Abstract

Pomegranate (Punica granatum), an ancient and well-recognized fruit, is highly valued in traditional medicine and the food industry for its rich composition of phytochemicals. This research investigated the effect of freeze-drying (FD) and oven-drying (OD) on the aroma profile and antibacterial activity of pomegranate seed essential oils (EOs). The aromatic compounds were evaluated using four different extraction techniques—hydrodistillation (HD), supercritical fluid extraction (SFE), headspace solid-phase microextraction (HS-SPME), and simultaneous hydrodistillation extraction (SHDE) for comparison. Antibacterial activity of the EO was tested in 7 microorganisms, including 3 Gram-positive (Enterococcus faecalis, Staphylococcus aureus, Bacillus cereus), 3 Gram-negative (Escherichia coli, Pseudomonas aeruginosa, Klebsiella pneumoniae), and yeast (Candida albicans). A total 93 compounds (FD) and 55 compounds (OD) were identified, belonging to groups such as carbonyls, fatty acids, esters, furans, alcohols, lactones, and other unspecified categories. Furthermore, there were no significant differences in the antimicrobial properties of the EOs between the two drying methods. E. coli exhibited the highest resistance to the tested EOs as its growth remained uninhibited. K. pneumoniae and P. aeruginosa demonstrated resistance, with no inhibitory effects observed except at the highest concentrations tested (4550 µg∙g−1 and 4580 µg∙g−1). Among the Gram-positive bacteria, S. aureus was inhibited at 4550 µg∙g−1 and 4580 µg∙g−1, B. cereus at 4550 µg∙g−1 and 2425–4580 µg∙g−1, and E. faecalis at 2275 µg∙g−1 and 2425–4850 µg∙g−1, while C. albicans was the most susceptible (1138 µg∙g−1 and 1213 µg∙g−1). SFE proved effective in extracting fatty acids, particularly saturated fatty acids (SFAs), while HD and SHDE were most effective in extracting carbonyl compounds.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

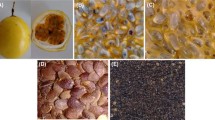

The pomegranate (Punica granatum) belongs to the Punicaceae family and is a fruit-bearing deciduous shrub. It originated from the Middle East and has spread worldwide due to its genetic adaptability, with India, China, and Iran being its major producers [1]. The species name, P. granatum, is derived from its high punicic acid content, which makes up 95% of its composition [1]. The shrub reaches heights between 3 and 6 m, features oblong leaves with a vibrant green color, and bears fruits that resemble berries with a bright red hue, composed mainly of arils and peel. The arils containing seeds are juicy and offer a unique sweet and sour flavor, and their juice is widely consumed [2]. Pomegranates are extensively used in pharmacology due to their diverse biochemical makeup, including alkaloids, anthocyanins, ellagotannins, flavonoids, and tannins, which contribute significantly to human health. However, the chemical profile of pomegranates can vary depending on the cultivation area, variety, maturity, and storage conditions [1].

Fatty acids, particularly polyunsaturated fatty acids (PUFA) such as linolenic, linoleic, arachidonic, and punicic acid, constitute a crucial component of pomegranate seed oil [1]. The oil has shown promise in combating cancers related to the reproductive system and inhibiting breast cancer cell proliferation. Additionally, they possess anti-inflammatory, antidiabetic, and antimicrobial properties [1]. PUFAs also play a preventative role in cardiovascular diseases. Punicic acid, the primary constituent of seed oil, is also found in trace amounts in the juice. Several preclinical studies [3,4,5,6,7] have focused on the beneficial effects of punicic acid, albeit without specifying the variety of pomegranates [1].

After the juice is extracted from pomegranate arils, the remaining seeds, typically discarded, can be processed to extract these beneficial oils [8]. This process mitigates waste and harnesses the potential applications of pomegranate seed oil in the pharmaceutical, cosmetic, and food industries [1]. However, like other seeds, pomegranate seed oil’s composition and functional properties can be influenced by the drying methods and extraction techniques employed. For instance, significant variations in chemical composition have been reported in essential oils from aniseed seeds that were dried in the oven or under the sun and then extracted via hydrodistillation, particularly affecting the levels of terpene compounds such as trans-anethole and estragole [9].

Different results were obtained when comparing the aromatic profile of the compounds present using hydrodistillation of freeze-dried and oven-dried grape skins and subsequent chromatographic analysis. Terpene compounds and alcohols formed a significant proportion in both extracts, but their proportion decreased in the oven-dried samples [10]. Oliver-Simancas et al. [11] compared volatile compounds from mango peels dehydrated at varying temperatures and freeze-dried and reported that both treatment methods increased the concentration of specific compounds.

Although extensive research has been conducted on pomegranates and their processing, the specific impact of seed drying methods on the volatile compound profile remains unexplored. Mphahlele et al. [12] examined the effects of oven and freeze-drying on the phenolic, tannin, and flavonoid contents in various pomegranate fruit parts. Similarly, John et al. [13] studied the chemical profile of methanol extracts from lyophilized pomegranate samples, focusing on ellagitannins. Al-Rawahi et al. [14] investigated the influence of four drying techniques, including freeze, air, vacuum, and sun drying, on the phenolic content of ethanol and methanol extracts of pomegranate peels. These studies suggest that lyophilization may be suitable for processing pomegranate seeds to preserve volatile compounds.

This study investigated different extraction methods for pomegranate seeds to elucidate the volatile profiles of the resultant extracts. Traditional distillation-based methods, commonly used for obtaining essential oils (EOs), are often time-consuming, produce low yields, and may degrade thermolabile components. Alternative techniques such as supercritical fluid extraction (SFE) and headspace solid-phase microextraction (HS-SPME) have been explored to address these challenges. They have also been explored for their potential to enhance efficiency and preserve sensitive compounds.

The primary objective of this research was to evaluate the impact of seed drying and essential oil extraction methods on the chemical composition of pomegranate seeds, with a particular focus on their bioactive compounds and antimicrobial properties. This study also aimed to assess the feasibility of utilizing pomegranate seed oil as a natural preservative in the food industry.

2 Materials and methods

2.1 Chemicals and material

A homologous series of standard n-alkanes (C8-C40) solubilized in n-hexane at 40 mg∙l−1 and n-hexane was procured from Sigma-Aldrich (Prague, Czech Republic). Helium 5.0 and carbon dioxide 4.5 were sourced from Linde Gas a.s. (Prague, Czech Republic). SPME fibers 85 μm CAR/PDMS (carboxen/polydimethylsiloxane), 50/30 µm DVB/CAR/PDMS (divinylbenzene/carboxen/polydimethylsiloxane), 65 μm PDMS/DVB (polydimethylsiloxane/divinylbenzene), 85 μm PA (polyacrylate), and 100 μm PDMS (polydimethylsiloxane) were purchased from Sigma-Aldrich (Prague, Czech Republic).

