Abstract

Bio-flocculation is a sustainable low-cost harvesting technique for microalgae biomass production; however, it is generally less efficient than chemical flocculants. This study aims to investigate the efficiency of Moringa oleifera seeds as a bio-flocculant for harvesting Tetradesmus dimorphus biomass. Four extracts from integral and residual (seeds without lipids) biomass of M. oleifera seeds using salt or aqueous solutions were used at four concentrations (100, 200, 300, and 400 ppm). Flocculation efficiency (FE) increased as the pH decreased. The addition of the extracts reduced the pH of the cultures, dispensing pH adjustment after dosing the flocculating agent. Salt extracts exhibited higher flocculation efficiency than aqueous extracts. The highest flocculation efficiency (~ 98%) was obtained using a salt extract of residual biomass of seeds in any concentration varying from 100 to 400 ppm. The predicted values obtained from a data modeling using response surface methodology approached the real values (r2 = 0.9382), resulting in an adequate optimization of the flocculant concentration of ~ 335 ppm and pH 5.6 for a predicted FE of ~ 106%. The findings of the present study confirmed that the salt extract from residual biomass of M. oleifera seeds is an effective bio-flocculant for T. dimorphus biomass harvesting.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Microalgae are organisms that convert light energy into chemical energy using efficient photosynthetic pathways and thus complete quickly their life cycle [1, 2]. The high diversity of microalgae species results in a wide range of metabolites produced from the primary and secondary metabolism of these microorganisms. Amino acids, fatty acids, carotenoids, and saccharides are some of the main metabolites synthesized by microalgae. This diversity of metabolites produced by microalgae can make the biomass of these microorganisms one of the most promising raw materials for sustainable development of agricultural industries, new drugs such as antibodies for vaccines, in addition to the potential use for biofuel production [3,4,5].

Microalgae from Scenedesmaceae (i.e., Acutodesmus, Scenedesmus, and Tetradesmus genera) present great potential for these applications. In short, the biomass of microalgae from this family can contain up to 60% of lipids, and under certain growing conditions, these compounds may be favorable for higher quality biodiesel production. Some studies have reported lipid productivity of about 200 mg L−1 day−1 [6, 7], and according to Arias-Peñaranda et al. [8], oil from a Scenedesmaceae strain had low viscosity, low oxidative power, and a high content of oleic acid—crucial factors for high-quality biodiesel [7].

Even after many years of research, economically viable biodiesel from microalgae is still unrealistic and unsustainable owing to expensive harvesting techniques—it represents 20 to 30% of production costs [9, 10]. Different methods have been investigated for microalgal biomass harvesting: filtration [11], centrifugation [12], electral based [13, 14], and flocculation [15]. However, the choice of an ideal method depends on cell size, culturing volume, biomass application intended for the final product destination, and the cost involved in the process [16].

Among the non-energy-intensive (and maybe low costly) methods, flocculation is an efficient method for harvesting both high- and low-density microalgae cultures. In summary, the addition of a flocculating agent neutralizes part of the negative charge on microalgal cell walls, reducing cellular repulsion [16, 17]. Polyvalent metal salts [FeCl3 and Fe2(SO4)3], cationic polymers (chitosan), and some starches (based on rice, maize, tapioca, etc.) are among the most commonly used flocculants to harvest microalgae biomass [18, 19]. Therefore, for flocculation to be ideally applicable for large-scale biomass harvesting, cheap, safe, and easily produced flocculants need to be explored.

Moringa oleifera is a common tree in several tropical and subtropical countries from Africa, America, and Asia. The wide diversity of metabolites produced by M. oleifera enables its application in nutrition [20], pharmaceuticals [21], and even in water treatment [22]. The usage of M. oleifera seeds for water treatment has been applied to low-income regions due to its abundant availability, low cost, biodegradability, and non-toxicity. These characteristics make it a promising bio-flocculant for microalgae biomass harvesting [23, 24]. Therefore, the objective of this work was to evaluate the efficiency of M. oleifera seeds as a bio-flocculant for harvesting Tetradesmus dimorphus biomass. The effects of seed concentration and processing method on flocculation efficiency, pH, and impacts on fatty acid profile and biodiesel properties were explored.

