Abstract

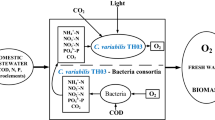

Water scarcity is a crucial environmental challenge. Wastewater remediation is an important way to tackle the challenge. Using nanoparticles of natural and agricultural wastes is considered a low-cost sustainable remediation technology. This study develops an effective prototype of a sustainable sewage wastewater (SWW) remediation process using zeolite and bagasse nanoparticles. All studied physico-chemical parameters and heavy metals of the SWW were reduced over the course of treatment with nanobagasse (NB), nanozeolite (NZ), and nanobagasse-nanozeolite double treatments (DT). After only 2 weeks of remediation, the chemical oxygen demand (COD), biological oxygen demand (BOD), total suspended solid (TSS), and total dissolved solid (TDS) concentrations were decreased (in NB 38, 33, 58, and 30%; in NZ 40, 30, 63, and 58%; and in DT 47, 38, 75, and 62%), respectively, compared to raw SWW. The DT for 4 and 6 weeks (DT4W and DT6W) show 0.94 and 0.67 Kelly ratios, respectively, which are suitable for irrigation. According to the water pollution index (WPI), all types of DT treatments produce excellent-quality water. DT6W recorded the highest significant rank of removal efficiency of COD, BOD, TSS, TDS, PO4, NO3, Ca, Mg, Na, Cu, Cd, Fe, and Ni (72.7, 59.6, 88.6, 74, 56.7, 88.2, 72.7, 58.7, 80.7, 94.6, 91.1, 65.3, and 84.4%). This remediated water may be used directly for irrigation or other purposes. Also, this study proves that DT4W and DT6W are suitable for Chlorella sorokiniana growth and production of safe protein-rich biomass, 26 and 31.8% protein, respectively. DT for 2, 4, and 6 weeks are suitable growth media for C. sorokiniana to produce diesel engines’ compatible biodiesel. Finally, this recent study presents an interpretation of the physiological status of C. sorokiniana cells grown in the raw SWW and DT media.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

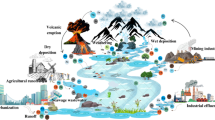

Due to the world’s growing population, industrial development, and climate change, the production of municipal, industrial, and agricultural wastewater has significantly increased. This has become a crucial environmental challenge that requires an urgent and sustainable solution [1]. Hence, the United Nations sustainable development goal 6 (UN-SDG 6) was adopted as a global goal with other goals in 2015 to work toward a sustainable and poverty-free world by 2030. SDG 6 seeks to ensure that people have access to clean water and adequate sanitation services worldwide. Globally, 56% of municipal wastewater flows were safely treated in 2020 (extrapolated from data from 128 countries representing 80% of the global population) [2]. In high-income countries, nearly 70% of the generated municipal and industrial wastewater is treated. That ratio drops to 38% in upper-middle-income countries and to 28% in lower-middle-income countries [3].

Often, effective municipal wastewater remediation is an integrated process. It depends mainly on the type of domestic wastewater and contaminants [4]. One of the main municipal wastewater types is sewage wastewater (SWW). SWW reclamation is a multi-stage process. It starts with pre-treatment to remove large objects and primary treatment to separate solid and liquid components. Then, the secondary biological treatment removes dissolved organic matter. Finally, tertiary advanced treatment further purifies the water before it is discharged or reused [5]. However, investigation of low-cost and applicable low technology is continuous.

Novel compounds such as nanoparticles have been a rising trend in wastewater treatment [6]. Specific nanoparticles have efficiently removed heavy metals, pathogens, chlorophenols contaminants, and toxins [7, 8]. Silver nanoparticles are commonly used due to their high reactivity and antimicrobial properties [9]. Titanium dioxide nanoparticles are also effective in removing organic pollutants through photocatalysis [10]. Similarly, iron oxide nanoparticles can be used for the removal of heavy metals [11]. Nevertheless, using eco-friendly or “green” nanoparticles in wastewater treatment is a hot research field in the last decade [12]. Many products of natural materials, e.g., nanozeolite, and agricultural wastes, e.g., nanobagasse, have proved to be effective in wastewater treatment where they efficiently adsorb nitrates and phosphates present in agricultural drainage wastewater [13, 14].

Natural zeolites are hydrated aluminosilicates of alkaline and alkaline-earth metals. It is known for its high capacity for ion exchange, adsorption, and catalytic power. Bagasse is the sugarcane waste remaining after the sugar extraction process, which is known for its high adsorption power. Fortunately, the global production of natural zeolite and sugarcane bagasse has been estimated to be 1 million and 1 billion tons/year, respectively [15, 16]. However, some critical questions need further investigation such as whether the nanoparticle of zeolite alone and bagasse alone can purify the SWW efficiently, which nanomaterial of those more efficient is, whether the interaction between the nanoparticles of zeolite and bagasse is a good synergistic dual physical treatment, what the effect of application time on the process is, and what the physiological responses of green microalga Chlorella sorokiniana are as a freshwater model organism.

This work aims to establish a low-cost effective prototype of a sustainable SWW remediation process using eco-friendly nanoparticles of zeolite and bagasse, measure the quality of treated water, and evaluate the effect of different types of remediated water on C. sorokiniana physiology during biomass and biodiesel production.

2 Materials and methods

2.1 Experimental design

All experiments and analyses were carried out during 2021–2023 at the facilities of the Plant Physiology Division, Department of Agricultural Botany, Cairo University, Egypt. The experimental design in all trials was a completely randomized design with 3 replicates.

2.2 Preparation of bagasse raw material

Bagasse as a by-product of the commercial sugarcane cultivar was used. The sample of 40 mill-able cane stalks was squeezed by an electric pilot mill (Sugar Crops Research Institute, Agriculture Research Center, Giza Agriculture Research Station, Giza, Egypt). Wet bagasse was collected and washed with tap water to remove any debris then sun-dried for 3 days and put in an oven at 110 °C until constant weight. Analysis of raw dry bagasse is shown in Table 1.

2.3 Synthesis of bagasse nanoparticles

The synthesis of bagasse nanoparticles was done using the bottom molecular physical and chemical approach method under pressure 1.5 MPa according to Taha et al. [17] and Mahmoud et al. [18] with some modifications. The raw material of bagasse was ground for 18 h continuously and then soaked in a solution of HCl:NaOH:hexametaphosphate (1:1:2) as a molar ratio under vigorous stirring for 12 h. Next, 3 mL of (TEOS) solution as tetrahedral molecule (prepared by alcoholysis of tetrachloride) was added and left for 72 h. The resulting material was washed thoroughly with deionized water in a water/toluene system using a high-speed stirrer and then washed again with ionized water alone for 3 h. After that, the material was filtered and then exposed to 120 °C for 72 h continuously. After that, it was left under pressure (1.5 MPa) for 36 h discontinuously. Finally, ultrasonication was done for 30 min to separate nanoparticle aggregation. The size and shape of bagasse nanoparticles were observed directly by transmission electron microscopy (TEM) using an electron acceleration voltage of 80 kV (Fig. 1). The chemical analysis of nanobagasse is shown in Table 1 using A. O. A. C. (1990) for determination of ash % and moisture % and C, H, N, S elemental analyzer based on the principle of Dumas method (ema 502, VELP scientifica Srl, made in Italy).