Mueller-Hinton agar and Mueller-Hinton broth were purchased from HiMedia Laboratories (Mumbai, Maharashtra, India). Nunclon 96-well microtiter plates were supplied by Thermo Scientific (Roskilde, Denmark).

2.2 Plant material and processing

Pomegranates (cv. Acco) were harvested at commercial maturity (13.37–14.53° Brix) in April 2021 from a commercial farm in Wellington, South Africa. The arils were manually juiced using a cheesecloth, ensuring the seeds remained undamaged. The pomegranate seeds (PS) were then isolated and rinsed with distilled water to remove membrane residues. Subsequently, the seeds were divided into two groups for drying. For freeze-drying, seeds were freeze-dried using a BUCHI Lyovapor freeze-dryer L-200 (Postfach, CH-9230, Flawil, Switzerland) at − 55 °C and 0.03 mbar for 72 h. Oven-drying was carried out using a cabinet oven (Labotec, South Africa) at 40 °C until the seeds reached a final moisture content of 8–12% w/w. The dried seeds were stored in airtight conditions at − 80 °C for subsequent analysis.

2.3 Essential oil extraction methods

2.3.1 Hydrodistillation (HD)

The extraction of EO was performed using a Clevenger apparatus. Approximately 200 g of dried pomegranate seeds was placed into a 2000 mL distillation flask, followed by the addition of 900 mL of distilled water. The distillation was considered complete once a steady yield of EO was observed. Due to the low yield, the HD process was repeated multiple times with new sample batches, and the EO from each batch was combined. After distillation, the EO was carefully separated from the aqueous phase using a syringe, weighed, and subsequently analyzed using gas chromatography-mass spectrometry (GC-MS) and gas chromatography-flame ionization detection (GC-FID). The EO yield was calculated as the percentage of oil relative to the total sample weight.

2.3.2 Simultaneous hydrodistillation extraction (SHDE)

During the distillation process, lipophilic components from the plant material are extracted as essential oil. However, hydrophilic components remain in the distilled water, creating a byproduct known as hydrolate. The SHDE was conducted using a Clevenger apparatus, with 1 mL of n-hexane added as a trapping solvent to the separator. The extraction proceeded by adding 100 g of pomegranate seeds with 900 mL of distilled water in a 2000 mL distillation flask. The distillation process lasted for 4 h, followed by separating the n-hexane extract from the water phase and subsequently analyzing it using GC-MS and GC-FID.

2.3.3 Supercritical fluid extraction (SFE)

The SFE process was conducted using a Spe-ed SFE Helix extractor (Applied Separations, Allentown, PA, USA), with carbon dioxide as the extraction medium. The extraction was performed in static and dynamic modes without adding any modifiers. The specific extraction conditions are summarized in Table 1. For the extraction, 30 g of pomegranate seeds was loaded into the extraction cartridge, which was then sealed and placed inside the Spe-ed SFE Helix extractor. The extract was collected using 2 mL of n-hexane as a trapping solvent. The static mode extraction yielded three fractions, each obtained under distinct conditions, while the dynamic mode extraction produced a single extract.

2.3.4 Headspace solid-phase microextraction (HS-SPME)

HS-SPME primarily depends on selecting a suitable fiber with an appropriate sorbent type. This study evaluated five different extraction fibers (see Section 3.2), and a 65 μm polydimethylsiloxane/divinylbenzene (PDMS/DVB) fiber was chosen for method optimization. The optimization process employed the Central Composite Design (CCD) method for structuring the experiment and Response Surface Methodology (RSM) for data analysis using STATISTICA software (StatSoft CR, Prague, Czech Republic). The extraction of volatile compounds from the pomegranate seed samples was performed with optimized parameters. A 500 mg sample was placed in a 20 mL headspace vial, sealed with a screw cap fitted with a Teflon septum, and agitated at a set temperature of 84 °C for 20 min. The HS-SPME utilized a 65 μm PDMS/DVB fiber for 60 min. After extraction, the compounds were desorbed at 230 °C for 15 s in the gas chromatography injection port. The analysis was then carried out using GC-MS and GC-FID.

2.4 Chromatographic analysis

2.4.1 Gas chromatography-mass spectrometry

Sample analysis was performed using a GC 2010 gas chromatograph equipped with a QP 2010 Plus mass spectrometer (both from Shimadzu, Kyoto, Japan) with a Combi Pal autosampler (CTC Analytics, AC, Zwingen, Switzerland). The complex mixture was separated on a SLB-5MS capillary column (30 m × 0.25 mm × 0.25 μm) from Supelco (Bellefonte, PA, USA). The carrier gas used was helium (Linde Gas a.s., Prague, Czech Republic) maintained at a constant linear velocity of 30 cm∙s−1. The sample was injected in a 1:10 split ratio. A temperature gradient was established for optimal separation of volatile compounds. The solvent cut time was set to 6 min from sample injection, resulting in ion detection starting at 6.5 min. The initial temperature was set at 40 °C and then gradually increased to 250 °C at 3 °C/min. The temperature of the injection port and interface was maintained at 200 °C. The total analysis time was 70 min. Ionization of the unknown compounds was achieved by electron ionization with an ionization energy of 70 eV. A simple quadrupole was used to separate the ions on the basis of the m/z ratio. The spectra were recorded in full SCAN mode, allowing detection of all ions in the 40–450 m/z range.

2.4.2 Gas chromatography-flame ionization detector

A 2010 gas chromatograph equipped with a flame ionization detector (Shimadzu, Kyoto, Japan) and a Combi Pal autosampler (CTC Analytics, AC, Zwingen, Switzerland) were utilized for the semiquantitative analysis. The detector temperature was maintained at 220 °C. The analysis was conducted using the same temperature program, column, dosed volume, and split ratio.

Retention indices were experimentally determined using a homologous series of n-alkanes that dissolved in n-hexane. The mass spectrum obtained was compared with the reference mass spectrum from the National Institute of Standards and Technology’s Mass Spectral Library (NIST´14 Mass Spectral Library) and the Flavour & Fragrance Natural & Synthetic Compounds (FFNSC) to identify unknown substances. Based on the homologous series of n-alkanes, GC-FID facilitated the calculation of retention indices, according to Van den Dool and Kratz. Upon comparison of the calculated retention indices from GC-MS and GC-FID, peak areas were assigned to the identified compounds. Subsequently, their relative abundance was expressed as a percentage of the total area of all peaks in the chromatogram.

