Abstract

The study uses ultrasonic-assisted chemical activation to describe an eco-friendly method for producing activated carbon with high specific surface area and porosity from high lignin-content palm kernel shells. The low activation temperature of 600 °C with the ultrasonic interaction was able to show excellent phenol and methylene blue adsorption, 72.67% and 67.52%, respectively. Carbonisation was carried out at 600 °C using argon gas to produce char, while chemical activation took place with the ultrasonic impregnation of 30% potassium hydroxide. During the activation phase, inert gas is reused as the oxidising agent at temperatures that vary from 600 to 750 and up to 900 °C. Palm kernel shell–activated carbon was characterised based on proximate analysis, field emission scanning electron microscopy (FESEM), and Fourier transform infrared spectroscopy (FTIR), respectively. The adsorption of methylene, phenol, and iodine by activated carbon was studied in this study in order to investigate the porous structure. The maximum specific surface area and highest iodine adsorption of activated carbon prepared at 750 °C with 40 min of ultrasonic impregnation were 138.21 m2/g and 45.36%, respectively. In addition, the highest phenol adsorption was shown by activated carbon prepared at 600 °C with 40 min of ultrasonic impregnation, up to 72.67%. Meanwhile, the activated carbon was prepared at 600 °C activation temperature with 120 min of ultrasonic impregnation, resulting in the highest methylene blue adsorption, 67.52%. Furthermore, the demonstrated ultrasonic-assisted chemical activation approach has been demonstrated to be more effective than previous activation methods for producing activated carbon from palm kernel shells at low activation temperatures.

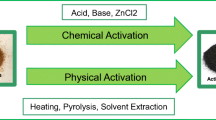

Graphical Abstract

Similar content being viewed by others

Data availability

All data generated or analysed during the study are included in this published article.

Abbreviations

- IN:

-

Number of iodine adsorbed by activated carbon (IN)

- q eq :

-

Amount of adsorption corresponding to methylene blue solution (mg/g)

- q e :

-

Amount of adsorption corresponding to phenol solution (mg/g)

- S BET :

-

Surface area using iodine number (m2/g)

References

Rasouli K, Rasouli J, Mohtaram MS, Sabbaghi S, Kamyab H, Moradi H, Chelliapan S (2023) Biomass-derived activated carbon nanocomposites for cleaner production: a review on aspects of photocatalytic pollutant degradation. J Cleaner Prod 138181 https://doi.org/10.1016/j.jclepro.2023.138181

Li Y, Zimmerman AR, He F, Chen J, Han L, Chen H, Hu X, Gao B (2020) Solvent-free synthesis of magnetic biochar and activated carbon through ball-mill extrusion with Fe3O4 nanoparticles for enhancing adsorption of methylene blue. Sci Total Environ 722 https://doi.org/10.1016/j.scitotenv.2020.137972

González-García P (2018) Activated carbon from lignocellulosics precursors: a review of the synthesis methods, characterization techniques and applications. In Renew Sustain Energy Rev 82:1393–1414. https://doi.org/10.1016/j.rser.2017.04.117

Lee CL, Chin KL, H’ng PS, Rashid U, Maminski M, Khoo PS (2021) Effect of pretreatment conditions on the chemical–structural characteristics of coconut and palm kernel shell: a potentially valuable precursor for eco-efficient activated carbon production. EnvironTechnol Innov 21. https://doi.org/10.1016/j.eti.2020.101309

Sangthong S, Phetwarotai W, Bakar MSA, Cheirsilp B, Phusunti N (2022) Phenol-rich bio-oil from pyrolysis of palm kernel shell and its isolated lignin. Indus Crops Prod 188 https://doi.org/10.1016/j.indcrop.2022.115648

Chantanumat Y, Phetwarotai W, Sangthong S, Palamanit A, Abu Bakar MS, Cheirsilp B, Phusunti N (2022) Characterization of bio-oil and biochar from slow pyrolysis of oil palm plantation and palm oil mill wastes. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-02291-2

