Abstract

Based on the suitability of the raw materials and treatment processes as well as the structural differences and complementarities of activated carbon prepared from coffee grounds (CG) and sludge, this study proposed a strategy to blend various sludge with the higher (50.91%) and lower (34.19%) ash contents into CG to prepare porous activated carbon for CO2 adsorption. Compared with sludge with higher ash content (HS), the activated carbon prepared from sludge with lower ash content (LS) had superior defect degree and carbon skeleton stability. Moreover, the activated carbon (CLSAC-20) derived from LS blended into coffee grounds under a ratio of 20% continued to optimize the structure of that from coffee grounds (CAC), which is mainly microporous. This was attributed to the LS exhibiting the structure-oriented role, which increased the pore volume (from 0.664 to 0.766 cm3/g) and specific surface area (from 1217.84 to 1355.65 m2/g). Because of the structural improvement achieved by LS blending, the CLSAC-20 had a better CO2 adsorption capacity (3.75 mmol/g) than CAC (3.27 mmol/g). Both were superior to commercial activated carbon (2.6 mmol/g) and the adsorption efficiencies still maintained above 90% after 5 cycles of regeneration. In summary, this study developed a simple, efficient, and environmentally friendly strategy to convert organic solid waste into high-value-added CO2 adsorbent.

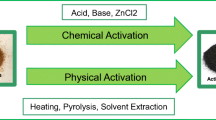

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Abbreviations

- BET:

-

Brunauer-Emmett-Teller

- BJH:

-

Barrett-Joyner-Halenda

- CAC:

-

Coffee grounds activated carbon

- CG:

-

Coffee grounds

- CHSAC-20:

-

Activated carbon prepared from 80% coffee grounds and 20% high-ash sludge

- CHSAC-35:

-

Activated carbon prepared from 65% coffee grounds and 35% high-ash sludge

- CHSAC-50:

-

Activated carbon prepared from 50% coffee grounds and 50% high-ash sludge

- CLSAC-20:

-

Activated carbon prepared from 80% coffee grounds and 20% low-ash sludge

- HS:

-

Sludge with higher ash content (50.91%)

- HSAC:

-

Activated carbon prepared from sludge with higher ash content (50.91%)

- LS:

-

Sludge with lower ash content (34.19%)

- LSAC:

-

Activated carbon prepared from sludge with lower ash content (34.19%)

- NLDFT:

-

Non-localized density functional theory

- SEM:

-

Scanning electron microscopy

References

Cheela VRS, Goel S, John M, Dubey B (2021) Characterization of municipal solid waste based on seasonal variations, source and socio-economic aspects. Waste Dispos Sustain Energy 3:275–288. https://doi.org/10.1007/s42768-021-00084-x

Shen T, Yan M, Xia Y et al (2022) Treatment of wastewater from food waste hydrothermal carbonization via Fenton oxidization combined activated carbon adsorption. Waste Dispos Sustain Energy 4:205–218. https://doi.org/10.1007/s42768-022-00106-2

Serafin J, Ouzzine M, Cruz OF et al (2021) Conversion of fruit waste-derived biomass to highly microporous activated carbon for enhanced CO2 capture. Waste Manag 136:273–282. https://doi.org/10.1016/j.wasman.2021.10.025

Wang L, Sha L, Zhang S et al (2022) Preparation of activated coke by carbonization, activation, ammonization and thermal treatment of sewage sludge and waste biomass for SO2 absorption applications. Fuel Process Technol 231:107233. https://doi.org/10.1016/j.fuproc.2022.107233

Xie D, Huang J, Wang Z et al (2023) Activated carbon derived from hydrochar of food waste for supercapacitor: effect of components on electrochemical performance. Fuel Process Technol 244:107691. https://doi.org/10.1016/j.fuproc.2023.107691

Li H, He X, Wu T et al (2022) Synthesis, modification strategies and applications of coal-based carbon materials. Fuel Process Technol 230:107203. https://doi.org/10.1016/j.fuproc.2022.107203

Bai J, Huang J, Yu Q et al (2023) One-pot synthesis of self S-doped porous carbon for efficient CO2 adsorption. Fuel Process Technol 244:107700. https://doi.org/10.1016/j.fuproc.2023.107700

Kabir SB, Khalekuzzaman M (2022) Co-liquefaction of organic solid waste with fecal sludge for producing petroleum-like biocrude for an integrated waste to energy approach. J Clean Prod 354:131718. https://doi.org/10.1016/j.jclepro.2022.131718

