, Zhang LQ (2022) Self-repairable, recyclable and heat-resistant polyurethane for high-performance automobile tires. Nano Energy 95:107012

Junik K, Lesiuk G, Barcikowski M, Błażejewski W, Niemiec A, Grobelny M, Otczyk K, Correia JAFO (2021) Impact of the hardness on the selected mechanical properties of rigid polyurethane elastomers commonly used in suspension systems. Eng Fail Anal 121:105201

Li XR, Li J, Wang JY, Yuan J, Jiang F, Yu XY, Xiao FP (2021) Recent applications and developments of polyurethane materials in pavement engineering. Constr Build Mater 304:124639

Jia YJ, Zhang LZ, Qin ML, Li Y, Gu SJ, Guan QB, You ZW (2022) Highly efficient self-healable and robust fluorinated polyurethane elastomer for wearable electronics. ChemEng J 430:133081

Lin CH, Liu H, Huang W, Shi ZF, Wang L, Chen YH, Yang JZ, Wu G, Jia YG (2023) Sustainable metal-free polyurethane elastomers from bile acids: self-healing properties and biocompatibility. Mater Today Chem 27:101331

Guo R, Zhang Q, Wu YS, Chen HB, Liu YH, Wang JJ, Duan XL, Chen Q, Ge ZS, Zhang YF (2023) Extremely strong and tough biodegradable poly(urethane) elastomers with unprecedented crack tolerance via hierarchical hydrogen-bonding interactions. Adv Mater 35:2212130

Xiang ZH, Qi F, Hu F, Zhang B, Qi FG, Zhao N, Ouyang XP (2022) A composite nanofiller with a nail column void structure to imitate beetle shell fiber to enhance the impact resistance of polyurethane elastomer. Compos SciTechnol 221:109304

Xie YS, Jiang J, Islam MA (2021) Applications of elastomers in slurry transport. Wear 477:203773

Xu CA, Chen GK, Tan ZY, Hu ZR, Qu ZC, Zhang Q, Lu MP, Wu K, Lu MG, Liang LY (2020) Evaluation of cytotoxicity in vitro and properties of polysiloxane-based polyurethane/lignin elastomers. React FunctPolym 149:104514

Zhao XW, Ding JJ, Ye L (2014) Structure and solvent-resistant property of fluorinated polyurethane elastomer. J Fluor Chem 159:38–47

Hu SK, Shou T, Zhao XY, Wang Z, Zhang SJ, Qin X, Guo MM, Zhang LQ (2020) Rational design of a novel NDI-based thermoplastic polyurethane elastomer with superior heat resistance. Polymer 205:122764

Wu JH, Li CH, Wu YT, Leu MT, Tsai Y (2010) Thermal resistance and dynamic damping properties of poly(styrene–butadiene–styrene)/thermoplastic polyurethane composites elastomer material. Compos SciTechnol 70:1258–1264

Rosu D, Tudorachi N, Rosu L (2010) Investigations on the thermal stability of a MDI based polyurethane elastomer. J Anal ApplPyrol 89:152–158

Lu RQ, Concellón A, Wang P, Swager TM, Hsieh AJ (2022) Supramolecular hierarchical polyurethane elastomers for thermal and mechanical property optimization. Polymer 260:125363

Lei WQ, Fang CQ, Zhou X, Li JB, Yang R, Zhang ZS, Liu DH (2017) Thermal properties of polyurethane elastomer with different flexible molecular chain based on para-phenylene diisocyanate. J Mater SciTechnol 33:1424–1432

Berta M, Lindsay C, Pans G, Camino G (2006) Effect of chemical structure on combustion and thermal behaviour of polyurethane elastomer layered silicate nanocomposites. PolymDegrad Stab 91:1179–1191

Jing X, Li XY, Di YL, Zhao YH, Wang JW, Kang MQ, Li QF (2021) Effect of the amide units in soft segment and urea units in hard segment on microstructures and physical properties of polyurethane elastomer. Polymer 233:124205

Cakić SM, Ristić IS, Krakovský I, Stojiljković DT, Bělský P, Kollová L (2014) Crystallization and thermal properties in waterborne polyurethane elastomers: influence of mixed soft segment block. Mater ChemPhys 144:31–40

Yang YM, Wang YK, Zhu MY, Zhao JB, Cai D, Cao H (2023) Valorization of lignin for renewable non-isocyanate polyurethanes: a state-of-the-art review. Mater Today Sustain 22:100367

Lei WQ, Fang CQ, Zhou X, Cheng YL, Yang R, Liu DH (2017) Morphology and thermal properties of polyurethane elastomer based on representative structural chain extenders. ThermochimActa 653:116–125

