Abstract

Bio-based polyamides (PAs) and their nanocomposites with nanoclay, carbon nanotubes (CNT) and graphene and their uses are studied mainly for automobile, flame retardant, packaging, and textile industries. Polyamides are renewable substances that have good processability and outstanding thermal properties. Polyamides and their composites are known as high-performance polymers because of their numerous applications in various industries such as automotive, medical, textile, etc. Studies on polyamide-based nanocomposite materials have been reported in the scientific literature for many years, as they significantly enhance the properties of various materials. These polymer nanocomposites are ecologically and economically important and they are employed in macromolecular chemistry and modern industries. We have conducted significant research works on naturally derived bio-based polyamides that have been synthesized using castor oil and vegetable oil for biodegradable applications. Solution, melt-blending, and in situ polymerization methods were used for the synthesis of polyamides and nanocomposites. Various properties of PA including magnetic, mechanical, surface, electrical and thermal properties are discussed and it is shown how these properties can be increased through its nanocomposites. In the end, we have discussed the applications of these polymer nanocomposites in the areas of flame retardancy, packaging, textile and automotive parts and focusing on the ecofriendly sustainability of polyamide nanocomposites.

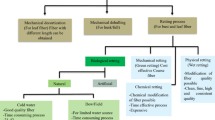

Graphical abstract

Similar content being viewed by others

Data availability

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.

References

Kim HT, Baritugo KA, Hyun SM, Khang TU, Sohn YJ, Kang KH, Joo JC (2019) Development of metabolically engineered Corynebacterium glutamicum for enhanced production n of cadaverine and its use for the synthesis of bio-polyamide 510. ACS Sustain Chem Eng 8:129–138

Smith JK, Hounshell DA, Wallace H (1985) Carothers and fundamental research at Du Pont. Science 229:436–442

Deopura BL, Alagirusamy R, Joshi M, Gupta B (2008) Polyesters and polyamides. CRC, Boca Raton

Matthies P, Seydl WF (1986) History and development of nylon 6. In High Performance Polymers: Their Origin and Development 1986:39–53

Quiles-Carrillo L, Montanes N, Boronat T, Balart R, Torres-Giner SJPT (2017) Evaluation of the engineering performance of different biobased aliphatic homopolyamide tubes prepared by profile extrusion. Polym Test 61:421–429

Dhanalakshmi M, Jog JP (2008) Preparation and characterization of electrospun fibers of Nylon 11. Exp Polym Lett 2:540–545

Meier MA, Metzger JO, Schubert US (2007) Plant oil renewable resources as green alternatives in polymer science. Chem Soc Rev 36:1788–1802

Ruehle DA, Perbix C, Castañeda M, Dorgan JR, Mittal V, Halley P, Martin D (2013) Blends of biorenewable polyamide-11 and polyamide-6, 10. Polymer 54:6961–6970

Youssef AM (2013) Polymer nanocomposites as a new trend for packaging applications. Polym Plast Tech Eng 52:635–660

Kausar A, Rafique I, Muhammad B (2017) Aerospace application of polymer nanocomposite with carbon nanotube, graphite, graphene oxide, and nanoclay. Polym Plast Techn Eng 56:1438–1456

Sudareva NN, Penkova AV, Kostereva TA, Polotskii AE, Polotskaya GA (2012) Properties of casting solutions and ultrafiltration membranes based on fullerene-polyamide nanocomposites. Express Polym Lett 6:178–188

Van Zyl WE, García M, Schrauwen BA, Kooi BJ, De Hosson JTM, Verweij H (2002) Hybrid polyamide/silica nanocomposites: synthesis and mechanical testing. Macro Mater Eng 287:106–110

Agrawal A, Sharma A, Awasthi KK, Awasthi A (2021) Metal oxides nanocomposite membrane for biofouling mitigation in wastewater treatment. Mater Today Chem 21:1–15

Ambrósio JD, Balarim CVM, de Carvalho GB (2016) Preparation, characterization, and mechanical/tribological properties of polyamide 11/Titanium dioxide nanocomposites. Polym Compos 37:1415–1424

Maity P, Basu S, Parameswaran V, Gupta N (2008) Degradation of polymer dielectrics with nanometric metal-oxide fillers due to surface discharges. IEEE Trans Dielectric Electr Insul 15:52–62

Hong N, Song L, Hull TR, Stec AA, Wang B, Pan Y, Hu Y (2013) Facile preparation of graphene supported Co3O4 and NiO for reducing fire hazards of polyamide 6 composites. Mater Chem Phys 142:531–538

Hajibeygi M, Shabanian M, Omidi-Ghallemohamadi M, Khonakdar HA (2017) Optical, thermal and combustion properties of self-colored polyamide nanocomposites reinforced with azo dye surface modified ZnO nanoparticles. Appl Surf Sci 416:628–638

Xu Q, Zhang N, He D, Liu Z, Li W, He W (2019) Preparation of polyamide 6/copper nanocomposites and its properties. Rev Roum Chim 64:479–484