2.5 Antimicrobial activity

The antibacterial susceptibility and resistance of 3 Gram-negative strains Escherichia coli (Czech Collection of Microorganisms, CCM 2024), Pseudomonas aeruginosa (CCM 1961), and Klebsiella pneumoniae (Culture Collection Department of Biological and Biochemical Sciences, University of Pardubice) and 3 Gram-positive strains Bacillus cereus (CCM 2010), Enterococcus faecalis (CCM 4224), and Staphylococcus aureus (CCM 4223), along with the yeast culture Candida albicans (CCM 8215), were tested against the essential oils obtained by hydrodistillation.

Multiplication of microorganisms was performed on Mueller-Hinton agar (MHA) plates. The inoculated plates were incubated at 37 °C for 24 h. Post-incubation, bacterial suspensions were prepared in saline from 24-h bacterial cultures. These suspensions corresponded to a turbidity of 0.5 on the McFarland turbidity scale (equivalent to a concentration of 1.5 × 108 CFU∙mL−1). Similarly, a yeast suspension was prepared, corresponding to grade 2 of the McFarland turbidity scale (equivalent to a concentration of 6.0 × 108 CFU∙mL−1).

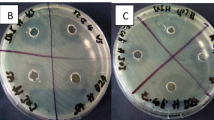

2.5.1 Broth microdilution volatilization method

The antimicrobial activity of essential oils was assessed using the broth microdilution volatilization method, according to Houdkova et al. [15], with minor modifications. The method was performed in a 96-well microtiter plate. EO stock solutions in n-hexane were prepared at 9700 µg/mL for freeze-dried seed EOs and 9100 µg/mL for oven-dried seed EOs. For liquid phase testing, 100 µL of Mueller-Hinton Broth (MHB) was added to each well. Serial dilutions of EO stock solutions were prepared, starting with 100 µL of EO in the first test well and diluting twofold across the plate, resulting in concentrations ranging from 4850 to 37.89 µg/mL for freeze-dried EOs and 4550 to 35.55 µg/mL for oven-dried EOs. A 5 µL bacterial suspension was added to all test wells. For vapor phase testing, 30 µL of Mueller-Hinton agar (MHA) was placed onto each microtiter plate lid cap and allowed to solidify. Then, 5 µL of bacterial suspension was inoculated onto the solidified agar. The plate was sealed and incubated at 37 °C for 24 h. After incubation, antibacterial activity was evaluated by inoculating each well onto MHA using a sterile plastic loop. The inoculated Petri dishes were incubated at 37 °C for 24 h, after which the effects of the different EOs were assessed. The effect of n-hexane alone was also tested as a solvent control at concentrations ranging from 0.39 to 50% in MHB.

3 Results and discussion

3.1 Extraction yield

The extraction process yielded 0.02% from freeze-dried seeds and 0.05% from oven-dried seeds, which was lower than the yields reported in other studies, where HD yielded 0.21% and SFE yielded 1.18% [16]. This discrepancy may be due to variations in the seed type and differences in sample drying conditions. Both static and dynamic modes were employed to assess the efficacy of different SFE modes. The extracts varied from thick yellow to slightly orange and were dissolved in 2 mL of n-hexane and analyzed using GC-MS. Despite the analyses, it was difficult to determine which mode was more effective, as each produced distinct results. Further research is necessary to make a definitive comparison between the static and dynamic modes of SFE.

3.2 Optimization of HS-SPME

Five distinct fibers were evaluated under different conditions for 30 min. The conditions and outcomes of the HS-SPME are summarized in Table 2. The performance evaluation indicated that the 65 μm PDMS/DVB fiber was the most effective for extraction. The performance ranked as 65 μm PDMS/DVB > 50/30 µm DVB/CAR/PDMS > 85 μm CAR/PDMS > 85 μm PA > 100 μm PDMS. The selection of the 65 μm PDMS/DVB fiber was based on its ability to extract the highest number of substances, making it the optimal choice for HS-SPME in this study.

Twelve sequential randomized experiments were conducted using PDMS-DVB fiber to optimize HS-SPME. The primary variables assessed were temperature and extraction time, which significantly influence the extraction efficiency, measured by the number of peaks (NoP) in the chromatograms. The experiments evaluated temperatures ranging from 50 to 110 °C and extraction times from 10 to 90 min. The design and results of the HS-SPME optimization experiment at constant temperatures are shown in Table 3. The optimal conditions were determined based on the NoP observed. The studies established that the optimal extraction temperature was 84 °C. Figure 1 illustrates that the NoP in the chromatograms increased with extended extraction times. However, an extraction time of 60 min was deemed sufficient for successful extraction. The efficacy of the model in replicating the observed data, or its reliability, is quantified by the R-squared (R²) value. This statistical measure represents the proportion of variance in the dependent variable that can be predicted from the independent variable(s). It indicates the goodness of fit of the model and the extent to which the model explains the variability of the response. For the PDMS/DVB fiber, the R² value was calculated to be 0.96576, with a residual error (r.e.) of 0.93722, indicating a high level of reliability in predicting the NoP.

Equation (1) was employed to compute the total NoP. In this equation, X and Y are the independent variables. Specifically, X denotes the extraction time (min), while Y signifies the extraction temperature (°C). This mathematical representation provides a quantitative framework for understanding the relationship between extraction time, temperature, and the resulting NoP.

3.3 Qualitative analysis

A total of 55 volatile compounds were identified in the EO of oven-dried pomegranate seed extracts. These compounds included 22 carbonyl compounds, 8 esters, 4 lactones, 11 acids, 4 alcohols, 2 furans, and 4 other compounds. In extracts obtained from freeze-dried seeds, 93 compounds were identified in all extraction techniques. These included 20 acids, 7 alcohols, 27 carbonyl compounds, 3 aliphatic hydrocarbons, 3 furans, 18 esters, 5 lactones, and 10 other volatile compounds. These are also listed in Table 4.

A Venn diagram in Fig. 2 delineates the common and specific compounds for each extraction technique. This diagram was generated using a Web-based Bioinformatics & Evolutionary System (URL http://bioinformatics.psb.ugent.be/webtools/Venn/), visually representing the overlap and differences in compound extraction across techniques.

In total, 29 compounds were identified in the S1 extract. In the S2 and S3 extracts, 15 and 26 volatiles were successfully identified, respectively. For the S4 and S5 extracts, 15 and 17 volatile components were detected, respectively. According to the Venn diagram, 11, 2, 8, 1, and 3 compounds were specific to S1, S2, S3, S4, and S5, respectively. Among the five extracts, only two volatiles, specifically (E, E)-2,4-nonadienal and valeric acid, were commonly identified.

A comparative analysis between FD and OD seeds indicated a higher count of substances in FD seeds. In the S1 extract obtained through HD, 28 compounds were identified. The S2 and S3 extracts identified 51 and 45 volatile compounds, respectively. The S4 extract revealed 30 unidentified compounds, while the S5 extract revealed 54 compounds. A second Venn diagram indicated that 2, 10, 7, 3, and 14 volatiles were specific to the S1, S2, S3, S4, and S5 fractions. The common presence of furfural, caproaldehyde, E-2-nonenal, (E,E)-2,4-nonadienal, and E-2-decenal was observed in all fractions from S1 to S5. Moreover, the S2, S3, and S5 extracts contained more characteristic substances, predominantly in the fatty acid group.

