Abstract

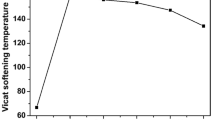

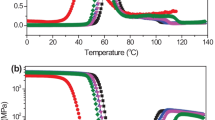

A bis(tert-butyl dioxy isopropyl) benzene (BIBP) was blended with 70/30 poly(lactic acid)/vinyl acetate ethylene (PLA/VAE) blend in order to improve the compatibility and properties of the blend. A series of samples with different BIBP contents were prepared by twin screw extruder. The gel fractions, rheological behaviors, morphologies, mechanical properties and thermal stability of the blends were investigated. Combined with the results of gel fractions and rheological behaviors, the gel fractions and complex viscosity gradually increased with increasing BIBP content, indicating that some crosslinked structures were formed after incorporation with BIBP. Crosslinking largely reduced the dispersed phase particle size and significantly increased the interfacial adhesion of PLA and VAE. Thus, the crosslinked structures could be considered as compatibilizers, which improved the compatibility between the two components. The mechanical properties were also improved remarkably when an appropriate content of BIBP was added. Upon addition of BIBP, the PLA/VAE blends not only were largely toughened but also exhibited some increase in the tensile strength. Moreover, shear yielding was considered as an important way for induced energy dissipation and led to a toughened blend. In addition, it was found that the introduction of BIBP resulted in an increase in the thermal stability of the blends. The output had certain reference values toward PLA modification strategy, and it may pave a route for endowing PLA materials with a specific required nature.

Graphical abstract

Similar content being viewed by others

References

Liu L, Xu Y, Di Y, Xu M, Pan Y, Li B (2020) Simultaneously enhancing the fire retardancy and crystallization rate of biodegradable polylactic acid with piperazine-1,4-diylbis (diphenylphosphine oxide). Compos B 202:108407

Bhasney SM, Mondal K, Kumar A, Katiyar V (2019) Effect of microcrystalline cellulose [MCC] fibres on the morphological and crystalline behaviour of high density polyethylene [HDPE]/polylactic acid [PLA] blends. Compos Sci Technol 187:107941

Deetuam C, Samthong C, Choksriwichit S, Somwangthanaroj A (2020) Isothermal cold crystallization kinetics and properties of thermoformed poly(lactic acid) composites: effects of talc, calcium carbonate, cassava starch and silane coupling agents. Iran Polym J 29:103–116

Paul GP, Virivinti N (2022) An outlook on recent progress in poly(lactic acid): polymerization, modeling, and optimization. Iran Polym J 31:59–81

Gurmeet SK, Ilham AQ, Adriaan SL (2018) Morphology and property changes in PLA/PHBV blends as function of blend composition. J Polym Res 25:196

Lai SM, Liu YH, Huang CT, Don TM (2017) Miscibility and toughness improvement of poly(lactic acid)/poly(3-hydroxybutyrate) blends using a melt-induced degradation approach. J Polym Res 24:102

Yang JN, Zhang XH, Li T, Wang Y, Xia BH, Jiang J, Chen MQ, Dong WF (2021) A novel biodegradable poly(propylene carbonate) with enhanced thermal and mechanical properties by incorporating tannic acid. Polym Adv Technol 33:1341–1347

Zhao L, Jia SL, Wang ZP, Chen YJ, Bian JJ, Han LJ, Zhang HL, Dong LS (2021) Thermal, rheological and mechanical properties of biodegradable poly(propylene carbonate)/epoxidized soybean oil blends. Chinese J Polym Sci 39:1572–1580

Ma QF, Shi K, SuTT WZY (2020) Biodegradation of polycaprolactone (PCL) with different molecular weights by Candida antarctica lipase. J Polym Environ 28:2947–2955

Pekdemir ME, Öner E, Kök M, Qader IN (2021) Thermal behavior and shape memory properties of PCL blends film with PVC and PMMA polymers. Iran Polym J30:633–641

Gigante V, Canesi I, Cinelli P, Coltelli MB, Lazzeri A (2019) Rubber toughening of polylacticacid (PLA) with poly(butylene adipate-co-terephthalate) (PBAT): mechanical properties, fracture mechanics and analysis of ductile-to-brittle behavior while varying temperature and test speed. Eur Polym J 115:125–137

Mahata D, Cherian A, Parab A, Gupta V (2020) In situ functionalization of poly(butylene adipate-co-terephthalate) polyester with a multi-functional macromolecular additive. Iran Polym J 29:1045–1055

Fan M, Zhang B, Fan L, Chen F, Fu Q (2021) Adsorbability of modified PBS nanofiber membrane to heavy metal ions and dyes. J Polym Environ 29:3029–3039

Puekpoonpoal N, Phattarateera S, Kerddonfag N, Aht-Ong D (2021) Morphology development of PLAs with different stereo-regularities in ternary blend PBSA/PBS/PLA films. Polym Plast Technol 60:1672–1685

