Abstract

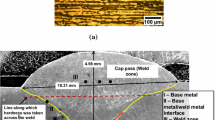

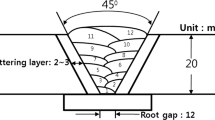

In the present study, shielded metal arc welding (SMAW) with electrode ER2209 was carried out on lean duplex grade LDX2101 by varying heat inputs, low heat (LH) 0.85 kJ/mm, and high heat (HH) 1.3 kJ/mm. The paper’s main objective was to understand the influence of heat inputs on microstructural behavior and its effect on the mechanical properties of weldments. Microstructure and volumetric phase analysis of weldments were done using an optical and scanning electron microscope. Grain boundary austenite, intra-granular austenite and Widmanstatten austenite, along with ferrite were observed in the microstructure of the weld zones. The morphology of the weldment revealed that the ferrite–austenite phase ratio can be adjusted by altering the heat inputs. Important mechanical properties such as tensile strength, impact toughness, micro-hardness and scratch hardness were investigated to understand the weld performance. The SMAW weldments exhibited an increase in micro-hardness, with values changing (from 227 ± 2.8 to 246 ± 5.2 HV10) for LH SMAW and (from 232 ± 3.2 to 242 ± 2.7 HV10) for HH SMAW. The tensile strength of the LH SMAW was slightly higher However, this enhancement in mechanical properties came at the expense of a slight reduction in ductility, as indicated by a fall in the percentage of elongation from 28.07 to 22.86. Impact toughness of the LH SMAW was 88.7% higher than the HH weldments. Electrochemical measurements of weldments were carried out using the potentiodynamic polarization test to estimate the corrosion rate. Scratch hardness was evaluated to understand the tribological characteristics of the weldment surface. The overall performance of the LH input weld exhibited promising results compared to the high heat.

Similar content being viewed by others

Abbreviations

- DSS:

-

Duplex stainless steels

- LDSS:

-

Lean duplex stainless steel

- SMAW:

-

Shielded metal arc welding

- ASS:

-

Austenitic stainless steel

- GTAW:

-

Gas tungsten arc welding

- CPT:

-

Critical pitting temperature

- BM:

-

Base material

- ASTM:

-

American standard testing method

- WZ:

-

Weld zone

- F:

-

Ferrite

- A:

-

Austenite

- GBA:

-

Grain boundary austenite

- IGA:

-

Intergranular austenite

- IZ:

-

Interface zone

- HAZ:

-

Heat affected zone

- SEM:

-

Scanning electron microscopy

- LH:

-

Low heat

- HH:

-

High heat

- UTS:

-

Ultimate tensile strength

- TF:

-

Traction force

- COF:

-

Coefficient of friction

- ER:

-

Electrode

- V :

-

Voltage (Volts)

- I :

-

Current (Amps)

- v :

-

Velocity (mm/s)

- H :

-

Heat input (KJ/mm)

- ŋ:

-

Efficiency

References

J. Lippold, D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels (Wiley, New York, 2005)

Z. Schulz, P. Whitcraft, D. Wachowiak, Availability and economics of using duplex stainless steels. NACE CORROSION, p. NACE-2014 (2014)

T. Oshima, Y. Habara, K. Kuroda, Efforts to save nickel in austenitic stainless steels. ISIJ Int. 47(3), 359–364 (2007)

M. Liljas, P. Johansson, H.P. Liu, C.O.A. Olsson, Development of a lean duplex stainless steel. Steel Res. Int. 79(6), 466–473 (2008)

P. Boillot, J. Peultier, Use of stainless steels in the industry: recent and future developments. Procedia Eng. 83, 309–321 (2014)

J. Verma, R.V. Taiwade, Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—a review. J. Manuf. Process. 25, 134–152 (2017)

H.Y. Liou, W.T. Tsai, Y.T. Pan, R.I. Hsieh, Effects of alloying elements on the mechanical properties and corrosion behaviors of 2205 duplex stainless steels. J. Mater. Eng. Perform. 10, 231–241 (2001)

V.A. Hosseini, S. Wessman, K. Hurtig, L. Karlsson, Nitrogen loss and effects on microstructure in multipass TIG welding of a super duplex stainless steel. Mater. Des. 98, 88–97 (2016)

V. Muthupandi, P. Bala Srinivasan, S.K. Seshadri, S. Sundaresan, Effect of nitrogen addition on formation of secondary austenite in duplex stainless steel weld metals and resultant properties. STWJ. 9(1), 47–52 (2004)