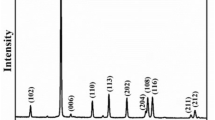

2.4 Synthesis of nanozeolite

Nanozeolite was prepared according to Hassan and Mahmoud [19]. Transmission electronic microscope examination and imaging (TEM) were done at the Cairo University Research Park (CURP) using an electron acceleration voltage of 80 kV (Fig. 2). Composition of nanozeolite is shown in Table 2 by X-ray fraction (XRF; X-MET 7500 mining analyzer, from Oxford instrument). The most abundant element in its composition was silicon dioxide (SiO2) with a percentage of 45.50%, and the least was strontium oxide (SrO) with a percentage of 0.22%.

2.5 Characteristics of treated and untreated wastewater

SWW was collected from the Al-Saff location, Giza governorate, Egypt. Then, wastewater was stored in 20-L containers and transferred to the laboratory where it was analyzed (Table 3) and then treated with different treatments.

The water pollution index (WPI) is calculated depending on all available data from water analyses according to Hossain and Patra [20]. Kelly ratio (KR), magnesium hazard (MH), and sodium adsorption ratio (SAR) were calculated according to the equations mentioned by Moursy and Negim [21]. The pH was monitored, and chemical oxygen demand (COD) was determined using HANNA® wastewater multiparameter benchtop photometer and pH meter HI83314 with COD medium-range reagent vials HI93754B-25 according to manufacturer instructions. Electrical conductivity (EC) and total dissolved solids (TDS) were measured by Adwa AD31 waterproof EC and TDS pocket tester (made in China) according to the manufacturer’s instructions. Total suspended solids (TSS) were separated by a 0.5-µm filter and then weighed on a 4-decimal electric balance. Biological oxygen demand (BOD) was determined using BOD Trak II Apparatus (HACH, USA). Phosphate (PO4) was quantified according to AOAC methods [22]. Nitrate (NO3) was determined according to APHA [23]. Other measured elements were quantified by atomic absorption (Fisher Scientific ice 3000). The removal efficiency (RE; %) was calculated according to the following equation [24]:

where Ci is the initial concentration at zero time (ti), while Ct is the concentration after a specific time (t).

2.6 Experimental setup of SWW remediation by bagasse and zeolite nanoparticles

SWW was equally distributed into pre-autoclaved ten 2-L containers, then treated as shown in Table 4.

At the end of each treatment, remediated water in each container was centrifuged at 1600 rpm for 30 min to get rid of zeolite and bagasse nanoparticles.

2.7 Culture conditions of C. sorokiniana and growth monitoring

C. sorokiniana isolate BENHA721_ABO4 [24], which was used in this study, was a gift from Dr. Hamed Eladel. Seed culture was grown in Bold’s Basel Medium (BBM) [25] for 10 days and then inoculated into fresh media: untreated SWW (UT), double-treated SWW with nanobagasse and nanozeolite for 2 weeks (DT2W), double-treated SWW with nanobagasse and nanozeolite for 4 weeks (DT4W), and double-treated SWW with nanobagasse and nanozeolite for 6 weeks (DT6W) after harvesting and washing twice with each medium. The initial cell dry weight after inoculation was nearly 0.182 ± 0.012 g·L−1 and OD680 = 0.88 ± 0.01. Under fully aseptic conditions, cultures were grown 300 mL each in 1-L blue cap bottles as bioreactor units under 32 ± 5 µmol photons m−2 s−1 and 16:8-h light:dark cycles at 20 ± 2 °C. Air pump flow rate was 1.75 L·min−1 through 0.22-µm filters.

In each time interval (days 0, 2, 4, 6, 8, and 10 after inoculation to the untreated medium or treated media), the growth was monitored in two different ways: measuring optical density at 680 nm by Helios gamma spectrophotometer (ThermoSpectronic) and weighing dried cells from 5-mL culture harvested by passing through 0.45-µm cellulose nitrate 47-mm filter (Sartorius).

The logistic growth model [26] was applied to represent growth curves using the following equation:

where Y is the cell dry weight (g·L−1); YM is the maximum population (g·L−1); Y0 is the starting population (g·L−1); k is the rate constant (d−1), indicating the maximum specific growth rate; and x is the X coordinate of the first inflection point (day) indicating lag phase period.

The specific growth rate (µ) and biomass productivity (BP) were calculated by the following equations mentioned by Eladel et al. [24]:

where CDWi is the cell dry weight (g·L−1) at zero time and CDWt is the CDW after time t.

Division time (DT) was calculated by dividing the specific growth rate by ln2 according to Moheimani et al. [27]:

Generation time (GT) was calculated as follows according to Moheimani et al. [27]:

2.8 Chemical analyses of algal experiments

On the last day of the experiments, 50 mL of C. sorokiniana cultures was collected by centrifugation for 5 min at 4 °C and 10,000 × g. Total lipids of microalgal cultures were determined as described by Bligh and Dyer [28]. FAMEs were prepared from total lipids using the rapid method according to ISO 12966–2 [29].

FAMEs were injected into (HP 6890 series GC) apparatus provided with a DB-23 column (60 m × 0.32 mm × 25 µm). The carrier gas was N2 with a flow rate of 1.5 mL/min, a splitting ratio of 1:50. The injector temperature was 250 °C and that of the Flame Ionization Detector (FID) was 280 °C. The temperature setting was as follows: 150 to 210 °C by increasing 5 °C/min, and then held at 210 °C for 25 min. Peaks were identified by comparing the retention times obtained with stander methyl esters (Supelco 37 component FAME mixture, Sigma).

The characteristics of biodiesel were estimated by BiodieselAnalyzer© version 2.2 http://brteam.org/analysis/#id02 [30] and compared to the US biodiesel standard ASTM D6751-20a [31] and the European standard EN 14214 [32].

The total nitrogen content of the dried material was determined using the modified micro-Kjeldahl method as described by Helrich [33]. The nitrogen percentage was multiplied by 6.25 to estimate the crude protein percentages. Phosphate was determined calorimetrically by using the stannous chloride molybdophosphoric blue color method in sulfuric acid according to Jackson [34]. The concentrations of Ca, Mg, Fe, Cu, Ni, and Cd were determined using Atomic Absorption Spectrophotometer with air-acetylene, fuel (Pye Unicam, model SP-1900, USA). Sodium cation was extracted from C. sorokiniana samples according to Garciadeblás et al. [35]. The determination of cation content was realized using a flame photometer (GENWAY PFP-7). Free proline concentration in Chlorella samples was done according to Bates et al. [36]. Total carbohydrates in samples were determined by the phosphomolybdic acid method according to Helrich [33].

The productivities of lipid (LP), protein (PP), and carbohydrates (CP) were calculated by multiplying the specific growth rate by percentages of lipid, protein, and carbohydrates, respectively, according to Moheimani et al. [27].

The Folin–Ciocalteau method is used to measure the total phenolic content of a sample. The resulting colorimetric reaction is measured at 765 nm and compared with a standard curve generated with gallic acid standard solutions [37]. Total flavonoid content was quantified by the method described by Salerno et al. [38] using catechin as a standard.

Activities of superoxide dismutase (SOD) and catalase (CAT) enzymes were determined according to the ultraviolet absorption method assays of Giannopotitis and Ries [39] and Stewart and Bewley [40], respectively. Determination of gibberellic acid (GA) and abscisic acid (ABA) were quantified according to Fales and Jaouni [41]. Malondialdehyde (MDA) was determined as an indicator of lipid peroxidation according to Senthilkumar et al. [42]. Total chlorophyll and carotenoid contents were estimated according to Wellburn method [43]. Tocopherol and vitamin C analyses were performed as detailed in Katoch [44].

