Abstract

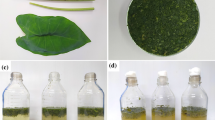

The alcohol industry is material-intensive, where the cost of grain on the production of ethyl alcohol exceeds 60% of the total production costs. The most effective way to use agricultural raw materials is the introduction of new plants. Plants from the Asteraceae family are a promising alternative source due to their inulin content that can be used for ethyl alcohol production. However, the fermentation of alternative raw materials might bring undesirable sub-products that compromise the quality of the ethyl alcohol, such as fuse oil, ester, and aldehyde. This article aims to obtain ethyl alcohol from four alternative plants that belong to the Asteraceae family. To do so, we evaluated the ethyl alcohol production from raw materials from four different plant species from the Asteraceae family: Helianthus tuberosus L., Dahlia, Cichorium intybus L., and Arctium lappa L. Our findings revealed that, after the first distillation, the alcohol content ranged between 5 and 12%. The concentration of waste products (fuse oil, ester, and aldehyde) can decrease to 1519 mg dm−3 after adsorption with activated carbon and calcium oxide. Therefore, those four plants are viable alternatives to alcohol production due to their inulin content. These alternative plant materials can improve the state of the alcohol and alcoholic beverage industry, and the introduction of new technologies presented here can potentially increase the profitability of bioethanol production.

Similar content being viewed by others

References

Zhukova YA, Naydanova MV, Mezenova OY (2011) Obtaining bioethanol from polysaccharide-containing raw materials of the Kaliningrad region. News of higher educational institutions. Food Technol 5(6):51–54

Chemical Encyclopaedical Dictionary (2005) – p. 792

Shoaib M, Shehzad A, Omar M, Rakha A, Raza H, Sharif HR, Shakeel A, Ansari A, Niazi S. Properties, health benefits and food applications. Carbohydrate Polymers 147:444–454

Apolinário AC, Damasceno BPGL, Beltrão NEM, Pessoa A, Converti A, da Silva JA (2014) Inulin-type fructans: a review on different aspects of biochemical and pharmaceutical technology. Carbohydr Polym 101:368–378

Abou-Arab AA, Talaat HA, Abu-Salem FM (2011) Physico-chemical properties of inulin produced from Jerusalem artichoke tubers on bench and pilot plant scale. Aust J Basic Appl Sci 5(5):1297–1309

Prangviset K, Songpim M, Yodsuwan N, Wannawilai S, Dejsungkranont M, Changlek P, Sirisansaneeyakul S (2018) Fructose production from Jerusalem artichoke using mixed inulinases. Agric Nat Resour 52(2):132–139

Viriyasuthee W, Jogloy S, Saksirirat W, Saepaisan S, Gleason ML, Chen RS (2019) Biological control of Alternaria leaf spot caused by Alternaria spp. in Jerusalem artichoke (Helianthus tuberosus L.) under two fertilization regimes. Plants 8(11):463

Mu Y, Gao W, Lv S, Li F, Lu Y, Zhao C (2021) The antioxidant capacity and antioxidant system of Jerusalem artichoke (Helianthus tuberosus L.) tubers in relation to inulin during storage at different low temperatures. Ind Crops Prod 161:113229

Paixão SM, Alves L, Pacheco R, Silva CM (2018) Evaluation of Jerusalem artichoke as a sustainable energy crop to bioethanol: energy and CO2eq emissions modeling for an industrial scenario. Energy 150:468–481

Dzhanaev KI, Gobeev VN (2012) Perspective of using the biomass of Jerusalem artichoke of the Skorospelka variety for bioethanol production. News Gorsky State Agrar Univ 1–2:396–398

Ananyina NA, Andreeva OA, Oganesyan ET (2008) Polysaccharides of Dahlia single l. Chemistry of vegetable raw materials. 2:135-136

Umarova FA, Khabibullayeva NH, Kychkorova UO, Mansurov AH (2019) Development of tincture technology from the burdock plant Arctium lappa L. Sci Time 5(65):86–89

