Abstract

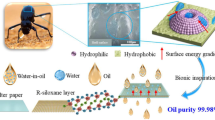

Degradable materials have been used for the preparation of oil-water separation membranes, especially cellulose-based membranes. However, the extraction of cellulose nanofibers is time, energy, and chemically intensive and the source of cellulose is mainly wood, bamboo, cotton, and flax. Herein, we report a top-down approach for the scalable production of structurally asymmetric composite cellulose membranes from loofah. The tear strength of the membrane was 388.7% times of the PVDF membrane and the preparation cost was only 3.3% of the price of commercially available nitrocellulose membrane. A superhydrophobic renewable and degradable cellulose membrane with a surface water contact angle of 152.3°can be prepared by a one-step method using the cellulose membrane as a substrate and dodecyltriethoxysilane as a modifier. The superhydrophobic cellulose membrane could separate oil and water by continuous filtration with high efficiency (98.1%) and high flux (2349Lm-2h-1). Such a simple and low-cost method could promote the popularity of separation membranes.

Similar content being viewed by others

Data availability

There is no dataset provided with this submission.

References

Schrope M (2010) Deepwater Horizon: a scientist at the centre of the spill. Nature 466:680–684. https://doi.org/10.1038/466680a

Jernelöv A (2010) How to defend against future oil spills. Nature 466:182–183. https://doi.org/10.1038/466182a

Ge J, Zhao H, Zhu H et al (2016) Advanced sorbents for oil-spill cleanup: recent advances and future perspectives. Adv Mater 28:10459–10490. https://doi.org/10.1002/adma.201601812

Deng Y, Peng C, Dai M et al (2020) Recent development of super-wettable materials and their applications in oil-water separation. Journal of Cleaner Production 266:121624. https://doi.org/10.1016/j.jclepro.2020.121624

Rasouli S, Rezaei N, Hamedi H et al (2021) Superhydrophobic and superoleophilic membranes for oil-water separation application: a comprehensive review. Materials & Design 204:109599. https://doi.org/10.1016/j.matdes.2021.109599

Ryerson TB, Camilli R, Kessler JD et al (2012) Chemical data quantify Deepwater Horizon hydrocarbon flow rate and environmental distribution. Proceedings of the National Academy of Sciences 109:20246–20253. https://doi.org/10.1073/pnas.1110564109

McNutt MK, Chu S, Lubchenco J et al (2012) Applications of science and engineering to quantify and control the Deepwater Horizon oil spill. Proceedings of the National Academy of Sciences 109:20222–20228. https://doi.org/10.1073/pnas.1214389109

Qiu L, Sun Y, Guo Z (2020) Designing novel superwetting surfaces for high-efficiency oil-water separation: design principles, opportunities, trends and challenges. Journal of Materials Chemistry A 8:16831–16853. https://doi.org/10.1039/d0ta02997a

Jing L, Wang L, Wang N et al (2017) A robust Cu (OH)2 nanoneedles mesh with tunable wettability for nonaqueous multiphase liquid separation. Small 13:1600499. https://doi.org/10.1002/smll.201600499

Gondal MA, Sadullah MS, Qahtan TF et al (2017) Fabrication and wettability study of WO3 coated photocatalytic membrane for oil-water separation: a comparative study with ZnO coated membrane. Sci Rep 7:1686. https://doi.org/10.1038/s41598-017-01959-y

Hou L, Wang L, Wang N et al (2016) Separation of organic liquid mixture by flexible nanofibrous membranes with precisely tunable wettability. NPG Asia Mater 8:e334–e334. https://doi.org/10.1038/am.2016.179

Kota AK, Kwon G, Choi W et al (2012) Hygro-responsive membranes for effective oil–water separation. Nature Communications 3:1025. https://doi.org/10.1038/ncomms2027

Zhang C, Liang F, Zhang W et al (2020) Constructing mechanochemical durable and self-healing superhydrophobic surfaces. ACS Omega 5:986–994. https://doi.org/10.1021/acsomega.9b03912

Ge M, Cao C, Huang J et al (2018) Rational design of materials interface at nanoscale towards intelligent oil–water separation. Nanoscale Horizons 3:235–260. https://doi.org/10.1039/C7NH00185A

Zhang J, Seeger S (2011) Polyester materials with superwetting silicone nanofilaments for oil/water separation and selective oil absorption. Advanced Functional Materials 21:4699–4704. https://doi.org/10.1002/adfm.201101090

Lin J, Lin F, Liu R et al (2020) Scalable fabrication of robust superhydrophobic membranes by one-step spray-coating for gravitational water-in-oil emulsion separation. Separation and Purification Technology 231:115898. https://doi.org/10.1016/j.seppur.2019.115898

Li L, Xu Z, Sun W et al (2020) Bio-inspired membrane with adaptable wettability for smart oil/water separation. Journal of Membrane Science 598:117661. https://doi.org/10.1016/j.memsci.2019.117661