2.9 Transmission electron microscopy and Fourier-transform infrared spectroscopy

In the Electronic Microscopy facility and Chemistry lab of CURP, nanoparticle imaging was done under the transmission electron microscope (TEM), and a Jasco FTIR 4600 plus instrument was used to obtain spectra from air-dried algal pellets harvested from 10 mL of each treatment grown for 10 days, respectively. The spectra were recorded in the frequency range of 400 to 4000 cm−1 at a resolution of nearly 1 cm−1.

2.10 Statistical analysis

Statistical software, SPSS Ver. 27, GraphPad prism ver. 9.0.2, JMP pro 16, and MS-Excel ver. 365, have been used to analyze and present the experimental data and study the relationship among variables by analysis of variance (ANOVA), Duncan’s post hoc test, and cluster analysis.

3 Results and discussion

3.1 Effects of bagasse and zeolite nanoparticles on SWW treatment over the time

Bagasse is a byproduct of sugarcane processing. It contains cellulose that can be extracted and used to produce nanoparticles. Bagasse nanoparticles are effective in removing pollutants from water due to their high surface area and ability to adsorb contaminants [45, 46]. SWW treatment typically involves multiple stages, including physical, biological, and chemical processes [47]. Bagasse nanoparticles can be used in the chemical stage of sewage treatment as an adsorbent for pollutants such as heavy metals and organic compounds [48]. The use of bagasse nanoparticles in sewage treatment has the potential to reduce costs and improve efficiency compared to traditional methods [49]. However, further research is needed to fully understand the effectiveness and potential drawbacks of using bagasse nanoparticles in SWW treatment. In this study (Tables 5 and 6), our results prove that nanobagasse (NB) reduced pH from slightly alkaline to neutral and reduced EC, COD, BOD, TSS, TDS, NO3, PO4, Ca, Mg, Na, Cu, Fe, Ni, and Cd of the SWW over the treatment time. The COD, BOD, TSS, and TDS concentrations after 2 weeks of remediation were 38, 33, 58, and 30% decreased, respectively, compared to those of untreated SWW. After more than 2 weeks there are still very slight decreases in all studied parameters.

Zeolite nanoparticles have a high adsorption capacity for heavy metals and organic pollutants [50, 51]. The use of zeolite nanoparticles can effectively reduce the concentration of pollutants in SWW [52, 53]. Zeolite nanoparticles can be easily synthesized and are cost-effective for large-scale production [54]. The use of zeolite nanoparticles in SWW treatment can improve the overall water quality leading to potential environmental and health benefits [55, 56]. However, further research is needed to optimize the use of zeolite nanoparticles in SWW treatment systems. In this study (Tables 5 and 6), our results prove that nanozeolite (NZ) and nanobagasse-nanozeolite double treatments (DTs) reduced pH from slight alkaline to neutral and reduced EC, COD, BOD, TSS, TDS, NO3, PO4, Ca, Mg, Na, Cu, Fe, Ni, and Cd of the SWW over the treatment time. The COD, BOD, TSS, and TDS concentrations after 2 weeks of remediation were 40, 30, 63, and 58% decreased by NZ and 47, 38, 75, and 62% decreased by DT, respectively, compared to those of untreated SWW. These decreases are continuous over time.

Kelly ratio (KR) is one of several indices that can be used to assess the water quality for irrigation, along with sodium absorption ratio (SAR) and magnesium hazard (MH) [57]. A KR of more than 1 indicates excessive sodium in water, which can affect the soil structure and crop growth. Therefore, water samples with a KR of less than 1 are suitable for irrigation, while those with a ratio of more than 1 are unsuitable [58]. KR is important because it can help to prevent soil salinization and sodification, which are common problems in arid and semi-arid regions where irrigation is practiced [59]. In Table 5, our results of nanobagasse treatments show that KR over time is higher than 1. That means of all nanobagasse-treated SWW contain high sodium to calcium and magnesium ratio, and they are not suitable for irrigation. The same results were noticed for all nanozeolite-treated SWW. However, the double-treated SWW for 4 and 6 weeks show 0.94 and 0.67 of KR, respectively, which are suitable for irrigation. This decrease in sodium to calcium and magnesium ratio may be due to the high ion exchange capacity of the mixture of nanobagasse and nanozeolite.

Also, the water pollution index (WPI) is a water quality index where a WPI of more than 1 indicates highly polluted water, greater than 0.75 to 1 is moderately polluted water, greater than 0.5 to 0.75 is good water, and less than 0.5 is excellent water [20]. Our results (Table 5) of nanobagasse treatments show that WPI over time is between 0.5 and 0.75, which means that those types of treated water are good quality water. Also, types of nanozeolite-treated water range from good (in NZ2W) to excellent quality water (in NZ4W and NZ6W). Interestingly, all types of double-treated water are excellent quality water. This may be due to the greater absorbent capacity of the nanoparticles’ mixture.

The dual treatment (DT) has the highest removal efficiencies (Table 6) for most parameters. This indicates that it is more effective in removing pollutants from the SWW than the nanobagasse (NB) or nanozeolite (NZ) alone. The retention time (2W, 4W, or 6W) influences some parameters such as COD, BOD, TSS, TDS, and heavy metals. Longer retention time leads to higher mean values for these parameters. This indicates that more pollutants are adsorbed by the nanoparticles over time. In more detail, DT6W recorded the highest significant rank of removal efficiency of COD, BOD, TSS, TDS, PO4, NO3, Ca, Mg, Na, Cu, Cd, Fe, and Ni (72.7, 59.6, 88.6, 74, 56.7, 88.2, 72.7, 58.7, 80.7, 94.6, 91.1, 65.3, and 84.4%). Also, DT4W recorded the highest significant removal rank of removal efficiency of PO4, NO3, and Cu (52.2, 83.6, and 93.5%) and the second significant removal efficiency rank of the rest of the studied parameters as mentioned in Table 6.

In the rural areas of lower-middle-income countries, less than 28% of SWW is remediated [3]. Our dual treatment for 4 and 6 weeks may be the most suitable low-cost applicable technique. In addition to the precipitation effects during 4 to 6 weeks of storing the SWW in septic tanks, the organic matter will be removed by 63.6 to 72.7% as COD and up to 91.1 and 84.4% Cd and Ni as the most hazardous heavy metals in SWW. This kind of pre-remediation may save more than 50% of SWW remediation costs. Also, this pre-remediation step, for instance, for 1 million m3 SWW will consume 10,000 tonnes of simply fabricated nanobagasse, the agricultural waste, and 10,000 tonnes of nanozeolite, the natural waste. In conclusion, this pre-remediated water may be collected for advanced remediation plants or used directly for irrigation purposes or as a safe culture medium for some microalgal dual-purpose biomass and biodiesel-producing species.

3.2 Growth parameters of C. sorokiniana grown in untreated and dual-treated SWW

In this study, we tried to validate our hypothesis that dual-treated SWW after 4 and 6 weeks are suitable for C. sorokiniana growth and production of safe protein-rich biomass. Also, we tried to validate that DT2W, DT4W, and DT6W are suitable growth media for C. sorokiniana to produce biodiesel. In the way of testing these hypotheses, growth parameters; photosynthetic pigments; growth regulators; enzymatic and non-enzymatic systems of antioxidation, chemical, and elemental composition; and fatty acid profiling are studied in C. sorokiniana grown in untreated SWW (as a control) and DT2W, DT4W, and DT6W.

