Abstract

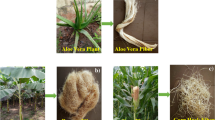

These days, natural fibers are used extensively as reinforcement in biocomposites because of their valuable characteristics, which include biodegradability, non-toxicity, and lightweight. Bagasse, halfa grass, and coir natural fibers are high-cellulose fibers that are cheap and abundant in India. The fibers from bagasse, halfa grass, and coir were extracted and treated with 5% NaOH. The properties of untreated and alkali treated fibers were investigated, and experimental determinations were made for their mechanical, thermal, chemical, and morphological properties, including tensile strength, thermogravimetric analysis (TGA), scanning electron microscope (SEM), and Fourier transform infrared spectrometry (FT-IR). A comparative study of untreated and treated fibers was carried out. It is interesting to note that coir fiber possesses significant high tensile of 183 MPa and thermal properties (31% of weight retention at 600 °C) than the others. FT-IR analyses were carried out to ascertain the chemical composition of three raw and alkali-treated fibers. The morphological examination of all three alkali-treated fibers using a SEM interpreted the removal of pollutants on the surface of the treated fibers. This study interprets that alkali-treated coir fiber possesses significantly better mechanical properties compared to other two fibers.

Similar content being viewed by others

References

Mohammed L, Ansari MN, Pua G, Jawaid M, Islam MS (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Polym Sci 2015:243947

Keya KN, Kona NA, Koly FA, Maraz KM, Islam MN, Khan RA (2019) Natural fiber reinforced polymer composites: history, types, advantages and applications. Mater Eng Res 1(2):69–85

Balaji A, Karthikeyan B, Swaminathan J (2019) Comparative mechanical, thermal, and morphological study of untreated and NaOH-treated bagasse fiber-reinforced cardanol green composites. Adv Compos Hybrid Mater 2(1):125–132

Azman MA, Asyraf MRM, Khalina A, Petrů M, Ruzaidi CM, Sapuan SM, Wan Nik WB, Ishak MR, Ilyas RA, Suriani MJ (2021) Natural fiber reinforced composite material for product design: a short review. Polymers 13(12):1917

Joshi SV, Drzal LT, Mohanty AK, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos A Appl Sci Manuf 35(3):371–376

Ead AS, Appel R, Alex N, Ayranci C, Carey JP (2021) Life cycle analysis for green composites: a review of literature including considerations for local and global agricultural use. J Eng Fibers Fabr 16:15589250211026940

Thirumalaisamy R, Senthil Kumar S, Chelladurai SJS, Gnanasekaran S, Sivananthan S, Geetha NK, Ramesh A, Assefa GB (2023) Study on water absorption characteristics, various chemical treatments, and applications of biological fiber-reinforced polymer matrix composites. J Nanomater 2023:1–7

Malkapuram R, Kumar V, Negi YS (2009) Recent development in natural fiber reinforced polypropylene composites. J Reinf Plast Compos 28(10):1169–1189

Cao Y, Shibata S, Fukumoto I (2006) Mechanical properties of biodegradable composites reinforced with bagasse fibre before and after alkali treatments. Compos A Appl Sci Manuf 37(3):423–429

Sakthivel JC, Mukhopadhyay S, Palanisamy NK (2005) Some studies on Mudar fibers. J Ind Text 35(1):63–76

Amoriello S, Bianco A, Eusebio L, Gronchi P (2011) Evolution of two acid steps sol–gel phases by FTIR. J Sol-Gel Sci Technol 58:209–217

Storozheva EN, Sekushin VN, Tsyganenko AA (2006) FTIR spectroscopy evidence for the basicity induced by adsorption. Meтoды и oбъeкты xимичecкoгo aнaлизa 1(1):79–83

Essien BA, Okereke PO, Oyeleye AD (2021) Industrial crops production. Agricultural Technology for Colleges, p.122.

Parida PK, Pradhan AK, Pandit MK (2023) Characterization of cellulose fiber extracted from stems of Myriostachya wightiana (MW) plants: a viable reinforcement for polymer composite. Fibers and Polymers 24(2):489–503

Konde KS, Nagarajan S, Kumar V, Patil SV, Ranade VV (2021) Sugarcane bagasse based biorefineries in India: potential and challenges. Sustainable Energy Fuels 5(1):52–78

El-Abbassi FE, Assarar M, Ayad R, Bourmaud A, Baley C (2020) A review on alfa fibre (Stipa tenacissima L.): from the plant architecture to the reinforcement of polymer composites. Compos Part A: Appl Sci Manuf 128:105677

Khan T, Singh B, Ahmad KA, Pai R (2022) Extraction of coir fibers by different methods. In: Coir fiber and its composites, Woodhead Publishing, p 19–42

Parre A, Karthikeyan B, Balaji A, Udhayasankar R (2020) Investigation of chemical, thermal and morphological properties of untreated and NaOH treated banana fiber. Mater Today: Proc 22:347–352

Udhayasankar R, Karthikeyan B, Balaji A (2018) Coconut shell particles reinforced cardanol–formaldehyde resole resin biocomposites: effect of treatment on thermal properties. Int J Polym Anal Charact 23(3):252–259

Devaraju A, Murali P (2020) Experimental investigation of mechanical and tribological properties of palm fiber composite with Al2O3 ceramic particles. Mater Today: Proc 22:1161–1166

Boopathi L, Sampath PS, Mylsamy KJCPBE (2012) Investigation of physical, chemical and mechanical properties of raw and alkali treated Borassus fruit fiber. Compos B Eng 43(8):3044–3052