Ma Y, Ye Y, Wan H, Chen L, Zhou H, Chen J (2019) In-situ synthesis strategy of monodispersed Ag2S nanoparticles to modify wear resistance of polyamide-imide nanocomposite lubricating coatings. Tribol Lett 67:1–11

Patel HA, Bocchini S, Frache A, Camino G (2010) Platinum nanoparticle intercalated montmorillonite to enhance the char formation of polyamide 6 nanocomposites. J Mater Chem 20:9550–9558

Zor S, Ilmieva N (2018) Corrosion behavior of PANI/Epoxy/nano SnO2 polymeric nanocomposite coated stainless steel in 3.5 wt% NaCl. Polym Compos 39:2415–2425

Gadhi TA, Qureshi A, Channa N, Mahar RB, Chiadò A, Novara C, Tagliaferro A (2021) Bi2O3/nylon multilayered nanocomposite membrane for the photocatalytic inactivation of waterborne pathogens and degradation of mixed organic pollutants. Environ Sci Nano 8:342–355

Xu Q, Chen F, Li X, Zhang Z (2013) The effect of surface functional groups of nanosilica on the properties of polyamide 6/SiO2 nanocomposite. Polym J Chem Tech 15:20–24

Shanmugan S, Gorjian S, Elsheikh AH, Essa FA, Omara ZM, Raghu AV (2021) Investigation into the effects of SiO2/TiO2 nanolayer on the thermal performance of solar box type cooker. Energy Sources A Recovery Util Environ Eff 43:2724–2737

Rakhshan N, Pakizeh M (2015) The effect of chemical modification of SiO2 nanoparticles on the nanofiltration characteristics of polyamide membrane. Korean J Chem Eng 32:2524–2533

Murray HH (2006) Applied Clay Mineralogy: occurrences, processing and applications of kaolins, bentonites, palygorskite-sepiolite, and common clays. Elsevier, Boston

Agarwal H, Yadav S, Jaiswar G (2017) Effect of nanoclay and barium sulfate nanoparticles on the thermal and morphological properties of polyvinylidene fluoride nanocomposites. J Therm Anal Calorim 129:1471–1479

Dai L (2006) From conventional technology to carbon nanotechnology: The fourth industrial revolution and the discoveries of C60, carbon nanotube and nanodiamond. Carbon Nanotechnol 2006:3–11

Jain VP, Chaudhary S, Sharma D, Dabas N, Lalji RSK, Singh BK, Jaiswar G (2021) Advanced functionalized nanographene oxide as a biomedical agent for drug delivery and anti-cancerous therapy: a review. Eur Polym J 142:110124

Schedin F, Geim AK, Morozov SV, Hill EW, Blake P, Katsnelson MI, Novoselov KS (2007) Detection of individual gas molecules adsorbed on graphene. Nat Mater 6:652–655

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58

Yakobson BI, Brabec CJ, Bernholc J (1996) Nanomechanics of carbon tubes: instabilities beyond linear response. Phys Rev Lett 76:2511

Tong X, Liu C, Cheng HM, Zhao H, Yang F, Zhang X (2004) Surface modification of single-walled carbon nanotubes with polyethylene via in situ Ziegler-Natta polymerization. J Appl Polym Sci 92:3697–3700

Sandler JKW, Pegel S, Cadek M, Gojny F, Van Es M, Lohmar J, Shaffer MSP (2004) A comparative study of melt spun polyamide-12 fibres reinforced with carbon nanotubes and nanofibres. Polymer 45:2001–2015

Wan X, Huang Y, Chen Y (2012) Focusing on energy and optoelectronic applications: a journey for graphene and graphene oxide at large scale. Acc Chem Res 45:598–607

Fu X, Yao C, Yang G (2015) Recent advances in graphene/polyamide 6 composites: a review. RSC Adv 5:61688–61702

Fu XA, Qutubuddin S (2001) Polymer-clay nanocomposites: exfoliation of organophilic montmorillonite nanolayers in polystyrene. Polymer 42:807–813

Arboleda-Clemente L, Ares-Pernas A, García X, Dopico S, Abad MJ (2016) Influence of polyamide ratio on the CNT dispersion in polyamide 66/6 blends by dilution of PA66 or PA6-MWCNT masterbatches. Synth Met 221:134–141

Güryel S, Alonso M, Hajgató B, Dauphin Y, Van Lier G, Geerlings P, De Proft F (2017) A computational study on the role of noncovalent interactions in the stability of polymer/graphene nanocomposites. J Mol Model 23:1–14

Prasai D, Tuberquia JC, Harl RR, Jennings GK, Bolotin KI (2012) Graphene: corrosion-inhibiting coating. ACS Nano 6:1102–1108

Chen X, Yi Z, Lei J, Yi H, Yao W, Zhu W, Duan T (2016) Preparation and performance of an aging-resistant nanocomposite film of binary natural polymer-graphene oxide. ACS Omega 1:1173–1181