Figure 3 shows the effect of combined zeolite and bagasse nanoparticle-treated SWW under different duration on the cell dry weight of C. sorokiniana. Although the start is almost similar in all treatments (0.17–0.19 g·L−1), as time passes, cell dry weight increases but slows down beginning from day 4 to 6. From then on until day 10, increases continue slowly except for DT6W, where increase in cell dry weight plateau (0.645 g·L−1 at day 10), but only lower from the other treatments on the last day of the experiment (UT = 0.88, DT2W = 0.796, and DT4W = 0.769 g·L−1). A similar trend was observed when plotting the optical density (OD680) of fresh cell cultures with time (Figure S1).

Growth curves of cell dry weight (CDW) of C. sorokiniana grown for 10 days under untreated sewage water (UT) and nanobagasse-nanozeolite double-treated sewage water for 2, 4, and 6 weeks (DT2W, DT4W, and DT6W respectively). Values are means of three biological replicates ± SD. Lines represent the logistic growth model’s curve fit. YM = maximum growth yield, Y0 = the starting inoculum, k = the first inflection point, and Xint = duration of the lag phase

According to the previously mentioned results in Table 5, macronutrients and micronutrients required for algal growth and biomass production are very poor. This can interpret the growth pattern shown in Fig. 3. Since levels of PO4, NO3, Ca, and Mg are 1.05, 0.08, 10.8, and 6.4 ppm in DT6W, respectively. This poorness, especially in nitrogen and phosphorus, is increasing the percentage of biodiesel in algal cells but decreasing the biomass and subsequently the biodiesel yield [60]. In large-scale production, this problem may be overcome by adding supplemental nutrients for increasing biomass production.

An evident trend can be observed in Table 7 where a general decrease in growth parameters (specific growth rate, number of cell divisions, speed of cell division, and biomass productivity) accompanies the increase of wastewater treatment duration, during which depletion of nutrients occurs. Nevertheless, these decreases are only detected as significant after 6 weeks of wastewater treatment and are only reflected in biomass productivity.

3.3 Photosynthetic pigments of C. sorokiniana grown in untreated and dual-treated SWW

The concentrations of photosynthetic pigment chlorophyll-a, -b, and total carotenoids in C. sorokiniana are shown in Fig. 4.

The concentrations of a chlorophyll-a, b chlorophyll-b, c total chlorophylls, d chlorophyll-a/b ratio, and e total carotenoids in C. sorokiniana grown in different durations of treatment with combined zeolite and bagasse nanoparticles. Values are means of three biological replicates ± SD. The same letter under the same time interval indicates no significant differences at p ≤ 0.05

The photosynthetic pigments in C. sorokiniana alga had the highest value at 0 day and decreased almost 50% after just 2 days. This can be interpreted by the photodegradation of photosynthetic pigments under the experimental light intensity in use which may be due to low cell density and low self-shading during the first 24 h. This last part of the interpretation agrees with Li et al. [61]. The photosynthetic pigments under untreated water and water treated for 2 weeks were similar throughout the whole experiment duration. Statistically significant differences were detected mostly in water treated for 6 weeks (lowest values in chlorophyll-a, total chlorophylls, chlorophyll-a/b ratio, and total carotenoids) and partly in 4-week treatment (slightly higher values). The explanation for that increase in chlorophyll-b concentration in DT6W at day 10 and the subsequent decrease of chlorophyll-a/b ratio could be due to the necessity of chlorophyll-b. The low cell density of C. sorokiniana grown in DT6W could lead to lower self-shading and higher light intensity for each cell. That could play a kind of photostress for chlorophyll-a molecules. During that light intensity level, chlorophyll-a molecules need the assistance of chlorophyll-b in absorbing more excess light photons and C. sorokiniana cells rearrange their light-harvesting antenna. These explanations are based on reviewing experimental data in another green microalga [62].

3.4 Endogenous growth regulators and enzymatic and non-enzymatic oxidative stress indicators

Concentrations of endogenous growth regulators and activities of enzymatic and concentration of non-enzymatic oxidative stress indicators in C. sorokiniana cells grown in untreated and dual-treated SWW for 10 days are shown in Table 8.

The results revealed significant decreases in concentrations of proline, abscisic acid (ABA), catalase (CAT), superoxide dismutase (SOD), malondialdehyde (MDA), total phenolic compounds, total flavonoids, and tocopherol as the duration of wastewater treatment increases, especially in treated wastewater for 6 weeks. On the other hand, concentrations of gibberellic acid (GA3) and ascorbic acid increased as the duration of wastewater treatment increased.

Proline plays a role in the regulation of osmotic balance and stress tolerance in green microalgae [63]. ABA is involved in the regulation of various physiological processes, including growth retardation and stress response [64]. Both SOD and CAT are antioxidant enzymes that help to protect cells from oxidative damage by converting superoxide radicals into less harmful forms which are reduced by CAT and other players [65]. MDA is a marker of lipid peroxidation and oxidative stress in cells [66]. Tocopherol, also known as vitamin E, has antioxidant properties and may help to protect against cellular damage [67,68,69]. Total phenolic compounds are secondary metabolites found in plants that have antioxidants [70]. Total flavonoids are classes of total phenolic compounds with potential health benefits due to their antioxidant activity [71]. Since there is a negative correlation among all these eight previously mentioned parameters from one side and the duration of wastewater treatment from another side. Thus, it can be inferred that C. sorokiniana cells grown in untreated SWW are suffering from oxidative stress because of the presence of high concentrations of Na and heavy metals.

GA3 is a plant hormone present in C. sorokiniana that promotes growth and development [72, 73]. Ascorbic acid, or vitamin C, also has antioxidant properties and may play a role in protecting cells from oxidative stress [69]. Both GA3 and ascorbic acid are positively correlated with the duration of wastewater treatment. This can be a result of growing C. sorokiniana cells in unpolluted water in DT4W and DT6W (from Table 5, the levels of Na, Cu, Fe, Ni, and Cd are 21.8, 1.2, 0.121, 0.011, and 0.002 ppm in DT4W and 11.5, 1, 0.11, 0.0078, and 0.0017 ppm in DT6W, respectively) avoiding oxidative stress and supporting cells to accumulate more proteins and carbohydrates as shown in Table 9. These very low levels of sodium and heavy metals ensure safe C. sorokiniana biomass for feedstuff [74, 75].

3.5 C. sorokiniana chemical and elemental analyses

In our way to validate our hypothesis that (1) dual-treated SWW after 4 and 6 weeks are suitable for C. sorokiniana growth and production of safe protein-rich biomass, (2) DT2W, DT4W, and DT6W are suitable growth media for C. sorokiniana for the purpose of producing biodiesel, chemical and elemental analyses of microalgal cells grown in untreated SWW and DT2W, DT4W, and DT6W were executed at the end of the experiment (day 10).

Our results in Table 9 show that the cellular lipids, proteins, and carbohydrates (%) significantly increase with increasing time of treatment, especially after 4 and 6 weeks. However, the productivities of lipids, proteins, and carbohydrates significantly differ earlier under wastewater remediated for 2 weeks when compared to untreated water. That is because the calculation of productivity depends not only on the component percentage but also on the cell dry weight, which is higher in UT, DT2W, and DT4W than this in DT6W. These results confirm our hypothesis that dual-treated SWW after 4 and 6 weeks are suitable for C. sorokiniana growth and production of safe protein-rich biomass (in DT4W, 26% and 32.7% and in DT6W, 31.8% and 34.9% proteins and carbohydrates, respectively).

