Abstract

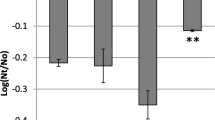

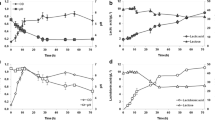

This research pivots around screening of idoneous lactic acid bacteria (LAB) from cow milk and subjecting them to adaptive evolution experiments to aid superior growth/robustness necessary for 3-phenyllactic acid (3-PLA) production. Conventional and statistical fermentation studies were conducted at batch scale using a non-axenic coculture of three novel LAB strains: Lactiplantibacillus plantarum str. nov. plantharim, Lactobacillus delbrueckki str. nov. delharim, and Pediococcus pentasaceous str. nov. pentharim. Statistically optimized fermentation using Box Behnken technique resulted in 1225 mg/L 3-PLA production using the growth medium: cheese whey—MRS medium mixture (5:2 ratio), phenylalanine (2.69% w/v), and glucose (9.6% w/v). Statistical optimization of fermentation parameters resulted in a substantial increase (17 times higher) compared to the non-optimized fermentation conditions (72 mg/L). Monad growth kinetics of the cow milk whey (CMW) coculture were calculated and estimated as: μmax = 0.336 h−1, Ks = 11.64 mg/mL, Yx/s = 0.835 mg/g, YP/S = 1.66 mg/g, YX/P = 0.112 mg/mg. The purified 3-PLA (1.93 mg/mL) showed antimicrobial activity with pathogenic bacteria like Pseudomonas aeruginosa, Escherichia coli, and Staphylococcus aureus, with a minimum inhibitory concentration of 12 mg/mL.

Similar content being viewed by others

Data availability

Schematic credits for Fig. 1 to FLATICON authors: amonrat rungreangfangsai, Freepik, Smashicons, Superarticons, wanicon, Paul J, photo3idea_studio, Vactor area, SBTS2018, rsetiawan, Darius Dan, Flat-icons-com, Pixelmeetup.

References

Virdis C, Sumby K, Bartowsky E, Jiranek V (2021) Lactic acid bacteria in wine: technological advances and evaluation of their functional role. Front Microbiol 11:612118. https://doi.org/10.3389/fmicb.2020.612118

Costa S, Summa D, Semeraro B, Zappaterra F, Rugiero I, Tamburini E (2021) Fermentation as a strategy for bio-transforming waste into resources: lactic acid production from agri-food residues. Fermentation 7(1):3. https://doi.org/10.3390/fermentation7010003

Rabaioli Rama G, Kuhn D, Beux S, Jachetti Maciel M, Souza C (2019) Potential applications of dairy whey for the production of lactic acid bacteria cultures. Int Dairy J 98:25–37. https://doi.org/10.1016/j.idairyj.2019.06.012

Escalante H, Castro L, Amaya MP, Jaimes L, Jaimes-Estévez J (2018) Anaerobic digestion of cheese whey: energetic and nutritional potential for the dairy sector in developing countries. Waste Manage 71:711–718. https://doi.org/10.1016/j.wasman.2017.09.026

Dopazo V, Illueca F, Luz C, Musto L, Moreno A, Calpe J et al (2023) Revalorization by lactic acid bacterial fermentation of goat whey from cheese industry as a potential antifungal agent. Food Bioscience 53:102586. https://doi.org/10.1016/j.fbio.2023.102586

Catone M, Palomino M, Legisa D, Fina Martin J, Monedero V, Ruzal S et al (2021) Lactic acid production using cheese whey based medium in a stirred tank reactor by a ccpA mutant of Lacticaseibacillus casei. World J Microbiol Biotechnol 37:61. https://doi.org/10.1007/s11274-021-03028-z

Rodríguez-Pazo N, da Silva SS, Salgado-Seara JM, Arni SA, de Souza Oliveira RP, Domínguez JM (2016) Optimisation of cheese whey enzymatic hydrolysis and further continuous production of antimicrobial extracts by Lactobacillus plantarum CECT-221. J Dairy Res 83(3):402–411. https://doi.org/10.1017/s0022029916000352

Rodríguez-Pazo N, Vázquez-Araújo L, Pérez-Rodríguez N, Cortés-Diéguez S, Domínguez JM (2013) Cell-free supernatants obtained from fermentation of cheese whey hydrolyzates and phenylpyruvic acid by Lactobacillus plantarum as a source of antimicrobial compounds, bacteriocins, and natural aromas. Appl Biochem Biotechnol 171(4):1042–1060. https://doi.org/10.1007/s12010-013-0408-7

Escrivá L, Manyes L, Vila-Donat P, Font G, Meca G, Lozano M (2021) Bioaccessibility and bioavailability of bioactive compounds from yellow mustard flour and milk whey fermented with lactic acid bacteria. Food Funct 12(22):11250–11261. https://doi.org/10.1039/D1FO02059E

Lappa IK, Papadaki A, Kachrimanidou V, Terpou A, Koulougliotis D, Eriotou E et al (2019) Cheese whey processing: integrated biorefinery concepts and emerging food applications. Foods (Basel, Switzerland) 8(8):347. https://doi.org/10.3390/foods8080347

Dopazo V, Illueca F, Luz C, Musto L, Moreno A, Calpe J et al (2023) Evaluation of shelf life and technological properties of bread elaborated with lactic acid bacteria fermented whey as a bio-preservation ingredient. LWT 174:114427. https://doi.org/10.1016/j.lwt.2023.114427

Jung S, Hwang H, Lee J-H (2019) Effect of lactic acid bacteria on phenyllactic acid production in kimchi. Food Control 106:106701. https://doi.org/10.1016/j.foodcont.2019.06.027

Mu W, Yu S, Zhu L, Zhang T, Jiang B (2012) Recent research on 3-phenyllactic acid, a broad-spectrum antimicrobial compound. Appl Microbiol Biotechnol 95(5):1155–1163. https://doi.org/10.1007/s00253-012-4269-8

Behera SS, El Sheikha AF, Hammami R, Kumar A (2020) Traditionally fermented pickles: how the microbial diversity associated with their nutritional and health benefits? J Funct Foods 70:103971. https://doi.org/10.1016/j.jff.2020.103971

Mora-Villalobos JA, Montero-Zamora J, Barboza N, Rojas-Garbanzo C, Usaga J, Redondo-Solano M et al (2020) Multi-product lactic acid bacteria fermentations: a review. Fermentation 6(1):23. https://doi.org/10.3390/fermentation6010023

Luo X, Zhang Y, Yin L, Zheng W, Fu Y (2020) Efficient synthesis of d-phenyllactic acid by a whole-cell biocatalyst co-expressing glucose dehydrogenase and a novel d-lactate dehydrogenase from Lactobacillus rossiae. 3 Biotech 10(1):14. https://doi.org/10.1007/s13205-019-2003-2

Liu J, Chan SHJ, Chen J, Solem C, Jensen PR (2019) Systems biology – a guide for understanding and developing improved strains of lactic acid bacteria. Front Microbiol. Sec Systems Microbiology 10(876). https://doi.org/10.3389/fmicb.2019.00876

Liu Changjian LQ, Jiang Bo, Sun Tianzhu, Yan Jianfang (2012) Isolation and identification of phenyllactic acid-producing LAB[J]. Sci Technol Food Ind (21):192–195. https://doi.org/10.13386/j.issn1002-0306.2012.21.049

Dieuleveux V, Van Der Pyl D, Chataud J, Gueguen M (1998) Purification and characterization of anti-Listeria compounds produced by Geotrichum candidum. Appl Environ Microbiol 64(2):800–803. https://doi.org/10.1128/aem.64.2.800-803.1998

Valerio F, Lavermicocca P, Pascale M, Visconti A (2004) Production of phenyllactic acid by lactic acid bacteria: an approach to the selection of strains contributing to food quality and preservation. FEMS Microbiol Lett 233(2):289–295. https://doi.org/10.1016/j.femsle.2004.02.020

Lavermicocca P, Valerio F, Evidente A, Lazzaroni S, Corsetti A, Gobbetti M (2000) Purification and characterization of novel antifungal compounds from the sourdough Lactobacillus plantarum strain 21B. Appl Environ Microbiol 66(9):4084–4090. https://doi.org/10.1128/aem.66.9.4084-4090.2000

Yu S, Zhu L, Zhou C, An T, Jiang B, Mu W (2013) Enzymatic production of D-3-phenyllactic acid by Pediococcus pentosaceus D-lactate dehydrogenase with NADH regeneration by Ogataea parapolymorpha formate dehydrogenase. Biotech Lett 36:627–631. https://doi.org/10.1007/s10529-013-1404-2

Sieuwerts S (2016) Microbial interactions in the yoghurt consortium: current status and product implications. SOJ Microbiol Infect Dis 4(2):1–5. https://doi.org/10.15226/sojmid/4/2/00150

Konstantinidis D, Pereira F, Geissen EM, Grkovska K, Kafkia E, Jouhten P et al (2021) Adaptive laboratory evolution of microbial co-cultures for improved metabolite secretion. Mol Syst Biol 17(8):e10189. https://doi.org/10.15252/msb.202010189