2 Materials and methods

2.1 Microalgal strain, culture medium, and culture conditions

Tetradesmus dimorphus strain was supplied by the Microalgae Culture Collection from Laboratório de Produção de Alimento Vivo (LAPAVI) at the Universidade Federal Rural de Pernambuco, Brazil. Cultures were kept in Provasoli’s medium (pH 7.0) [25].

Tetradesmus dimorphus was grown in semicontinuous mode, and cultures were maintained in the exponential growth phase. The seed culture was grown photoautotrophically in 2-L Erlenmeyer flasks for 7 days, using the same culture medium, under 300 μmol photons m−2 s−1 irradiance. Then, the seed culture was transferred to a 20-L fiberglass tank, and finally, this culture was used to inoculate a 200-L fiberglass tank. All cultures were kept at 27 ± 1 °C, pH between 7 and 8, and with constant homogenization with atmospheric air. Qualitative and quantitative monitoring of cultures (cell concentration and viability, and eventual contaminations by bacteria or protozoa) was performed periodically using a hemocytometer and an optical microscope.

2.2 Plant material and preparation of bio-flocculants from M. oleifera seeds

Seed pods of M. oleifera were collected from Pernambuco state, Brazil, and the taxa were properly identified and deposited in the Dárdano de Andrade Lima herbarium at the Instituto Agronômico de Pernambuco, Brazil (n°. 73.345). The desired seeds were unshelled from dry pods manually and then naturally dried in the sunlight for three days.

After complete drying of the seeds, they were crushed and stored in a freezer at − 20 °C. Lipids from half of the seeds were extracted using n-hexane by the classical method of Soxhlet [26]. The seed powder without lipids was called residual biomass of seeds (RBS). Another half was used in integral form and then called integral biomass of seeds (IBS). Both RBS and IBS were used for the production of aqueous (RBS − A and IBS − A) and salt (RBS − S and IBS − S) extracts. Briefly, a 10% mixture (w/v) of seed biomasses and deionized water was homogenized by a magnetic shaker for 16 h at 25 °C. After that, the solution was filtered (0.45-μm fiberglass micro-filter) and centrifugated (at 9000 × g for 15 min), and the supernatant (aqueous extract) was collected and stored. For salt extracts (RBS − S and IBS − S), a solution of NaCl (0.15 M) was added to RBS and IBS biomasses (also at 10%, w/v) which were then homogenized, filtered, centrifugated, and stored at the same conditions described above.

2.3 Flocculation experiments

The 200-L culture of T. dimorphus (in stationary growth phase) with a cell concentration of 9.5 × 106 cells mL−1 (equivalent biomass of approximately 1.0 g L−1), and a pH of 8.5, was fractionated in 1-L glass beakers for flocculation experiment. A two-factorial design (4 × 4) was used to evaluate the flocculation efficiency (FE): factor 1, four types of extract (RBS − A, IBS − A, RBA − S, and IBS − S), and factor 2, four concentrations of the extracts (100, 200, 300, and 400 ppm; equivalent to 10, 20, 30, and 40 mL of stocking solutions, respectively). The flocculation experiment was performed with three independent replicates for each treatment.

After bio-flocculants dosing, cultures were mixed for 2 min at 100 rpm using a magnetic shaker to ensure homogenization of the flocculants in the experimental units. Then, the cultures were allowed to settle for 1 h. A flowchart of microalgae culture scale-up and flocculation proceedings is shown in Fig. 1.

After 1 h of settle, a 10-mL aliquot was pipetted at a height two-thirds from the bottom of the beaker. The cell concentration of this aliquot sample was calculated to determine the flocculation efficiency (FE). The FE was determined using Eq. (1):

where Ci and Cf imply the cell concentration of the microalgal culture before and after flocculation, respectively. The pH of the microalgal culture after bio-flocculant dosing was measured using a pH meter (model 350 M, analyzer).

