Abstract

This work proposes to design, build, and operate a raw gas cleaning system integrated with an existing 50-kWth two-stage downdraft gasifier, considering the gas specifications for its potential application. in a solid oxide fuel cell system, that is it main novelty. Variations in total air flow and air ratio (AR) as the main methods for the gas cleaning system had a significant effect on the gasification temperature, reducing tar, particulate, H2S, HCl, and NH3 at 12.50 mg/Nm3, 6.00 mg/Nm3, 2.85 mg/Nm3, 102.60 mg/Nm3, and 15.25 mg/Nm3, respectively. Subsequently, a new secondary method for gas cleaning included the external installation of a granular sand bed filter, a venturi scrubber, a spray scrubber, a fixed-bed adsorber with activated carbon, and a ceramic filter to remove contaminants. As a result of using the secondary cleaning method, the concentrations of tar, PM, H2S, NH3, and HCl could be reduced to 12.51 mg/Nm3, 6.02 mg/Nm3, 2.85 mg/Nm3, 121.72 mg/Nm3, and 9.18 mg/Nm3, respectively. It is possible to conclude that the proposed secondary gas cleaning system, coupled with primary measures, can produce gas with concentrations of pollutants low enough to satisfy fuel cleaning requirements in a SOFC.

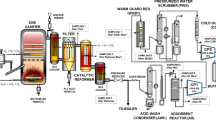

Graphical abstract

Similar content being viewed by others

Abbreviations

- AFC:

-

alkaline fuel cell

- AR:

-

air ratio

- BTX:

-

benzene, toluene, and xylene

- CFE:

-

candle filter element

- CGC:

-

cold gas cleaning

- CGE:

-

cold gas efficiency

- CHP:

-

combined heat and power

- DEFC:

-

direct-ethanol fuel cell

- ER:

-

equivalence ratio

- FBA:

-

fixed-bed adsorber

- FCT:

-

fuel cell technologies

- FID:

-

flame ionization detector

- GSBF:

-

granular sand bed filter

- GC:

-

gas chromatography

- GCS:

-

gas cleaning system

- ICE:

-

internal combustion engine

- IEM:

-

Institute of Mechanical Engineering

- LHV:

-

lower heating value

- MBDG:

-

moving-bed downdraft gasifier

- MCFC:

-

molten-carbonate fuel cell

- MS:

-

mass spectrometry

- NEST:

-

excellence group in thermal power and distributed generation

- PAFC:

-

phosphoric acid fuel cell

- PAH:

-

polycyclic aromatic hydrocarbon

- PEMFC:

-

polymeric electrolyte membrane fuel cell

- PCCF:

-

porous ceramic candle filter

- PVC:

-

polyvinyl chloride

- PM:

-

particulate matter

- RPG:

-

raw producer gas

- SOFC:

-

solid oxide fuel cell

- SS:

-

spray scrubber

- Syngas:

-

synthesis gas

- TAF:

-

total air flow

- UNIFEI:

-

Federal University of Itajubá

- USA:

-

United States of America

- VOC:

-

volatile organic compound

- VS:

-

venturi scrubber

- WHSV:

-

weight hourly space velocity

- A :

-

area (m²)

- AR :

-

ratio between first and second-stage air flows (%)

- C :

-

coefficient (dimensionless)

- D :

-

diameter (m)

- ER :

-

equivalence ratio (dimensionless)

- f :

-

correlation parameter for Calvert’s model ranging from 0.1 to 0.7

- g :

-

standard acceleration due to gravity (m/s²)

- H :

-

height (m)

- K :

-

inertial impaction parameter (dimensionless)

- k :

-

porosity (m³/m² min)

- L :

-

length (m)

- LHV :

-

lower heating value (MJ/kg)

- m :

-

mass flow rate (kg/s)

- N :

-

number (dimensionless)

- P :

-

pressure (Pa)

- Pt :

-

penetration (dimensionless)

- Pw :

-

power (W)

- Q :

-

volumetric flow rate (m³/s or Nm³/s)

- Re :

-

Reynolds number (dimensionless)

- T :

-

temperature (°C)

- t :

-

time (s)

- Th :

-

thickness (m)

- U :

-

velocity (m/s)

- V :

-

volume (m³)

- W :

-

weight (kg)

- x :

-

mole fraction (dimensionless)

- α:

-

constant primary characteristic of the aerosol (W/m³s)

- γ:

-

constant primary characteristic of the aerosol (dimensionless)

- Δ:

-

difference between two parameters

- ε:

-

mean porosity of the material (dimensionless)

- η:

-

efficiency (dimensionless)

- λ:

-

mean free path of the molecules (μm)

- μ:

-

dynamic viscosity (kg/ms)

- ρ:

-

density (kg/m³)

- σ:

-

surface tension (Pa)

- 1st :

-

flow through the primary stage

- 2nd :

-

flow through the secondary stage

- 32 :

-

Sauter mean diameter

- act :

-

Actual

- air :

-

air

- b :

-

bed

- bio :

-

biomass

- C :

-

Cunningham slip correction factor

- can :

-

candle filter element

- CGE :

-

cold gas efficiency

- cel :

-

average cell

- CH 4 :

-

methane

- CO :

-

carbon monoxide

- col :

-

collar

- D :

-

drag

- d :

-

droplet

- di :

-

instantaneous droplet

- e :

-

electric power

- es :

-

exposed surface area

- f :

-

filtration

- FBA :

-

fixed-bed adsorber

- flg :

-

flange

- flt :

-

filter

- g :

-

gas

- H 2 :

-

hydrogen

- IC :

-

particle collection efficiency of a single droplet

- ins :

-

inside

- l :

-

liquid

- med :

-

medium

- min :

-

minimum

- N :

-

number of candle filter elements

- out :

-

outside

- p :

-

particle

- ss :

-

spray scrubber

- stoic :

-

stoichiometry

- swe :

-

sweeping

- t :

-

total

- th :

-

thermal power

- thr :

-

throat

- tu :

-

transfer units

- vs :

-

venturi scrubber

- WHSV :

-

weight hourly space velocity

References

Wilberforce T, Alaswad A, Palumbo A, Dassisti M, Olabi AG (2016) Advances in stationary and portable fuel cell applications. Int J Hydrogen Energy 41(37):16509–16522

Martínez JD, Silva Lora EE, Andrade RV, Jaén RL (2011) Experimental study on biomass gasification in a double air stage downdraft reactor. Biomass Bioenergy 35(8):3465–3480

Lora EES, Palacio JCE, Rocha MH, Renó MLG, Venturini OJ, Almazán OO (2011) Issues to consider, existing tools and constraints in biofuels sustainability assessments. Energy 36(4):2097–2110

Santiago YC, González AM, Venturini OJ, Maya DMY (2021) Assessment of the energy recovery potential of oil sludge through gasification aiming electricity generation. Energy 215(B):119210. https://doi.org/10.1016/j.energy.2020.119210

Maya DMY, Silva Lora EE, Andrade RV, Albert R, Angel M (2021) Biomass gasification using mixtures of air, saturated steam, and oxygen in a two-stage downdraft gasifier. Assessment using a CFD modeling approach. Renew Energy 177:1014–1030. https://doi.org/10.1016/j.renene.2021.06.051

Rocha MH, Lora EES, Venturini OJ (2008) Life Cycle Analysis of different alternatives for the treatment and disposal of ethanol vinasse. Zuckerindustrie(Sugar Industry) 133(2):88–93

Bilgen S, Keleş S, Sarikaya İ, Kaygusuz K (2015) A perspective for potential and technology of bioenergy in Turkey: present case and future review. Renew Sustain Energy Rev 48:228–239

Espinosa Sarmiento AL, Ramirez Camacho RG, de Oliveira W (2020) Performance analysis of radial-inflow turbine of ORC: new combined approach of preliminary design and 3D CFD study. J Mech Sci Technol 34:2403–2422. https://doi.org/10.1007/s12206-020-0517-5

Sarmiento ALE, Ramirez Camacho RG, de Oliveira W, Gutiérrez Velásquez EI, Murthi M, Diaz Gautier NJ (2021) Design and off-design performance improvement of a radial-inflow turbine for ORC applications using metamodels and genetic algorithm optimization. Appl Therm Eng 183(2):116197. https://doi.org/10.1016/j.applthermaleng.2020.116197

Nikolaidis P, Poullikkas A (2017) A comparative overview of hydrogen production processes. Renew Sustain Energy Rev 67:597–611

Sansaniwal SK, Pal K, Rosen MA, Tyagi SK (2017) Recent advances in the development of biomass gasification technology: a comprehensive review. Renew Sustain Energy Rev 72:363–384

Molino A, Chianese S, Musmarra D (2016) Biomass gasification technology: the state of the art overview. J Energy Chem 25(1):10–25

Pio DT, Tarelho LAC, Matos MAA (2017) Characteristics of the gas produced during biomass direct gasification in an autothermal pilot–scale bubbling fluidized bed reactor. Energy 120:915–928

Santhanam S, Schilt C, Turker B, Woudstra T, Aravind PV (2016) Thermodynamic and evaluation of high efficiency heat pipe integrated biomass gasifier–solid oxide fuel cells–gas turbine systems. Energy 109:751–764

Sreejith CC, Haridasan N, Muraleedharan C, Arun P (2014) Allothermal air–steam gasification of biomass with CO2 (carbon dioxide) sorption: performance prediction based on a chemical kinetic model. Energy 69:399–408

Pandey DS, Kwapinska M, Gómez-Barea A, Horvat A, Fryda LE, Rabou LPLM, Leahy JJ, Kwapinski W (2016) Poultry litter gasification in a fluidized bed reactor: effects of gasifying agent and limestone addition. Energy Fuels 30(4):3085–3096

Basu P (2013) Biomass Gasification, pyrolysis and torrefaction – practical design and theory, 2nd ed. Academic Press Elsevier, London UK, p 530

Heidenreich S, Foscolo PU (2015) New concepts in biomass gasification. Prog Energy Combust Sci 46:72–95

Kirkels AF, Verbong GPJ (2011) Biomass gasification: still promising: a 30–year global overview. Renew Sustain Energy Rev 15(1):471–481

Siedlecki M, de Jong W, Verkooijen AHM (2011) Fluidized bed gasification as a mature and reliable technology for the production of bio-syngas and applied in the production of liquid transportation fuels – a review. Energies 4(3):389–434

E4Tech Energy Sustainability. Review of technologies for gasification of biomass and wastes – final report. NNFCC project 09/008, York: NNFCC, 126 pp., 2009. Available at: <http://www.e4tech.com/wp-content/uploads/2016/01/gasification2009.pdf> [Accessed 08.03.2017 (in English)].

Mikulandrić R, Lončar D, Böhning D, Böhme R, Beckmann M (2014) Artificial neural network modelling approach for a biomass gasification process in fixed bed gasifiers. Energy Convers Manage 87:1210–1223

Sikarwar VS, Zhao M, Clough P, Yao J, Zhong X, Memon MZ, