Abstract

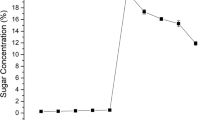

The study explores the effectiveness of alkaline pretreatment using various concentrations of NaOH (2%, 4%, 6%, 8%, and 10%) on lignocellulosic biomass, specifically paddy straw and sugarcane bagasse, and its impact on the biomass structure and subsequent bioethanol production. Among the 2–10% NaOH pretreatment, samples at 2% NaOH exhibited a significant removal of lignin and increased reducing sugar yields of 8.369 g/L from paddy straw and 7.635 g/L from sugarcane bagasse compared to untreated samples. The growth patterns of two yeast strains, Saccharomyces cerevisiae and Yarrowia lipolytica, were analyzed under different treatment conditions using paddy straw and sugarcane bagasse as carbon sources. The results indicated that S. cerevisiae showed enhanced growth when dextrose was present with paddy straw but exhibited lower growth with sugarcane bagasse. In contrast, Y. lipolytica exhibited higher growth with the addition of dextrose regardless of the carbon source. Scanning electron micrographs (SEM) and Fourier transform infrared (FTIR) analysis further confirmed the structural changes and lignocellulose degradation after 2% NaOH pretreatment. Among the treatment conditions, the highest ethanol yield of 65.6 ml/L was obtained when S. cerevisiae and Y. lipolytica were co-fermented with sugarcane bagasse as the carbon source without the addition of dextrose. Overall, this study demonstrates the effectiveness of alkaline pretreatment using 2%NaOH in removing lignin from paddy straw and sugarcane bagasse, resulting in improved bioethanol production. The findings highlight the potential of utilizing lignocellulosic biomass as a sustainable feedstock for biofuel production through efficient treatment methods.

Graphical Abstract

Similar content being viewed by others

Data availability

All the datasets are presented in the main manuscript.

References

Toor M, Kumar SS, Malyan SK, Bishnoi NR, Mathimani T, Rajendran K et al (2020) An overview on bioethanol production from lignocellulosic feedstocks. Chemosphere 242:125080

Awoyale AA, Lokhat D (2021) Experimental determination of the effects of pretreatment on selected Nigerian lignocellulosic biomass in bioethanol production. Sci Rep 11:557

Sonwani R, Gupta SB, Soni R (2020) Production of bioethanol from biodegraded alkali pretreated rice straw. Vegetos 33:128–134

Aziz T, Shah Z, Sarwar A, Ullah N, Khan AA, Sameeh MY et al (2023) Production of bioethanol from pretreated rice straw, an integrated and mediated upstream fermentation process. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04283-w

Tsegaye B, Balomajumder C, Roy P (2019) Alkali pretreatment of wheat straw followed by microbial hydrolysis for bioethanol production. Environ Technol 40:1203–1211

S Rakesh K Subburamu N Arunkumar 2021 Pretreatment of paddy straw for sustainable bioethanol production Sustainable Bioprocessing for a Clean and Green Environment CRC Press 93 102

Mirahmadi K, Kabir MM, Jeihanipour A, Karimi K, Taherzadeh MJ (2010) Alkaline pretreatment of spruce and birch to improve bioethanol and biogas production. Bioresour 5(2):928–38

Ashoor S, Mallapureddy KK, Sukumaran RK (2022) Sequential mild acid and alkali pretreatment of rice straw to improve enzymatic saccharification for bioethanol production. Prep Biochem Biotechnol 53(3):231–8

Shah TA, Majeed T, Rahman SU, Ihsan T, Aziz T, Alharbi M et al. (2023) Synergistic treatment of crude enzymes from Bacillus sp. strains to boost anaerobic fermentation of rice straw. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-05090-z

Ullah N, Rehman MU, Sarwar A, Nadeem M, Nelofer R, Shakir HA et al (2022) Purification, characterization, and application of alkaline protease enzyme from a locally isolated Bacillus cereus strain. Fermentation 8:628

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37:19–27

Zhu Wang Y, Zheng J, Nawaz M, Yang F, Hu J, Gao MT.(2022) Oligosaccharide-phenolic compound conjugates in soluble polysaccharides from rice straw alleviate ethanol fermentation stresses in Saccharomyces cerevisiae. Ind Crops Prod 181:114782

Zou J, Chang X (2022) Past, present, and future perspectives on whey as a promising feedstock for bioethanol production by yeast. J Fungus 8:395