Parcheta P, Głowińska E, Datta J (2020) Effect of bio-based components on the chemical structure, thermal stability and mechanical properties of green thermoplastic polyurethane elastomers. EurPolym J 123:109422

Wongsamut C, Suwanpreedee R, Manuspiya H (2020) Thermoplastic polyurethane-based polycarbonate diol hot melt adhesives: the effect of hard-soft segment ratio on adhesion properties. Int J AdhesAdhes 102:102677

Huang JH, Wang HX, Liu WF, Huang JH, Yang DJ, Qiu XQ, Zhao L, Hu FC, Feng YX (2023) Solvent-free synthesis of high-performance polyurethane elastomer based on low-molecular-weight alkali lignin. Int J BiolMacromol 225:1505–1516

Cheng BX, Gao WC, Ren XM, Ouyang XY, Zhao Y, Zhao H, Wu W, Huang CX, Liu Y, Liu XY, Li HN, Li RKY (2022) A review of microphase separation of polyurethane: characterization and applications. Polym Test 107:107489

Sun N, Di MW, Liu Y (2021) Lignin-containing polyurethane elastomers with enhanced mechanical properties via hydrogen bond interactions. Int J BiolMacromol 184:1–8

Mothé CG, Araújo CRD (2000) Properties of polyurethane elastomers and composites by thermal analysis. ThermochimActa 357–358:321–325

Lei WQ, Pei H, Fang CQ, Zhou X, Zhang X, Pu MY (2022) Influence of nanocrystalline cellulose extracted from different precursors on properties of polyurethane elastomer composites. Compos SciTechnol 218:109159

Lei WQ, Fang CQ, Zhou X, Li YG, Pu MY (2018) Polyurethane elastomer composites reinforced with waste natural cellulosic fibers from office paper in thermal properties. CarbohydrPolym 197:385–394

Mi HY, Li Z, Turng LS, Sun Y, Gong S (2014) Silver nanowire/thermoplastic polyurethane elastomer nanocomposites: thermal, mechanical, and dielectric properties. Mater Des 56:398–404

Chen WY, Qiao HB, Zhang DW, Tian XM, Jin L (2023) Silane coupling agent γ-aminopropyltriethoxysilane-modified nanoparticles/polyurethane elastomer nanocomposites. Iran Polym J 32:715–727

Pagacz J, Hebda E, Janowski B, Sternik D, Jancia M, Pielichowski K (2018) Thermal decomposition studies on polyurethane elastomers reinforced with polyhedral silsesquioxanes by evolved gas analysis. PolymDegrad Stab 149:129–142

Lewicki JP, Pielichowski K, Croix PTDL, Janowski B, Todd D, Liggat JJ (2010) Thermal degradation studies of polyurethane/POSS nanohybrid elastomers. PolymDegrad Stab 95:1099–1105

Xia T, Kovochich M, Liong M, Mädler L, Gilbert B, Shi H, Yeh JI, Zink JI, Nel AE (2008) Comparison of the mechanism of toxicity of zinc oxide and cerium oxide nanoparticles based on dissolution and oxidative stress properties. ACS Nano 2:2121–2134

Qi M, Jia XZ, Wang GF, Xu ZH, Zhang Y, He Q (2020) Research on high temperature friction properties of PTFE/fluorosilicone rubber/silicone rubber. Polym Test 91:106817

Akishino JK, Cerqueira DP, Silva GC, Swinka-Filho V, Munaro M (2016) Morphological and thermal evaluation of blends of polyethylene wax and paraffin. ThermochimActa 626:9–12

Huang QR, Guo ZW, Wu ZM, Yuan CQ (2021) Insight into the tribological performance of polyurethane composites under high temperature water lubrication. TribolInt 155:106784

Wu ZM, Guo ZW, Yuan CQ (2019) Influence of polyethylene wax on wear resistance for polyurethane composite material under low speed water-lubricated conditions. Wear 426–427:1008–1017

Sut A, Metzsch-Zilligen E, Großhauser M, Pfaendner R, Schartel B (2019) Synergy between melamine cyanurate, melamine polyphosphate and aluminum diethylphosphinate in flame retarded thermoplastic polyurethane. Polym Test 74:196–204

Zhou R, Lu DH, Jiang YH, Li QN (2005) Mechanical properties and erosion wear resistance of polyurethane matrix composites. Wear 259:676–683

Shoaib M, Bahadur A, Iqbal S, Rahman MSU, Ahmed S, Shabir G, Javaid MA (2017) Relationship of hard segment concentration in polyurethane-urea elastomers with mechanical, thermal and drug release properties. J Drug DelivSciTechnol 37:88–96