Pagacz J, Raftopoulos KN, Leszczyńska A, Pielichowski K (2016) Bio-polyamides based on renewable raw materials. J Therm Anal Calorim 123:1225–1237

Mark J (1999) Polymer Data Handbook. Oxford University, Oxford

Stavila E, Arsyi RZ, Petrovic DM, Loos K (2013) Fusarium solanipisicutinase-catalyzed synthesis of polyamides. Eur Polym J 49:834–842

Duda A, Kowalski A, Penczek S, Uyama H, Kobayashi S (2002) Kinetics of the ring-opening polymerization of 6-, 7-, 9-, 12-, 13-, 16-, and 17-membered lactones: comparison of chemical and enzymatic polymerizations. Macromolecules 35:4266–4270

Biangardi HJ (1990) Brill transition of polyamide 6.12. J Macromol Sci B 29:139–153

Platt DK (2003) Engineering and high-performance plastics market report: A Rapra market report. Smithers Rapra Pub, UK

Ragupathy L, Ziener U, Dyllick-Brenzinger R, von Vacano B, Landfester K (2012) Enzyme-catalyzed polymerizations at higher temperatures: synthetic methods to produce polyamides and new poly (amide-co-ester) s. J Mol Catal B Enzym 76:94–105

Rydz J, Sikorska W, Kyulavska M, Christova D (2014) Polyester-based (bio) degradable polymers as environmentally friendly materials for sustainable development. Int J Mol Sci 16:564–596

Valapa RB, Loganathan S, Pugazhenthi G, Thomas S, Varghese TO (2017) An overview of polymer-clay nanocomposites. ClayPolym Nanocompos 1:29–81

Vo VS, Mahouche-Chergui S, Babinot J, Nguyen VH, Naili S, Carbonnier B (2016) Photo-induced SI-ATRP for the synthesis of photoclickable intercalated clay nanofillers. RSC Adv 6:89322–89327

Zhou Y, Pervin F, Rangari VK, Jeelani S (2007) Influence of montmorillonite clay on the thermal and mechanical properties of conventional carbon fiber reinforced composites. J Mater Process Technol 191:347–351

Ray SS, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog Polym Sci 28:1539–1641

Herrero M, Asensio M, Nunez K, Merino JC, Pastor JM (2019) Morphological, thermal, and mechanical behavior of polyamide11/sepiolite bio-nanocomposites prepared by melt compounding and in situ polymerization. Polym Compos 40:704–713

Stojšić J, Raos P, Milinović A, Damjanović D (2022) A Study of the flexural properties of PA12/clay nanocomposites. Polymer 14:434

Asensio M, Herrero M, Núñez K, Merino JC, Pastor JM (2020) The influence of sepiolite orientation and concentration, on the morphological, thermal and mechanical properties of bio-polyamide 4.10 nanocomposites. Polym Eng Sci 60:1035–1043

Mekhzoum MEM, Raji M, Rodrigue D, Bouhfid R (2020) The effect of benzothiazolium surfactant modified montmorillonite content on the properties of polyamide 6 nanocomposites. Appl Clay Sci 185:1–14

Li TC, Ma J, Wang M, Tjiu WC, Liu T, Huang W (2007) Effect of clay addition on the morphology and thermal behavior of polyamide 6. J Appl Polym Sci 103:1191–1199

Xie S, Zhang S, Wang F, Yang M, Séguéla R, Lefebvre JM (2007) Preparation, structure and thermomechanical properties of nylon-6 nanocomposites with lamella-type and fiber-type sepiolite. ComposSci Technol 67:2334–2341

Bilotti E, Zhang R, Deng H, Quero F, Fischer HR, Peijs T (2009) Sepiolite needle-like clay for PA6 nanocomposites: an alternative to layered silicates. Compos Sci Technol 69:2587–2595

García-López D, Fernández JF, Merino JC, Santarén J, Pastor JM (2010) Effect of organic modification of sepiolite for PA6 polymer/organoclay nanocomposites. Compos Sci Technol 70:1429–1436

García-López D, Fernández JF, Merino JC, Pastor JM (2013) Influence of organic modifier characteristic on the mechanical properties of polyamide 6/organosepiolite nanocomposites. Compos B 45:459–465

Bilotti E, Duquesne E, Deng H, Zhang R, Quero F, Georgiades SN, Peijs T (2014) In situ polymerised polyamide 6/sepiolite nanocomposites: Effect of different interphases. Eur Polym J 56:131–139

Vyas A, Iroh JO (2014) Thermal behavior and structure of clay/nylon-6 nanocomposite synthesized by in situ solution polymerization. J Therm Anal Calorim 117:39–52

Risite H, Mabrouk KE, Bousmina M, Fassi-Fehri O (2016) Role of polyamide 11 interaction with clay and modifier on thermal, rheological and mechanical properties in polymer clay nanocomposites. J Nanosci Nanotechnol 16:7584–7593