Bühlmann CH, Mickan BS, Tait S, Batstone DJ, Mercer GD, Bahri PA (2022) Lactic acid from mixed food waste fermentation using an adapted inoculum: influence of pH and temperature regulation on yield and product spectrum. Journal of Cleaner Production 373:133716. https://doi.org/10.1016/j.jclepro.2022.133716

Meruvu H, Donthireddy SRR (2014) Optimization studies for Chitinase production from Parapeneopsis hardwickii (spear shrimp) exoskeleton by solid-state fermentation with marine isolate Citrobacter freundii str. Nov. haritD11. Arabian J Sci Eng 39(7):5297–306. https://doi.org/10.1007/s13369-014-1117-4

Li X, Jiang B, Pan B, Mu W, Zhang T (2007) Effects of phenylalanine and phenylpyruvic acid on biosynthesis of phenyllactic acid with Lactobacillus sp. SK007. Chin J Proc Eng 7(6):1206. https://doi.org/10.1002/biot.201800478

Wu H, Guang C, Zhang W, Mu W (2021) Recent development of phenyllactic acid: physicochemical properties, biotechnological production strategies and applications. Crit Rev Biotechnol 43(2):293–308. https://doi.org/10.1080/07388551.2021.2010645

Bo J, Beilei PAN, Wanmeng MU, Fengli LIU (2008) Method for producing phenyl-lactic acid by controlling pH value, feeding and fermenting, Jiangnan University, 101333547, https://patentscope.wipo.int/search/en/detail.jsf?docPN=CN101333547

Kawaguchi H, Miyagawa H, Nakamura-Tsuruta S, Takaya N, Ogino C, Kondo A (2019) Enhanced phenyllactic acid production in Escherichia coli via oxygen limitation and shikimate pathway gene expression. Biotechnol J 14(6):1800478. https://doi.org/10.1002/biot.201800478

Yvon M, Thirouin S, Rijnen L, Fromentier D, Gripon JC (1997) An aminotransferase from Lactococcus lactis initiates conversion of amino acids to cheese flavor compounds. Appl Environ Microbiol 63(2):414–419. https://doi.org/10.1128/aem.63.2.414-419.1997

Jia J, Mu W, Zhang T, Jiang B (2010) Bioconversion of phenylpyruvate to phenyllactate: gene cloning, expression, and enzymatic characterization of D-and L1-lactate dehydrogenases from Lactobacillus plantarum SK002. Appl Biochem Biotechnol 162(1):242–251. https://doi.org/10.1007/s12010-009-8767-9

Meruvu H (2022) Redefining methods for augmenting lactic acid bacteria robustness and phenyllactic acid biocatalysis: integration valorizes simplicity. Crit Rev Food Sci Nut. Online ahead of print. https://doi.org/10.1080/10408398.2022.2141681

Meruvu H, Harsa ST (2022) Lactic acid bacteria: isolation–characterization approaches and industrial applications. Crit Rev Food Sci Nutri 1–20. https://doi.org/10.1080/10408398.2022.2054936

Li X, Jiang B, Pan B, Mu W, Zhang T (2008) Purification and partial characterization of Lactobacillus species SK007 lactate dehydrogenase (LDH) catalyzing phenylpyruvic acid (PPA) conversion into phenyllactic acid (PLA). J Agric Food Chem 56(7):2392–2399. https://doi.org/10.1021/jf0731503

Box G, Hunter S, Hunter W (2005) Statistics for experimenters. Design, innovation, and discovery. 2nd ed. 2 ed., vol 559 of Wiley Series in Probability and Statistics. https://pages.stat.wisc.edu/~yxu/Teaching/16%20spring%20Stat602/%5BGeorge_E._P._Box,_J._Stuart_Hunter,_William_G._Hu(BookZZ.org).pdf

Lunavath R, Mohammad SH, Bhukya KK, Barigela A, Banoth C, Banothu AK et al (2023) Antimycotic effect of 3-phenyllactic acid produced by probiotic bacterial isolates against Covid-19 associated mucormycosis causing fungi. PLOS ONE 18(3):e0279118. https://doi.org/10.1371/journal.pone.0279118

Xu H, Feng L, Deng Y, Chen L, Li Y, Lin L et al (2023) Change of phytochemicals and bioactive substances in Lactobacillus fermented Citrus juice during the fermentation process. LWT. 180(15 April):114715. https://doi.org/10.1016/j.lwt.2023.114715

Wang H, Shen F, Xiao R, Zhou Y, Dai Y (2013) Purification and characterization of antifungal compounds from Bacillus coagulans TQ33 isolated from skimmed milk powder. Ann Microbiol 63(3):1075–1081. https://doi.org/10.1007/s13213-012-0564-y

Dieuleveux V, Lemarinier S, Guéguen M (1998) Antimicrobial spectrum and target site of D-3-phenyllactic acid. Int J Food Microbiol 40(3):177–183. https://doi.org/10.1016/s0168-1605(98)00031-2

LaBauve AE, Wargo MJ (2012) Growth and laboratory maintenance of Pseudomonas aeruginosa. Current protocols in microbiology 25; Chapter 6: Unit 6E, 6E.1.1-6E.1.8. https://doi.org/10.1002/9780471729259.mc06e01s25

Aljumaah MR, Alkhulaifi MM, Abudabos AM (2020) In vitro antibacterial efficacy of non-antibiotic growth promoters in poultry industry. J Poult Sci 57(1):45–54. https://doi.org/10.2141/jpsa.0190042

Ansel HC, Norred WP, Roth IL (1969) Antimicrobial activity of dimethyl sulfoxide against Escherichia coli, Pseudomonas aeruginosa, and Bacillus megaterium. J Pharm Sci 58(7):836–839. https://doi.org/10.1002/jps.2600580708

Meruvu H (2023) Strategy for revalorization of cheese whey streams to produce phenyllactic acid. Engineering Proceedings, 2nd International Electronic Conference on Processes: Process Engineering—Current State and Future Trends (ECP 2023). MDPI: Basel, Switzerland (organizer). 37(1): 88. https://doi.org/10.3390/ECP2023-14708

Krieg NR, Ludwig W, Whitman WB, Hedlund BP, Paster BJ, Staley JT, Ward N, Brown D, Parte A (2010) [1984(Williams & Wilkins)]. George M. Garrity (ed.). The Bacteroidetes, Spirochaetes, Tenericutes (Mollicutes), Acidobacteria, Fibrobacteres, Fusobacteria, Dictyoglomi, Gemmatimonadetes, Lentisphaerae, Verrucomicrobia, Chlamydiae, and Planctomycetes. Bergey's Manual of Systematic Bacteriology. Vol. 4 (2nd ed.). New York: Springer. p. 908. ISBN 978-0-387-95042-6. British Library no. GBA561951

Wheeler D, Bhagwat M (2007) BLAST QuickStart: example-driven web-based BLAST tutorial. Methods Mol Biol 395:149–176. https://doi.org/10.1007/978-1-59745-514-5_9

Meruvu H (2019) Polyextremotolerant amylase produced from novel Enterococcus with potpourri of applications. Int J Pept Res Ther 25:1669–1678. https://doi.org/10.1007/s10989-019-09809-3

Yang X, Li J, Shi G, Zeng M, Liu Z (2019) Improving 3-phenyllactic acid production of Lactobacillus plantarum AB-1 by enhancing its quorum-sensing capacity. J Food Sci Technol 56(5):2605–2610. https://doi.org/10.1007/s13197-019-03746-1

Nabeel O (2022) IR spectroscopy in qualitative and quantitative analysis. In: Marwa E-A, Khalid A-S, Ahmed SE-S, editors. Infrared Spectroscopy. Rijeka: IntechOpen. p. Ch. 4. https://doi.org/10.5772/intechopen.106625

Wu W, Deng G, Liu C, Gong X, Ma G, Yuan Q et al (2020) Optimization and multiomic basis of phenyllactic acid overproduction by Lactobacillus plantarum. J Agric Food Chem 68(6):1741–1749. https://doi.org/10.1021/acs.jafc.9b07136

Lipinska-Zubrycka L, Klewicki R, Sojka M, Bonikowski R, Milczarek A, Klewicka E (2020) Anticandidal activity of Lactobacillus sp. in the presence of galactosyl polyols. Microbiol Res 240:126540. https://doi.org/10.1016/j.micres.2020.126540

Yu S, Zhou C, Zhang T, Jiang B, Mu W (2015) Short communication: 3-Phenyllactic acid production in milk by Pediococcus pentosaceus SK25 during laboratory fermentation process. J Dairy Sci 98(2):813–817. https://doi.org/10.3168/jds.2014-8645

Funding

This article is part of project work supported by the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No. 801509 and TÜBİTAK—2236 Co-Funded Brain Circulation Scheme 2: Project number 121C360, Dr. Haritha Meruvu (grant recipient) profoundly expresses her gratitude for the same.

Author information

Authors and Affiliations

Contributions

Haritha Meruvu: Project Coordinator/ Executive (experienced researcher), conceptualization, experimental design, resources, funding acquisition, writing—original draft, review, editing.

Corresponding author

Ethics declarations

Declarations

No case studies were involved so there are no requirements for consent to participate and consent for publication.

Ethical approval

This research work does not require ethical approval as no animals were used.

Competing interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meruvu, H. Enhanced production of 3-phenyllactic acid from novel non-axenic coculture: adaptive evolution and statistical fermentation studies. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04895-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04895-2