I. Moreno, J.F. Almagro, X. Llovet, Determination of nitrogen in duplex stainless steels by EPMA. Microchim. Acta. 139, 105–110 (2002)

A.B. Başyiğit, A. Kurt, The effects of nitrogen gas on microstructural and mechanical properties of TIG welded s32205 duplex stainless steel. Metals. 8(4), 226 (2018)

R. Unnikrishnan, K.S. Idury, T.P. Ismail, A. Bhadauria, S.K. Shekhawat, R.K. Khatirkar, S.G. Sapate, Effect of heat input on the microstructure, residual stresses and corrosion resistance of 304L austenitic stainless-steel weldments. Mater. Charact. 93, 10–23 (2014)

C.M. Garzón, A.J. Ramirez, Growth kinetics of secondary austenite in the welding microstructure of a UNS S32304 duplex stainless steel. Acta Mater. 54, 3321–3331 (2006)

M. Liljas, P. Johansson, H.P. Liu, C.O. Olsson, Development of a lean duplex stainless steel. Mater. Technol. 79, 466–473 (2008)

R.M. Davison, J.D. Redmond, Practical guide to using duplex stainless steels. Mater. Des. 12, 187–192 (1990)

G.R. Mohammed, M. Ishak, S.N. Aqida, H.A. Abdulhadi, Effects of heat input on microstructure, corrosion and mechanical characteristics of welded austenitic and duplex stainless steels: a review. Metals. 7(2), 39 (2017)

R.S. Funderburk, A look at input. Weld. Innov. 16(1), 359 (1999)

S. Gudikandula, A. Sharma, Microstructural behavior and corrosion analysis of lean duplex stainless steel 2101 under the influence of variable heat inputs using gas tungsten arc welding. Iran. J. Mater. Sci. Eng. 19(4), 1–11 (2022)

P.K. Baghel, Effect of SMAW process parameters on similar and dissimilar metal welds: An overview. Heliyon. 8, e12161 (2022)

L. Ma, S. Hu, J. Shen, Microstructure, properties and weldability of duplex stainless steel 2101. J. Mater. Eng. Perform. 26, 250–257 (2017)

J. Verma, R.V. Taiwade, R.K. Khatirkar, A. Kumar, A comparative study on the effect of electrode on microstructure and mechanical properties of dissimilar welds of 2205 austeno-ferritic and 316L austenitic stainless steel. Mater. Trans. 57, 494–500 (2016)

T.R. Dandekar, A. Gupta, A. Kumar, R.K. Khatirkar, B. Vadavadagi, Shielded metal arc welding of UNS S32750 steel: microstructure, mechanical properties and corrosion behaviour. Mater. Res. Express. 5, 106506 (2018)

D.C. Sicupira, R. Cardoso, A.Q. Bracarense, G.S. Frankel, V.D.F.C. Lins, Cyclic polarization study of thick welded joints of lean duplex stainless steel for application in biodiesel industry. Mater. Res. 20, 161–167 (2016)

A. Gupta, A. Kumar, T. Baskaran, S.B. Arya, R.K. Khatirkar, Effect of heat input on microstructure and corrosion behavior of duplex stainless steel shielded metal arc welds. Trans. Indian Inst. Metals. 71, 1595–1606 (2018)

B. Belkessa, D. Miroud, N. Ouali, B. Cheniti, Microstructure and mechanical behavior in dissimilar SAF 2205/API X52 welded pipes. Acta Metal. Sin. 29, 674–682 (2016)

Y. Hu, Y. Li, Y. He, J. Wang, X. Liu, Y. Zhang, P. Han, Effects of micro-sized ferrite and austenite grains on the pitting corrosion behavior of lean duplex stainless steel 2101. Metals. 7, 168 (2017)

L. Li, Z. Du, X. Sheng, M. Zhao, L. Song, B. Han, X. Li, Comparative analysis of GTAW+ SMAW and GTAW welded joints of duplex stainless steel 2205 pipe. Int. J. Press. Vessel. 199, 104748 (2022)

L. Zhang, W. Zhang, Y. Jiang, B. Deng, D. Sun, J. Li, Influence of annealing treatment on the corrosion resistance of lean duplex stainless steel 2101. Electrochem. Acta. 54, 5387–5392 (2009)

M.A. Makhdoom, A. Ahmad, M. Kamran, K. Abid, W. Haider, Microstructural and electrochemical behaviour of 2205 duplex stainless steel weldments. Surf. Interfaces. 9, 189–195 (2017)