Hindeleh AM, Johnson DJ (1978) Crystallinity and crystallite size measurement in polyamide and polyester fibres. Polymer 19:27–32

Yebra-Rodriguez A, Fernandez-Barranco C, La Rubia MD, Yebra A, Rodriguez-Navarro AB, Jimenez-Millan J (2014) Thermooxidative degradation of injection-moulded sepiolite/polyamide 66 nanocomposites. Mineral Mag 78:1227–1239

Qin H, Su Q, Zhang S, Zhao B, Yang M (2003) Thermal stability and flammability of polyamide 66/montmorillonite nanocomposites. Polymer 44:7533–7538

Chae DW, Lim JH, Seo JS, Kim BC (2012) Variation of physical properties of nylon-66/clay nanocomposites with preparation conditions. Korea Aust Rheol J 24:45–52

Stoclet G, Sclavons M, Devaux J (2013) Relations between structure and property of polyamide 11 nanocomposites based on raw clays elaborated by water-assisted extrusion. J Appl Polym Sci 127:4809–4824

Fernandez-Barranco C, Yebra-Rodriguez A, La Rubia-Garcia MD, Navas-Martos FJ, Alvarez-Lloret P (2015) Mechanical and crystallographic properties of injection-molded polyamide 66/sepiolite nanocomposites with different clay loading. Polym Compos 36:2326–2333

Fernandez-Barranco C, Kozioł AE, Skrzypiec K, Rawski M, Drewniak M, Yebra-Rodriguez A (2016) Reprint of study of spatial distribution of sepiolite in sepiolite/polyamide 6, 6 nanocomposites. Appl Clay Sci 130:50–54

Borić A, Kalendová A, Urbanek M, Pepelnjak T (2019) Characterisation of polyamide (PA) 12 nanocomposites with montmorillonite (MMT) filler clay used for the incremental forming of sheets. Polymers 11:1–20

Benobeidallah B, Benhamida A, Dorigato A, Sola A, Messori M, Pegoretti A (2019) Structure and properties of polyamide 11 nanocomposites filled with fibrous palygorskite clay. J Renew Mater 7:89–102

Benobeidallah B, Benhamida A, Kaci M, Lopez-Cuesta JM (2020) Combined effect of palygorskite and melamine polyphosphate on flame retardancy properties of polyamide 11 nanocomposites. Appl Clay Sci 198:1–9

Breuer O, Sundararaj U (2004) Big returns from small fibers: a review of polymer/carbon nanotube composites. Polym Compos 25:630–645

Calvert P (1999) A recipe for strength. Nature 399:210–211

Mahmood N, Islam M, Hameed A, Saeed S, Khan AN (2014) Polyamide-6-based composites reinforced with pristine or functionalized multi-walled carbon nanotubes produced using melt extrusion technique. J Compos Mater 48:1197–1207

Jiang J, Zhang D, Zhang Y, Zhang K, Wu G (2013) Influences of carbon nanotube networking on the conductive, crystallization, and thermal expansion behaviors of pa610-based nanocomposites. J Macromol Sci B 52:910–923

Chiu FC, Kao GF (2012) Polyamide 46/multi-walled carbon nanotube nanocomposites with enhanced thermal, electrical, and mechanical properties. Compos A 43:208–218

Madhukar K, Sainath AVS, Bikshamaiah N, Srinivas Y, Babu NM, Ashok B, Rao BS (2014) Thermal properties of single walled carbon nanotubes composites of polyamide 6/poly (methyl methacrylate) blend system. J Therm Anal Calorim 115:345–354

Otaegi I, Aranburu N, Iturrondobeitia M, Ibarretxe J, Guerrica-Echevarría G (2019) The effect of the preparation method and the dispersion and aspect ratio of CNTs on the mechanical and electrical properties of biobased polyamide-4, 10/CNT nanocomposites. Polymers 11:1–16

Meincke O, Kaempfer D, Weickmann H, Friedrich C, Vathauer M, Warth H (2004) Mechanical properties and electrical conductivity of carbon-nanotube filled polyamide-6 and its blends with acrylonitrile/butadiene/styrene. Polymer 45:739–748

Kodgire PV, Bhattacharyya AR, Bose S, Gupta N, Kulkarni AR, Misra A (2006) Control of multiwall carbon nanotubes dispersion in polyamide 6 matrix: An assessment through electrical conductivity. Chem Phys Lett 432:480–485

Otaegi I, Aramburu N, Müller AJ, Guerrica-Echevarría G (2018) Novel biobased polyamide 410/polyamide 6/CNT nanocomposites. Polymers 10:1–18

Vidakis N, Petousis M, Tzounis L, Velidakis E, Mountakis N, Grammatikos SA (2021) Polyamide 12/multiwalled carbon nanotube and carbon black nanocomposites manufactured by 3D printing fused filame. nt fabrication: a comparison of the electrical, thermoelectric, and mechanical properties. C 7(2):38