3.4 Semiquantitative analysis

The results of the chromatographic analysis of EO from OD pomegranate seeds and the extracts obtained from techniques S1, S2, S3, S4, and S5 are presented in Table 4. These diverse extraction methods facilitate the extraction of a broad spectrum of unknown substances, each with varying relative abundances. Among all techniques, S3 was the most effective, enabling the identification of substances with the highest total relative abundance of 71.99%. Conversely, S4 was the least efficient, yielding substance with a total relative abundance of 69.81%. The relative abundances for S5 and S2 were 46.07% and 63.11%, respectively. The lower relative abundance in S1 could be attributed to potential component decomposition due to high temperatures [17].

In the OD pomegranate seed extracts, the group of fatty acids exhibited the highest relative abundance, ranging from 58.90 to 64.92%. The composition and type of fatty acids are crucial quality parameters for oil utilization in the food and pharmaceutical industries. It should be noted that heat treatment of seeds may modify the fatty acid composition, particularly affecting the stability of polyunsaturated fatty acids [17].

In the extracted sample from FD seeds, volatile components constituted 37.50–49.86% of the total relative abundance. Generally, the volatile components included in the S1–S5 fractions did not exceed 50% of the total relative abundance. Techniques S1 and S4 were less effective for extracting the fatty acid group, with total relative abundances in S2, S3, and S5 ranging from 7.04 to 37.71%.

The primary components of the fatty acid group were caproic acid, heptanoic acid, and capric acid. In this context, techniques S1 and S5 were most effective for extracting carbonyl compounds, with relative abundances ranging from 23.22 to 40.35%.

Our experiment primarily focuses on the content of fatty acids. It is noteworthy that lipids tend to decompose into acids at elevated temperatures, leading to the formation of hydroperoxides. These hydroperoxides are further transformed into carbonyl compounds, esters, furans, and alcohols [18]. This observation may align with the outcomes from technique S1, where the carbonyl compound group was predominantly represented. The primary constituents of this group included hexanol, hepta-(2E)-enal, octanol, 2-octanol(2E), nonanal, nona(2E,4E)-dienal, 2-undecenal, E, and undec-(8Z)-enal. Gao et al. [18] investigated the chemical composition of pomegranate seed extracts, with a primary emphasis on fatty acids and their potential degradation pathways. Linolenic acid, for instance, can degrade into (E)-2-hexenal, butyraldehyde, octanal, nonanal, hexanal, and hexanol. Oleic acid can break down into octanal, nonanal, pentanal, and pentanol. Linoleic acid, another significant seed component, can convert into pentanal, pentanol, benzaldehyde, and 2-butylfuran. Stearic acid, the last significantly represented component, degrades into 2-butylfuran. In our experiment, all these components, except for butyraldehyde, were identified.

The aroma profile comparison of the EO and OD pomegranate seed extracts is depicted in Fig. 3. Each bubble in the graph represents volatile elements, with the bubble size corresponding to relative abundance. The graph illustrates that the S1–S5 fractions enabled the extraction of compounds with an RI ranging from 800 to 2180, representing a broad spectrum of substances whose nature varies depending on the extraction technique employed. Volatiles with a lower RI were not identified due to the solvent cut for n-hexane (RI 600).

In the S1 and S5 fractions, carbonyl compounds with an RI less than 1360 were significantly represented. From a relative representation perspective, the furan group, with an RI between 887 and 992, was also notably present. Similar to S1 and S5, S4 facilitated the extraction of substances with an RI of less than 1365. However, it was not effective for the extraction of carbonyls. The main component in S4 was SFA, specifically valeric acid, which accounted for more than half of the total relative abundance of all identified substances. The S2 and S3 fractions enabled the extraction of volatile components with an RI greater than 1365 (Fig. 3).

SFE is particularly adept at extracting nonpolar substances, which could explain why our SFE extracts are enriched with this group. However, the primary component was valeric acid, with a low RI of 800. Additionally, SFE facilitated the extraction of further fatty acids with an RI ranging from 1969 to 2161.

Similarly, a graph was constructed to compare the aroma profile of EO and lyophilized pomegranate seed extracts. Upon initial observation, it is clear that the lyophilized seeds provided a more suitable matrix regarding the number of substances extracted (Fig. 4), with an RI ranging from 800 to 2492. The main components in the S1 and S5 fractions were again carbonyls, with an RI between 800 and 1484. In the S4 fraction, in addition to carbonyl components with an RI less than 1363, a monoterpene group was also represented, primarily limonene (RI 1027). Generally, it can be inferred that S1, S4, and S5 were more effective for extracting substances with a lower RI than the S2 and S3 fractions.

The S2 and S3 fractions facilitated the extraction of substances with an RI less than 2492. In S3, the ester group (RI 809–2388), primarily ethyl palmitate (RI 1988), constituted the majority of the total relative abundance. Furthermore, stearic acid (RI 2169) was not identified in any other fraction and was detected in the S2 and S3 fractions.

The chemical composition of pomegranate is primarily composed of alcohols, specifically hexanol, 2-ethylhexanol, and (Z)-3-hexenol. This is followed by carbonyl compounds, which include hexanal, (E)-2-hexenal, heptanal, octanal, nonanal, (Z)-3-hexenal, and 6-methyl-5-hepten-2-one. Additionally, terpene compounds such as α-, β-pinene, p-cymene, α-, γ-terpinene, limonene, α-terpineol, α-bergamotene, β-caryophyllene, and β-bisabolene are also present. The aforementioned list of substances is derived from analyzing several pomegranate varieties. However, these were not compared with the globally renowned “Wonderful” variety [19]. Numerous studies have been conducted to investigate the chemical composition of different parts of the pomegranate.

The composition of the SFE pomegranate seed extract exhibited variations compared to the findings by Durdevic et al. [20]. The sample from Bosnia and Herzegovina underwent a process where impurities were initially separated from the seeds. The seeds were subsequently dried and extracted. Fatty acids were analyzed as methyl esters using GC-MS and GC-FID analysis. According to the authors, the extracts were enriched with fatty acids in the following order: saturated fatty acids (SFA) < monounsaturated fatty acids (MUFA) < polyunsaturated fatty acids (PUFA). In contrast, the order was reversed in our study, and PUFAs were not quantified. SFAs, primarily valeric and caproic acid, constituted the largest proportion of the total relative abundance, ranging from 34.88 to 45.10% for valeric acid and 0.08–12.42% for caproic acid.

