Abstract

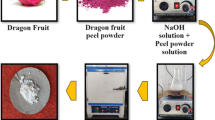

The thermal, physical, and mechanical properties of ecologically sustainable composite materials made of sponge gourd outer skin fiber and vinyl ester matrix are examined in this study. Vinyl ester was compression molded using sponge gourd outer skin fiber, a novel reinforcing material. Sponge gourd outer skin fiber was prepared using chemical, sun-drying, and furnace-drying methods. At different fiber loadings (0, 10, 15, 20, and 30 wt.%), the study examined mechanical (tensile, flexural, impact, hardness), physical (water absorption, biodegradability), thermal, chemical, and matrix-fiber bonding properties. The composite material with 30% fiber loading has better mechanical characteristics over 0 wt.% such as 2.1 times in tensile strength, 2.2 times in flexural strength, and 4.5 times in impact strength as compared to the pure vinyl ester material, greatest average hardness value of 96 on the Shore A scale. FTIR and TGA were used to study chemical distribution and thermal stability. The study found that 30% fiber loading improved tensile, flexural, impact, and hardness. The material’s biodegradability studies showed its environmental friendliness. The results support sustainable composites in aircraft, automotive, and construction. As a link between surface shape and stress-strain distribution, the fiber-matrix interface affects material characteristics. By reducing dependency on non-renewable resources, natural fibers in composite materials increase performance and environmental sustainability.

Similar content being viewed by others

Data availability

The corresponding author will provide the datasets created during and/or analyzed during the current investigation upon reasonable request.

Abbreviations

- SGOSF:

-

Sponge gourd outer skin fiber

- VE:

-

Vinyl ester

- MEKP:

-

Methyl ethyl ketone peroxide

- ASTM:

-

American Society for Testing and Materials

- UTM:

-

Universal Testing Machine

- FTIR:

-

Fourier transform infrared

- TGA:

-

Thermogravimetric analysis

- SEM:

-

Scanning electron microscope

- wt.%:

-

Weight percentage

- KeV:

-

Kiloelectronvolts

References

Balaji A, Karthikeyan B, Swaminathan J, Sundar C (2017) Mechanical and thermal properties of untreated bagasse fiber reinforced cardanol eco-friendly biocomposites. Adv Nat Appl Sci 11(8):73–78

Paulraj P, Balakrishnan K, Rajendran RRMV, Alagappan B (2021) Investigation on recent research of mechanical properties of natural fiber reinforced polymer (NFRP) materials. Mater Plast 58(2):100–118

Prabhu P, Balaji A, Jayabalakrishnan D, Velmurugan N, Vimalnathan P, Karthikeyan B et al (2022) Study on machining parameters and mechanical properties of hybrid Agave sisalana and glass fiber-reinforced polyester composites (A/GFRP). J Nat Fibers 19(15):11644–11657

Balaji A, Kannan S, Purushothaman R, Mohanakannan S, Maideen AH, Swaminathan J et al (2024) Banana fiber and particle-reinforced epoxy biocomposites: mechanical, water absorption, and thermal properties investigation. Biomass Convers Biorefinery 14(6):7835–7845

Sahayaraj AF, Muthukrishnan M, Jenish I (2023) Extraction and characterization of sponge gourd outer skin fiber. J Nat Fibers 20(2):2208888

Vigneshwaran GV, Jenish I, Sivasubramanian R (2014) Design, fabrication and experimental analysis of pandanus fibre reinforced polyester composite. Adv Mater Res 984:253–256

Ramli R, Yunus RM, Beg MDH, Alam AKMM (2011) Effects of different coupling agents on the mechanical and interfacial properties of oil palm fiber reinforced polypropylene composites. J Reinf Plast Compos 30(4):301–308

Taborda-Ríos JA, López-Botello O, Zambrano-Robledo P, Reyes-Osorio LA, Garza C (2020) Mechanical characterisation of a bamboo fibre/polylactic acid composite produced by fused deposition modelling. J Reinf Plast Compos 39(23–24):932–944

Peng X, Fan M, Hartley J, Al-Zubaidy M (2012) Properties of natural fiber composites made by pultrusion process. J Compos Mater 46(2):237–246

Rajak DK, Pagar DD, Menezes PL, Linul E (2019) Fiber-reinforced polymer composites: manufacturing, properties, and applications. Polymers 11(10):1667

Pantano A, Bongiorno F, Marannano G, Zuccarello B (2021) Enhancement of static and fatigue strength of short sisal fiber biocomposites by low fraction nanotubes. Appl Compos Mater 28:91–112

