Abstract

The use of microwave-assisted acid hydrolysis (MAAH) for the co-production of furfural, furfuryl alcohol, and formic acid from several lignocellulosic-based waste materials was investigated. The MAAH experiments were carried out in a microwave system based on the single reaction chamber (SRC) technology. Experimental conditions were selected using grass as a model of lignocellulosic waste, by evaluating the feedstock amount (10 to 700 mg), temperature (120 to 240 °C), time (1 to 40 min), and H2SO4 concentration (10 mL solution, 1 to 9%). One-pot conversion of grass, sugarcane straw, rice husk and wood waste into furfural (37–42%), furfuryl alcohol (10–26%), formic acid (10–15%), and glucose (0.6–8.1 %) was achieved even without a specific step for lignin removal. Higher biomass amount (0.5 L load, grass as model) was performed using a microwave SRC reactor. MAAH showed to be efficient for processing of several types of biomass waste, and the co-production of several interesting industrial products.

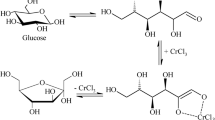

Graphical abstract

Similar content being viewed by others

References

Jaccard M (2006) Sustainable fossil fuels: The unusual suspect in the quest for clean and enduring energy. Cambridge University Press, New York

Stancin H, Mikulcic H, Wang X, Duic N (2020) A review on alternative fuels in future energy system. Renew Sustain Energy Rev 128:109927. https://doi.org/10.1016/j.rser.2020.109927

Bozell JJ (2008) Feedstocks for the future - Biorefinery production of chemicals from renewable carbon. Clean Soil Air Water 36:641–647. https://doi.org/10.1002/clen.200800100

Abbasi T, Abbasi SA (2010) Biomass energy and the environmental impacts associated with its production and utilization. Renew Sustain Energy Rev 14:919–937. https://doi.org/10.1016/j.rser.2009.11.006

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J Radiat Res Appl Sci 7:163–173. https://doi.org/10.1016/j.jrras.2014.02.003

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour Bioprocess 4:1–10. https://doi.org/10.1186/s40643-017-0137-9

Jong E, Gosselink RJA (2014) Chapter 17 - Lignocellulose-based chemical products. In: Gupta VK, Tuohy MG, Kubicek CP, Saddler J, Xu F (eds) Bioenergy research: Advances and applications. Elsevier, Amsterdam, pp 277–313

FitzPatrick M, Champagne P, Cunningham MF, Whitney RA (2010) A biorefinery processing perspective: Treatment of lignocellulosic materials for the production of value-added products. Bioresour Technol 101:8915–8922. https://doi.org/10.1016/j.biortech.2010.06.125

Holladay JE, Bozell JJ, White JF, Johnson D (2007) Top value-added chemicals from biomass. DOE Report PNNL, 16983

Mariscal R, Maireles-Torres P, Ojeda M, Sadaba I, Granados ML (2016) Furfural: A renewable and versatile platform molecule for the synthesis of chemicals and fuels. Energy Environ Sci 9:1144–1189. https://doi.org/10.1039/c5ee02666k

Machado G, Leon S, Santos F, Lourega R, Dullius J, Mollmann ME et al (2016) Literature review on furfural production from lignocellulosic biomass. Nat Resour 7:115–129. https://doi.org/10.4236/nr.2016.73012

Bulushev DA, Ross JRH (2018) Towards sustainable production of formic acid. ChemSusChem 11:821–836. https://doi.org/10.1002/cssc.201702075

Jong Ed, Higson A, Walsh P, Wellisch M (2012) Bio-based chemicals value added products from biorefineries. IEA Bioenergy, Task 42 Biorefinery

Chen X, Liu Y, Wu J (2020) Sustainable production of formic acid from biomass and carbon dioxide. Mol Catal 483:110716. https://doi.org/10.1016/j.mcat.2019.110716

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38:522–550. https://doi.org/10.1016/j.pecs.2012.02.002

Shinde SH, Hengne A, Rode CV (2020) Chapter 1 - Lignocellulose-derived platform molecules: An introduction. In: Saravanamurugan S, Pandey A, Li H, Riisager A (eds) Biomass, Biofuels, Biochemicals. Elsevier, Amsterdam, pp 1–31

Li X, Jia P, Wang T (2016) Furfural: A promising platform compound for sustainable production of C4 and C5 chemicals. ACS Catal 6:7621–7640. https://doi.org/10.1021/acscatal.6b01838

Zhang L, Yu H, Wang P (2013) Solid acids as catalysts for the conversion of d-xylose, xylan and lignocellulosics into furfural in ionic liquid. Bioresour Technol 136:515–521. https://doi.org/10.1016/j.biortech.2013.03.054

Peleteiro S, Rivas S, Alonso JL, Santos V, Parajo JC (2016) Furfural production using ionic liquids: A review. Bioresour Technol 202:181–191. https://doi.org/10.1016/j.biortech.2015.12.017

Peleteiro S, Santos V, Parajo JC (2016) Furfural production in biphasic media using an acidic ionic liquid as a catalyst. Carbohyd Polym 153:421–428. https://doi.org/10.1016/j.carbpol.2016.07.093

Oliveira JSS, Picoloto RS, Bizzi CA, Mello PA, Barin JS, Flores EMM (2015) Microwave-assisted ultraviolet digestion of petroleum coke for the simultaneous determination of nickel, vanadium and sulfur by ICP-OES. Talanta 144:1052–1058. https://doi.org/10.1016/j.talanta.2015.07.060

