Abstract

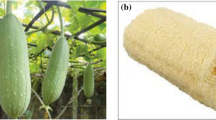

This study investigated the manufacturing and characteristics of luffa fibre reinforced epoxy composites with different stacking sequences and fibre treatments. The composites were created using a manual lay-up approach mixed with compression moulding. Three laminates were tested: L1 with untreated luffa fibres, L2 with HCl-treated fibres, and L3 with NaOH-treated fibres. Mechanical tests demonstrated that chemical treatments considerably increased tensile, flexural, interlaminar shear, and impact strengths when compared to the untreated L1 laminate. L3 with NaOH-treated fibres had the highest tensile strength of 16.47 N/mm2, flexural strength of 11.205 N/mm2, interlaminar shear strength of 4.105 N/mm2, and improved impact energy absorption. The alkali treatment was more successful than the acid treatment at improving fibre-matrix adhesion by removing hemicellulose and lignin. Scanning electron microscopy analysis revealed enhanced interfacial bonding and decreased debonding in the treated fibre laminates. Water absorption experiments revealed that the NaOH-treated L3 laminate absorbed the least amount of moisture after 28 days of immersion, at approximately 6–7%. The results show that chemically treated luffa fibre reinforced composites can be tailored for medium load structural applications by adjusting the fibre surface characteristics.

Similar content being viewed by others

Data availability

Not applicable.

References

Faruk O, Bledzki AK, Fink H-P, Sain M (2012) Biocomposites reinforced with natural fibers: 2000–2010. Prog Polym Sci 37(11):1552–1596

Das Lala S, Deoghare AB, Chatterjee S (2018) Effect of reinforcements on polymer matrix bio-composites—an overview. Sci Eng Compos Mater 25(6):1039–1058

Yashas Gowda TG, Sanjay MR, Subrahmanya Bhat K, Madhu P, Senthamaraikannan P, Yogesha B (2018) Polymer matrix-natural fiber composites: an overview. Cogent Eng 5(1). https://doi.org/10.1080/23311916.2018.1446667

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos Part B Eng 43(7):2883–2892

Shalwan A, Yousif BF (2013) In state of art: mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater Des 48:14–24

Arpitha GR, Jain N, Verma A (2023) Banana biofiber and glass fiber reinforced hybrid composite for lightweight structural applications: mechanical, thermal, and microstructural characterization. Biomass Convers Biorefinery: 1–10. https://doi.org/10.1007/s13399-023-04300-y

Mwaikambo LY, Ansell MP (2002) Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J Appl Polym Sci 84(12):2222–2234

Thwe MM, Liao K (2002) Effects of environmental aging on the mechanical properties of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos - Part A Appl Sci Manuf 33(1):43–52 (9)

Sanjay MR, Arpitha GR, Naik LL, Gopalakrishna K, Yogesha B (2016) Applications of natural fibers and its composites: an overview. Nat Resour 7(3):108–114

Tudela J, Martínez M, Valdivia R, Romo J, Portillo M, Rangel R (2010) Enhanced reader.pdf. Nature 388:539–547

Mohammed L, Ansari MNM, Pua G, Jawaid M, Islam MS (2015) A review on natural fiber reinforced polymer composite and its applications. Int J Polym Sci. https://doi.org/10.1155/2015/243947

Anidha S, Latha N, Muthukkumar M (2020) Effect of polyaramid reinforced with sisal epoxy composites: tensile, impact, flexural and morphological properties. J Mater Res Technol 9(4):7947–7954. https://doi.org/10.1016/j.jmrt.2020.04.081

Kamarudin SH et al (2022) A review on natural fiber reinforced polymer composites (NFRPC) for sustainable industrial applications. Polymers (Basel) 14(17):1–36

Berthelot J-M, Ling FF (1999) Composite materials: mechanical behavior and structural analysis, vol 435. Springer

Rao KMM, Rao KM (2007) Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Compos Struct 77(3):288–295

Thakur VK, Thakur MK (2014) Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr Polym 109:102–117

Sathishkumar TP, Satheeshkumar S, Naveen J (2014) Glass fiber-reinforced polymer composites—a review. J Reinf Plast Compos 33(13):1258–1275

Priyanka P, Dixit A, Mali HS (2019) High strength Kevlar fiber reinforced advanced textile composites. Iran Polym J 28(7):621–638

Prashanth S, Subbaya KM, Nithin K, Sachhidananda S (2017) Fiber reinforced composites—a review. J Mater Sci Eng 6(03):2–6

Kalia S et al (2011) Cellulose-based bio-and nanocomposites: a review. Int J Polym Sci. https://doi.org/10.1155/2011/837875

Adeyanju CA, Ogunniyi S, Ighalo JO, Adeniyi AG, Abdulkareem SA (2021) A review on Luffa fibres and their polymer composites. J Mater Sci 56(4):2797–2813

Shariff MM, Arpitha GR, Jain N, Shankar U, Verma A, Shivakumar ND (2023) A comparative study on the effect of reinforcing boron nitride/alumina in epoxy-based hybrid composite with Millettia pinnata leaf powder and glass sheets: experimental fabrication, mechanical and micro-structural characterization. Hybrid Adv 4:100095