2.4 Lipids extraction and fatty acid quantification

Lipids were extracted according to the classical method of Bligh and Dyer [27] with some modifications. One gram of dry biomass was mixed with 20 mL of chloroform/methanol (1:1 v/v), vortexed for 2 min, incubated twice in an ultrasonic bath for 15 min, and then cooled on ice for 5 min. The sample was then centrifuged at 10,000 × g for 15 min. The supernatant was transferred to a new tube, and 7.5 mL of Milli-Q water was added and again vortexed for 2 min, followed by new centrifugation (at 10,000 × g for 5 min). The sample was carefully transferred to a separatory funnel, and after 1 h, the organic phase was collected. The solvent was evaporated, and the lipid sample was transesterified with 0.5 mL of KOH in methanol followed by homogenization in the vortex for 2 min. Subsequently, 2 mL of vortexed n-hexane was added for 2 min and centrifuged (at 4500 × g for 6 min). The nonpolar phase was collected, filtered (Millipore 0.22 μm), and stored in vials.

The analysis of fatty acid methyl esters (FAMEs) was performed in a gas chromatograph (7890A model, Agilent Technologies) equipped with a flame ionization detector and coupled to the capillary column DB5 − MS (30 m × 0.32 mm × 0.25 μm; Agilent Technologies). The injection volume was 1 μL with a split rate of 100:1. The heating ramp started with an isotherm of 150 °C for 5 min, followed by a heating rate of 4 °C min−1 until the temperature reached 280 °C, and maintained for 5 min. The temperatures of the detector and the injector were adjusted to 300 °C.

The identification of the FAMEs was performed by comparison with the retention time of an authentic standard (Fatty Acid Methyl Ester mix SupelcoTM C4–C24) and the quantification by a percentage based on the area normalization of the obtained peaks.

2.5 Biodiesel properties

The quality of the potential biodiesel to be produced was investigated based on the physical and chemical properties of the FAMEs. The unsaturation degree (DU), kinematic viscosity (υi, mm2 s−1), specific gravity (SG, kg−1), cloud point (CP, °C), cetane number (CN), iodine value (IV, g I2/100 g oil), and higher heating value (HHV, MJ kg−1) were calculated according to Hoekman et al. [28] using the following equations:

where N is the number of carbon–carbon double bonds in fatty acid constituent and Mf is the mass fraction of fatty acid constituent.

2.6 Statistical analysis

The FE, pH, FAMEs, and properties of biodiesel were statistically analyzed using a two-way ANOVA, followed by a post hoc means comparison test. The assumptions of normality (Jarque–Bera test) and homogeneity (Levene test) were previously tested. For all analyses, a level of significance of 0.05 was adopted. All the analyses were performed using RStudio software (Version 3.1.1; R Core Team 2015).

Response surface methodology was conducted with a Box–Behnken design (BBD) also using RStudio software and using RMS package [29]. The BBD with two independent variables (X1 = pH, X2 = dosage of flocculant) at three levels (− 1, 0, + 1) was used. The response variable (Y) that represented the FE was fitted to a second-order model in the form of a quadratic polynomial equation:

where n is the number of independent variables and β0, βi, βii, and βij represent the regression coefficients for the constant, linear, quadratic, and interaction between Xi and Xj terms, respectively.

3 Results and discussion

3.1 Flocculation efficiency

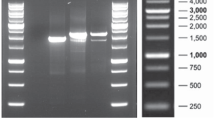

The four flocculants (RBS − A, RBS − S, IBS − A, and IBS − S) were efficient in the harvesting of T. dimorphus biomass (Fig. 2). Significant differences (p < 0.05) were found between two factors (processing type and concentration), their combination, and also in relation to the control (no bio-flocculant dosing). Lower FE were observed for aqueous extracts from both integral biomass of seeds (IBS − A), at the four concentrations evaluated, ranging from 29.86 ± 1.06% to 46.07 ± 2.74% at 100 and 400 ppm, and also for the residual biomass of seeds (RBS − A), at 100 (47.45 ± 2.64%) and 200 (54.47 ± 1.03%) ppm. At higher concentrations (i.e., 300 and 400 ppm) RBS − A treatment presented FE of 81.13 ± 5.17% and 87.93 ± 1.05%, an efficiency similar (p > 0.05) to the IBS − S at 100 (84.07 ± 3.66%) and 200 (87.80 ± 1.86%) ppm. Nevertheless, higher FE found in the present study were with the use of IBS − S at higher concentrations (92.10 ± 0.50% and 95.83 ± 0.45% at 300 and 400 ppm, respectively) and for all concentrations of RBS − S (ranging from 96.30 ± 0.50 to 98.70 ± 0.29% at 100 and 400 ppm). However, even at the lowest concentration, the FE using RBS − S had similar values (p > 0.05).