Hossain MK, Karim MR, Chowdhury MR, Imam MA, Hosur M, Jeelani S, Farag R (2014) Comparative mechanical and thermal study of chemically treated and untreated single sugarcane fiber bundle. Ind Crops Prod 58:78–90

Mylsamy K, Rajendran I (2010) Investigation on physio-chemical and mechanical properties of raw and alkali-treated Agave americana fiber. J Reinf Plast Compos 29(19):2925–2935

Barretoa JC, Titaa DL, Orlandia MO (2019) Development of an automated method to perform a quantitative study of particle size distribution and the effect of a conductive layer in scanning electron microscopy. Quim Nova 42(4):447–452

Chakravarthy S, Madhu S, Raju JSN, Md JS (2020) Characterization of novel natural cellulosic fiber extracted from the stem of Cissus vitiginea plant. Int J Biol Macromol 161:1358–1370

Sahu P, Gupta MK (2020) A review on the properties of natural fibres and its bio-composites: effect of alkali treatment. Proc Inst Mech Eng, Part L: J Mater: Des Appl 234(1):198–217

Rajeshkumar G, Hariharan V, Sathishkumar TP (2016) Characterization of Phoenix sp natural fiber as potential reinforcement of polymer composites. J Ind Text 46(3):667–683

Rao KMM, Rao KM (2007) Extraction and tensile properties of natural fibers: vakka, date and bamboo. Compos Struct 77(3):288–295

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Joseph K, Tolêdo Filho RD, James B, Thomas S, Carvalho LHD (1999) A review on sisal fiber reinforced polymer composites. Rev Bras Eng Agríc Ambient 3:367–379

Shahzad A (2012) Hemp fiber and its composites–a review. J Compos Mater 46(8):973–986

De Rosa IM, Santulli C, Sarasini F (2010) Mechanical and thermal characterization of epoxy composites reinforced with random and quasi-unidirectional untreated Phormium tenax leaf fibers. Mater Des 31(5):2397–2405

Gu H (2009) Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater Des 30(9):3931–3934

Obi Reddy K, Sivamohan Reddy G, Uma Maheswari C, Varada Rajulu A, Madhusudhana Rao K (2010) Structural characterization of coconut tree leaf sheath fiber reinforcement. J For Res 21(1):53–58

Cruz G, Santiago PA, Braz CE, Seleghim P, Crnkovic PM (2018) Investigation into the physical–chemical properties of chemically pretreated sugarcane bagasse. J Therm Anal Calorim 132:1039–1053

Amin MN, Ahmad W, Khan K, Ahmad A (2022) A comprehensive review of types, properties, treatment methods and application of plant fibers in construction and building materials. Materials 15(12):4362

Umashankaran M, Gopalakrishnan S (2021) Effect of sodium hydroxide treatment on physico-chemical, thermal, tensile and surface morphological properties of Pongamia pinnata L bark fiber. J Nat Fibers 18(12):2063–2076

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86(12–13):1781–1788

Ike-Eze IE, Aigbodion VS, Ude SN, Omah AD, Offor PO (2019) Experimental study on the effects of surface treatment reagents on tensile properties of banana fiber reinforced polyester composites. J Mater Environ Sci J 10(5):402–410

Barreto ACH, Rosa DS, Fechine PBA, Mazzetto SE (2011) Properties of sisal fibers treated by alkali solution and their application into cardanol-based biocomposites. Compos A Appl Sci Manuf 42(5):492–500

Udhayasankar R, Karthikeyan B, Balaji A (2020) Comparative mechanical, thermal properties and morphological study of untreated and NaOH-treated coconut shell-reinforced cardanol environmental friendly green composites. J Adhes Sci Technol 34(16):1720–1740

Azwa ZN, Yousif BF, Manalo AC, Karunasena W (2013) A review on the degradability of polymeric composites based on natural fibres. Mater Des 47:424–442

Pandey KK, Pitman AJ (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegradation 52(3):151–160

Jayamani E, Loong TG, Bakri MKB (2020) Comparative study of Fourier transform infrared spectroscopy (FTIR) analysis of natural fibres treated with chemical, physical and biological methods. Polym Bull 77(4):1605–1629

Swaminathan J, Ramalingam M, Sundaraganesan N (2009) Molecular structure and vibrational spectra of 3-amino-5-hydroxypyrazole by density functional method. Spectrochim Acta Part A Mol Biomol Spectrosc 71(5):1776–1782

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15:149–159

Swaminathan J, Ramalingam M, Saleem H, Sethuraman V, Ameen MN (2009) FT-IR and FT-Raman vibrational assignment of 2-bromobenzoic acid with the help of ab initio and DFT calculations. Spectrochim Acta Part A Mol Biomol Spectrosc 74(5):1247–1253

Sharmila Tagore S, Swaminathan J, Manikandan D, Gomathi S, Nirmal Ram S, Ramalingam M, Sethuraman V (2020) Molecular, vibrational (FT-IR and FT-Raman), NMR and UV spectral analysis of imidazo[1,2-b] pyridazine using experimental and DFT calculations. Chem Phys Lett 739:136943

Punyamurthy R, Sampathkumar D, Srinivasa CV, Bennehalli B (2012) Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources 7(3):3515–3524

Author information

Authors and Affiliations

Contributions

S. Mohanakannan: conceptualization, methodology, data curation, writing—original draft.

A. Balaji: supervision, review and editing, validation.

J. Swaminathan: investigation, formal analysis, visualization.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Informed consent was obtained from all individual participants included in the study.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohanakannan, S., Balaji, A. & Swaminathan, J. Investigation of mechanical, thermal, and chemical properties of raw and NaOH-treated bagasse/halfa grass/coir fiber. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05700-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05700-4