N. Ouali, K. Khenfer, B. Belkessa, J. Fajoui, B. Cheniti, B. Idir, S. Branchu, Effect of heat input on microstructure, residual stress, and corrosion resistance of UNS 32101 lean duplex stainless steel weld joints. J. Mater. Eng. Perform. 28, 4252–4264 (2019)

Y. Hu, Y. Shi, K. Wang, J. Huang, Effect of heat input on the microstructure and mechanical properties of local dry underwater welded duplex stainless steel. Materials. 16(6), 2289 (2023)

ASTM E3-95, Standard Practice for Preparation of Metallographic Specimens (1995). Accessed 10 Mar 2021

G.F. Vander Voort, S.R. Lampman, B.R. Sanders, G.J. Anton, C. Polkowski, J. Kinson, K. Muldoon, S.D. Henry, Scott, Jr., ASM Handbook. Metallography and Microstructures, vol. 9, 44073-0002 (2004)

ASTM E562-11, Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count

ASTM E9, Standard Test Methods for Tension Testing of Metallic Materials. Annual book of ASTM Standards (2001). Accessed 10 Jan 2022

ASTM E23, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials (2007). Accessed 22 Jun 2021

ISO E, Destructive Tests on Welds in Metallic Materials–Impact Tests (2012). Accessed 13 Oct 2021

ASTM E92, Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials (2017). Accessed 15 Apr 2022

ASTM A G171, Standard Test Method for Scratch Hardness of Materials Using a Diamond Stylus (2009). Accessed 20 Jan 2021

Y.T. Shin, H.S. Shin, H.W. Lee, Effects of heat input on pitting corrosion in super duplex stainless steel weld metals. Metals Mater. Int. 18, 1037–1040 (2012)

L.L. Bao, Y. Wang, T. Han, Microstructure and properties of lean duplex stainless steel UNS s32101 welded joint by hot wire tig welding. Mater. Sci. Forum. 993, 466–473 (2020)

S. Wang, Q. Ma, Y. Li, Characterization of microstructure, mechanical properties and corrosion resistance of dissimilar welded joint between 2205 duplex stainless steel and 16MnR. Mater. Des. 32, 831–837 (2011)

V. Muthupandi, P.B. Srinivasan, S.K. Seshadri, S. Sundaresan, Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless-steel welds. Mater. Sci. Eng. 358, 9–16 (2003)

E.M. Westin, C.O. Olsson, S. Hertzman, Weld oxide formation on lean duplex stainless steel. Corros. Sci. 50, 2620–2634 (2008)

Z. Brytan, J. Niagaj, Microstructural characterization of lean duplex stainless steel UNS S32101 welded joints using electron backscatter diffraction. Chiang Mai J. Sci. 40(5), 923–937 (2013)

M.A. Elsaady, W. Khalifa, M.A. Nabil, I.S. El-Mahallawi, Effect of prolonged temperature exposure on pitting corrosion of duplex stainless steel weld joints. Ain Shams Eng. 9, 1407–1415 (2018)

S. Wen, C.D. Lundin, G. Batten, Metallurgical evaluation of cast duplex stainless steels and their weldments (2000)

P. Sathiya, S. Aravindan, R. Soundararajan, A. NoorulHaq, Effect of shielding gases on mechanical and metallurgical properties of duplex stainless-steel welds. J. Mater. Sci. 44, 114–121 (2009)

A.J. Ramirez, J.C. Lippold, S.D. Brandi, The relationship between chromium nitride and secondary austenite precipitation in duplex stainless steels. Metall. Mater. Trans. 34, 1575–1597 (2003)

R. Mohammed, G.M. Reddy, K.S. Rao, Effect of welding process on microstructure, mechanical and pitting corrosion behaviour of 2205 duplex stainless steel welds, in IOP Conference Series: Materials. Science and Engineering, vol. 330, p. 012026 (2018)

C.Y. Ma, L. Zhou, R.X. Zhang, D.G. Li, F.Y. Shu, X.G. Song, Y.Q. Zhao, Enhancement in mechanical properties and corrosion resistance of 2507 duplex stainless steel via friction stir processing. J. Mater. Res. Technol. 9, 8296–8305 (2020)

R. Mohammed, G.M. Reddy, K.S. Rao, Microstructure and pitting corrosion of shielded metal arc welded high nitrogen stainless steel. Def. Technol. 11, 237–243 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gudikandula, S., Sharma, A. Study of Heat Input Effects on the Microstructure of Lean Duplex 2101 Shielded Metal Arc Weld and Its Effect on Mechanical Properties, Corrosion, and Scratch Behavior. Metallogr. Microstruct. Anal. 12, 834–848 (2023). https://doi.org/10.1007/s13632-023-01001-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-01001-w