From the MUFA category, palmitolinoleic, oleic, and cis-vaccenic acids were quantified, with relative abundances ranging from 0.53 to 3.69%. In their study, Durdevic et al. [20] determined MUFAs with relative abundances ranging from 0.44 to 6.51%. Ara et al. [16] isolated the volatiles and EO of Iranian pomegranate peel using HD and SFE, identifying 46 and 73 substances in the respective extracts, a count that exceeds our results. SFE appears to be more selective, facilitating the determination of a larger proportion of substances with higher molecular weights (i.e., higher RI) and mitigating the risk of thermal degradation.

The main components of EO were borneol (12.97%), palmitic acid (9.86%), oleic acid (11.64%), and butylbenzene (4.88%). These represent significant differences in chemical composition compared to our work. In contrast, our work predominantly identified carbonyl compounds such as hexanal, (E)-2-heptenal, and (E, E)-2,4-nonadienal. Limonene was the only monoterpene determined, with a lower representation (0.58%) than the study by Ara et al. [16]. SFE extracts were characterized by fatty acids, predominantly oleic, stearic, and palmitic acids. Reidel et al. [21] employed an HS-SPME, coupled with a GC-MS system, to isolate volatile components from various pomegranate sections. Samples were procured from a wild plant located in Pisa. The most prevalent class in the extracts derived from the leaves and flower parts of P. granatum was sesquiterpenes. The stem extracts also reflected this composition, where α-humulene constituted a significant proportion. Aldehydes and esters were the most represented compounds in the arils. In contrast to our findings, the study by Reidel et al. [21] identified a markedly higher number of volatile compounds, specifically 115, with an overall relative abundance ranging from 87.70 to 99.40%. In our study, the extracts represented 37.50–69.81% of the total relative abundance, with valeric acid accounting for over 50% of the total relative abundance in the OD HS-SPME extract [21]. The primary constituent of the HS-SPME extract was the monoterpene limonene, whereas the content quantified by Reidel et al. [21] was lower (1.10–10.50%). Conversely, in our experiment, decanal and nonanal (20.30% and 17.20%) constituted the highest proportion of non-terpenic compounds in dried seed extracts. Octanal and (E,E)-2,4-nonadienal were predominant in our work. The aroma profile of the pomegranate juice extracts was examined by Calin-Sánchez et al. [22]. Extracts obtained from 3 varieties (sweet, sour, and sweet-sour) originating from Spain were isolated using HD. Among the 18 compounds determined, (2E)-2-hexanal, 3-carene, α-terpinene, and α-terpineol constituted the highest proportion. These substances contribute to the characteristic aroma of citrus and vegetables. Similarly, Calín-Sánchez et al. [22] reported that pomegranate juice does not possess an intense odor due to the low concentrations of volatile components. The food industry is intensifying its efforts to eliminate undesirable alcohols and aldehydes, including hexanol, hexanal, and (2E)-hexenol, which were identified in our EOs except for (2E)-hexenol [22]. Yi et al. [23] isolated the volatile components of pomegranate juice and juice along with seeds using headspace solid-phase microextraction (HS-SPME), simultaneous hydrodistillation-extraction (SHDE), and purge & trap. Our study identified a larger number of compounds exclusively in the SHDE extract of freeze-dried (FD) seeds.

The primary compounds were palmitic acid, myristic acid, caproic acid, and linoleic acid. Our experimental results indicated that SFAs, specifically valeric, caprylic, and pelargonic acids, were the predominant constituents. This chemical composition mirrors Asparagus racemosus, Bergenia ciliale, Terminalia chebula [24]. The extracts obtained through the HS-SPME method predominantly comprise aldehydes, alcohols, and the ester group. In contrast, our study found that aldehydes were the major constituents, with alcohols only being semiquantified in SHDE extracts at concentrations ranging from 0.12 to 0.22%. The purge & trap method demonstrated superior efficiency regarding the diversity of extracted compounds. Terpene compounds, known for their pleasant fruity aroma, were found in higher concentrations in the juice based on the data obtained [23]. Numerous comparative studies have examined the chemical composition of extracts from different parts of various pomegranate varieties. For instance, out of 60 substances, seven volatile compounds were identified as key constituents in the seeds. These include alcohols (specifically 1-hexanol, (Z)-3-hexen-ol), terpene compounds (β-myrcene, E-caryophyllene), and aldehydes ((E)-2-hexen-1-al, 3-methylbutanal) across five different varieties in Turkey. The HS-SME GC-MS system was employed to isolate these volatile compounds. 1-Hexanol (49–64%) and β-myrcene (5–15%) were identified as the primary components, likely contributing to the lower relative abundance of other components. However, these compounds were not detected in our samples. The chemical composition of the sour varieties is primarily made up of carbonyl compounds ((E)-2-hexen-1-al and 2,4-hexadienal). However, these compounds constituted less than 1% of our work using four extraction techniques [25]. Beaulieu et al. [19] focused on varieties originating in California. Using the HS-SPME GC-MS methods, they identified 38 compounds common to all tested varieties. They also noted that industrial production processes result in a loss of volatile compounds, leading to commercially produced juice having a much less intense aroma than fresh juice. The findings align with those of Güler and Gül [25], where 1-hexanol, hexanal, limonene, and (Z)-, (E)-3-hexenol were identified, collectively constituting over 50% of the total relative abundance of all detected compounds [19]. A comprehensive HS-SPME GC-MS analysis of Spanish variety juice extracts was performed by Andreu-Sevilla et al. [26]. The aroma profile primarily comprised the monoterpene limonene, comprising 55–63% of the total. In comparison to the studies by Beaulieu et al. [19] and Güler and Gül [25], as well as our samples, 1-hexanol was either a minor component or not detected [19, 25, 26].

Each extraction technique allows the extraction of distinct compounds with a significantly different relative abundance. The disparities in relative abundance are likely attributable to the variations in extraction techniques and their respective conditions. Based on the available data, it can be concluded that the extraction efficiency is influenced by many factors. Specifically, the quality of the plant matrix, its provenance, the method of harvesting, purity, and storage conditions may be among the primary determinants. The results [16, 20,21,22,23, 25, 26] indicate differences that are likely also associated with the occasion of the sample, the part extracted, and the treatment before extraction. In the extracts from oven-dried seeds, valeric acid accounted for a significant portion of the total relative abundance, although it was not identified in any of the cited publications. Based on the available data, it can be concluded that the juice is characterized by the presence of terpene compounds. Of those identified in our samples, only o-cymene and limonene were detected. However, the relative content of pulegone was further quantified (approximately 3%), which was not identified in the cited works. The sensory profile of processed and fresh fruits is strongly influenced by a complex mixture of bioactive compounds, including carbonyl compounds, esters, terpenes, and alcohol. Their concentration depends on climatic conditions, ripeness, variety, and other technological aspects. During ripening, the color, texture, and aroma of pomegranates undergo various changes. Alcohols and carbonyl compounds primarily originate from fatty acids found in the inner membrane of the plant, which aligns with our findings, as the seeds are predominantly rich in the fatty acid group [22].