Qi S, Gao X, Su Y, Zhou Y, Dong X, Wang D (2022) Effect of carbon nanotubes on mechanical properties of polyamide 12 parts by fused filament fabrication. Polymer 247:124784

Deng H, Bilotti E, Zhang R, Wang K, Zhang Q, Peijs T, Fu Q (2011) Improving tensile strength and toughness of melt processed polyamide 6/multiwalled carbon nanotube composites by in situ polymerization and filler surface functionalization. J Appl Polym Sci 120:133–140

Zhang WD, Shen L, Phang IY, Liu T (2004) Carbon nanotubes reinforced nylon-6 composite prepared by simple melt-compounding. Macromolecules 37:256–259

Liu T, Phang IY, Shen L, Chow SY, Zhang WD (2004) Morphology and mechanical properties of multiwalled carbon nanotubes reinforced nylon-6 composites. Macromolecules 37:7214–7222

Bhattacharyya AR, Pötschke P (2006) Mechanical properties and morphology of melt-mixed PA6/SWNT composites: effect of reactive coupling. Macromol Symp 233:161–169

Jose MV, Steinert BW, Thomas V, Dean DR, Abdalla MA, Price G, Janowski GM (2007) Morphology and mechanical properties of nylon 6/MWNT nanofibers. Polymer 48:1096–1104

Yang M, Gao Y, Li H, Adronov A (2007) Functionalization of multiwalled carbon nanotubes with polyamide 6 by anionic ring-opening polymerization. Carbon 45:2327–2333

Meng H, Sui GX, Fang PF, Yang R (2008) Effects of acid-and diamine-modified MWNTs on the mechanical properties and crystallization behavior of polyamide 6. Polymer 49:610–620

Kang S, Kim J, Park JH, Jung I, Park M (2020) Multiwalled carbon nanotube pretreatment to enhance tensile properties, process stability, and filler dispersion of polyamide 66 nanocomposites. Compos B 198:1–11

Chatterjee S, Nüesch FA, Chu BT (2011) Comparing carbon nanotubes and graphene nanoplatelets as reinforcements in polyamide 12 composites. Nanotech 22:275714

Socher R, Krause B, Müller MT, Boldt R, Pötschke P (2012) The influence of matrix viscosity on MWCNT dispersion and electrical properties in different thermoplastic nanocomposites. Polymer 53:495–504

Sethy S, Barwal V, Satapathy BK (2022) Tunable thermo-sensitive electrical conductivity of melt-mixed PA-12/PP-MWCNT nanocomposites. Compos Sci Technol 217:109099

Ehteramian M, Ghasemi I, Azizi H, Karrabi M (2021) Functionalization of multi-walled carbon nanotube and its effect on shape memory behavior of nanocomposite based on thermoplastic polyurethane/polyvinyl chloride/multi-walled carbon nanotube (TPU/PVC/MWCNT). Iran Polym J 30:411–422

Kim HS, Park BH, Yoon JS, Jin HJ (2007) Nylon 610/functionalized multiwalled carbon nanotubes composites by in situ interfacial polymerization. Mater Lett 61:2251–2254

Logakis E, Pandis C, Peoglos V, Pissis P, Pionteck J, Pötschke P, Omastová M (2009) Electrical/dielectric properties and conduction mechanism in melt processed polyamide/multi-walled carbon nanotubes composites. Polymer 50:5103–5111

Gorrasi G, Bredeau S, Di Candia C, Patimo G, De Pasquale S, Dubois P (2011) Electroconductive polyamide 6/MWNT nanocomposites: effect of nanotube surface-coating by in situ catalyzed polymerization. Macromol Mater Eng 296:408–413

Huang Y, Tan L, Zheng S, Liu Z, Feng J, Yang MB (2015) Enhanced dielectric properties of polyamide 11/multi-walled carbon nanotubes composites. J Appl Polym Sci 132:1–9

Kazemi Y, Kakroodi AR, Mark LH, Filleter T, Park CB (2019) Effects of polymer-filler interactions on controlling the conductive network formation in polyamide 6/multi-walled carbon nanotube composites. Polymer 178:121684

Sethy S, Satapathy BK (2020) Microstructural interpretations on thermo-mechanical relaxation and electrical conductivity of polyamide-12/polypropylene-MWCNT nanocomposites. J Polym Res 27:1–12

Xu Z, Gao C (2010) In situ polymerization approach to graphene-reinforced nylon-6 composites. Macromolecules 43:6716–6723

Dixon D, Lemonine P, Hamilton J, Lubarsky G, Archer E (2015) Graphene oxide-polyamide 6 nanocomposites produced via in situ polymerization. J Thermoplast Compos Mater 28:372–389

Gautam J, Pal MK, Singh B, Bhatnagar U (2011) Thermal and electrical properties of acrylic acid grafted onto starch by ceric ammonium nitrate and potassium permanganate initiator. Int J Plast Technol 15:188–198