Mean values (n = 3) of flocculation efficiency of Tetradesmus dimorphus biomass using Moringa oleifera seeds at different concentrations. Bars indicate standard deviation. RBS − A: aqueous extract from residual biomass of seeds; RBS − S: salt extract from residual biomass of seeds; IBS − A: aqueous extract from integral biomass of seeds; and IBS − S: salt extract from residual biomass of seeds

Flocculating agents from M. oleifera seeds have poor precipitation ability and can be hard to dissolve in water. According to Madrona et al. [30], certain concentrations of salt solution can be beneficial for the flocculant to get an effective dissolution. Therefore, in the present study, the salt extracts (RBS − S and IBS − S) cation probably increased the surface charge of protein molecules promoting positive interaction with water and then accelerating protein dissolution [31]. This can justify the differences in FE for salt over aqueous extracts. In a recent study conducted by Wen et al. [31], a maximum FE of 83.13% of Chlorella vulgaris biomass using M. oleifera extracts microspheres at 0.7 g L−1 was reported. These authors showed that pH plays a more important role than ionic strength in harvesting efficiency. Other results of harvesting microalgae biomass using M. oleifera were summarized in Table 1.

The use of M. oleifera seeds without lipids (RBS − A and − S) improved the FE in comparison to integral seeds. This fact can be attributed to the polarity of lipids that make them poorly water soluble. Thus, these molecules may have acted as a chemical barrier in the extraction of intracellular compounds from seeds. The M. oleifera seeds can contain more than 35% of lipids and 45% (w/w) of oleic acid, and several studies have been reported these seeds as promising raw materials for biodiesel production [35,36,37]. Therefore, the use of seeds after lipid extraction for efficient flocculation of T. dimorphus biomass may represent a potential integrated chain of high sustainability for the production of biodiesel from M. oleifera seeds and T. dimorphus biomass.

3.2 pH changes and interactions between variables

Changes in pH values after flocculant dosing are shown in Table 2. The addition of any flocculants to the T. dimorphus culture promoted a reduction in pH when compared to the control (8.2 ± 0.01). The lowest pH value (a mean reduction of 2.47 in relation to the control) was found with the use of the flocculant RBS − S at 400 ppm; on the other hand, the highest pH (a mean reduction of 0.13 compared to the control) was reported for the flocculant IBS − A at 100 ppm.

Data represent mean ± standard deviation (n = 3). Different uppercase and lowercase letters on the same line represent a significant difference between the flocculants and the concentrations, respectively, by Tukey’s test at 5% of significance. RBS − A: aqueous extract from residual biomass of seeds; RBS − S: salt extract from residual biomass of seeds; IBS − A: aqueous extract from integral biomass of seeds; and IBS − S: salt extract from residual biomass of seeds.

Wen et al. [31] showed that an adjustment of pH from 2.0 to 7.0 increases FE from 61 to 89% of C. vulgaris biomass using M. oleifera extracts, which suggests that FE improved under neutral conditions. Nevertheless, Yang et al. [32] reported that M. oleifera has a fixed Zeta potential (− 2.29 mV) across the range of pH values between 2.0 and 12.0, in contrast to the flocculants tanfloc, chitosan, and cationic starch, that have a positive Zeta potential across acid − pH and negative in neutral/basic − pH. This stability of the Zeta potential in M. oleifera extracts suggests that the coagulation of microalgal cells does not depend on the pH value of the medium. However, in the present study, FE showed an inverse relationship with pH values.