Also, concentrations of nitrogen (N), phosphorus (P), potassium (K), calcium (Ca), magnesium (Mg), sodium (Na), and iron (Fe) in cells of C. sorokiniana cells grown for 10 days in UT, DT2W, DT4W, and DT6W are shown in Table 10. Our results reveal that the only element concentration that increased as the duration of wastewater treatment increased was nitrogen. This result interprets the increase of protein % with the duration of wastewater treatment increasing and in line with the Fourier-transform infrared spectroscopy (FTIR) results (Fig. 5). The rest of the elements measured in our experiments presented a decreasing trend as the duration of wastewater treatment increased. These results are in line with the UT, DT2W, DT4W, and DT6W analyses in Table 5.

Fourier-transform infrared (FTIR) spectroscopy was used to identify the functional groups of microalgal biomass and intracellular metabolites. The FTIR spectra of microalgal biomass showed the presence of peaks of alcohol (− OH at 3400 and 1470 cm−1), alkane (C–H at 2920 and 1470 cm−1), amine (N–H at 2860 cm−1 and C–N at 1020 cm−1), carboxyl (− COOH at 1750 cm−1), and ester (C–O–C at 1170 cm−1) groups. The FTIR analysis revealed the biochemical composition of microalgal biomass and confirmed its potential as a biofuel feedstock. The presence of alcohol, carboxyl, amino, ester, and aliphatic groups indicated that microalgal biomass contained proteins, carbohydrates, and lipids that can be converted into higher alcohols, bioethanol, and biodiesel, respectively.

3.6 Fatty acid profile and biodiesel characteristics

The results of this study, in Fig. 6, show that the content of heptadecanoic (C17:0), cis-10-heptadecanoic (C17:1), cis-9-oleic (C18:1), cis-9,12-linoleic (C18:2), and gamma-linolenic (C18:3) fatty acids in C. sorokiniana decreased in DT4W. However, the content of stearic (C18:0) and heneicosanoic (C21:0) fatty acids increased under the same treatment. The content of cis-9-oleic (C18:1) and cis-9,12-linoleic (C18:2) fatty acids significantly increased in DT6W compared to their values in DT4W. These results suggest that the treatment of wastewater with zeolite and bagasse nanoparticles for different periods can have a differential effect on the growth of C. sorokiniana alga by altering the content of certain fatty acids in the alga. The alterations in the fatty acid profiles lead to the alteration of biodiesel characteristics as shown in Table 11.

Major fatty acids in C. sorokiniana grown for 10 days in untreated sewage water (UT) and nanobagasse-nanozeolite double-treated sewage water for 2, 4, and 6 weeks (DT2W, DT4W, and DT6W, respectively). Bars represent the means of three biological replicates ± SD. The same letter on the same fatty acid bars indicates no significant differences at p ≤ 0.05

The estimated characteristics of biodiesel produced by C. sorokiniana grown for 10 days at UT, DT2W, DT4W, and DT6W show that the iodine value (IV) of all the biodiesel samples is lower than the EN 14214 limit, indicating a low degree of unsaturation and good oxidative stability. Moreover, the cetane number (CN) of all the biodiesel samples is higher than the ASTM D6751-20 and EN 14214 limits, indicating good ignition quality and low emissions. Also, the cold filter plugging point (CFPP) and cloud point (CP) of all the biodiesel samples are compatible with EN 14214 limits, indicating a good low-temperature performance. The oxidation stability (OS) of all the biodiesel samples is slightly higher than the EN 14214 limit, indicating a probability of low oxidation resistance. The viscosity (υ) of all the biodiesel samples is within the ASTM D6751-20 limits. However, the density (ρ) of all samples is less than the ASTM D6751-20 and EN 14214 limits. Overall, all biodiesel samples show characteristics that are well-compatible with diesel engines.

3.7 Physiology of C. sorokiniana in raw SWW and dual-treated media

In this section, we can conclude the physiological status of C. sorokiniana grown for 10 days (early stationary phase) in UT, DT2W, DT4W, and DT6W media. Figure 7 displays that C. sorokiniana grown at DT2W and DT4W have the same clade which is closer to those grown at UT than those grown at DT6W. Microalgal cells grown in UT medium have the highest values in growth parameters (SGR, DivT, BP, and CDW), oxidative stress indicators (ABA, proline, MDA, CAT, SOD, total phenolics, total flavonoids, and tocopherol), fatty acids (C17:0, C17:1, and C18:3), and some elements (phosphorus, Na, K, Mg, Ca, Fe, Cu, Cd, and Ni). They have the lowest values in generation time, protein %, carbohydrate %, lipid %, productivities of lipids and proteins, palmitic acid, nitrogen, GA3, and ascorbic acid. These results may refer to a suffering state of stress conditions. These cells suffer from heavy metals and imbalanced nutritive medium.

A heat map and two cluster hierarchies illustrate the relations among all studied parameters and treatments in C. sorokiniana grown for 10 days in untreated sewage wastewater (UT) and nanobagasse-nanozeolite double-treated sewage water for 2, 4, and 6 weeks (DT2W, DT4W, and DT6W, respectively). Red color represents the highest value, yellow color represents the middle value, and green color represents the lowest value. SGR, specific growth rate; DivT, division time; BP, biomass productivity; CDW, cell dry weight; ABA, abscisic acid; MDA, malondialdehyde; CAT, catalase; SOD, superoxide dismutase; CP, carbohydrate productivity; Chl-a, chlorophyll-a; T. Chl, total chlorophylls; Chl-a/b, the ratio between chlorophyll-a to chlorophyll-b; Chl-b, chlorophyll-b; T. Carot, total carotenoids; GenT, generation time; Prot, proteins; Carb, carbohydrates; GA3, gibberellic acid; LP, lipid productivity; PP, protein productivity

Vice versa, C. sorokiniana cells grown in DT6W have the lowest values in growth parameters (SGR, DivT, BP, and CDW), oxidative stress indicators (ABA, proline, MDA, CAT, SOD, total phenolics, total flavonoids, and tocopherol), photosynthetic pigments (chlorophyll-a, chlorophyll-b, total chlorophylls, total carotenoids, and chlorophyll-a to chlorophyll-b ratio), some fatty acids (C18:0 and C21:0), and some elements (phosphorus, Na, K, Mg, Ca, Fe, Cu, Cd, and Ni). They have the highest values in generation time, protein %, carbohydrate %, lipid %, productivities of lipids and proteins, C16:0, C17:0, C18:1, C18:2, nitrogen, GA3, and ascorbic acid. These results may reflect another kind of stress. These cells suffer from the nutrient deficit and imbalance.

The cells grown in DT2W and DT4W have less heavy metal and nutrient deficit stress. That is the reason why they have middle values of growth parameters and productivities of main chemical components.