Martínez I, Kulakova V, Grasa G, Murillo R (2020) Experimental investigation on sorption enhanced gasification (SEG) of biomass in a fluidized bed reactor for producing a tailored syngas. Fuel 259:116252. https://doi.org/10.1016/j.fuel.2019.116252

Kamran U, Rhee KY, Lee S-Y, Park S-J (2022) Solvent-free conversion of cucumber peels to N-doped microporous carbons for efficient CO2 capture performance. J Clean Prod 369:133367. https://doi.org/10.1016/j.jclepro.2022.133367

Li D, Yang J, Zhao Y et al (2022) Ultra-highly porous carbon from wasted soybean residue with tailored porosity and doped structure as renewable multi-purpose absorbent for efficient CO2, toluene and water vapor capture. J Clean Prod 337:130283. https://doi.org/10.1016/j.jclepro.2021.130283

Serafin J (2017) Utilization of spent dregs for the production of activated carbon for CO2 adsorption. Pol J Chem Technol 19:44–50. https://doi.org/10.1515/pjct-2017-0026

Ghanbari T (2020) A review on production of metal organic frameworks (MOF) for CO2 adsorption. Sci Total Environ 707:135090. https://doi.org/10.1016/j.scitotenv.2019.135090

Kencana KS (2023) Enhancing the CO2 adsorption kinetics on Na-RHO and Cs-MER zeolites by NH4F/H2O2 etching induced mesoporosity. Chem Eng J 451:138520. https://doi.org/10.1016/j.cej.2022.138520

Serafin J, Narkiewicz U, Morawski AW et al (2017) Highly microporous activated carbons from biomass for CO2 capture and effective micropores at different conditions. J CO2 Util 18:73–79. https://doi.org/10.1016/j.jcou.2017.01.006

Guo Y, Tan C, Sun J et al (2020) Porous activated carbons derived from waste sugarcane bagasse for CO2 adsorption. Chem Eng J 381:122736. https://doi.org/10.1016/j.cej.2019.122736

Zhang Z, Lei Y, Li D et al (2020) Sudden heating of H3PO4-loaded coconut shell in CO2 flow to produce super activated carbon and its application for benzene adsorption. Renew Energy 153:1091–1099. https://doi.org/10.1016/j.renene.2020.02.059

Tran TKN, Ngo TCQ, Nguyen QV et al (2022) Chemistry potential and application of activated carbon manufactured from coffee grounds in the treatment of wastewater: a review. Mater Today: Proc 60:1914–1919. https://doi.org/10.1016/j.matpr.2022.01.020

Kusuma J, Indartono YS, Mujahidin D (2023) Biodiesel and activated carbon from arabica spent coffee grounds. MethodsX 10:102185. https://doi.org/10.1016/j.mex.2023.102185

Querejeta N, Gil MV, Rubiera F, Pevida C (2018) Sustainable coffee-based CO2 adsorbents: toward a greener production via hydrothermal carbonization: original research article: sustainable coffee-based CO2 adsorbents: toward a greener production via hydrothermal carbonization. Greenhouse Gas Sci Technol 8:309–323. https://doi.org/10.1002/ghg.1740

Travis W, Gadipelli S, Guo Z (2015) Superior CO2 adsorption from waste coffee ground derived carbons. RSC Adv 5:29558–29562. https://doi.org/10.1039/C4RA13026J

Mukherjee A (2021) Carbon dioxide capture from flue gas in biochar produced from spent coffee grounds: effect of surface chemistry and porous structure. J Environ Chem Eng 9(5):106049. https://doi.org/10.1016/j.jece.2021.106049

Liu S-H, Huang Y-Y (2018) Valorization of coffee grounds to biochar-derived adsorbents for CO2 adsorption. J Clean Prod 175:354–360. https://doi.org/10.1016/j.jclepro.2017.12.076

Gu S, He J, Zhu Y et al (2016) Facile carbonization of microporous organic polymers into hierarchically porous carbons targeted for effective CO2 uptake at low pressures. ACS Appl Mater Interfaces 8:18383–18392. https://doi.org/10.1021/acsami.6b05170

Zhuo H, Hu Y, Tong X et al (2016) Sustainable hierarchical porous carbon aerogel from cellulose for high-performance supercapacitor and CO2 capture. Ind Crop Prod 87:229–235. https://doi.org/10.1016/j.indcrop.2016.04.041

Huang Y-F, Chiueh P-T, Lo S-L (2019) CO2 adsorption on biochar from co-torrefaction of sewage sludge and leucaena wood using microwave heating. Energy Procedia 158:4435–4440. https://doi.org/10.1016/j.egypro.2019.01.772