To demonstrate the optimal levels of variables (pH and flocculant concentration) to harvest T. dimorphus biomass, the response surface methodology was used for the optimization of the flocculation process (Fig. 3). The strong correlation (r2 = 0.9382) between real and predicted values confirmed that the response model was adequate to reflect the expected optimization (Fig. 3A). Moreover, a three-dimensional surface plot (Fig. 3B) was constructed according to Eq. (9). In general, the concentration of the flocculant has the best effect on the FE only at pH between 7 and 8. On the other hand, at a pH close to 6, the FE remains almost stable irrespective of the concentration. Regardless of the way seeds were processed, the optimized conditions obtained using the response surface methodology were as follows: flocculant concentration, ~ 335 ppm; pH, 5.6; for a predicted FE of ~ 106%.

3.3 FAMEs and biodiesel properties

Although the model suggested a concentration close to 300 ppm, the value used was 100 ppm for the RBS − S extract to assess the quality of the FAMEs since it did not differ significantly from the higher concentrations. Furthermore, using a lower concentration would inevitably result in less use of M. oleifera seeds.

Towards a detailed evaluation of the impacts of the use of a salt extract of M. oleifera residual seeds (RBS − S) at lower concentration (i.e., 100 ppm), we compared the T. dimorphus biomass harvested using this flocculant agent with centrifugated biomass in terms of FAMEs profile and also the suitability of FAMEs as biodiesel feedstock. The main FAMEs found in the T. dimorphus biomass using the flocculating agent RBS-S were very similar to those obtained by the centrifugation process (Fig. 3A and C). The FAMEs found in greater percentages in the biomass of T. dimorphus, regardless of the harvesting methodology, were oleic (C18:1), palmitic (C16:0), linoleic (C18:2), and nervonic (C24:1) acids. Meanwhile, the biodiesel properties did not show significant differences (p < 0.05) between harvesting methodology (Fig. 3B and D), and in general, vi, SG, CN, and IV showed close values to the main international standards (ASTM D6751 and EN14214).

In the stationary growth phase, some microalgae tend to accumulate certain reserve compounds in greater amounts, such as saturated fatty acids and carbohydrates. For example, the lack of nitrogen in the medium can limit protein biosynthesis, thus increasing the lipid-to-protein ratio [38]. Furthermore, the biosynthesis of unsaturated fatty acids has a higher chemical energy demand (mainly in ATP and NADPH forms) than the biosynthesis of saturated fatty acids. Therefore, this leads microalgae cells to produce more saturated fatty acids in the stationary growth phase in order to reduce energy expenditure [39], which is why the FAME profile of T. dimorphus biomass can be attributed not only to taxon characteristics, but also to the phase of the growth curve.

Wang et al. [40] and Oliveira et al. [17] have shown that the flocculation of a Scenedesmaceae taxon (i.e., Tetradesmus obliquus) using chemical compound and cationic polymer, respectively, was efficient in terms of biomass harvesting and biodiesel quality. These studies suggest that, due to the higher yield of FAMEs, the better physical and chemical properties of biodiesel and the lower energy consumption, the flocculation process is considered superior to centrifugation from an economic point of view. However, it is worth emphasizing that for pharmacological and food applications, the use of chemical flocculants is not recommended, as there may be possible residues of flocculating agents in the microalgal biomass. Nonetheless, the use of flocculants from a natural source such as seeds from M. oleifera may become a promising option not only for biodiesel production but also for nutraceutical applications, enabling microalgae biorefinery models [41] (Fig. 4).

Radar plots depicting main fatty acid methyl esters and biodiesel properties from Tetradesmus dimorphus harvested using the saline extract from residual biomass of Moringa oleifera seeds (A and C) and centrifugation (B and D).C12:0, lauric acid; C16:0, palmitic acid; C18:0, stearic acid; C18:1, oleic acid; C18:2, linoleic acid; C24:1, nervonic acid; vi, kinematic viscosity; SG, specific gravity; CP, cloud point; CN, cetane number; IV, iodine value; HHV, higher heating value