4 Conclusions

This research developed a low-cost, effective prototype of a sustainable sewage wastewater (SWW) remediation process using zeolite and bagasse nanoparticles. All nanobagasse (NB)- and nanozeolite (NZ)-treated SWW recorded above 1 in Kelly ratio (KR). However, the double-treated SWW for 4 and 6 weeks show 0.94 and 0.67 of KR, respectively, which are suitable for irrigation. This decrease in KR may be due to the high ion exchange capacity of the mixture of NB and NZ. According to the water pollution index (WPI), all NB treatments and NZ2W produce good-quality water. NZ4W, NZ6W, and all types of double-treated (DT) treatments produce excellent-quality water. This may be due to the greater absorbent capacity of the nanoparticles’ mixture. DT treatments have the highest removal efficiencies for most parameters. This indicates that they are more effective in removing pollutants from the SWW than the NB or NZ alone. The longer the remediation time, the higher the removal efficiency. DT6W recorded the highest significant rank of removal efficiency of COD, BOD, TSS, TDS, PO4, NO3, Ca, Mg, Na, Cu, Cd, Fe, and Ni (72.7, 59.6, 88.6, 74, 56.7, 88.2, 72.7, 58.7, 80.7, 94.6, 91.1, 65.3, and 84.4%). DT4W and DT6W treatments may be the most suitable low-cost applicable technique used in septic tanks in rural areas. The organic matter will be removed by 63.6 to 72.7% as COD and up to 91.1 and 84.4% Cd and Ni, respectively. This kind of pre-remediation may save more than 50% of SWW remediation costs. This pre-remediated water may be collected to advanced remediation plants or used directly for irrigation purposes or as a safe culture medium for several species of microalgae for biomass and biodiesel dual-purpose production.

Also, this study validated our hypothesis that dual-treated SWW after 4 and 6 weeks are suitable for C. sorokiniana growth and production of safe protein-rich biomass. Moreover, it validated that DT2W, DT4W, and DT6W are suitable growth media for C. sorokiniana in the purpose of producing biodiesel. This biodiesel shows estimated characteristics compatible with diesel engines. Microalgal cells grown in UT medium have the highest values in growth parameters, oxidative stress indicators, fatty acids (C17:0, C17:1, and C18:3), and some elements (P, Na, K, Mg, Ca, Fe, Cu, Cd, and Ni). They have the lowest values in generation time, protein %, carbohydrate %, lipid %, productivities of lipids and proteins, palmitic acid, nitrogen, GA3, and ascorbic acid. This pattern is exactly the opposite pattern of C. sorokiniana cells grown in DT6W. Cells grown in UT may suffer from stressful conditions, heavy metals, and imbalanced nutritive medium. However, cells grown in DT6W may suffer from other kinds of stress, nutrient deficit, and imbalance. The cells grown in DT2W and DT4W have a less heavy metal and nutrient deficit and imbalance stresses. That is the reason they have middle values of growth parameters and productivities of main chemical components.

Data availability

Any required data can be sent upon request.

References

Shrestha S, Anal AK, Salam PA, Van der Valk M (2015) Managing water resources under climate uncertainty. Springer International. https://doi.org/10.1007/978-3-319-10467-6

UN-Habitat and WHO (2021) Progress on wastewater treatment — global status and acceleration needs for SDG indicator 6.3.1. United Nations Human Settlements Programme (UN-Habitat) and World Health Organization (WHO), Geneva. https://unhabitat.org/sites/default/files/2021/08/sdg6_indicator_report_631_progress_on_wastewater_treatment_2021_english_pages.pdf

WWAP (United Nations World Water Assessment Programme) (2017) The United Nations World Water Development Report 2017 Wastewater: The Untapped Resource Paris, UNESCO https://unesdoc.unesco.org/ark:/48223/pf0000247153

Sarmadi M, Foroughi M, Saleh H, Sanaei D, Zarei AA, Ghahrchi M, Bazrafshan E (2020) Efficient technologies for carwash wastewater treatment: a systematic review. Environ Sci Pollut Res 27:34823–34839. https://doi.org/10.1007/s11356-020-09741-w

Topare NS, Attar SJ, Manfe MM (2011) Sewage/wastewater treatment technologies: a review. Sci Revs Chem Commun 1(1):18–24. https://www.tsijournals.com/articles/sewagewastewater-treatment-technologies-a-review.pdf

Singh S, Kumar V, Romero R, Sharma K, Singh J (2019) Applications of nanoparticles in wastewater treatment In: Prasad R Kumar V Kumar M Choudhary D (Eds) Nanobiotechnology in Bioformulations Nanotechnology in the Life Sciences Springer Cham. 395–418 https://doi.org/10.1007/978-3-030-17061-5_17

Hlongwane GN, Sekoai PT, Meyyappan M, Moothi K (2019) Simultaneous removal of pollutants from water using nanoparticles: a shift from single pollutant control to multiple pollutant control. Sci Total Environ 656:808–833. https://doi.org/10.1016/j.scitotenv.2018.11.257

Ajiboye TO, Oyewo OA, Onwudiwe DC (2021) Simultaneous removal of organics and heavy metals from industrial wastewater: a review. Chemosphere 262:128379. https://doi.org/10.1016/j.chemosphere.2020.128379

Palani G, Trilaksana H, Sujatha RM, Kannan K, Rajendran S, Korniejenko K, Nykiel M, Uthayakumar M (2023) Silver nanoparticles for wastewater management. Molecules 28:3520. https://doi.org/10.3390/molecules28083520

Abel S, Jule LT, Belay F, Shanmugam R, Dwarampudi LP, Nagaprasad N, Krishnaraj R (2021) Application of titanium dioxide nanoparticles synthesized by sol-gel methods in wastewater treatment. J Nanomater 2021:1–6. https://doi.org/10.1155/2021/3039761

Jabbar KQ, Barzinjy AA, Hamad SM (2022) Iron oxide nanoparticles: preparation methods, functions, adsorption and coagulation/flocculation in wastewater treatment. Environ Nanotechnol Monit Manag 17:100661. https://doi.org/10.1016/j.enmm.2022.100661

Goutam SP, Saxena G, Roy D, Yadav AK, Bharagava RN (2020) Green synthesis of nanoparticles and their applications in water and wastewater treatment. Bioremediation of Industrial Waste. 349–379. https://doi.org/10.1007/978-981-13-1891-7_16

Gupta VK, Jain CK, Ali I, Sharma M, Saini VK (2003) Removal of cadmium and nickel from wastewater using bagasse fly ash—a sugar industry waste. Water Res 37(16):4038–4044. https://doi.org/10.1016/S0043-1354(03)00292-6

de Magalhães LF, da Silva GR, Peres AEC (2022) Zeolite application in wastewater treatment. Adsorpt Sci Technol. https://doi.org/10.1155/2022/4544104

U.S. Geological Survey Publications (2023) Zeolites (Natural). Ch in Mineral Commodity Summaries. https://pubs.usgs.gov/periodicals/mcs2023/mcs2023-zeolites.pdf

Ajala EO, Ighalo JO, Ajala MA, Anal AK, Salam PA (2021) Sugarcane bagasse: a biomass sufficiently applied for improving global energy, environment, and economic sustainability. Bioresour Bioprocess 8:87. https://doi.org/10.1186/s40643-021-00440-z

Taha SM, Amer ME, Elmarsafy AE, Elkady MY (2014) Adsorption of 15 different pesticides on untreated and phosphoric acid treated biochar and charcoal from water. J Environ Chem Eng 2(4):2013–2025. https://doi.org/10.1016/j.jece.2014.09.001

Mahmoud AWM, Abdelaziz SM, El-Mogy MM, Abdeldaym EA (2019) Effect of foliar ZnO and FeO nanoparticles application on growth and nutritional quality of red radish and assessment of their accumulation on human health. Agriculture 65:55–66. https://doi.org/10.2478/agri-2019-0002

Hassan AZA, Mahmoud AWM (2015) Hydrothermal synthesis of nano crystals (AM) zeolite using variable temperature programs. J Nanomater Mol Nanotechnol 4:4. https://doi.org/10.4172/2324-8777.1000168

Hossain M, Patra PK (2020) Water pollution index — a new integrated approach to rank water quality. Ecol Indic 117:106668. https://doi.org/10.1016/j.ecolind.2020.106668

Moursy ARA, Negim OIA (2022) Quality assessment and spatial variability mapping of water sources of Sohag Area. Egypt Alexandria J Soil Water Sci 6:63–77. https://doi.org/10.21608/ajsws.2022.161615.1004

AOAC (2023) Official methods of analysis (22nd ed.). Association of Official Agricultural Chemists International New York AOAC Publications. https://doi.org/10.1093/9780197610145.001.0001.