Igalavithana AD, Choi SW, Shang J et al (2020) Carbon dioxide capture in biochar produced from pine sawdust and paper mill sludge: Effect of porous structure and surface chemistry. Sci Total Environ 739:139845. https://doi.org/10.1016/j.scitotenv.2020.139845

Liu C, Wu Y, Lan G et al (2022) CO2 capture performance of biochar prepared from sewage sludge after conditioning with different dewatering agents. J Environ Chem Eng 10:108318. https://doi.org/10.1016/j.jece.2022.108318

Li K, Niu X, Zhang D et al (2022) Renewable biochar derived from mixed sewage sludge and pine sawdust for carbon dioxide capture. Environ Pollut 306:119399. https://doi.org/10.1016/j.envpol.2022.119399

Alkasrawi M, Al-Othman A, Tawalbeh M et al (2021) A novel technique of paper mill sludge conversion to bioethanol toward sustainable energy production: Effect of fiber recovery on the saccharification hydrolysis and fermentation. Energy 223:120018. https://doi.org/10.1016/j.energy.2021.120018

Sanz-Santos E, Álvarez-Torrellas S, Larriba M et al (2022) Enhanced removal of neonicotinoid pesticides present in the Decision 2018/840/EU by new sewage sludge-based carbon materials. J Environ Manag 313:115020. https://doi.org/10.1016/j.jenvman.2022.115020

Hu Z, Ma X, Chen Y et al (2015) Co-combustion of coal with printing and dyeing sludge: numerical simulation of the process and related NOX emissions. Fuel 139:606–613. https://doi.org/10.1016/j.fuel.2014.09.047

Huang H, Liu J, Evrendilek F et al (2022) Bottom slag-to-flue gas controls on S and Cl from co-combustion of textile dyeing sludge and waste biochar: their interactions with temperature, atmosphere, and blend ratio. J Hazard Mater 435:129007. https://doi.org/10.1016/j.jhazmat.2022.129007

Pauline AL, Joseph K (2021) Hydrothermal carbonization of oily sludge for solid fuel recovery – investigation of chemical characteristics and combustion behavior. J Anal Appl Pyrolysis 157:105235. https://doi.org/10.1016/j.jaap.2021.105235

Hao B (2022) Hydrothermal liquefaction of municipal sludge: coupling effects of temperature and time on nitrogen migration. J Anal Appl Pyrolysis 165:105562. https://doi.org/10.1016/j.jaap.2022.105562

Lu J, Zhang Q, An Q et al (2022) Hierarchical porous carbon for high-performance capacitor derived from sewage sludge by KHCO3 activation. J Energy Storage 50:104644. https://doi.org/10.1016/j.est.2022.104644

Kim D (2022) Enhanced hydrogen production from anaerobically digested sludge using microwave assisted pyrolysis. Fuel 314:123091. https://doi.org/10.1016/j.fuel.2021.123091

Hakami O (2023) Urea-doped hierarchical porous carbons derived from sucrose precursor for highly efficient CO2 adsorption and separation. Surf Interfaces 37:102668. https://doi.org/10.1016/j.surfin.2023.102668

Wu M, Li X, Liu W et al (2022) Targeting application of hierarchical porous carbon by facile one-step site-specific activation of wood powder: CO2 adsorption and supercapacitors. J Electroanal Chem 920:116580. https://doi.org/10.1016/j.jelechem.2022.116580

Dresselhaus MS, Jorio A, Hofmann M et al (2010) Perspectives on carbon nanotubes and graphene Raman spectroscopy. Nano Lett 10:751–758. https://doi.org/10.1021/nl904286r

Liu S, Zuo P, Wang Y et al (2018) Nitrogen-doped ordered mesoporous carbon microspheres made from m-aminophenol-formaldehyde resin as promising electrode materials for supercapacitors. Microporous Mesoporous Mater 259:54–59. https://doi.org/10.1016/j.micromeso.2017.09.032

Lv Z, Li X, Chen X et al (2019) One-step site-specific activation approach for preparation of hierarchical porous carbon materials with high electrochemical performance. ACS Appl Energy Mater 2:8767–8782. https://doi.org/10.1021/acsaem.9b01729

Sun J, Niu J, Liu M et al (2018) Biomass-derived nitrogen-doped porous carbons with tailored hierarchical porosity and high specific surface area for high energy and power density supercapacitors. Appl Surf Sci 427:807–813. https://doi.org/10.1016/j.apsusc.2017.07.220

Lin G, Ma R, Zhou Y et al (2018) Three-dimensional interconnected nitrogen-doped mesoporous carbons as active electrode materials for application in electrocatalytic oxygen reduction and supercapacitors. J Colloid Interface Sci 527:230–240. https://doi.org/10.1016/j.jcis.2018.05.020