Peng NX, Ju YH, Lv RH, Na B, Liu QX, Wang B (2016) Toughening biodegradable polylactide with nanopores. J Polym Res 23:261

Drumright RE, Gruber PR, Henton DE (2000) Polylactic acid technology. Adv Mater 12:1841–1846

Ramlee NA, Tominaga Y (2018) Preparation and characterization of poly(ethylene carbonate)/poly(lactic acid) blends. J Polym Res 25:54

Xia XL, Shi XY, Liu WT, He SQ, Zhu CS, Liu H (2020) Effects of gamma irradiation on properties of PLA/flax composites. Iran Polym J 29:581–590

Luangkachao J, Sirisinha K (2020) Role of Sn-based and Ti-based catalysts on melt copolymerization of PLA-polyols. IOP Conference Series: Mater Sci Eng 773:012058

Greco A, Ferrari F (2021) Thermal behavior of PLA plasticized by commercial and cardanol-derived plasticizers and the effect on the mechanical properties. J Therm Anal Calorim 146:131–141

Chaochanchaikul K, Pongmuksuwan P (2022) Influence of ozonized soybean oil as a biobased plasticizer on the toughness of polylacticacid. J Polym Environ 30:1095–1105

Alias NF, Ismail H, Ishak KMK (2021) Poly(lactic acid)/natural rubber/kenaf biocomposites production using poly(methyl methacrylate) and epoxidized natural rubber as co-compatibilizers. Iran Polym J 30:737–749

Tessanan W, Phinyocheep P (2022) Toughening modification of poly(lactic acid) using modified natural rubber. Iran Polym J 31:455–469

Bian YJ, Han CY, Han LJ, Lin HJ, Zhang HL, Bian JJ, Dong LS (2014) Toughening mechanism behind intriguing stress-strain curves in tensile tests of highly enhanced compatibilization of biodegradable poly(lactic acid)/poly(3-hydroxybutyrate-co-4-hydroxybutyra) blends. RSC Adv 4:41722–41733

Hao YP, YangPan HLHW, Zhang HL, Ran XH (2018) Heat resistant and mechanical properties of biodegradable poly(lactic acid)/poly(butylene succinate) blends crosslinked by polyaryl/polymethylene-isocyanate. Polym Plast Technol 57:1882–1892

Pan HW, Li ZL, Yang J, Li X, Ai X, Hao YP, Zhang HL, Dong LS (2018) The effect of MDI on the structure and mechanical properties of poly(lactic acid) and poly(butylene adipate-co-butylene terephthalate) blends. RSC Adv 8:4610–4623

Shi YY, Du XC, Yang JH, Huang T, Zhang N, Wang Y, Yuan GP, Zhang CL (2014) Super toughened poly(L-lactide)/thermoplastic polyurethane blends achieved by adding dicumylperoxide. Polym Plast Technol 53:1344–1353

Ai X, Wang DM, Li X, Pan HW, Kong JJ, Yang HL, Zhang HL, Dong LS (2019) The properties of chemical cross-linked poly(lactic acid) by bis(tert-butyl dioxy isopropyl) benzene. Polym Bull 76:575–594

Ai X, Li X, Yu YL, Pan HW, Yang J, Wang DM, Yang HL, Zhang HL, Dong LS (2019) The mechanical, thermal, rheological and morphological properties of PLA/PBAT blown films by using bis(tert-butyl dioxy isopropyl) benzene as crosslinking agent. Polym Eng Sci 59:E227–E236

Han CD (1976) Rheology in Polymer Processing. Academic, New York

Han CD (1981) Multiphase Flow in Polymer Processing. Academic, New York

Utracki LA (1988) Viscoelastic behavior of polymer blends. Polym Eng Sci 28:1401–1404

Semba T, Kitagawa K, Ishiaku US, Hamada H (2006) The effect of crosslinking on the mechanical properties of polylactic acid/polycaprolactone blends. J Appl Polym Sci 101:1816–1825

Doyle CD (1961) Kinetic analysis of thermogravimetric data. J Appl Polym Sci 5:285–292

Wu DF, Wu L, Zhang M, Zhao YL (2008) Viscoelasticity and thermal stability of polylactide blends with various functionalized carbon nanotubes. Polym Degrad Stabil 93:1577–1584

Acknowledgements

This work was supported by the fund of the Chinese Science Academy (Changchun Branch) (No. 2021SYHZ0044).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, Y., Tian, H., Chen, J. et al. Poly(lactic acid)/vinyl acetate ethylene blends: effect of crosslinking on their rheological, mechanical and thermal stability behavior. Iran Polym J 32, 13–22 (2023). https://doi.org/10.1007/s13726-022-01097-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01097-x