Duan X, Yu B, Yang T, Wu Y, Yu H, Huang T (2018) In situ polymerization of nylon 66/reduced graphene oxide nanocomposites. J Nanomater 2018:1–9

Rafiq R, Cai D, Jin J, Song M (2010) Increasing the toughness of nylon 12 by the incorporation of functionalized graphene. Carbon 48:4309–4314

Attar S, Chen B, Cicala G, Catalanotti G, Scalici T, Falzon BG (2022) On the mechanical properties of melt-blended nylon 6/ethylene-octene copolymer/graphene nanoplatelet nanocomposites. Polymer 243:124619

Nakhaei MR, Naderi G, Ghoreishy MHR (2021) Fracture mechanisms and failure analysis of PA6/NBR/graphene nanocomposites by essential work of fracture. Iran Polym J 30:975–987

Wu J, Gan H, Liu H (2021) Coagulation-assisted preparation of graphene oxide/polyamide 6 composites. Mater Chem Phys 266:1–10

Chiu FC, Huang IN (2012) Phase morphology and enhanced thermal/mechanical properties of polyamide 46/graphene oxide nanocomposites. Polym Test 31:953–962

Cai Z, Meng X, Han Y, Ye H, Cui L, Zhou Q (2015) Reinforcing polyamide 1212 with graphene oxide via a two-step melt compounding process. Compos A 69:115–123

Kausar A (2018) Composite coatings of polyamide/graphene: microstructure, mechanical, thermal, and barrier properties. Compos Interface 25:109–125

Lee J, Yun YS, Kim B, Cho SY, Jin HJ (2014) Nylon 610/graphene oxide composites prepared by in-situ interfacial polymerization. J Nanosci Nanotechnol 14:5703–5707

Zhang PP, Zhu KY, Su LQ, Xiao R (2013) Preparation and properties of graphene/polyamide 6 composites by melt compounding. In Adv Mater Res 621:31–34

Zhu D, Ren Y, Liao G, Jiang S, Liu F, Guo J, Xu G (2017) Thermal and mechanical properties of polyamide 12/graphene nanoplatelets nanocomposites and parts fabricated by fused deposition modeling. J Appl Polym Sci 134:1–13

Liu M, Li M, Hou H, Li R (2015) Thermal properties of PA6 nanocomposites by addition of graphene non-covalently functionalized with dendronized polyamide. J Therm Anal Calorim 120:1303–1310

Zhuang YF, Cao XY, Zhang JN, Ma YY, Shang XX, Lu JX, Ma YM (2019) Monomer casting nylon/graphene nanocomposite with both improved thermal conductivity and mechanical performance. Compos A 120:49–55

Xu BF, Lin ZD, Du CM, Lin HB, Liang KY, Qiu WP, Yang GL (2015) Mechanical properties, morphology and thermal conductivity of polyamide composites filled with graphene nanoplatelets, Al2O3 and graphite. Mater Res Innov 19:1–388

Ren Y, Zhang Y, Guo H, Lv R, Bai SL (2019) A double mixing process to greatly enhance thermal conductivity of graphene filled polyamide 6 composites. Compos A 126:1–8

Gaikwad S, Tate JS, Theodoropoulou N, Koo JH (2013) Electrical and mechanical properties of PA11 blended with nanographene platelets using industrial twin-screw extruder for selective laser sintering. J Compos Mater 47:2973–2986

Yoo Y, Lee HL, Ha SM, Jeon BK, Won JC, Lee SG (2014) Effect of graphite and carbon fiber contents on the morphology and properties of thermally conductive composites based on polyamide 6. Polym Int 63:151–157

Ding P, Su S, Song N, Tang S, Liu Y, Shi L (2014) Highly thermal conductive composites with polyamide-6 covalently-grafted graphene by an in-situ polymerization and thermal reduction process. Carbon 66:576–584

Hofmann D, Keinath M, Thomann R, Mülhaupt R (2014) Thermoplastic carbon/polyamide 12 composites containing functionalized graphene, expanded graphite, and carbon nanofillers. Macromol Mater Eng 299:1329–1342

Mayoral B, Harkin-Jones E, Khanam PN, AlMaadeed MA, Ouederni M, Hamilton AR, Sun D (2015) Melt processing and characterisation of polyamide 6/graphene nanoplatelet composites. Rsc Adv 5:52395–52409

Hwang SH, Kim BJ, Baek JB, Shin HS, Bae IJ, Lee SY, Park YB (2016) Effects of process parameters and surface treatments of graphene nanoplatelets on the crystallinity and thermomechanical properties of polyamide 6 composite fibers. Compos B 100:220–227

Chen B, Davies R, Liu Y, Yi N, Qiang D, Zhu Y, Ghita O (2020) Laser sintering of graphene nanoplatelets encapsulated polyamide powders. Addit Manuf 35:1–9