APHA (2005) Standard methods for the examination of water and wastewater (21st ed.) American Public Health Association /American Water Works Association/Water Environment Federation Washington DC

Eladel H, Abomohra AE-F, Battah M, Mohmmed S, Radwan A, Abdelrahim H (2019) Evaluation of C. sorokiniana isolated from local municipal wastewater for dual application in nutrient removal and biodiesel production Bioprocess. Biosyst Eng 42:425–433. https://doi.org/10.1007/s00449-018-2046-5

Stein JR (1973) Handbook of phycological methods: culture methods and growth measurements. Cambridge University Press

Peleg M, Corradini MG, Normand MD (2007) The logistic (Verhulst) model for sigmoid microbial growth curves revisited. Food Res Int 40(7):808–818. https://doi.org/10.1016/j.foodres.2007.01.012

Moheimani NR, Isdepsky BMA, Sing A, SF, (2012) Standard methods for measuring growth of algae and their composition. Springer, Netherlands 5:265–284. https://doi.org/10.1007/978-94-007-5479-9_16

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917. https://doi.org/10.1139/o59-099

ISO, U N I (2017) 12966–2 Animal and vegetables fat and oils gas chromatography of fatty acid methyl esters Part 2: preparation of methyl esters of fatty acids International Organization for Standardization: Geneva, Switzerland

Talebi AF, Tabatabaei M, Chisti Y (2014) BiodieselAnalyzer©: a user-friendly software for predicting the properties of prospective biodiesel. Biofuel Res J 2:55–57. https://www.biofueljournal.com/article_5546_5cf1b1819b042cb8fec2fea7415da6f9.pdf

ASTM_INTERNATIONAL (2020) Standard specification for biodiesel fuel blend stock (B100) for middle distillate fuels, ASTM D6751- 20a. https://www.astm.org/d6751-20a.html

ECS (2008) Automotive fuels: fatty acid methyl esters (FAME) for diesel engines: requirements and test methods, EN14214. https://www.en-standard.eu/bs-en-14214-2012-a2-2019-liquid-petroleum-products-fatty-acid-methyl-esters-fame-for-use-in-diesel-engines-and-heating-applications-requirements-and-test-methods

Helrich K (1990) Official methods of analysis 1:673. https://doi.org/10.1016/0003-2670(91)87088-o

Jackson ML (1973) Soil chemical analysis textbook Printice-Hall of India, Private Limited: New Delhi, India p 381

Garciadeblás B, Senn ME, Bañuelos MA, Rodríguez-Navarro A (2003) Sodium transport and HKT transporters: the rice model. Plant J 34(6):788–801. https://doi.org/10.1046/j.1365-313X.2003.01764.x

Bates LS, Waldren RA, Teare ID (1973) Rapid determination of free proline for water-stress studies. Plant Soil 39:205–207. https://doi.org/10.1007/BF00018060

Kupina S, Fields C, Roman MC, Brunelle SL (2018) Determination of total phenolic content using the Folin-C assay: single-laboratory validation. J AOAC Int 101:1466–1472. https://doi.org/10.5740/jaoacint.18-0031

Salerno L, Modica MN, Pittalà V, Romeo G, Siracusa MA, Giacomo C, Sorrenti V, Acquaviva R (2014) Antioxidant activity and phenolic content of microwave-assisted Solanum melongena extracts. Sci World J 2014:719486. https://doi.org/10.1155/2014/719486

Giannopotitis CN, Ries SK (1977) Superoxide dismutase in higher plants. Plant Physiol 59(2):309–314. https://doi.org/10.1104/pp.59.2.309

Stewart RR, Bewley JD (1980) Lipid peroxidation associated with accelerated aging of soybean axes. Plant Physiol 65(2):245–248. https://doi.org/10.1104/pp.65.2.245

Fales HM, Jaouni TM, Babashak JF (1973) Simple device for preparing ethereal diazomethane without resorting to codistillation. Anal Chem 45(13):2302–2303. https://doi.org/10.1021/ac60335a020

Senthilkumar M, Amaresan N and Sankaranarayanan A (2021) “Estimation of malondialdehyde (MDA) by thiobarbituric acid (TBA) assay” in Plant-microbe interactions (Humana New York NY Springer Protocols Handbooks). https://doi.org/10.1007/978-1-0716-1080-0

Wellburn AR (1994) The spectral determination of chlorophylls a and b as well as total carotenoids using various solvents with spectrophotometers of different resolution. J Plant Physiol 144(3):307–313. https://doi.org/10.1016/S0176-1617(11)81192-2

Katoch R (2011). Analytical techniques in biochemistry and molecular biology Springer Science & Business Media Berlin/Heidelberg Germany. https://doi.org/10.1007/978-1-4419-9785-2_15

Shah G, Nasir M, Imran M, Bakhat H, Rabbani F, Sajjad M, Farooq A, Ahmad S, Song L (2018) Biosorption potential of natural pyrolysed and acid-assisted pyrolysed sugarcane bagasse for the removal of lead from contaminated water. PeerJ 6:e5672. https://doi.org/10.7717/peerj.5672

Guo Y, Tan C, Sun J, Li W, Zhang J, Zhao C (2020) Porous activated carbons derived from waste sugarcane bagasse for CO2 adsorption. Chem Eng J 381:122736. https://doi.org/10.1016/j.cej.2019.122736

Amor C, Marchão L, Lucas M, Peres J (2019) Application of advanced oxidation processes for the treatment of recalcitrant agro-industrial wastewater: a review. Water. https://doi.org/10.3390/W11020205

Qu J, Tian X, Jiang Z, Cao B, Akindolie M, Hu Q, Feng C, Feng Y, Meng X, Zhang Y (2019) Multi-component adsorption of Pb(II), Cd(II) and Ni(II) onto microwave-functionalized cellulose: kinetics, isotherms, thermodynamics, mechanisms, and application for electroplating wastewater purification. J hazard mater 387:121718. https://doi.org/10.1016/j.jhazmat.2019.121718

Bahrodin M, Zaidi N, Kadier A, Hussein N, Syafiuddin A, Boopathy R (2022) A novel natural active coagulant agent extracted from the sugarcane bagasse for wastewater treatment. Appl Sci 12(16):7972. https://doi.org/10.3390/app12167972

Wang L, Xu S, He S, Xiao F (2018) Rational construction of metal nanoparticles fixed in zeolite crystals as highly efficient heterogeneous catalysts. Nano Today 20:74–83. https://doi.org/10.1016/j.nantod.2018.04.004

Irannajad M, Haghighi H (2021) Removal of heavy metals from polluted solutions by zeolitic adsorbents: a review. Environ Processes 8:7–35. https://doi.org/10.1007/s40710-020-00476-x

Gao F, Xiao L, Zhang H (2018) Potential of using synthesized nano-zeolite for ammonium and phosphate immobilization in dairy wastewater. J Dairy Res 85(3):375–378. https://doi.org/10.1017/S0022029918000560