Jenish I, Chinnasamy SGV, Basavarajappa S, Indran S, Divya D, Liu Y (2020) Tribo-mechanical characterization of carbonized coconut shell micro particle reinforced with Cissus quadrangularis stem fiber/epoxy novel composite for structural application. J Nat Fibers

Shaw SJ (1987) High-temperature polymers for adhesive and composite applications. Mater Sci Technol 3(8):589–599

Raghavendra G, Ojha S, Acharya SK, Pal SK (2014) Jute fiber reinforced epoxy composites and comparison with the glass and neat epoxy composites. J Compos Mater 48(20):2537–2547

Singh N, Rani A (2013) Extraction and processing of Sesbania aculeata fib. Asian J Home Sci, pp 399–402

Tímár-Balázsy Á, Eastop D (2012) Chemical principles of textile conservation. Routledge

Shen X, Jia J, Chen C, Li Y, Kim JK (2014) Enhancement of mechanical properties of natural fiber composites via carbon nanotube addition. J Mater Sci 49:3225–3233

Taha I, Ziegmann G (2006) A comparison of mechanical properties of natural fiber filled biodegradable and polyolefin polymers. J Compos Mater 40(21):1933–1946

Symington MC, Banks WM, West OD, Pethrick RA (2009) Tensile testing of cellulose based natural fibers for structural composite applications. J Compos Mater 43(9):1083–1108

Sathish S, Prabhu L, Gokulkumar S, Karthi N, Balaji D, Vigneshkumar N (2021) Extraction, treatment and applications of natural fibers for bio-composites–a critical review. Int Polym Process 36(2):114–130

Wang BC, Huang YD, Liu L (2006) Effects of fibre surface silanisation on silica fibre/phenolics composites produced by resin transfer moulding process. Mater Sci Technol 22(2):206–212

Kumar V, Arun A, Rajkumar K, Palaniyappan S (2024) Effect of Kigelia pinnata biochar inclusion on mechanical and thermal properties of curtain climber fiber reinforced epoxide biocomposites. Polym Compos

Vishal K, Rajkumar K, Sabarinathan P, Arun A (2023) Mechanical and thermal characteristics of steam-exploded silane grafted Kigelia Pinnata fruit (KPF) fiber reinforced vinyl ester polymer composites. Polym Compos 1(1):1–17

Elenchezhian MRP, Das PP, Rahman M, Vadlamudi V, Raihan R, Reifsnider K (2021) Stiffness degradation in fatigue life of composites using dielectric state variables. Compos Struct 273:114272

Nitin MS, Suresh Kumar S (2022) Ballistic performance of synergistically toughened Kevlar/epoxy composite targets reinforced with multiwalled carbon nanotubes/graphene nanofillers. Polym Compos 43(2):782–797

Singh AA, Palsule S (2014) Coconut fiber reinforced chemically functionalized high-density polyethylene (CNF/CF-HDPE) composites by Palsule process. J Compos Mater 48(29):3673–3684

da Silva RV, Voltz H, Filho AI, Xavier Milagre M, Carvalho Machado CDS (2021) Hybrid composites with glass fiber and natural fibers of sisal, coir, and luffa sponge. J Compos Mater 55(5):717–728

Cavalcanti DK, Banea MD, Neto JDSS, Lima RAA (2021) Comparative analysis of the mechanical and thermal properties of polyester and epoxy natural fibre-reinforced hybrid composites. J Compos Mater 55(12):1683–1692

Thomason JL, Rudeiros-Fernández JL (2018) A review of the impact performance of natural fiber thermoplastic composites. Front Mater 5:60

Jackson Singh T, Samanta S, Singh H (2017) Influence of kevlar hybridization on dielectric and conductivity of bamboo fiber reinforced epoxy composite. J Nat Fibers 14(6):837–845

Zhou G (1995) Damage mechanisms in composite laminates impacted by a flat-ended impactor. Compos Sci Technol 54(3):267–273

Sharath BN, Yashas Gowda TG, Madhu P, Pradeep Kumar CB, Jain N, Verma A et al (2024) Fabrication of raw and chemically treated biodegradable Luffa aegyptica fruit fibre-based hybrid epoxy composite: a mechanical and morphological investigation. Biomass Convers Biorefinery, pp 1–14

Thyavihalli Girijappa YG, Mavinkere Rangappa S, Parameswaranpillai J, Siengchin S (2019) Natural fibers as sustainable and renewable resource for development of eco-friendly composites: a comprehensive review. Front Mater 6:226