In conclusion, determining the optimal extraction technique is challenging, as each method yielded distinct chemical compositions with varying relative abundances. Supercritical fluid extraction (SFE) is suitable for extracting nonpolar fatty acids, while hydrodistillation (HD) and simultaneous hydrodistillation-extraction (SHDE) are more effective for isolating low-molecular-weight carbonyl compounds. Meanwhile, headspace solid-phase microextraction (HS-SPME) offers a modern, solvent-free alternative that minimizes sample preparation and can isolate both fatty acids and carbonyl compounds. Unlike previous techniques, HS-SPME is primarily used for qualitative analysis rather than obtaining extracts. The diversity in extraction outcomes suggests the need to select the appropriate method based on the specific target compounds. HS-SPME is particularly noteworthy for its qualitative versatility and minimal preparation requirements.

3.5 Antimicrobial activity

The antimicrobial activity of EOs derived from OD (EO1) and FD (EO2) pomegranate seeds was tested in liquid and vapor phases against 7 microorganisms. These microorganisms included Gram-negative and Gram-positive bacteria, as well as yeast, which are known nosocomial pathogens. These pathogens pose significant threats to immunocompromised individuals, causing respiratory diseases and urinary tract infections [27, 28]. Current knowledge regarding the antimicrobial activity of pomegranate seed EO obtained via HD is limited. The antimicrobial activity of essential oils was assessed using the microdilution volatilization method. The samples were dissolved in n-hexane, demonstrating no inhibitory effect against tested microorganisms. The EOs exhibited antimicrobial activity at varying concentrations. The EO derived from oven-dried seeds did not inhibit the growth of Gram-negative bacteria, specifically E. coli and K. pneumoniae. P. aeruginosa was identified as the next most resistant bacterium, inhibited only at the highest tested concentration in both phases. Among the Gram-positive bacteria tested, S. aureus and B. cereus were inhibited at the highest tested concentration. In contrast, half the concentration was sufficient to inhibit E. faecalis in both phases, indicating its higher sensitivity to the tested EO. The yeast C. albicans was found to be the least resistant. Similarly, the EO derived from freeze-dried seeds exhibited no inhibitory effect on Gram-negative bacteria, except for K. pneumoniae, which was eradicated in the vapor phase at the maximum concentration of the EO. The EO inhibited the growth of all Gram-positive bacteria at the highest concentration, except for B. cereus and E. faecalis, which showed no growth at half the concentration in the broth medium. The inhibitory effects of the tested EOs are summarized in Table 5.

The main difference between essential oils from freeze-dried (FD-EO) and oven-dried (OD-EO) seeds was observed for P. aeruginosa, where OD-EO was effective at the highest concentration tested in both liquid and vapor phases. Conversely, FD-EO demonstrated greater efficacy in the liquid phase against B. cereus; in the vapor phase, FD-EO was more effective against K. pneumoniae and E. faecalis. Overall, no major differences were observed for both oils regarding antimicrobial effects.

The antibacterial activity of EOs is influenced by numerous variables, encompassing the chemical constitution of the EOs, the functional group of bioactive compounds, and their synergistic effect. Plant-derived secondary metabolites frequently comprise aldehydes, which play a key role in the antimicrobial effect. The mechanism of action is conjectured to initiate at the bacterial cell surface [29]. Generally, Gram-positive bacteria exhibit a heightened susceptibility to EOs. The lipopolysaccharide complex of Gram-negative bacteria restricts the penetration of bioactive compounds, adequate to obstruct the transit of antimicrobial components. On the contrary, the lipophilic termini of the lipoteichoic acid in the cellular membrane of Gram-positive bacteria facilitate their penetration [30]. The antimicrobial activity of a group of carbonyl compounds, which constitute the primary component of our EO, was evaluated by Aljaafari et al. [31]. They demonstrated the inhibitory impacts of various EOs containing aldehydes and ketones on the microorganisms tested. Moreover, Bisignano et al. [29] describe the antimicrobial activity of benzaldehyde against L. monocytogenes, S. enteritidis, and L. plantarum. Benzaldehyde, also identified in our oil, can be partially attributed to the observed antimicrobial activity. The mechanism of action leads to the disruption of the bacterial cell membrane. Concurrently, EOs exhibit lipid solubility, thereby enabling the wetting of the phospholipid and polysaccharide layer and facilitating the penetration of antibacterial molecules into the bacterial cell [31]. Furthermore, Bisignano et al. [29] describes that fatty aldehydes, specifically hexanal and nonanal, do not significantly contribute to the antimicrobial activity. Conversely, aldehydes possessing a long hydrocarbon chain and α, β double bond exhibit potent antimicrobial activity [29]. (2E) alkenals could potentially find extensive applications in the future, particularly in the food industry, as they inhibit tyrosinase, thereby preventing the darkening of vegetable beverages and foods [29].

Due to the undesirable side effects of antibiotics, there is a growing demand for herbal formulations as potential replacements for synthetic substances. Herbal formulations are favored for inhibiting and eliminating microorganisms without adversely affecting the human body. Numerous studies have investigated the antimicrobial activity of diverse extracts and various parts of the pomegranate (Table 6). Mahboubi et al. [32] demonstrated that the ability of plants to inhibit the proliferation of pathogenic microorganisms is correlated with the total phenolic compounds and flavonoids present in the extract. The experiment focused on the MBC and MIC of pomegranate flower extracts. A pronounced antimicrobial activity was observed for polar extracts compared to less polar ones (e.g., chloroform fraction), likely due to the phenolic content of the extract. Further analysis would be required to determine whether phenolics also contribute to the enhanced antimicrobial activity in our EO [32].

The antimicrobial activity of the pomegranate peel derived from six cultivars sourced from the primary pomegranate germplasm bank was also reported by Rosas-Burgos et al. [33]. A comparative analysis of the results reveals that the peel extract exhibited a superior antimicrobial effect relative to our experiment. L. monocytogenes and B. subtilis were inhibited by methanolic peel extract. These pathogens pose a significant risk due to their low infectious doses, elevated mortality rates, and frequent prevalence in food. The most resilient was K. pneumoniae, which remained uninhibited by our tested samples [34]. Additionally, Prashanth et al. [35] underscored the varying antimicrobial activities of extracts. The methanolic extract seemed to be more potent, particularly against P. vulgaris, although it was not evaluated in our study [35].

Despite the availability of numerous studies on the mechanism of antibacterial activity of extracts derived from diverse plant matrices, attributing the activity to a specific constituent remains challenging. EOs and extracts constitute a complex amalgamation of bioactive compounds that exhibit a synergistic action against bacteria. Their mechanism of action is predicated on the destruction of organelles, consequent to diffusion across the membrane. This leads to morphological changes and, owing to the disruption of the respiratory chain, results in bacterial death [36].