Babaei S, Nematollahi MH, Abedini R (2020) Pure and mixed gas permeation study of silica incorporated polyurethane-urea membrane modified by MOCA chain extender. Can J ChemEng 98:1543–1557

Li T, Zhang C, Xie Z, Xu J, Guo BH (2018) A multi-scale investigation on effects of hydrogen bonding on micro-structure and macro-properties in a polyurea. Polymer 145:261–271

Yang XJ, Yu ZW, Fang WJ, Wan Z, Qian Q, Li WW, Jiao HW, Li JZ, Chang JY, Li Q (2022) Improving antistatic and mechanical properties of glass fiber reinforced polypropylene composites through polar adsorption and anchoring effect of organic salt. Compos SciTechnol 220:109285

Tilmatine O, Zeghloul T, Medles K, Dascalescu L, Fatu A (2022) Effect of ambient air relative humidity on the triboelectric properties of polypropylene and polyvinyl chloride slabs. J Electrostat 115:103651

Bao LX, Lei JX, Wang JL (2013) Preparation and characterization of a novel antistatic poly(vinyl chloride)/quaternary ammonium based ion-conductive acrylate copolymer composites. J Electrostat 71:987–993

Kosiński S, Rykowska I, Gonsior M, Krzyżanowski P (2022) Ionic liquids as antistatic additives for polymer composites—a review. Polym Test 112:107649

Liu HC, Yu YF, Zhang MJ, Yu H, Li L, Liu YP, Yang HJ, Tian ZB (2023) Effect of sizing agent on properties of basalt fiber/blended resin matrix composites. J Mater Sci 58:5642–5657

Khan MS, Franke R, Lehmann D, Heinrich G (2009) Physical and tribological properties of PTFE micropowder-filled EPDM rubber. TribolInt 42:890–896

Pan GF, Wang Z, Kong DQ, Sun TW, Zhai H, Tian T, Wang YF, Xing RG, Zhang BW (2022) Transparent, flame-retarded, self-healable, mechanically strong polyurethane elastomers: enabled by the synthesis of phosphorus/nitrogen-containing oxime chain-extender. J ApplPolymSci 139:51598

Tayfun U, Kanbur Y, Abacı U, Güney HY, Bayramlı E (2016) Mechanical, electrical, and melt flow properties of polyurethane elastomer/surface-modified carbon nanotube composites. J Compos Mater 51:1987–1996

Chen JH, Liu J, Peng ZL, Yao Y, Chen SH (2021) The microscopic mechanism of size effect in silica-particle reinforced silicone rubber composites. EngFractMech 255:107945

Guo YB, Zhang ZQ, Cao Z, Wang DG (2019) Wear behavior of hollow glass beads (HGB) reinforced nitrile butadiene rubber: effects of silane coupling agent and filler content. Mater Today Commun 19:366–373

Tabuani D, Bellucci F, Terenzi A, Camino G (2012) Flame retarded thermoplastic polyurethane (TPU) for cable jacketing application. PolymDegrad Stab 97:2594–2601

Somani RH, Hsiao BS, Nogales A, Srinivas S, Tsou AH, Sics I, Balta-Calleja FJ, Ezquerra TA (2000) Structure development during shear flow-induced crystallization of i-PP: in-situ small-angle X-ray scattering study. Macromolecules 33:9385–9394

Huang A, Wang H, Peng X, Turng LS (2018) Polylactide/thermoplastic polyurethane/polytetrafluoroethylene nanocomposites with in situ fibrillated polytetrafluoroethylene and nanomechanical properties at the interface using atomic force microscopy. Polym Test 67:22–30

Corcuera MA, Rueda L, Saralegui A, Martín MD, Fernández-d’Arlas B, Mondragon I, Eceiza A (2011) Effect of diisocyanate structure on the properties and microstructure of polyurethanes based on polyols derived from renewable resources. J ApplPolymSci 122:3677–3685

Thirumal M, Khastgir D, Nando GB, Naik YP, Singha NK (2010) Halogen-free flame retardant PUF: effect of melamine compounds on mechanical, thermal and flame retardant properties. PolymDegrad Stab 95:1138–1145

Acknowledgements

We thank the National Natural Science Foundation of China (No. 51474003).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, W., Zhang, D., Wang, H. et al. A comparative evaluation of mechanically reinforced and heat-resistant organic powder/polyurethane elastomer hybrid composites. Iran Polym J 33, 105–117 (2024). https://doi.org/10.1007/s13726-023-01237-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01237-x