Vinod A, Gowda TY, Vijay R, Sanjay MR, Gupta MK, Jamil M et al (2021) Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: a sustainable and green material for cleaner production. J Clean Prod 294:126337

Adeyanju CA, Ogunniyi S, Ighalo JO, Adeniyi AG, Abdulkareem SA (2021) A review on Luffa fibres and their polymer composites. J Mater Sci 56(4):2797–2813

Saeed A, Iqbal M (2013) Loofa (Luffa cylindrica) sponge: review of development of the biomatrix as a tool for biotechnological applications. Biotechnol Prog 29(3):573–600

Koçak D, Mistik SI, Akalin M, Merdan N (2015) The use of Luffa cylindrica fibres as reinforcements in composites. In: Biofiber reinforcements in composite materials. Woodhead Publishing, pp 689–699

Sathishkumar S, Suresh AV, Nagamadhu M, Krishna M (2017) The effect of alkaline treatment on their properties of jute fiber mat and its vinyl ester composites. Mater Today: Proc 4(2):3371–3379

Yang HR, Kwon H, Lee KB (2011) Fabrication and characterisation of AZ91/SiC composite by pressureless infiltration method. Mater Sci Technol 27(6):1053–1058

Saw SK, Purwar R, Nandy S, Ghose J, Sarkhel G (2013) Fabrication, characterization, and evaluation of luffa cylindrica fiber reinforced epoxy composites. BioResources 8(4):4805–4826

Aidi A, Rehali H, Menasra H, Fadel A, Ddjezza Z, Abdousr A (2023) Activated carbon from walnut shells for efficient removal of humic substances: synthesis, characterization, and adsorption kinetics. NeuroQuantology 21(7):703–717

Kozłowski R, Władyka-Przybylak M (2008) Flammability and fire resistance of composites reinforced by natural fibers. Polym Adv Technol 19(6):446–453

Fuqua MA, Huo S, Ulven CA (2012) Natural fiber reinforced composites. Polym Rev 52(3):259–320

Kerni L, Singh S, Patnaik A, Kumar N (2020) A review on natural fiber reinforced composites. Mater Today: Proc 28:1616–1621

Wambua P, Ivens J, Verpoest I (2003) Natural fibres: can they replace glass in fibre reinforced plastics? Compos Sci Technol 63(9):1259–1264

Saravana Kumar A, Maivizhi Selvi P, Rajeshkumar L (2017) Delamination in drilling of sisal/banana reinforced composites produced by hand lay-up process. Appl Mech Mater 867:29–33

Prasad V, Muhammed Hunize CV, Abhiraj RI, Jospeh MA, Sekar K, Ali M (2019) Mechanical properties of flax fiber reinforced composites manufactured using hand layup and compression molding—a comparison. In: Advances in industrial and production engineering: select proceedings of FLAME 2018. Springer, Singapore, pp 781–789

Meenakshi C, Krishnamoorthy AJMTP (2018) Preparation and mechanical characterization of flax and glass fiber reinforced polyester hybrid composite laminate by hand lay-up method. Mater Today Proc 5(13):26934–26940

Akil HM, Omar MF, Mazuki AM, Safiee SZAM, Ishak ZM, Bakar AA (2011) Kenaf fiber reinforced composites: a review. Mater Des 32(8–9):4107–4121

Kalia S, Kaith BS, Kaur I (2009) Pretreatments of natural fibers and their application as reinforcing material in polymer composites—a review. Polym Eng Sci 49(7):1253–1272

Adeyanju CA, Ogunniyi S, Ighalo JO, Adeniyi AG, Abdulkareem SA (2021) A review on Luffa fibres and their polymer composites. J Mater Sci 56(4):2797–2813

Alhijazi M, Safaei B, Zeeshan Q, Asmael M, Eyvazian A, Qin Z (2020) Recent developments in luffa natural fiber composites. Sustainability 12(18):7683

Mohanta N (2016) Preparation and characterization of Luffa Cylindrica fiber reinforced polymer composite (doctoral dissertation)

Mani P, Dellibabu GV, Anilbasha K, Anbukarsi K (2014) Tensile and flexural properties of Luffa fiber reinforced composite material. Int J Eng Res 3(5)

Arockiasamy FS (2022) Experimental investigation on the effect of fiber volume fraction of sponge gourd outer skin fiber reinforced epoxy composites. Polym Compos 43(10):6932–6942

Da Silva AN, Teixeira SCS, Widal ACC, Coutinho FMB (2001) Mechanical properties of polymer composites based on commercial epoxy vinyl ester resin and glass fiber. Polym Test 20(8):895–899