Tsigie YA, Wu C-H, Huynh LH, Ismadji S, Ju Y-H (2013) Bioethanol production from Yarrowia lipolytica Po1g biomass. Bioresour Technol 145:210–216

Drzymała K, Mirończuk AM, Pietrzak W, Dobrowolski A (2020) Rye and oat agricultural wastes as substrate candidates for biomass production of the non-conventional yeast Yarrowia lipolytica. Sustainability 12:7704

T Jayakumar S Rakesh 2022 A study exploring the effects of cell disruption techniques on lipid recovery in co-cultivated microalgae and oleaginous yeast Bioenergy Res 16 3 1537 47

Mueansichai T, Rangseesuriyachai T, Thongchul N, Assabumrungrat S (2022) Lignocellulosic bioethanol production of napier grass using Trichoderma reesei and Saccharomyces cerevisiae co-culture fermentation. Int J Renew Energy Dev 11:423–433

Otoikhian SK, Amune OU (2022) Comparative assessment of the co-production of bioethanol and single cell proteins from sugarcane bagasse, rice husks, and cassava peels using Saccharomyces cerevisiae. GSC Adv Eng Technol 3:001–009

Miller GL (1972) Analytical chemistry. McGraw Hill Book, New York

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Sharma S, Nandal P, Arora A (2019) Ethanol production from NaOH pretreated rice straw: a cost effective option to manage rice crop residue. Waste Biomass Valorization 10:3427–3434

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48

Goshadrou A (2019) Bioethanol production from Cogongrass by sequential recycling of black liquor and wastewater in a mild-alkali pretreatment. Fuel 258:116141

Silva TAL, Zamora HDZ, Varão LHR, Prado NS, Baffi MA, Pasquini D (2018) Effect of steam explosion pretreatment catalysed by organic acid and alkali on chemical and structural properties and enzymatic hydrolysis of sugarcane bagasse. Waste Biomass Valorization 9:2191–2201

Saratale GD, Saratale RG, Kim SH, Kumar G (2018) Screening and optimization of pretreatments in the preparation of sugarcane bagasse feedstock for biohydrogen production and process optimization. Int J Hydrogen Energy 43:11470–11483

Kumar N, Yadav A, Singh G, Singh A, Kumar P, Aggarwal NK (2023) Comparative study of ethanol production from sodium hydroxide pretreated rice straw residue using Saccharomyces cerevisiae and Zymomonas mobilis. Arch Microbiol 205:146

El-Sakhawy M, Kamel S, Salama A, Tohamy H-AS (2018) Preparation and infrared study of cellulose based amphiphilic materials. Cellul Chem Technol 52:193–200

Cao Y, Tan H (2002) Effects of cellulase on the modification of cellulose. Carbohydr Res 337:1291–1296

Binod P, Satyanagalakshmi K, Sindhu R, Janu KU, Sukumaran RK, Pandey A (2012) Short duration microwave assisted pretreatment enhances the enzymatic saccharification and fermentable sugar yield from sugarcane bagasse. Renew Energy 37:109–116

Md Salim R, Asik J, Sarjadi MS (2021) Chemical functional groups of extractives, cellulose and lignin extracted from native Leucaena leucocephala bark. Wood Sci Technol 55:295–313. https://doi.org/10.1007/s00226-020-01258-2

Reddy KO, Ashok B, Reddy KRN, Feng YE, Zhang J, Rajulu AV (2014) Extraction and characterization of novel lignocellulosic fibers from Thespesia lampas plant. Int J Polym Anal Charact 19:48–61

Nath Barman D, Haque MA, Kang TH, Kim GH, Kim TY, Kim MK et al (2014) Effect of mild alkali pretreatment on structural changes of reed (Phragmites communis Trinius) straw. Environ Technol 35:232–241

Kumari D, Singh R (2022) Rice straw structure changes following green pretreatment with petha wastewater for economically viable bioethanol production. Sci Rep 12:10443

Chandel AK, Antunes FA, Anjos V, Bell MJ, Rodrigues LN, Polikarpov I et al (2014) Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid–base pretreatment and ethanol production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol Biofuels 7:63. https://doi.org/10.1186/1754-6834-7-63

Gabhane J, Kumar S, Sarma AK (2020) Effect of glycerol thermal and hydrothermal pretreatments on lignin degradation and enzymatic hydrolysis in paddy straw. Renew Energy 154:1304–1313