Cho BG, Joshi SR, Han JH, Kim GH, Park YB (2021) Interphase strengthening of carbon fiber/polyamide 6 composites through mixture of sizing agent and reduced graphene oxide coating. Compos A 149:1–16

Radzik P, Leszczyńska A, Pielichowski K (2020) Modern biopolyamide-based materials: synthesis and modification. Polym Bull 77:501–528

Fan J, Njuguna J (2016) An introduction to lightweight composite materials and their use in transport structures. Lightweight Compos Struct Transport 2016:3–34

Kausar A (2019) Trends in graphene reinforced polyamide nanocomposite for functional application: a review. Polym Plast Tech Mater 58:917–933

Silvestre C, Duraccio D, Cimmino S (2011) Food packaging based on polymer nanomaterials. Prog Polym Sci 36:1766–1782

Swain SK, Priyadarshini PP, Patra SK (2012) Soy protein/clay bionanocomposites as ideal packaging materials. Polym Plast Tech Eng 51:1282–1287

Smolander M, Chaudhry Q (2010) Nanotechnologies in food packaging. Nanotech Food 14:86–101

Temizel-Sekeryan S, Wu F, Hicks AL (2021) Global scale life cycle environmental impacts of single-and multi-walled carbon nanotube synthesis processes. Int J LCA 26:656–672

Shahbazi M, Rajabzadeh G, Sotoodeh S (2017) Functional characteristics, wettability properties and cytotoxic effect of starch film incorporated with multi-walled and hydroxylated multi-walled carbon nanotubes. Int J Biol Macromol 104:597–605

Kausar A, Anwar Z, Khan LA, Muhammad B (2017) Functional graphene nanoplatelet reinforced epoxy resin and polystyrene-based block copolymer nanocomposite. Fuller Nanotub Carbon Nanostruct 25:47–57

Wang H, Maiyalagan T, Wang X (2012) Review on recent progress in nitrogen-doped graphene: synthesis, characterization, and its potential applications. ACS Catal 2:781–794

Han J, Qiu W, Cao Z, Hu J, Gao W (2013) Adsorption of ethinylestradiol (EE2) on polyamide 612: molecular modeling and effects of water chemistry. Water Res 47:2273–2284

Kumar S, Satapathy BK, Maiti SN (2013) Correlation of morphological parameters and mechanical performance of polyamide-612/poly (ethylene-octene) elastomer blends. Polym Adv Technol 24:511–519

Pal MK, Gautam J (2013) Effects of inorganic nanofillers on the thermal degradation and UV-absorbance properties of polyvinyl acetate. J Therm Anal Calorim 111:689–701

Rathore S, Madhav H, Jaiswar G (2019) Efficient nano-filler for the phase transformation in polyvinylidene fluoride nanocomposites by using nanoparticles of stannous sulfate. Mater Res Innov 23:183–190

Wu H, Krifa M, Koo JH (2014) Flame retardant polyamide 6/nanoclay/intumescent nanocomposite fibers through electrospinning. Textile Research J 84:1106–1118

Bachs-Herrera A, Yousefzade O, del Valle LJ, Puiggali J (2021) Melt electrospinning of polymers: blends, nanocomposites, additives and applications. Appl Sci 11:1–39

Yin X, Krifa M, Koo JH (2015) Flame-retardant polyamide 6/carbon nanotube nanofibers: processing and characterization. J Eng Fiber Fabric 10:1–11

Majka TM, Witek M, Radzik P, Komisarz K, Mitoraj A, Pielichowski K (2020) Layer-by-layer deposition of copper and phosphorus compounds to develop flame-retardant polyamide 6/montmorillonite hybrid composites. Appl Sci 10:1–20

Shabanian M, Hajibeygi M, Roohani M (2015) Synthesis of a novel CNT/polyamide composite containing phosphine oxide groups and its flame retardancy and thermal properties. New Carbon Mater 30:397–403

Xing W, Yang W, Yang W, Hu Q, Si J, Lu H, Yuen RK (2016) Functionalized carbon nanotubes with phosphorus-and nitrogen-containing agents: effective reinforcer for thermal, mechanical, and flame-retardant properties of polystyrene nanocomposites. ACS Appl Mater Interface 8:26266–26274

Shi Y, Long Z, Yu B, Zhou K, Gui Z, Yuen RK, Hu Y (2015) Tunable thermal, flame retardant and toxic effluent suppression properties of polystyrene based on alternating graphitic carbon nitride and multi-walled carbon nanotubes. J Mater Chem A 3:17064–17073

Zhou K, Gao R (2017) The influence of a novel two-dimensional graphene-like nanomaterial on thermal stability and flammability of polystyrene. J Colloid Interface Sci 500:164–171

Xiao L, Xu L, Yang Y, Zhang S, Huang Y, Bielawski CW, Geng J (2017) Core-shell structured polyamide 66 nanofibers with enhanced flame retardancy. ACS Omega 2:2665–2671