The aforementioned results [30] substantiate the assertion that Gram-negative bacteria exhibit increased resistance to the tested EOs due to the presence of a lipopolysaccharide complex. In contrast, Gram-positive bacteria were more susceptible to the EOs. The mechanism of action of EOs against microorganisms is not attributed to a singular mechanism but rather to the cumulative effect of a series of reactions. The disruption of the bacterial cell is caused by the hydrophobicity of EOs, which prevents their removal from the cell membrane. This hydrophobicity facilitates the penetration of hydrophobic molecules into bacterial cells, subsequently leading to the degradation of the cell wall and alterations in the cytoplasm [37]. In general, E. coli and K. pneumoniae have demonstrated the greatest resistance to extracts from various pomegranate parts. Among the Gram-positive bacteria, E. faecalis exhibits particular sensitivity to the antimicrobial constituents of the extracts [32,33,34,35]. These observations are congruent with our findings. Previous studies [32, 33] have identified B. cereus and S. aureus as the most sensitive, and in our study, they were inhibited solely at the highest concentration, except for B. cereus, which was inhibited by EO from freeze-dried seeds at half the concentration.

4 Conclusion

This study provides a comprehensive analysis of the chemical composition and antimicrobial activity of essential oils (EOs) derived from oven-dried (OD) and freeze-dried (FD) pomegranate seeds, a byproduct of pomegranate processing. Supercritical fluid extraction (SFE) proved effective in extracting fatty acids (16 compounds), particularly saturated fatty acids (SFAs), though polyunsaturated fatty acids (PUFAs) were not detected. The ability of SFE to extract thermolabile substances without residual solvents makes it suitable for food industry applications. Hydrodistillation (HD) and steam hydrodistillation extraction (SHDE) were most effective in quantifying carbonyl compounds, while headspace solid-phase microextraction (HS-SPME) identified both groups, albeit in lower numbers. The study demonstrates the potential of EOs as natural alternatives to synthetic preservatives. Both OD-EO and FD-EO showed similar inhibitory effects against microorganisms, with notable effectiveness against P. aeruginosa by OD-EO. E. coli was resistant to both EOs, while C. albicans was the most sensitive. These findings suggest that pomegranate seed EOs could be utilized to inhibit undesirable microorganisms, offering a viable natural preservative option for the food industry.

References

Melgarejo-Sánchez P, Núñez-Gómez D, Martínez-Nicolas JJ, Hernández F, Legua P, Melgarejo P (2021) Pomegranate variety and pomegranate plant part, relevance from bioactive point of view: a review. Bioresources Bioprocess 8(1). https://doi.org/10.1186/s40643-020-00351-5

Coronado-Reyes JA, Cortés-Penagos CD, González-Hernández JC (2022) Chemical composition and great applications to the fruit of the pomegranate (Punica granatum): a review. Food Sci Technol 42. https://doi.org/10.1590/fst.29420

Banihani SA, Makahleh SM, El-Akawi Z, Al-Fashtaki RA, Khabour OF, Gharibeh MY et al (2014) Fresh pomegranate juice ameliorates insulin resistance, enhances β-cell function, and decreases fasting serum glucose in type 2 diabetic patients. Nutr Res 34(10):862–867. https://doi.org/10.1016/j.nutres.2014.08.003

Mirmiran P, Fazeli MR, Asghari G, Shafiee A, Azizi F (2010) Effect of pomegranate seed oil on hyperlipidaemic subjects: a double-blind placebo-controlled clinical trial. Br J Nutr 104(3):402–406. https://doi.org/10.1017/s0007114510000504

Rocha A, Wang L, Penichet M, Martins-Green M (2012) Pomegranate juice and specific components inhibit cell and molecular processes critical for metastasis of breast cancer. Breast Cancer Res Treat 136(3):647–658. https://doi.org/10.1007/s10549-012-2264-5

Sahebkar A, Gurban C, Serban A, Andrica F, Serban MC (2016) Effects of supplementation with pomegranate juice on plasma C-reactive protein concentrations: a systematic review and meta-analysis of randomized controlled trials. Phytomedicine 23(11):1095–1102. https://doi.org/10.1016/j.phymed.2015.12.008

Wang L, Ho J, Glackin C, Martins-Green M (2012) Specific Pomegranate Juice Components as potential inhibitors of prostate Cancer metastasis. Translational Oncol 5(5):345–U120. https://doi.org/10.1593/tlo.12190

Mohagheghi M, Rezaei K, Labbafi M, Mousavi SME (2011) Pomegranate seed oil as a functional ingredient in beverages. Eur J Lipid Sci Technol 113(6):730–736. https://doi.org/10.1002/ejlt.201000334

Rebey IB, Bourgou S, Ben Kaab S, Wannes WA, Ksouri R, Tounsi MS et al (2020) On the effect of initial drying techniques on essential oil composition, phenolic compound and antioxidant properties of anise (Pimpinella anisum L.) seeds. J Food Meas Charact 14(1):220–228. https://doi.org/10.1007/s11694-019-00284-4

de Torres C, Díaz-Maroto MC, Hermosín-Gutiérrez I, Pérez-Coello MS (2010) Effect of freeze-drying and oven-drying on volatiles and phenolics composition of grape skin. Anal Chim Acta 660(1–2):177–182. https://doi.org/10.1016/j.aca.2009.10.005

Oliver-Simancas R, Díaz-Maroto MC, Pérez-Coello MS, Alañón ME (2020) Viability of pre-treatment drying methods on mango peel by-products to preserve flavouring active compounds for its revalorization. J Food Eng 279. https://doi.org/10.1016/j.jfoodeng.2020.109953

Mphahlele RR, Fawole OA, Mokwena LM, Opara UL (2016) Effect of extraction method on chemical, volatile composition and antioxidant properties of pomegranate juice. South Afr J Bot 103:135–144. https://doi.org/10.1016/j.sajb.2015.09.015

John KMM, Bhagwat AA, Luthria DL (2017) Swarm motility inhibitory and antioxidant activities of pomegranate peel processed under three drying conditions. Food Chem 235:145–153. https://doi.org/10.1016/j.foodchem.2017.04.143

Al-Rawahi AS, Rahman MS, Guizani N, Essa MM (2013) Chemical Composition, Water Sorption Isotherm, and phenolic contents in Fresh and dried pomegranate peels. Drying Technol 31(3):257–263. https://doi.org/10.1080/07373937.2012.710695

Houdkova M, Rondevaldova J, Doskocil I, Kokoska L (2017) Evaluation of antibacterial potential and toxicity of plant volatile compounds using new broth microdilution volatilization method and modified MTT assay. Fitoterapia 118:56–62. https://doi.org/10.1016/j.fitote.2017.02.008