Jafari M, Zendehdel R, Rafieepour A, Pour M, Irvani H, Khodakarim S (2019) Comparison of Y and ZSM-5 zeolite modified with magnetite nanoparticles in removal of hydrogen sulfide from air. Inter J Environ Sci Tech 17:187–194. https://doi.org/10.1007/s13762-019-02348-w

Yue Y, Guo X, Liu T, Liu H, Wang T, Yuan P, Zhu H, Bai Z, Bao X (2020) Template free synthesis of hierarchical porous zeolite beta with natural kaolin clay as alumina source. Microporous Mesoporous Mater 293:109772. https://doi.org/10.1016/j.micromeso.2019.109772

Sivalingam S, Sen S (2018) Rapid ultrasound assisted hydrothermal synthesis of highly pure nano-zeolite X from fly ash for efficient treatment of industrial effluent. Chemosphere 210:816–823. https://doi.org/10.1016/j.chemosphere.2018.07.091

Rad L, Anbia M (2021) Zeolite-based composites for the adsorption of toxic matters from water: a review. J environ chem eng 9(5):106088. https://doi.org/10.1016/j.jece.2021.106088

Güher H, Öterler B, Elipek B, Yeler O, Aydin G (2021) Spatial and temporal evaluation of physicochemical quality of drinking/using water in Kırklareli Reservoir (Turkish Thrace). J Serbian Chem Society 87(3):389–399. https://doi.org/10.2298/JSC210601074G

Yang Q, Li Z, Xie C, Liang J, Ma H (2020) Risk assessment of groundwater hydrochemistry for irrigation suitability in Ordos Basin China. Nat Hazards 101:309–325. https://doi.org/10.1007/s11069-018-3451-4

Bhardwaj S, Sharma R, Aggarwal R (2019) Suitability assessment of Sirsa River water for irrigation in Shiwalik Foothills of Northwestern Himalaya. Current World Environ 14(1):159–169. https://doi.org/10.12944/CWE.14.1.15

Zhu L, Li S, Hu T, Nugroho Y, Yin Z, Hu D, Chu R, Mo F, Liu C, Hiltunen E (2019) Effects of nitrogen source heterogeneity on nutrient removal and biodiesel production of mono- and mix-cultured microalgae. Energy Convers Manag 201:112144. https://doi.org/10.1016/j.enconman.2019.112144

Li Y, Han D, Hu G, Sommerfeld M, Hu Q (2010) Inhibition of starch synthesis results in overproduction of lipids in Chlamydomonas reinhardtii. Biotechnol Bioeng 107(2):258–268

Erickson E, Wakao S, Niyogi KK (2015) Light stress and photoprotection in Chlamydomonas reinhardtii. Plant J 82(3):449–465. https://doi.org/10.1111/tpj.12825

Fal S, Aasfar A, Rabie R, Smouni A, Arroussi ELH (2022) Salt induced oxidative stress alters physiological, biochemical and metabolomic responses of green microalga Chlamydomonas reinhardtii. Heliyon 8(1):e08811. https://doi.org/10.1016/j.heliyon.2022.e08811

Chen K, Li GJ, Bressan RA, Song CP, Zhu JK, Zhao Y (2020) Abscisic acid dynamics, signaling, and functions in plants. J Integr Plant Biol 62(1):25–54. https://doi.org/10.1111/jipb.12899

Gauthier MR, Senhorinho GNA, Scott JA (2020) Microalgae under environmental stress as a source of antioxidants. Algal Res 52:102104. https://doi.org/10.1016/j.algal.2020.102104

Tsikas D (2017) Assessment of lipid peroxidation by measuring malondialdehyde (MDA) and relatives in biological samples: analytical and biological challenges. Anal Biochem 524:13–30. https://doi.org/10.1016/j.ab.2016.10.021

Safafar H, van Wagenen J, Møller P, Jacobsen C (2015) Carotenoids, phenolic compounds and tocopherols contribute to the antioxidative properties of some microalgae species grown on industrial wastewater. Mar Drugs 13(12):7339–7356. https://doi.org/10.3390/md13127069

Hamidi M, Kozani PS, Kozani PS, Pierre G, Michaud P, Delattre C (2019) Marine bacteria versus microalgae: who is the best for biotechnological production of bioactive compounds with antioxidant properties and other biological applications? Mar Drugs 18(1):28. https://doi.org/10.3390/md18010028

Coulombier N, Jauffrais T, Lebouvier N (2021) Antioxidant compounds from microalgae: a review. Mar Drugs 19(10):549. https://doi.org/10.3390/md19100549

Zhang Y, Cai P, Cheng G, Zhang Y (2022) A brief review of phenolic compounds identified from plants: their extraction, analysis and biological activity. Nat Prod Commun 17(1). https://doi.org/10.1177/1934578X211069721

Shen N, Wang T, Gan Q, Liu S, Wang L, Jin B (2022) Plant flavonoids: classification, distribution, biosynthesis and antioxidant activity. Food Chem 383:132531. https://doi.org/10.1016/j.foodchem.2022.132531

Park WK, Yoo G, Moon M, Kim CW, Choi Y-E, Yang J-W (2013) Phytohormone supplementation significantly increases growth of Chlamydomonas reinhardtii cultivated for biodiesel production. Appl Biochem Biotechnol 171:1128–1142. https://doi.org/10.1007/s12010-013-0386-9

Han X, Zeng H, Bartocci P, Fantozzi F, Yan Y (2018) Phytohormones and effects on growth and metabolites of microalgae: a review. Fermentation 4(2):25. https://doi.org/10.3390/fermentation4020025

Gong X, Huang D, Liu Y, Zeng G, Chen S, Wang R, Xu P, Cheng M, Zhang C, Xue W (2019) Biochar facilitated the phytoremediation of cadmium contaminated sediments: metal behavior, plant toxicity and microbial activity. Sci total environ 666:1126–1133. https://doi.org/10.1016/j.scitotenv.2019.02.215

Marazzi F, Bellucci M, Rossi S, Fornaroli R, Ficara E, Mezzanotte V (2019) Outdoor pilot trial integrating a side stream microalgae process for the treatment of centrate under non optimal climate conditions. Algal Res 39:101430. https://doi.org/10.1016/j.algal.2019.101430

Acknowledgements

The authors are grateful to the Plant Physiology Division, Department of Agricultural Botany, and “Increasing Bio-fuel Productivity from Microalgae Grown in Nanotechnology-Treated Wastewater” Project, Faculty of Agriculture, Cairo University, for providing facilities and equipment to finalize this work.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). Present research work was supported by the “Increasing Bio-fuel Productivity from Microalgae Grown in Nanotechnology-Treated Wastewater” Project, Faculty of Agriculture, Cairo University.

Author information

Authors and Affiliations

Contributions

Sherif Morgan: conceptualization, funding acquisition, project administration, writing — review and editing.

M. A. W. Mahmoud: conceptualization, funding acquisition, investigation, methodology, project administration, resources, validation, supervision, writing — review and editing.

Shady Abdel Mottaleb: conceptualization, formal analysis, investigation, methodology, validation, writing — original draft, writing — review and editing.

Reham M. El-Bahbohy: investigation, methodology, validation, writing — original draft, writing — review and editing.

Mohamed Mahmoud-Aly: conceptualization, formal analysis, investigation, methodology, resources, validation, visualization, writing — original draft, writing — review and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Morgan, S.H., Mahmoud, M.A.W., Mottaleb, S.A. et al. A sustainable nanotechnology producing high-quality remediated sewage wastewater used for microalgal protein-rich biomass and biodiesel production. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05016-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05016-9