Asadpour R, Yavari S, Kamyab H, Ashokkumar V, Chelliapan S, Yuzir A (2021) Study of oil sorption behaviour of esterified oil palm empty fruit bunch (OPEFB) fibre and its kinetics and isotherm studies. Environ Technol Innov 22:101397. https://doi.org/10.1016/j.eti.2021.101397

Nyamful A, Nyogbe EK, Mohammed L, Zainudeen MN, Darkwa SA, Phiri I, Mohammed M, Ko JM (2021) Processing and characterization of activated carbon from coconut shell and palm kernel shell waste by H3PO4 activation. Ghana J Sc 61(2):91–104. https://doi.org/10.4314/gjs.v61i2.9

Feng P, Li J, Wang H, Xu Z (2020) Biomass-based activated carbon and activators: preparation of activated carbon from corncob by chemical activation with biomass pyrolysis liquids. ACS Omega 5(37):24064–24072. https://doi.org/10.1021/acsomega.0c03494

Thongpat W, Taweekun J, Maliwan K (2021) Synthesis and characterization of microporous activated carbon from rubberwood by chemical activation with KOH. Carbon Letters 31(5):1079–1088. https://doi.org/10.1007/s42823-020-00224-z

Zengin H, Kalayci G, Zengin G (2014) Effect of sonication in the preparation of activated carbon particles on adsorption performance. Sep Sci Technol (Philadelphia) 49(12):1807–1816. https://doi.org/10.1080/01496395.2014.902383

Karamifar M, Sabbaghi S, Mohtaram MS, Rasouli K, Mohsenzadeh M, Kamyab H, Chelliapan S (2023) Ultrasonic-assisted synthesis of TiO2/MWCNT/Pani nanocomposite: photocatalyst characterization and optimization of efficient variables in the degradation of benzene via RSM-CCD. Powder Technol 119176. https://doi.org/10.1016/j.powtec.2023.119176

Kong SH, Chin CYJ, Yek PNY, Wong CC, Wong CS, Cheong KY, Liew RK, Lam SS (2022) Removal of heavy metals using activated carbon from microwave steam activation of palm kernel shell. Environ Adv 9. https://doi.org/10.1016/j.envadv.2022.100272

Hussaro K (2014) Preparation of activated carbon from palm oil shell by chemical activation with Na2CO3 and ZnCl2 as impregnated agents for H2S adsorption. Am J Environ Sci 10(4):336–346. https://doi.org/10.3844/ajessp.2014

Ademiluyi FT, David-West EO (2012) Effect of chemical activation on the adsorption of heavy metals using activated carbons from waste materials. ISRN Chem Eng 2012:1–5. https://doi.org/10.5402/2012/674209

Atunwa BT, Dada AO, Inyinbor AA, Pal U (2022) Synthesis, physiochemical and spectroscopic characterization of palm kernel shell activated carbon doped AgNPs (PKSAC@AgNPs) for adsorption of chloroquine pharmaceutical waste. Mater Today: Proc 65:3538–3546. https://doi.org/10.1016/j.matpr.2022.06.099

Dada AO, Adekola FA, Odebunmi EO, Dada FE, Bello OS, Ogunlaja AS (2020) Bottom-up approach synthesis of core-shell nanoscale zerovalent iron (CS-nZVI): physicochemical and spectroscopic characterization with Cu(II) ions adsorption application. MethodsX, 7. https://doi.org/10.1016/j.mex.2020.100976

Prahas D, Kartika Y, Indraswati N, Ismadji S (2008) Activated carbon from jackfruit peel waste by H3PO4 chemical activation: pore structure and surface chemistry characterization. Chem Eng J 140(1–3):32–42. https://doi.org/10.1016/j.cej.2007.08.032

Hoc Thang N, Sy Khang D, Duy Hai T, Thi Nga D, Dinh Tuan P (2021) Methylene blue adsorption mechanism of activated carbon synthesised from cashew nut shells. RSC Adv 11(43):26563–26570. https://doi.org/10.1039/d1ra04672a

Mopoung S, Moonsri P, Palas W, Khumpai S (2015) Characterization and properties of activated carbon prepared from tamarind seeds by KOH activation for Fe(III) adsorption from aqueous solution. Sci World J. https://doi.org/10.1155/2015/415961

Kuang Y, Zhang X, Zhou S (2020) Adsorption of methylene blue in water onto activated carbon by surfactant modification. Water (Switzerland) 12:2. https://doi.org/10.3390/w12020587

Kassahun E, Mekuria S, Beyan SM (2022) Specific surface area enhancement of waste tire-based activated carbon by demineralization technique and adsorption of methylene blue. Int J Chem Eng. https://doi.org/10.1155/2022/8198551

Lorenc-Grabowska E, Diez MA, Gryglewicz G (2016) Influence of pore size distribution on the adsorption of phenol on PET-based activated carbons. J Colloid Interface Sci 469:205–212. https://doi.org/10.1016/j.jcis.2016.02.007

Xie B, Qin J, Wang S, Li X, Sun H, Chen W (2020) Adsorption of phenol on commercial activated carbons: modelling and interpretation. Int J Environ Res Public Health 17:3. https://doi.org/10.3390/ijerph17030789

Mojoudi N, Mirghaffari N, Soleimani M, Shariatmadari H, Belver C, Bedia J (2019) Phenol adsorption on high microporous activated carbons prepared from oily sludge: equilibrium, kinetic and thermodynamic studies. Sci Rep 9:1. https://doi.org/10.1038/s41598-019-55794-4

Du C, Liu B, Hu J, Li H (2021) Determination of iodine number of activated carbon by the method of ultraviolet–visible spectroscopy. Mater Lett 285:129137. https://doi.org/10.1016/j.matlet.2020.129137

Dada AO, Inyinbor AA, Bello OS, Tokula BE (2021) Novel plantain peel activated carbon–supported zinc oxide nanocomposites (PPAC-ZnO-NC) for adsorption of chloroquine synthetic pharmaceutical used for COVID-19 treatment. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01828-9

Abdullah NA, Abdullah PS, Amin MFM, Zainol NA (2018) Preparation and characterization of a new biocarbon material derived from Macaranga gigantea (giant ‘Mahang’) leaf biomass as precursor. Materials Today: Proceedings 5(10):21888–21896. https://doi.org/10.1016/j.matpr.2018.07.047

Bergna D, Varila T, Romar H, Lassi U (2018) Comparison of the properties of activated carbons produced in one-stage and two-stage processes. J Carbon Res 4:41–51. https://doi.org/10.3390/c4030041

Heidarinejad Z, Dehghani MH, Heidari M, Javedan G, Ali I, Sillanpää M (2020) Methods for preparation and activation of activated carbon: a review. In Environ Chem Lett 18(2):393–415. https://doi.org/10.1007/s10311-019-00955-0. (Springer)

Abechi SE, Gimba CE, Dallatu UA (2013) Preparation and characterization of activated carbon from palm kernel shell by chemical activation. In Res J Chem Sci 3:7

Shaikh RB, Saifullah B, urRehman F, Shaikh RI (2018) Greener method for the removal of toxic metal ions from the wastewater by application of agricultural waste as an adsorbent. Water (Switzerland) 10:10. https://doi.org/10.3390/w10101316

Baby R, Hussein MZ (2020) Ecofriendly approach for treatment of heavy-metal-contaminated water using activated carbon of kernel shell of oil palm. Materials 13:11. https://doi.org/10.3390/ma13112627

Beri KYV, Barbosa DP, Zbair M, Ojala S, de Oliveira SB (2021) Adsorption of estradiol from aqueous solution by hydrothermally carbonized and steam activated palm kernel shells. Energy Nexus 1:100009. https://doi.org/10.1016/j.nexus.2021.100009

Kouotou D, Manga HN, Baçaoui A, Yaacoubi A, Mbadcam JK (2013) Optimization of activated carbons prepared by H3PO4 and steam activation of oil palm shells. J Chem. https://doi.org/10.1155/2013/654343

Yorgun S, Vural N, Demiral H (2009) Preparation of high-surface area activated carbons from Paulownia wood by ZnCl2 activation. Microporous Mesoporous Mater 122(1–3):189–194. https://doi.org/10.1016/j.micromeso.2009.02.032

Mistar EM, Alfatah T, Supardan MD (2020) Synthesis and characterization of activated carbon from Bambusa vulgaris striata using two-step KOH activation. J Market Res 9(3):6278–6286. https://doi.org/10.1016/j.jmrt.2020.03.041

Nandi R, Jha MK, Guchhait SK, Sutradhar D, Yadav S (2023) Impact of KOH activation on rice husk derived porous activated carbon for carbon capture at flue gas alike temperatures with High CO2/N2 selectivity. ACS Omega 8(5):4802–4812. https://doi.org/10.1021/acsomega.2c06955

Moosavi S, Lai CW, Gan S, Zamiri G, Akbarzadeh Pivehzhani O, Johan MR (2020) Application of efficient magnetic particles and activated carbon for dye removal from wastewater. ACS Omega 5(33):20684–20697. https://doi.org/10.1021/acsomega.0c01905

Nicholas AF, Hussein MZ, Zainal Z, Khadiran T (2018) Palm kernel shell activated carbon as an inorganic framework for shape-stabilized phase change material. Nanomaterials 8:9. https://doi.org/10.3390/nano8090689

Ahmedna M, Marshall WE, Husseiny AA, Rao RM, Goktepe I (2004) The use of nutshell carbons in drinking water filters for removal of trace metals. Water Res 38(4):1062–1068. https://doi.org/10.1016/j.watres.2003.10.047

Darban Z, Shahabuddin S, Gaur R, Ahmad I, Sridewi N (2022) Hydrogel-based adsorbent material for the effective removal of heavy metals from wastewater: a comprehensive review. In Gels 8:5. https://doi.org/10.3390/gels8050263

Song X, Zhang Y, Yan C, Jiang W, Chang C (2013) The Langmuir monolayer adsorption model of organic matter into effective pores in activated carbon. J Colloid Interface Sci 389(1):213–219. https://doi.org/10.1016/j.jcis.2012.08.060

Loredo-Cancino M, Soto-Regalado E, Cerino-Córdova FJ, García-Reyes RB, García-León AM, Garza-González MT (2013) Determining optimal conditions to produce activated carbon from barley husks using single or dual optimization. J Environ Manage 125:117–125. https://doi.org/10.1016/j.jenvman.2013.03.028

Tseng RL, Tseng SK, Wu FC, Hu CC, Wang CC (2008) Effects of micropore development on the physicochemical properties of KOH-activated carbons. J Chin Inst Chem Eng, 39(1):37–47. https://doi.org/10.1016/j.jcice.2007.11.005

Yu Q, Guo J, Muhammad Y, Li Q, Lu Z, Yun J, Liang Y (2020) Mechanisms of enhanced hexavalent chromium removal from groundwater by sodium carboxymethyl cellulose stabilized zerovalent iron nanoparticles. J Environ Manag 276. https://doi.org/10.1016/j.jenvman.2020.111245

Yu Q, Liu G, Shi J, Wen T, Li L (2022) Magnetic-activated carbon composites derived from sludge and steel converter slag for wastewater treatment. J Environ Chem Eng 10:5. https://doi.org/10.1016/j.jece.2022.108553

Mady AH, Baynosa ML, Tuma D, Shim JJ (2019) Heterogeneous activation of peroxymonosulfate by a novel magnetic 3D Γ-MnO2@ZnFe2O4/rGO nanohybrid as a robust catalyst for phenol degradation. Appl Catal B 244:946–956. https://doi.org/10.1016/j.apcatb.2018.11.086

Yu Q, Tang M, Liu G, Liu M, Ye J (2023) Phenol removal by activation of persulfate using magnetic carbon generated from sludge and steel converter slag. Chem Eng Process Process Intensif 186 https://doi.org/10.1016/j.cep.2023.109313