Babaeva EY, Burova AE, Voroshilov AI (2015) On the quality of the roots of burdock (Arctium lappa L.) depending on the modes of drying. Vestnik PFUR, Med Ser 1:113–114

Dyakova NA (2015) Development and validation of express methods of quantitative determination of water-soluble polysaccharides in the roots of burdock (Arctium lappa L.). Chemicopharm J 49(9):35–38

Chirkova YN, Arkhipov IV (2018) Rational use of fusel oil - waste of bioethanol production. ICNS "Science and Education" Best student article 2018 collection of articles of the XVIII International research competition. 68–70

Azimbaeva GE, Kudaibergenova GN, Butin BM, Sharipova SA (2016) Method of inulin production from Dahlia variabilis. Bull Sci Educ Dev 2:6–10

Holt R (1954) Volumetric determination of pectin as calcium pectate. Analyst 79(943):623–627

Kamysbaeva AK, Azimbaeva GE (2021) Biologically active substances of some species of the genus Asteraceae. Bull Natl Eng Acad Repub Kazakhstan 1:62–69

Moldes AB, Alonso JL, Parajo JC (2001) Strategies to improve the bioconversion of processed wood into lactic acid by simultaneous saccharification and fermentation. J Chem Technol Biotechnol 76(3):279–284

Yarovenko VL, Marinchenko VA, Smirnov VA (2002) Technology of alcohol Moscow: Kolos, Kolos-press, 3–10

GOST 5964–93 (2005) Ethyl alcohol. Acceptance rules and analysis methods. Interstate Council for standardization. Metrol Certif Minsk 2–6

Kalashnik O, Remisova N, Rachinska Z (2016) The study of quality and safety parameters of the special vodka of native production. EUREKA: Life Sci (3):8–13. https://doi.org/10.21303/2504-5695.2016.00142

GOST 5962–2013 (2014) Group H74 rectified ethyl alcohol from food raw materials. Interstate standard Moscow, 6–8

Serbaeva ER, Yakupova AB, Magasumova YR, Farhutdinova KA, Akhmetova GR, Kuluev BR (2020) Kuluev. Inulin: natural sources, features of metabolism in plants and practical application. Biomica 12(1):57–79

Chuprova NA, Ryazanova TV (2010) Obtaining bioethanol from the vegetative part of Jerusalem artichoke. Chem Plant Raw Mater 2:49–52

Kovalev AA, Ryazanova TV, Chuprova NA (2016) Complex processing of Jerusalem artichoke to obtain bioethanol. Federal state budgetary educational institution of higher education Siberian state University of science and technology named after academician M. F. Reshetnev (Krasnoyarsk) Reshetnev Read 2:312–313

Akhmedov HM, Partoev K, Tashbaev GA (2015) Chemical composition, biological and economic productivity of Jerusalem artichoke. Proceedings of the Academy of Sciences of the Republic of Tajikistan. Dep Phys Math Chem Geol Tech Sci 3(160):124–131

Lim S-H, Ryu J-M, Lee H, Jeon JH, Sok D-E, Choi E-S (2011) Ethanol fermentation from Jerusalem artichoke powder using Saccharomyces cerevisiae KCCM50549 without pretreatment for inulin hydrolysis. Biores Technol 102(2):2109–2111

Matías J, Encinar JM, González J, González JF (2015) Optimisation of ethanol fermentation of Jerusalem artichoke tuber juice using simple technology for a decentralised and sustainable ethanol production. Energy Sustain Dev 25:34–39

Güneş A, Kordali Ş, Turan M, Bozhüyük AU (2019) Determination of antioxidant enzyme activity and phenolic contents of some species of the Asteraceae family from medicinal plants. Ind Crops Prod 137:208–213

Zhukova YuA, Mezenova OY (2011) Technology for production of bioethanol from wheat straw. Vestn Int Acad Refrig 4:21–25

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Azimbayeva, G.E., Kamysbayeva, A.K., Sagimbayeva, A.E. et al. Production of ethyl alcohol from plants of the Asteraceae family. Biomass Conv. Bioref. 13, 9775–9781 (2023). https://doi.org/10.1007/s13399-022-02840-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02840-3