Verma A, Jain N, Mishra RR (2022) Applications and drawbacks of epoxy/natural fiber composites. Handbook of Epoxy/Fiber Composites. Singapore, Springer Singapore, pp 1–15

Lila MK, Verma A, Bhurat SS (2022) Impact behaviors of epoxy/synthetic fiber composites. Handbook of epoxy/fiber composites. Singapore, Springer Singapore, pp 1–18

Dogra V, Kishore C, Verma A, Rana AK, Gaur A (2021) Fabrication and experimental testing of hybrid composite material having biodegradable bagasse fiber in a modified epoxy resin: evaluation of mechanical and morphological behavior. Appl Sci Eng Prog 14(4):661–667

Rastogi S, Singh VK, Verma A (2020) Experimental response of nonwoven waste cellulose fabric–reinforced epoxy composites for high toughness and coating applications. Mater Perform Charact 9(1):151–172

Verma A, Negi P, Singh VK (2018) Physical and thermal characterization of chicken feather fiber and crumb rubber reformed epoxy resin hybrid composite. Adv Civil Eng Mater 7(1):538–557

Verma A, Negi P, Singh VK (2019) Experimental analysis on carbon residuum transformed epoxy resin: chicken feather fiber hybrid composite. Polym Compos 40(7):2690–2699

Verma A, Singh VK (2019) Mechanical, microstructural and thermal characterization of epoxy-based human hair–reinforced composites. J Test Eval 47(2):1193–1215

Verma A, Negi P, Singh VK (2018) Experimental investigation of chicken feather fiber and crumb rubber reformed epoxy resin hybrid composite: mechanical and microstructural characterization. J Mech Behav Mater 27(3–4):20180014

Verma A, Budiyal L, Sanjay MR, Siengchin S (2019) Processing and characterization analysis of pyrolyzed oil rubber (from waste tires)-epoxy polymer blend composite for lightweight structures and coatings applications. Polym Eng Sci 59(10):2041–2051

Verma A, Parashar A, Jain N, Singh VK, Rangappa SM, Siengchin S (2020) Surface modification techniques for the preparation of different novel biofibers for composites. Synthesis, Characterization and Properties, Biofibers and Biopolymers for Biocomposites, pp 1–34

Jain N, Verma A, Singh VK (2019) Dynamic mechanical analysis and creep-recovery behaviour of polyvinyl alcohol based cross-linked biocomposite reinforced with basalt fiber. Mater Res Express 6(10):105373

Arpitha GR, Verma A, Sanjay MR, Siengchin S (2021) Preparation and experimental investigation on mechanical and tribological performance of hemp-glass fiber reinforced laminated composites for lightweight applications. Adv Civil Eng Mater 10(1):427–439

Singh K, Singh VK, Chauhan S, Jain N, Verma A (2020) Functionalized graphite–reinforced cross-linked poly (vinyl alcohol) nanocomposites for vibration isolator application: morphology, mechanical, and thermal assessment. Mater Perform Charact 9(1):215–230

Verma A, Baurai K, Sanjay MR, Siengchin S (2020) Mechanical, microstructural, and thermal characterization insights of pyrolyzed carbon black from waste tires reinforced epoxy nanocomposites for coating application. Polym Compos 41(1):338–349

Bharath KN, Madhu P, Gowda TG, Verma A, Sanjay MR, Siengchin S (2020) A novel approach for development of printed circuit board from biofiber based composites. Polym Compos 41(11):4550–4558

Chaurasia A, Verma A, Parashar A, Mulik RS (2019) Experimental and computational studies to analyze the effect of h-BN nanosheets on mechanical behavior of h-BN/polyethylene nanocomposites. J Phys Chem C 123(32):20059–20070

Verma A, Gaur A, Singh VK (2017) Mechanical properties and microstructure of starch and sisal fiber biocomposite modified with epoxy resin. Mater Perform Charact 6(1):500–520

Verma A, Joshi K, Gaur A, Singh VK (2018) Starch-jute fiber hybrid biocomposite modified with an epoxy resin coating: fabrication and experimental characterization. J Mech Behav Mater 27(5–6):20182006

Agrawal PK, Sharma P, Verma A, Singh VK, Chaudhary AK, Chauhan S (2024) Impact of graphite particle surface modification on the strengthening of cross-linked polyvinyl alcohol composites: a comprehensive investigation. Proc Inst Mech Eng Part L: J Mater: Des Appl 238(1):181–197

Gunge A, Koppad PG, Nagamadhu M, Kivade SB, Murthy KVS (2019) Study on mechanical properties of alkali treated plain woven banana fabric reinforced biodegradable composites. Compos Commun 13:47–51. https://doi.org/10.1016/j.coco.2019.02.006

Vinod A et al (2021) Novel Muntingia Calabura bark fiber reinforced green-epoxy composite: a sustainable and green material for cleaner production. J Clean Prod 294:126337