Yin W-J, Krack M, Wen B et al (2015) CO2 Capture and conversion on rutile TiO2 (110) in the water environment: insight by first-principles calculations. J Phys Chem Lett 6:2538–2545. https://doi.org/10.1021/acs.jpclett.5b00798

Wang H, Li X, Cui Z et al (2020) Coffee grounds derived N enriched microporous activated carbons: efficient adsorbent for post-combustion CO2 capture and conversion. J Colloid Interface Sci 578:491–499. https://doi.org/10.1016/j.jcis.2020.05.125

Ma C, Bai J, Demir M et al (2022) Water chestnut shell-derived N/S-doped porous carbons and their applications in CO2 adsorption and supercapacitor. Fuel 326:125119. https://doi.org/10.1016/j.fuel.2022.125119

García S, Gil MV, Martín CF et al (2011) Breakthrough adsorption study of a commercial activated carbon for pre-combustion CO2 capture. Chem Eng J 171:549–556. https://doi.org/10.1016/j.cej.2011.04.027

Meng F, Gong Z, Wang Z et al (2019) Study on a nitrogen-doped porous carbon from oil sludge for CO2 adsorption. Fuel 251:562–571. https://doi.org/10.1016/j.fuel.2019.04.046

Karimi M, Zafanelli LFAS, Almeida JPP et al (2020) Novel insights into activated carbon derived from municipal solid waste for CO2 uptake: synthesis, adsorption isotherms and scale-up. J Environ Chem Eng 8:104069. https://doi.org/10.1016/j.jece.2020.104069

Karimi M, Shirzad M, Silva JAC, Rodrigues AE (2022) Biomass/Biochar carbon materials for CO2 capture and sequestration by cyclic adsorption processes: a review and prospects for future directions. J CO2 Util 57:101890. https://doi.org/10.1016/j.jcou.2022.101890

Wawrzyńczak D, Panowski M, Majchrzak-Kucęba I (2019) Possibilities of CO2 purification coming from oxy-combustion for enhanced oil recovery and storage purposes by adsorption method on activated carbon. Energy 180:787–796. https://doi.org/10.1016/j.energy.2019.05.068

Nasri NS, Hamza UD, Ismail SN et al (2014) Assessment of porous carbons derived from sustainable palm solid waste for carbon dioxide capture. J Clean Prod 71:148–157. https://doi.org/10.1016/j.jclepro.2013.11.053

Álvarez-Gutiérrez N, García S, Gil MV et al (2014) Towards bio-upgrading of biogas: biomass waste-based adsorbents. Energy Procedia 63:6527–6533. https://doi.org/10.1016/j.egypro.2014.11.688

Luu CL, Nguyen TTV, Nguyen T, Hoang TC (2015) Synthesis, characterization and adsorption ability of UiO-66-NH2. Adv Nat Sci Nanosci Nanotechnol 6:025004. https://doi.org/10.1088/2043-6262/6/2/025004

Karimi M, Shirzad M, Silva JAC, Rodrigues AE (2023) Carbon dioxide separation and capture by adsorption: a review. Environ Chem Lett 21:2041–2084. https://doi.org/10.1007/s10311-023-01589-z

Funding

This study was funded by National Natural Science Foundation (Nos. 52170141, 52236008, and 52206178), the Key Research and Development Program of Zhejiang Province (No. 2022C03092), and the State Key Laboratory of Clean Energy Utilization (Open Fund Project No. ZJUCEU2021002).

Author information

Authors and Affiliations

Contributions

Zehuang Zhang: investigation, methodology, and writing–original draft; Qianqian Guo: methodology and writing—review and editing; Long Jiao and Nan Zhou: resources and data curation; Xu Wang and Mingzhe Li: investigation and methodology; Yanjun Hu: conceptualization, validation, and supervision.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Zehuang Zhang and Qianqian Guo contribute to the work equally.

Highlights

• Blending LS increased pore volume from 0.664 to 0.766 cm3/g.

• Blending LS showed a higher defect level and better carbon skeleton structure.

• The pore structure improvement was attributed to structure-oriented role of LS.

• CLSAC-20 behaved the maximum CO2 adsorption capacity of 3.75 mmol/g.

• The performances of CLSAC-20 and CAC were superior to commercial activated carbon.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Z., Guo, Q., Jiao, L. et al. Insights into the microstructure evolution and CO2 adsorption of activated carbon derived from spent coffee grounds and sewage sludge. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04878-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04878-3