Piovesan N, Viera VB, Mello RD, Santos RCV, Vaucher RD, Dressler VL et al (2017) Microwave-assisted extraction of bioactive compounds from blueberry (Vaccinium ashei Reade) and their antioxidant and antimicrobial capacity. Int Food Res J 24:2526–2533

Bizzi CA, Pedrotti MF, Silva JS, Barin JS, Nobrega JA, Flores EMM (2017) Microwave-assisted digestion methods: Towards greener approaches for plasma-based analytical techniques. J Anal At Spectrom 32:1448–1466. https://doi.org/10.1039/c7ja00108h

Feng Y, Li GY, Li XY, Zhu N, Xiao B, Li J et al (2016) Enhancement of biomass conversion in catalytic fast pyrolysis by microwave-assisted formic acid pretreatment. Bioresour Technol 214:520–527. https://doi.org/10.1016/j.biortech.2016.04.137

Mihiretu GT, Brodin M, Chimphango AF, Oyaas K, Hoff BH, Gorgens JF (2017) Single-step microwave-assisted hot water extraction of hemicelluloses from selected lignocellulosic materials - A biorefinery approach. Bioresour Technol 241:669–680. https://doi.org/10.1016/j.biortech.2017.05.159

Srogi K (2006) A Review: Application of microwave techniques for environmental analytical chemistry. Anal Lett 39:1261–1288. https://doi.org/10.1080/00032710600666289

Vinatoru M, Mason TJ, Calinescu I (2017) Ultrasonically assisted extraction (UAE) and microwave assisted extraction (MAE) of functional compounds from plant materials. TrAC Trends Anal Chem 97:159–178. https://doi.org/10.1016/j.trac.2017.09.002

Cravotto G, Carnaroglio D (2017) Microwave chemistry. De Gruyter, Berlin

Yemis O, Mazza G (2011) Acid-catalyzed conversion of xylose, xylan and straw into furfural by microwave-assisted reaction. Bioresour Technol 102:7371–7378. https://doi.org/10.1016/j.biortech.2011.04.050

Yemis O, Mazza G (2012) Optimization of furfural and 5-hydroxymethylfurfural production from wheat straw by a microwave-assisted process. Bioresour Technol 109:215–223. https://doi.org/10.1016/j.biortech.2012.01.031

Lacerda VS, López-Sotelo JB, Correa-Guimarães A, Hernández-Navarro S, Sánchez-Bascones M, Navas-Gracia LM et al (2015) A kinetic study on microwave-assisted conversion of cellulose and lignocellulosic waste into hydroxymethylfurfural/furfural. Bioresour Technol 180:88–96. https://doi.org/10.1016/j.biortech.2014.12.089

Li W, Zhu Y, Lu Y, Liu Q, Guan S, Hm C et al (2017) Enhanced furfural production from raw corn stover employing a novel heterogeneous acid catalyst. Bioresour Technol 245:258–265. https://doi.org/10.1016/j.biortech.2017.08.077

Bizzi CA, Santos D, Sieben TC, Motta GV, Mello PA, Flores EMM (2019) Furfural production from lignocellulosic biomass by ultrasound-assisted acid hydrolysis. Ultrason Sonochem 51:332–339. https://doi.org/10.1016/j.ultsonch.2018.09.011

Estevinho BN, Ferraz A, Santos L, Rocha F, Alves A (2013) Uncertainty in the determination of glucose and sucrose in solutions with chitosan by enzymatic methods. J Braz Chem Soc 24:931–938. https://doi.org/10.5935/0103-5053.20130119

Deng W, Wang Y, Yan N (2016) Production of organic acids from biomass resources. Curr Opin Green Sustain Chem 2:54–58. https://doi.org/10.1016/j.cogsc.2016.10.002

Tabasso S, Grillo G, Carnaroglio D, Gaudino EC, Cravotto G (2016) Microwave-Assisted gamma-Valerolactone Production for Biomass Lignin Extraction: A Cascade Protocol. Molecules 21:413. https://doi.org/10.3390/molecules21040413

Carnaroglio D, Tabasso S, Kwasek B, Bogdal D, Gaudino EC, Cravotto G (2015) From Lignocellulosic Biomass to Lactic- and Glycolic-Acid Oligomers: A Gram-Scale Microwave-Assisted Protocol. ChemSusChem 8:1342–1349. https://doi.org/10.1002/cssc.201403183

Tabasso S, Montoneri E, Carnaroglio D, Caporaso M, Cravotto G (2014) Microwave-assisted flash conversion of non-edible polysaccharides and post-harvest tomato plant waste to levulinic acid. Green Chem 16:73–76. https://doi.org/10.1039/c3gc41103f

Montipó S, Ballesteros I, Fontana RC, Liu S, Martins AF, Ballesteros M et al (2018) Integrated production of second generation ethanol and lactic acid from steam-exploded elephant grass. Bioresour Technol 249:1017–1024. https://doi.org/10.1016/j.biortech.2017.11.001

Andrade MF, Colodette J (2016) Production of printing and writing paper grade pulp from elephant grass. Cerne 22:325–336. https://doi.org/10.1590/01047760201622032186

Acknowledgements

The authors are grateful to Conselho Nacional de Desenvolvimento Científico e Tecnológico—Brazil (CNPq, Grant nr. 313786/2019-4; 309297/2016-8) and Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul—Brazil (FAPERGS, Grant nr. 17/2551-0000960-6; 17/2551-0000985-1) for supporting this study. This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil (CAPES)—Finance code 001.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Santos, D., Iop, G.D., Mello, P.A. et al. Biomass waste valorization assisted by microwaves: a feasible approach for the co-production of value-added products. Biomass Conv. Bioref. 13, 13911–13919 (2023). https://doi.org/10.1007/s13399-021-02104-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02104-6