Kumar S, Prasad L, Patel VK, Kumar V, Kumar A, Yadav A, Winczek J (2021) Physical and mechanical properties of natural leaf fiber-reinforced epoxy polyester composites. Polymers 13(9):1369

El-Shekeil YA, Sapuan SM, Abdan K, Zainudin ES (2012) Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater Des 40:299–303

Jariwala H, Jain P (2019) A review on mechanical behavior of natural fiber reinforced polymer composites and its applications. J Reinf Plast Compos 38(10):441–453

Haque MM, Hasan M, Islam MS, Ali ME (2009) Physico-mechanical properties of chemically treated palm and coir fiber reinforced polypropylene composites. Bioresour Technol 100(20):4903–4906

Alkbir MFM, Sapuan SM, Nuraini AA, Ishak MR (2016) Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: a literature review. Compos Struct 148:59–73

Devireddy SBR, Biswas S (2017) Physical and mechanical behavior of unidirectional banana/jute fiber reinforced epoxy based hybrid composites. Polym Compos 38(7):1396–1403

Alam MM, Ahmed T, Haque MM, Gafur MA, Kabir AH (2008) Mechanical properties of natural fiber containing polymer composites. Polym-Plast Technol Eng 48(1):110–113

Gu H, Miao M (2014) Optimising fibre alignment in twisted yarns for natural fibre composites. J Compos Mater 48(24):2993–3002

Prabhu P, Karthikeyan B, Vannan RRRM, Balaji A (2022) Mechanical, thermal conductivity, biodegradability property, DMA analysis and fractography analysis of nanoclay-cotton fiber/hybrid resin composites. NeuroQuantology 20(22):549

Raj SS, Kuzmin AM, Subramanian K, Sathiamoorthyi S, Kandasamy KT (2021) Philosophy of selecting ASTM standards for mechanical characterization of polymers and polymer composites. Mater Plast 58(3):247–256

Haug R (2018) The practical handbook of compost engineering. Routledge

Siddiqui A, Braden M, Patel MP, Parker S (2010) An experimental and theoretical study of the effect of sample thickness on the shore hardness of elastomers. Dent Mater 26(6):560–564

Mulvaney RL (1996) Nitrogen—inorganic forms. Methods of soil analysis: part 3 chemical methods. 5:1123–1184

Munajad A, Subroto C, Suwarno (2018) Fourier transform infrared (FTIR) spectroscopy analysis of transformer paper in mineral oil-paper composite insulation under accelerated thermal aging. Energies 11(2):364

Alam SS, Munshi MR, Shufian A, Haque MM, Haque MR, Hasan M et al (2023) Influence of alkalisation and eggshell particles on mechanical, thermal and physical properties of rattan-bamboo fibre reinforced hybrid polyester laminated composite. Adv Mater Process Technol, pp 1–20

Abdel-Hakim A, El-Basheer TM, Abd El-Aziz AM, Afifi M (2021) Acoustic, ultrasonic, mechanical properties and biodegradability of sawdust/recycled expanded polystyrene eco-friendly composites. Polym Test 99:107215

Keeney DR, Nelson DW (1982) Nitrogen-Inorganic forms. In: Miller AL, R. H, Keeney D.R.(eds) Methods of soil analysis part 2: Chemical and microbiological properties. Agronomy 9/2, American society of Agronomy, Madison, WI, pp 643-698

Paul EA, Clark F E (1996) Soil microbiology and biochemistry

Zak DR, Holmes WE, White DC, Peacock AD, Tilman D (2003) Plant diversity, soil microbial communities, and ecosystem function: are there any links? Ecology 84(8):2042–2050

Nannipieri P, Ascher J, Ceccherini M, Landi L, Pietramellara G, Renella G (2003) Microbial diversity and soil functions. Eur J Soil Sci 54(4):655–670

Franzluebbers AJ, Stuedemann JA (2010) Surface soil changes during twelve years of pasture management in the southern Piedmont USA. Soil Sci Soc Am J 74(6):2131–2141

Shakeri A, Ghasemian A (2010) Water absorption and thickness swelling behavior of polypropylene reinforced with hybrid recycled newspaper and glass fiber. Appl Compos Mater 17:183–193

Sanjeevi S, Shanmugam V, Kumar S, Ganesan V, Sas G, Johnson DJ et al (2021) Effects of water absorption on the mechanical properties of hybrid natural fibre/phenol formaldehyde composites. Sci Rep 11(1):13385