Madhu P, Sanjay MR, Jawaid M, Siengchin S, Khan A, Pruncu CI (2020) A new study on effect of various chemical treatments on Agave Americana fiber for composite reinforcement: physico-chemical, thermal, mechanical and morphological properties. Polym Test 85:106437

Jayaramudu J et al (2011) Structure and properties of new natural cellulose fabrics from Cordia dichotoma. Carbohydr Polym 86(4):1623–1629. https://doi.org/10.1016/j.carbpol.2011.06.071

Odera RS, Onukwuli OD, Aigbodion VS (2019) Effect of alkali-silane chemical treatment on the tensile properties of raffia palm fibre. Aust J Multi-Discip Eng 15(1):91–99

Vijay R et al (2019) Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int J Biol Macromol 125:99–108. https://doi.org/10.1016/j.ijbiomac.2018.12.056

Senthilkumar K et al (2022) Dual cantilever creep and recovery behavior of sisal/hemp fibre reinforced hybrid biocomposites: effects of layering sequence, accelerated weathering and temperature. J Ind Text 51(2):2372S-2390S

Chen W, Yu H, Liu Y, Hai Y, Zhang M, Chen P (2011) Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process. Cellulose 18:433–442

Siddika S, Mansura F, Hasan M, Hassan A (2014) Effect of reinforcement and chemical treatment of fiber on the properties of jute-coir fiber reinforced hybrid polypropylene composites. Fibers Polym 15:1023–1028

Chowdhury T, Ahmed M, Mahdi E, Haque MR, Haque MM, Gafur MA, Hasan M (2023) An experimental study on mechanical, physical, and thermal properties of waste hair-rattan hybrid fiber-reinforced composite. Biomass Conversion and Biorefinery: 1–14. https://doi.org/10.1007/s13399-023-05179-5

Haque MM, Rejaul Haque M, Munshi MR, Alam SS, Hasan M, Gafur MA, Rahman F, Firdaus M, Ahmod S (2021) Physico-mechanical properties investigation of sponge-gourd and betel nut reinforced hybrid polyester composites. Adv Mater Process Technol 7(2):304–316

Kumar V, Arun A, Rajkumar K, Palaniyappan S (2024) Effect of Kigelia pinnata biochar inclusion on mechanical and thermal properties of curtain climber fiber reinforced epoxide biocomposites. Polym Compos 45(5):4459–4472. https://doi.org/10.1002/pc.28073

Sabarinathan P, Rajkumar K, Gnanavelbabu AJJAER (2016) Investigation of mechanical properties of Luffa cylindrical and flax reinforced hybrid polymer composite. J Adv Eng Res 3(2):124–127

Atiqah A, Jawaid M, Sapuan SM, Ishak MR, Ansari MNM, Ilyas RA (2019) Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J Mater Res Technol 8(5):3726–3732. https://doi.org/10.1016/j.jmrt.2019.06.032

Arpitha GR, Jain N, Verma A, Madhusudhan M (2022) Corncob bio-waste and boron nitride particles reinforced epoxy-based composites for lightweight applications: fabrication and characterization. Biomass Convers Biorefinery: 1–8. https://doi.org/10.1007/s13399-022-03717-1

Jain N, Sharma P, Verma A, Gupta J (2023) Enhancement of thermo-mechanical, creep-recovery, and anti-microbial properties in PVA-based biodegradable films through cross-linking with oxalic acid: implications for packaging application. Biomass Convers Biorefinery: 1–10. https://doi.org/10.1007/s13399-023-04748-y

Bisht N, Verma A, Chauhan S, Singh VK (2021) Effect of functionalized silicon carbide nano-particles as additive in cross-linked PVA based composites for vibration damping application. J Vinyl Add Tech 27(4):920–932

Senthamaraikannan P, Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis.L. Carbohydr Polym 186:332–343

Refiadi G, Syamsiar Y, Judawisastra H (2019) The tensile strength of petung bamboo fiber reinforced epoxy composites: the effects of alkali treatment, composites manufacturing, and water absorption. IOP Conf Ser Mater Sci Eng 547(1):01204. IOP Publishing. https://doi.org/10.1088/1757-899X/547/1/012043

Funding

The corresponding author “Akarsh Verma” would like to thank the University of Petroleum and Energy Studies, Dehradun, India (SEED Grant program) for the academic and monetary support. Also, this research work was supported by the National Science, Research and Innovation Fund (NSRF) (Fundamental Fund 2024) and King Mongkut’s University of Technology North Bangkok (Project no. KMUTNB-FF-67-A-01).

Author information

Authors and Affiliations

Contributions

All the authors equally contributed to conceptualisation, methodology, writing, reviewing, and editing.

Corresponding authors

Ethics declarations

Ethical approval

The authors hereby state that the present work is in compliance with the ethical standards.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharath, B.N., Yashas Gowda, T.G., Madhu, P. et al. Fabrication of raw and chemically treated biodegradable Luffa aegyptica fruit fibre-based hybrid epoxy composite: a mechanical and morphological investigation. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05570-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05570-w