Cai J, Wang Y, Liu J, Zhang X, Li F (2022) Pretreatment enhanced structural disruption, enzymatic hydrolysis, fermentative hydrogen production from rice straw. Int J Hydrog Energy 47:11778–11786

Ahmad A, Naqvi SA, Jaskani MJ, Waseem M, Ali E, Khan IA et al (2021) Efficient utilization of date palm waste for the bioethanol production through Saccharomyces cerevisiae strain. Food Sci Nutr 9:2066–2074

Onoghwarite OE, Obiora NVI, Ben EA, Moses N-OE (2016) Bioethanol production from corn stover using Saccharomyces cerevisiae. Int J Sci Eng Res 7:290–293

Muthusamy S, Selvan ST, Arunachalam P, Grasian I (2019) Bioconversion and bioethanol production from agro-residues through fermentation process using mangrove-associated actinobacterium Streptomyces olivaceus (MSU3). Biofuels 10:167–179

Wine P, Jerry O, Aleke K, Chika E, Anthonia N, Ikechukwu M (2016) Bioethanol production from corncob hydrolysed by cellulase of Aspergillus niger using zymomonas mobilis and Saccharomyces cerevisiae isolated from International Journal of Current Research in Biosciences and Plant Biology bioethanol production from Cornco. Int J Curr Res Biosci Plant Biol 3:39–45

Wang Y, Liu S (2014) Kinetic modeling of ethanol batch fermentation by Escherichia coli FBWHR using hot-water sugar maple wood extract hydrolyzate as substrate. Energies 7:8411–8426

Ezebuiro V, Ogugbue CJ, Oruwari B, Ire FS (2015) Bioethanol production by an ethanol-tolerant Bacillus cereus strain GBPS9 using sugarcane bagasse and cassava peels as feedstocks. J Biotechnol Biomater 5:1

Nikhil B, Adhyaru D, Thakor P (2012) Production of xylanase by Aspergillus flavus FPDN1 on pearl millet bran: optimization of culture conditions and application in bioethanol production. Int J Res Chem Environ 2:204–210

Mushimiyimana, I. and Tallapragada, P. (2017) Bioethanol production from agro wastes by acid hydrolysis and fermentation process. J Sci Ind Res

Wu X, Zhang J, Xu E, Liu Y, Cheng Y, Addy M et al (2016) Microbial hydrolysis and fermentation of rice straw for ethanol production. Fuel 180:679–686

Kim I, Lee B, Park J-Y, Choi S-A, Han J-I (2014) Effect of nitric acid on pretreatment and fermentation for enhancing ethanol production of rice straw. Carbohydr Polym 99:563–567

Arora A, Priya S, Sharma P, Sharma S, Nain L (2016) Evaluating biological pretreatment as a feasible methodology for ethanol production from paddy straw. Biocatal Agric Biotechnol 8:66–72

Canilha L, Carvalho W, De Almeida Felipe MDG, De Almeida E, Silva JB, Giulietti M (2010) Ethanol production from sugarcane bagasse hydrolysate using Pichia stipitis. Appl Biochem Biotechnol 161:84–92. https://doi.org/10.1007/s12010-009-8792-8

da Silveira dos Santos D, Camelo AC, Rodrigues KC, Carlos LC, Pereira N (2010) Ethanol production from sugarcane bagasse by Zymomonas mobilis using simultaneous saccharification and fermentation (SSF) process. Appl Biochem Biotechnol 161:93–105. https://doi.org/10.1007/s12010-009-8810-x

de Carvalho DM, de Queiroz JH, Colodette JL (2016) Assessment of alkaline pretreatment for the production of bioethanol from eucalyptus, sugarcane bagasse and sugarcane straw. Ind Crops Prod 94:932–941

Acknowledgements

The authors thank the Biofuel Research Laboratory of the Department of Microbiology, Central University of Tamil Nadu, India.

Funding

This project is supported by the Central University of Tamil Nadu, Thiruvarur. This work is financially supported by the SERB DST Project (EEQ/2023/000530).

Author information

Authors and Affiliations

Contributions

TJ: writing the original draft and carrying out the work; AVK: alkali pretreatment and ethanol estimation; AKB: reviewing and suggestions for improvement; SR: conceptualization, reviewing, and final editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tharunkumar, J., Arosha, V.K., Bajhaiya, A.K. et al. Optimizing alkaline pretreatment for delignification of paddy straw and sugarcane bagasse to enhance bioethanol production. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05458-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05458-9