Regarding the biodiesel properties, saturated fatty acids improve biodiesel viscosity and density and generally have a higher calorific value releasing more energy than unsaturated fatty acids [42, 43]. The values for vi and CN remained within the recommended by European (EN 14,214) and American (ASTM D6751) standards. The EN 14,214 sets a maximum limit of IV of 120, which gives good oxidative stability of biodiesel. According to El-Sheekh et al. [44], the IV value is correlated to the levels of PUFAs—lower PUFAs result in a lower IV. It is worth noting that regulation in Brazil (ANP 07/2008) renewed the requirement to maintain the mandatory blending of 10% of biodiesel in the fossil diesel sold in the country. As a result, there was negative repression to try to stop this obligation (which has been in force since 2008), due to the increase in the soybeans price in recent years due to the COVID-19 pandemic. Soybeans represent around 90% of the Brazilian biodiesel energy matrix [45], and new raw materials such as microalgae biomass can become a competitive alternative for the Brazilian scenario [46, 47]. Considering that there is also a great abundance of M. oleifera in Brazil [48] and that some studies have already indicated that the seeds of this plant are favorable for the production of biodiesel [36], a mixture of oils from M. oleifera seeds and T. dimorphus biomass (harvested from the residual seeds), seems to be a promising biorefinery with high sustainability.

4 Conclusions

Seeds from M. oleifera showed to be an effective natural flocculant for T. dimorphus biomass harvesting, obtaining flocculation efficiencies up to 90%. We found that the concentration of M. oleifera seed extracts was less determinant than the pH on the flocculation efficiency. Moreover, the way of processing seeds can also affect the flocculation efficiency—salt extracts exhibited higher flocculation efficiency than aqueous extracts. Finally, the highest flocculation efficiency (~ 98%) was obtained using a salt extract of residual biomass of seeds in any concentration varying from 100 to 400 ppm.

References

Ratha SK, Prasanna R (2012) Bioprospecting microalgae as potential sources of “Green Energy”—challenges and perspectives. Appl Biochem Microbiol 48(2):109–125

Prasad R, Gupta SK, Shabnam N, Oliveira CYB, Nema AK, Ansari FA, Bux F (2021) Role of microalgae in global CO2 sequestration: physiological mechanism, Recent Development, Challenges, and Future Prospective. Sustainability 13(23):13061

Tibbetts SM, Milley JE, Lall SP (2015) Chemical composition and nutritional properties of freshwater and marine microalgal biomass cultured in photobioreactors. J Appl Phycol 27(3):1109–1119

Roy SS, Pal R (2015) Microalgae in aquaculture: a review with special references to nutritional value and fish dietetics. In Proceedings of the Zoological Society 68(1):1–8 (Springer India)

Chew KW, Yap JY, Show PL, Suan NH, Juan JC, Ling TC et al (2017) Microalgae biorefinery: high-value products perspectives. Bioresour Technol 229:53–62

Damiani MC, Popovich CA, Constenla D, Martínez AM, Doria E, Longoni P et al (2014) Triacylglycerol content, productivity and fatty acid profile in Scenedesmus acutus PVUW12. J Appl Phycol 26(3):1423–1430

Oliveira CYB, Oliveira CDL, Prasad R, Ong HC, Araujo ES, Shabnam N, Gálvez AO (2021) A multidisciplinary review of Tetradesmus obliquus: a microalga suitable for large-scale biomass production and emerging environmental applications. Rev Aquac 13(3):1594–1618

Arias−Peñaranda MT, Cristiani−Urbina E, Montes−Horcasitas C, Esparza−Garcı́a F, Torzillo G, Cañizares−Villanueva RO (2013) Scenedesmus incrassatulus CLHE−Si01: a potential source of renewable lipid for high quality biodiesel production. Bioresour Technol 140:158–164

Molina−Grima E, Belarbi EH, Fernández FA, Medina AR, Chisti Y (2003) Recovery of microalgal biomass and metabolites: process options and economics. Biotechnol Adv 20(7–8):491–515

Mathimani T, Mallick N (2018) A comprehensive review on the harvesting of microalgae for biodiesel–key challenges and future directions. Renew Sust Energ Rev 91:1103–1120

Giménez JB, Bouzas A, Carrere H, Steyer JP, Ferrer J, Seco A (2018) Assessment of cross−flow filtration as microalgae harvesting technique before anaerobic digestion: evaluation of biomass integrity and energy demand. Bioresour Technol 269:188–194

Dassey AJ, Theegala CS (2013) Harvesting economics and strategies using centrifugation for cost-effective separation of microalgae cells for biodiesel applications. Bioresour Technol 128:241–245