Zhang W, Shi Z, Zhang F et al (2013) Superhydrophobic and superoleophilic PVDF membranes for effective separation of water-in-oil emulsions with high flux. Advanced Materials 25:2071–2076. https://doi.org/10.1002/adma.201204520

Lu KJ, Zhao D, Chen Y et al (2020) Rheologically controlled design of nature-inspired superhydrophobic and self-cleaning membranes for clean water production. npj Clean. Water 3:1–10. https://doi.org/10.1038/s41545-020-0078-2

Peng Y, Zhu W, Shen S et al (2017) Strain-induced surface micro/nanosphere structure: a new technique to design mechanically robust superhydrophobic surfaces with rose petal-like morphology. Advanced Materials Interfaces 4:1700497. https://doi.org/10.1002/admi.201700497

Wang D, Sun Q, Hokkanen MJ et al (2020) Design of robust superhydrophobic surfaces. Nature 582:55–59. https://doi.org/10.1038/s41586-020-2331-8

Leslie HA, van Velzen MJM, Brandsma SH et al (2022) Discovery and quantification of plastic particle pollution in human blood. Environment International 163:107199. https://doi.org/10.1016/j.envint.2022.107199

Hussain SM, Braydich-Stolle LK, Schrand AM et al (2009) Toxicity evaluation for safe use of nanomaterials: recent achievements and technical challenges. Advanced Materials 21:1549–1559. https://doi.org/10.1002/adma.200801395

Hu R, Yang J, Li S et al (2020) Fabrication of special wettability functionalized Mg (OH)(2)@cotton fabric for oil/water mixtures and emulsions separation. Cellulose 27:7739–7749. https://doi.org/10.1007/s10570-020-03315-2

Wang X, Xu S, Tan Y et al (2016) Synthesis and characterization of a porous and hydrophobic cellulose-based composite for efficient and fast oil–water separation. Carbohydrate Polymers 140:188–194. https://doi.org/10.1016/j.carbpol.2015.12.028

Peng Q, Cheng J, Lu S, Li Y (2020) Electrospun hyperbranched polylactic acid–modified cellulose nanocrystals/polylactic acid for shape memory membranes with high mechanical properties. Polymers for Advanced Technologies 31:15–24. https://doi.org/10.1002/pat.4743

Wang D-C, Yang X, Yu H-Y et al (2020) Smart nonwoven fabric with reversibly dual-stimuli responsive wettability for intelligent oil-water separation and pollutants removal. Journal of Hazardous Materials 383:121123. https://doi.org/10.1016/j.jhazmat.2019.121123

Gao S, Dong X, Huang J et al (2018) Rational construction of highly transparent superhydrophobic coatings based on a non-particle, fluorine-free and water-rich system for versatile oil-water separation. Chemical Engineering Journal 333:621–629. https://doi.org/10.1016/j.cej.2017.10.006

Li Z, Chen C, Xie H et al (2021) Sustainable high-strength macrofibres extracted from natural bamboo. Nat Sustain. 5:235–244. https://doi.org/10.1038/s41893-021-00831-2

Xing T, Dong C, Wang X et al (2022) Biodegradable, superhydrophobic walnut wood membrane for the separation of oil/water mixtures. Front Chem Sci Eng 16:1377–1386. https://doi.org/10.1007/s11705-022-2157-z

Popescu CM, Popescu MC, Vasile C (2011) Structural analysis of photodegraded lime wood by means of FT-IR and 2D IR correlation spectroscopy. International Journal of Biological Macromolecules 48:667–675. https://doi.org/10.1016/j.ijbiomac.2011.02.009

Liu C, Wang S, Shi J, Wang C (2011) Fabrication of superhydrophobic wood surfaces via a solution-immersion process. Applied Surface Science 258:761–765. https://doi.org/10.1016/j.apsusc.2011.08.077

Arkles B, Larson GL (2013) Silicon compounds: silanes & silicones, 3rd edn. Gelest, Inc., Morrisville, PA

Labbé N, Rials TG, Kelley SS et al (2005) FT-IR imaging and pyrolysis-molecular beam mass spectrometry: new tools to investigate wood tissues. Wood Sci Technol 39:61–76. https://doi.org/10.1007/s00226-004-0274-0

Funding

The authors profusely thank the Natural Science Foundation of China [grant number 51776070], and the State Grid Science and Technology Program [SGGNSW00YWJS2100024].

Author information

Authors and Affiliations

Contributions

Changqing Dong and Xiaoying Hu contributed to conceptualization and methodology. Tong Xing contributed to the investigation, data analysis, and writing the original draft and all other authors contribute to the review, editing, and preparation of the final draft. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xing, T., Dong, C., Hu, X. et al. Cellulose membranes via a top-down approach from loofah for oil/water separation. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03766-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03766-0