Munshi MR, Alam SS, Haque MM, Shufian A, Rejaul Haque M, Gafur MA et al (2022) An experimental study of physical, mechanical, and thermal properties of rattan-bamboo fiber reinforced hybrid polyester laminated composite. J Nat Fibers 19(7):2501–2515

Sabarinathan P, Rajkumar K, Gnanavelbabu A (2016) Investigation of mechanical properties of Luffa cylindrical and flax reinforced hybrid polymer composite. J Adv Eng Res 3(2):124–127

Martins GA, Pereira PHF, Mulinari DR (2013) Chemical modification of palm fibres surface with zirconium oxychloride. BioResources 8(4):6373–6382

Rachchh NV, Ujeniya PA, Misra RK (2014) Mechanical characterisation of rattan fibre polyester composite. Procedia Mater Sci 6:1396–1404

Virk AS, Hall W, Summerscales J (2012) Modulus and strength prediction for natural fibre composites. Mater Sci Technol 28(7):864–871

Olusegun DS, Stephen A, Adekanye TA (2012) Assessing mechanical properties of natural fibre reinforced composites for engineering applications. J Miner Mater Charact Eng 11(1):780–784

Yousif BF, Wong KJ, El-Tayeb NSM (2007) An investigation on tensile, compression and flexural properties of natural fibre reinforced polyester composites. In: ASME international mechanical engineering congress and exposition, vol 42975, pp 619–624

Prasanna Venkatesh R, Ramanathan K, Srinivasa Raman V (2016) Tensile, flexual, impact and water absorption properties of natural fibre reinforced polyester hybrid composites. Fibres Text East Eur

Arrakhiz FZ, El Achaby M, Malha M, Bensalah MO, Fassi-Fehri O, Bouhfid R et al (2013) Mechanical and thermal properties of natural fibers reinforced polymer composites: Doum/low density polyethylene. Mater Des 43:200–205

García M, Garmendia I, García J (2008) Influence of natural fiber type in eco-composites. J Appl Polym Sci 107(5):2994–3004

Jayamani E, Hamdan S, Rahman MR, Bakri MKB (2014) Investigation of fiber surface treatment on mechanical, acoustical and thermal properties of betelnut fiber polyester composites. Procedia Eng 97:545–554

Jayamani E, Hamdan S, Rahman MR, Bakri MKB (2014) Comparative study of dielectric properties of hybrid natural fiber composites. Procedia Eng 97:536–544

Chowdhury T, Ahmed M, Mahdi E, Haque MR, Haque MM, Gafur MA, Hasan M (2023) An experimental study on mechanical, physical, and thermal properties of waste hair-rattan hybrid fiber-reinforced composite. Biomass Convers Biorefinery:1–14

Haque MM, Rejaul Haque M, Munshi MR, Alam SS, Hasan M, Gafur MA et al (2021) Physicomechanical properties investigation of sponge-gourd and betel nut reinforced hybrid polyester composites. Adv Mater Process Technol 7(2):304–316

Khalid AA (2006) The effect of testing temperature and volume fraction on impact energy of composites. Mater Des 27(6):499–506

Siddika S, Mansura F, Hasan M, Hassan A (2014) Effect of reinforcement and chemical treatment of fiber on the properties of jute-coir fiber reinforced hybrid polypropylene composites. Fibers Polym 15:1023–1028

Savitha K, Annapoorani GS, Sampath VR, Atalie D (2019) Physical characterization of cellulosic fibres from Sesbania grandiflora stem. Indian Journal of Fibre & Textile Research (IJFTR) 44(4):437–441

Acknowledgements

The testing facilities required for the study were provided by the Bangladesh Council of Scientific and Industrial Research (BCSIR) and Bangladesh University of Engineering and Technology (BUET). The authors would like to express their gratitude to them.

Author information

Authors and Affiliations

Contributions

All the authors assisted with the initial idea and concept of the composite design. Md. Muib Hossain Antor, Md Tainjinul Islam Anik, S.M. Masuk Al Faisal, Mohammad Rejaul Haque contributed to the fabrication of the composite. Eshat Ar Rafi, Mahbub Hasan, M. A. Gafur, Md. Abdus Sabur contributed during testing of the composites. All the authors provide insightful comments with recommendations while obtaining data, analyzing results, and creating the final text.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Antor, M.M.H., Anik, M.T.I., Al Faisal, S.M. et al. Mechanical, thermal, chemical, and physical properties of sponge gourd outer skin fiber-reinforced vinyl ester composites. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05728-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05728-6