Ara KM, Raofie F (2016) Application of response surface methodology for the optimization of supercritical fluid extraction of essential oil from pomegranate (Punica granatum L.) peel. J Food Sci Technology-Mysore 53(7):3113–3121. https://doi.org/10.1007/s13197-016-2284-y

Kaseke T, Opara UL, Fawole OA (2021) Quality and antioxidant properties of cold-pressed oil from blanched and microwave-pretreated pomegranate seed. Foods 10(4). https://doi.org/10.3390/foods10040712

Gao LL, Zhang LH, Liu J, Zhang X, Lu YH (2023) Analysis of the volatile flavor compounds of pomegranate seeds at different processing temperatures by GC-IMS. Molecules 28(6). https://doi.org/10.3390/molecules28062717

Beaulieu JC, Lloyd SW, Preece JE, Moersfelder JW, Stein-Chisholm RE, Obando-Ulloa JM (2015) Physicochemical properties and aroma volatile profiles in a diverse collection of California-grown pomegranate (Punica granatum L.) germplasm. Food Chem 181:354–364. https://doi.org/10.1016/j.foodchem.2015.02.026

Durdevic S, Milovanovic S, Savikin K, Ristic M, Menkovic N, Pljevljakusic D et al (2017) Improvement of supercritical CO2 and n-hexane extraction of wild growing pomegranate seed oil by microwave pretreatment. Ind Crops Prod 104:21–27. https://doi.org/10.1016/j.indcrop.2017.04.024

Reidel RVB, Cioni PL, Pistelli L (2018) Volatiles from different plant parts of Punica granatum grown in Tuscany (Italy). Sci Hort 231:49–55. https://doi.org/10.1016/j.scienta.2017.12.019

Calín-Sánchez A, Martínez JJ, Vázquez-Araújo L, Burló F, Melgarejo P, Carbonell-Barrachina AA (2011) Volatile composition and sensory quality of Spanish pomegranates (Punica granatum L). J Sci Food Agric 91(3):586–592. https://doi.org/10.1002/jsfa.4230

Yi ZY, Feng T, Zhuang HN, Ye R, Li MM, Liu T (2016) Comparison of different extraction methods in the analysis of Volatile compounds in Pomegranate Juice. Food Anal Methods 9(8):2364–2373. https://doi.org/10.1007/s12161-016-0410-0

Gyawali R, Kim K-S (2012) Bioactive volatile compounds of three medicinal plants from Nepal. Kathmandu University J Sci Eng Technol 8(1):51–62

Güler Z, Gül E (2017) Volatile organic compounds in the aril juices and seeds from selected five pomegranate (Punica granatum L.) cultivars. Int J Food Prop 20(2):281–293. https://doi.org/10.1080/10942912.2016.1155057

Andreu-Sevilla AJ, Mena P, Martí N, Viguera CG, Carbonell-Barrachina AA (2013) Volatile composition and descriptive sensory analysis of pomegranate juice and wine. Food Res Int 54(1):246–254. https://doi.org/10.1016/j.foodres.2013.07.007

Kramer A, Schwebke I, Kampf G (2006) How long do nosocomial pathogens persist on inanimate surfaces? A systematic review. Bmc Infect Dis 6. https://doi.org/10.1186/1471-2334-6-130

Bottone EJ (2010) Bacillus cereus, a Volatile Human Pathogen. Clin Microbiol Rev 23(2):382–398. https://doi.org/10.1128/cmr.00073-09

Bisignano G, Laganà MG, Trombetta D, Arena S, Nostro A, Uccella N et al (2001) In vitro antibacterial activity of some aliphatic aldehydes from Olea europaea L. FEMS Microbiol Lett 198(1):9–13. https://doi.org/10.1111/j.1574-6968.2001.tb10611.x

Sonam Chouhan KS (2017) Sanjay Guleria antimicrobial activity of some essential oils—present status and future perspectives. Medicines 4(3). https://doi.org/10.3390/medicines4030058

Aljaafari MN, Alkhoori MA, Hag-Ali M, Cheng WH, Lim SHE, Loh JY et al (2022) Contribution of aldehydes and their derivatives to antimicrobial and immunomodulatory activities. Molecules 27(11). https://doi.org/10.3390/molecules27113589

Mahboubi A, Asgarpanah J, Sadaghiyani PN, Faizi M (2015) Total phenolic and flavonoid content and antibacterial activity of Punica granatum L. var. Pleniflora flowers (Golnar) against bacterial strains causing foodborne diseases. Bmc Complement Altern Med 15. https://doi.org/10.1186/s12906-015-0887-x

Rosas-Burgos EC, Burgos-Hernández A, Noguera-Artiaga L, Kacániová M, Hernández-García F, Cárdenas-López JL et al (2017) Antimicrobial activity of pomegranate peel extracts as affected by cultivar. J Sci Food Agric 97(3):802–810. https://doi.org/10.1002/jsfa.7799

Al-Zoreky NS (2009) Antimicrobial activity of pomegranate (Punica granatum L.) fruit peels. Int J Food Microbiol 134(3):244–248. https://doi.org/10.1016/j.ijfoodmicro.2009.07.002

Prashanth D, Asha MK, Amit A (2001) Antibacterial activity of Punica granatum. Fitoterapia 72(2):171–173. https://doi.org/10.1016/s0367-326x(00)00270-7

Jamalova DN, Gad HA, Akramov DK, Tojibaev KS, Ai Musayeib NM, Ashour ML et al (2021) Discrimination of the essential oils obtained from four Apiaceae species using multivariate analysis based on the chemical compositions and their biological activity. Plants-Basel 10(8). https://doi.org/10.3390/plants10081529

Nazzaro F, Fratianni F, De Martino L, Coppola R, De Feo V (2013) Effect of essential oils on pathogenic bacteria. Pharmaceuticals 6(12):1451–1474. https://doi.org/10.3390/ph6121451

Funding

Open access publishing supported by the National Technical Library in Prague. This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization—T.B., P.B., O.A.F.

Data curation—T.B., J.K.

Formal analysis—J.K., I.S.

Investigation—J.K., I.S.

Methodology—T.B., P.B., O.A.F.

Resources—O.A.F., P.B.

Supervision—T.B.

Writing—original draft—J.K.

Writing—review and editing—P.B., T.B., O.A.F.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

This chapter does not contain any studies with human participants or animals performed by any of the authors. Informed consent was obtained from all authors included in the study.

Consent for publication

Consent was obtained from all authors to publish in the journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kubáleková, J., Bajerová, P., Stará, I. et al. Comparative analysis of volatile profiles and antimicrobial activities of freeze-dried and oven-dried pomegranate seeds: implications for waste valorization in a circular economy. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05817-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05817-6