Kundu CK, Li Z, Li X, Zhang Z, Hu Y (2020) Graphene oxide functionalized biomolecules for improved flame retardancy of polyamide 66 fabrics with intact physical properties. Int J Bio Macromol 156:362–371

Malkappa K, Bandyopadhyay J, Ojijo V, Ray SS (2022) Superior flame retardancy, antidripping, and thermomechanical properties of polyamide nanocomposites with graphene-based hybrid flame retardant. J Appl Polym Sci 139:52867

Selmy AI, Abd El-baky MA, Hegazy DA (2019) Mechanical properties of inter-ply hybrid composites reinforced with glass and polyamide fibers. J Thermo Compos Mater 32:267–293

Selmy AI, Abd El-baky MA, Hegazy DA (2020) Wear behavior of glass-polyamide reinforced epoxy hybrid composites. J Thermo Compos Mater 33:214–235

Chamkouri H, Pooresmaeil M, Namazi H (2021) Carbon fiber/epoxy resin/α-aluminum oxide nanocomposites: fabrication, mechanical and thermal analysis. Iran Polym J 30:523–533

Devaux E, Bourbigot S, Achari AE (2002) Crystallization behavior of PA-6 clay nanocomposite hybrid. J Appl Polym Sci 86:2416–2423

Bourbigot S, Devaux E, Flambard X (2002) Flammability of polyamide-6/clay hybrid nanocomposite textiles. Polym Degrad Stabil 75:397–402

Mészáros L, Deák T, Balogh G, Czvikovszky T, Czigány T (2013) Preparation and mechanical properties of injection moulded polyamide 6 matrix hybrid nanocomposite. Compos Sci Technol 75:22–27

Toghchi MJ, Campagne C, Cayla A, Bruniaux P, Loghin C, Cristian I, Chen Y (2019) Electrical conductivity enhancement of hybrid PA6, 6 composite containing multiwall carbon nanotube and carbon black for shielding effectiveness application in textiles. Synth Met 251:75–84

Saini P (2013) Electrical properties and electromagnetic interference shielding response of electrically conducting thermosetting nanocomposites. Thermoset Nanocompos 12:211–237

Zhang Y, Lu Y, Yan X, Gao W, Chen H, Chen Q, Bai Y (2019) Functional and enhanced graphene/polyamide 6 composite fiber constructed by a facile and universal method. Compos A 123:149–157

Pavlidou S, Papaspyrides CD (2008) A review on polymer-layered silicate nanocomposites. Prog Polym Sci 33:1119–1198

Megahed M, Abd El-baky MA, Alsaeedy AM, Alshorbagy AE (2019) An experimental investigation on the effect of incorporation of different nanofillers on the mechanical characterization of fiber metal laminate. Compos B 176:1–12

Megahed M, El-baky A, Alsaeedy AM, Alshorbagy AE (2021) Synthesis effect of nano-fillers on the damage resistance of GLARE. Fiber Polym 22:1366–1377

Megahed M, El-baky A, Alsaeedy AM, Alshorbagy AE (2020) Improvement of impact and water barrier properties of GLARE by incorporation of different types of nanoparticles. Fiber Polym 21:840–848

Jagannatham M, Chandran P, Sankaran S, Haridoss P, Nayan N, Bakshi SR (2020) Tensile properties of carbon nanotubes reinforced aluminum matrix composites: A review. Carbon 160:14–44

Kiziltas A, Liu W, Tamrakar S, Mielewski D (2021) Graphene nanoplatelet reinforcement for thermal and mechanical properties enhancement of biobased polyamide 6,10 nanocomposites for automotive applications. Composites Part C 6:1–9

Alamgir M, Nayak GC, Mallick A, Sahoo S (2021) Effects of TiO2 and GO nanoparticles on the thermomechanical properties of bioactive poly-HEMA nanocomposites. Iran Polym J 30:1089–1099

Zhang X, Yang G, Lin J (2006) Synthesis, rheology, and morphology of nylon-11/layered silicate nanocomposite. J Polym Sci Part B 44:2161–2172

Lao SC, Koo JH, Moon TJ, Londa M, Ibeh CC, Wissler GE, Pilato LA (2011) Flame-retardant polyamide 11 nanocomposites: further thermal and flammability studies. J Fire Sci 29:479–498

Acknowledgements

The author Deepa Sharma wishes to acknowledge the Council of Scientific and Industrial Research (CSIR), Government of India, New Delhi, India for providing financial support during the study as Senior Research Fellowship (SRF), (Award No. 09/197(0007)/2019-EMR-I) and also Head Department of Chemistry, Dr. Bhimrao Ambedkar University, Agra for providing space for research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declare that they have no known competing financial interests or personal relationship that could have appeared to influence the work reported in this paper and also declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, D., Kumar, M., Jain, V.P. et al. Bio-based polyamide nanocomposites of nanoclay, carbon nanotubes and graphene: a review. Iran Polym J 32, 773–790 (2023). https://doi.org/10.1007/s13726-023-01164-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01164-x