Hamdaoui O, Naffrechoux E, Tifouti L, Petrier C (2003) Effects of ultrasound on adsorption-desorption of p-chlorophenol on granular activated carbon. Ultrason Sonochem 10:109–114. https://doi.org/10.1016/S1350-4177(02)00137-2

Hamdaoui O, Naffrechoux E, Suptil J, Fachinger C (2005) Ultrasonic desorption of p-chlorophenol from granular activated carbon. Chem Eng J 106(2):153–161. https://doi.org/10.1016/j.cej.2004.10.010

Kilic M, Apaydin-Varol E, Pütün AE (2011) Adsorptive removal of phenol from aqueous solutions on activated carbon prepared from tobacco residues: equilibrium, kinetics and thermodynamics. J Hazard Mater 189(1–2):397–403. https://doi.org/10.1016/j.jhazmat.2011.02.051

Kumar, D. P., Ramesh, D., Subramanian, P., Karthikeyan, S., & Surendrakumar, A. (2022). Activated carbon production from coconut leaflets through chemical activation: process optimization using Taguchi approach. Bioresource Technol Rep 19. https://doi.org/10.1016/j.biteb.2022.101155

Saka C (2012) BET, TG-DTG, FT-IR, SEM, iodine number analysis and preparation of activated carbon from acorn shell by chemical activation with ZnCl2. J Anal Appl Pyrol 95:21–24. https://doi.org/10.1016/j.jaap.2011.12.020

Tubino M, Aricetti JA (2013) A green potentiometric method for the determination of the iodine number of biodiesel. Fuel 103:1158–1163. https://doi.org/10.1016/j.fuel.2012.10.011

Deng H, Li G, Yang H, Tang J, Tang J (2010) Preparation of activated carbons from cotton stalk by microwave assisted KOH and K2CO3 activation. Chem Eng J 163(3):373–381. https://doi.org/10.1016/j.cej.2010.08.019

Mitome T, Uchida Y, Egashira Y, Hayashi K, Nishiura A, Nishiyama N (2013) Adsorption of indole on KOH-activated mesoporous carbon. Colloids Surf, A 424:89–95. https://doi.org/10.1016/j.colsurfa.2013.02.022

Hui TS, Zaini MAA (2015) Potassium hydroxide activation of activated carbon: a commentary. In Carbon Letters 16(4):275–280. https://doi.org/10.5714/CL.2015.16.4.275. (Korean Carbon Society)

Puziy AM, Poddubnaya OI, Martınez-Alonso A, Suarez-Garcıa F, Tascon JMD (2002) Synthetic carbons activated with phosphoric acid II. Porous Struct Carbon 40(9):1507–1519. https://doi.org/10.1016/S0008-6223(01)00318-9

Anuwar NA, Megat Khamaruddin PF (2020) Optimization of chemical activation conditions for activated carbon from coconut shell using response surface methodology (RSM) and its ability to adsorb CO 2. Adv Eng Res 200

Lan X, Jiang X, Song Y, Jing X, Xing X (2019) The effect of activation temperature on structure and properties of blue coke-based activated carbon by CO2 activation. Green Process Synth 8(1):837–845. https://doi.org/10.1515/gps-2019-0054

Acknowledgements

The research team would like to acknowledge Universiti Tun Hussein Onn Malaysia (UTHM) for making their Laboratory available during the preparation and analysis of the sample.

Author information

Authors and Affiliations

Contributions

TA, conceptualization, experimentation, and writing of the manuscript. AY helped in refining and reviewing and editing. NA supervised and provided resources and facilities for this work. AY, validation, methodology, and editing. HK, conceptualization, data curation, and editing. NFCP, review and editing in the first and revised version. SR, bibliography, methodology, and editing. MNMH helped in reviewing, editing, and finalising this manuscript.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Consent for publication

All authors agree to the submission of the manuscript to Biomass Conversion and Biorefinery.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arumugham, T., Yuniarto, A., Abdullah, N. et al. Preparation and characterisation of porous activated carbon using potassium hydroxide chemical activation with ultrasonic association. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05201-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05201-w