Ramos LC, Batista R, Carneiro DC, Sousa LJ, Sales AN, Lima STC (2020) Evaluation of electroflocculation harvesting on the antioxidant activity and toxicity of extracts from the microalgae Isochrysis galbana and Phaeodactylum tricornutum. J Appl Phycol 32(6):3853–3859

Gao S, Yang J, Tian J, Ma F, Tu G, Du M (2010) Electro−coagulation–flotation process for algae removal. J Hazard Mater 177(1–3):336–343

Vandamme D, Foubert I, Muylaert K (2013) Flocculation as a low−cost method for harvesting microalgae for bulk biomass production. Trend Biotechnol 31(4):233–239

Barros AI, Gonçalves AL, Simões M, Pires JC (2015) Harvesting techniques applied to microalgae: a review. Renew Sust Energ Rev 41:1489–1500

Oliveira CYB, Viegas TL, Lopes RG, Cella H, Menezes RS, Soares AT et al (2020) A comparison of harvesting and drying methodologies on fatty acids composition of the green microalga Scenedesmus obliquus. Biomass Bioenerg 132:105437

Wyatt NB, Gloe LM, Brady PV, Hewson JC, Grillet AM, Hankins MG, Pohl PI (2012) Critical conditions for ferric chloride-induced flocculation of freshwater algae. Biotechnol Bioeng 109(2):493–501

Blockx J, Verfaillie A, Thielemans W, Muylaert K (2018) Unravelling the mechanism of chitosan−driven flocculation of microalgae in seawater as a function of pH. ACS Sustain Chem Eng 6(9):11273–11279

Gopalakrishnan L, Doriya K, Kumar DS (2016) Moringa oleifera: a review on nutritive importance and its medicinal application. Food Sci Hum Wellness 5(2):49–56

Stohs SJ, Hartman MJ (2015) Review of the safety and efficacy of Moringa oleifera. Phytother Res 29(6):796–804

Yamaguchi NU, Cusioli LF, Quesada HB, Ferreira MEC, Fagundes−Klen MR, Vieira MAS et al (2021) A review of Moringa oleifera seeds in water treatment: trends and future challenges. Process Saf Environ Prot 147:405–420

Hamid SHA, Lananan F, Khatoon H, Jusoh A, Endut A (2016) A study of coagulating protein of Moringa oleifera in microalgae bio−flocculation. In Biodeteior Biodegradation 113:310–317

Hasan M, Khalekuzzaman M, Hossain N, Alamgir M (2021) Anaerobic digested effluent phycoremediation by microalgae co−culture and harvesting by Moringa oleifera as a natural coagulant. J Clean Prod 292:126042

Provasoli L (1968) Cultures and collections of algae. Proceedings of the U.S. – Japan Conference (Watanabe, A. & Hattori, A. ed.). Japanese Society of Plant Physiology, Hakone, 63−75.

Soxhlet F (1879) Dinglers Polytech J 232(1879):461

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Hoekman SK, Broch A, Robbins C, Ceniceros E, Natarajan M (2012) Review of biodiesel composition, properties, and specifications. Renew Sust Energ Rev 16(1):143–169

Lenth RV (2010) Response−surface methods in R, using rsm. J Stat Softw 32:1–17

Madrona GS, Serpelloni GB, Vieira AMS, Nishi L, Cardoso KC, Bergamasco R (2010) Study of the effect of saline solution on the extraction of the Moringa oleifera seed’s active component for water treatment. Water Air Soil Pollut 211(1):409–415

Wen H, Zhang H, He M, Zhang X (2021) A novel approach for harvesting of the microalgae Chlorella vulgaris with Moringa oleifera extracts microspheres by Buoy−bead flotation method. Algal Res 60:102479

Yang Z, Hou J, Miao L (2021) Harvesting freshwater microalgae with natural polymer flocculants. Algal Res 57:102358

Teixeira CMLL, Kirsten FV, Teixeira PCN (2012) Evaluation of Moringa oleifera seed flour as a flocculating agent for potential biodiesel producer microalgae. J Appl Phycol 24(3):557–563

Singh G, Patidar SK (2020) Water quality restoration by harvesting mixed culture microalgae using Moringa oleifera. Water Environ Res 92(9):1268–1282

Rashid U, Anwar F, Moser BR, Knothe G (2008) Moringa oleifera oil: a possible source of biodiesel. Bioresour Technol 99(17):8175–8179

Esmaeili H, Yeganeh G, Esmaeilzadeh F (2019) Optimization of biodiesel production from Moringa oleifera seeds oil in the presence of nano−MgO using Taguchi method. Int Nano Lett 9(3):257–263

da Silva JP, Serra TM, Gossmann M, Wolf CR, Meneghetti MR, Meneghetti SM (2010) Moringa oleifera oil: studies of characterization and biodiesel production. Biomass Bioenerg 34(10):1527–1530

Converti A, Casazza AA, Ortiz EY, Perego P, Del Borghi M (2009) Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chem Eng Process 48(6):1146–1151

Bellou S, Baeshen MN, Elazzazy AM, Aggeli D, Sayegh F, Aggelis G (2014) Microalgal lipids biochemistry and biotechnological perspectives. Biotechnol Adv 32(8):1476–1493

Wang S, Yerkebulan M, Abomohra AEF, El−Khodary S, Wang Q (2019) Microalgae harvest influences the energy recovery: a case study on chemical flocculation of Scenedesmus obliquus for biodiesel and crude bio−oil production. Bioresour Technol 286:121371

Oliveira CYB, Nader C, Silva MF, Fracalossi DM, Gálvez AO, Lopes RG, Derner RB (2022) Integrated use of microalgal biomass of Choricystis minor var. minor: a promising model for production of biodiesel and aquafeeds. Biomass Convers Bioferinery 12:1565–1573

Chandra R, Rohit MV, Swamy YV, Mohan SV (2014) Regulatory function of organic carbon supplementation on biodiesel production during growth and nutrient stress phases of mixotrophic microalgae cultivation. Biores Technol 165:279–287

Oliveira CYB, D’Alessandro EB, AntoniosiFilho NR, Lopes RG, Derner RB (2021) Synergistic effect of growth conditions and organic carbon sources for improving biomass production and biodiesel quality by the microalga Choricystis minor var. minor. Sci Total Environ 759:143476

El−Sheekh M, Abomohra AEF, Eladel H, Battah M, Mohammed S (2018) Screening of different species of Scenedesmus isolated from Egyptian freshwater habitats for biodiesel production. Renew Energ 129:114–120

Rodrigues ACC (2021) Policy, regulation, development and future of biodiesel industry in Brazil. Clean Eng Technol 4:100197

Matos ÂP (2021) Advances in microalgal research in Brazil. Braz Arch Biol Technol 64:e21200531

Brasil BSAF, Silva FCP, Siqueira FG (2017) Microalgae biorefineries: the Brazilian scenario in perspective. New Biotechnol 39:90–98

Oliveira FA, Oliveira MKT, Silva RCP, Silva OMP, Maia PME, Cândido WS (2013) Crescimento de mudas de Moringa em função da salinidade da água e da posição das sementes nos frutos. Rev Árvore 37:79–87

Funding

This study was financed in part by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil (CAPES, Finance Code 001) and Conselho Nacional de Desenvolvimento Científico e Tecnológico [CNPq, for provided a fellowship to AOG (PQ 308063/2019 − 8)].

Author information

Authors and Affiliations

Contributions

Y. F. Marinho: conceptualization, methodology, formal analysis, and writing—original draft; A. P. S. Oliveira: data curation and formal analysis; C. Y. B. Oliveira: data curation, formal analysis, and writing—original draft; T. H. Napoleão: formal analysis and writing—review and editing; P. M. G. Paiva: writing—review and editing; M. C. S. Sant’Anna: writing—review and editing; C. B. Malafaia: writing—review and editing; A. O. Gálvez: supervision, resources, and writing—review and editing.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Marinho, Y.F., de Oliveira, A.P.S., Oliveira, C.Y.B. et al. Usage of Moringa oleifera residual seeds promotes efficient flocculation of Tetradesmus dimorphus biomass. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-02789-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-02789-3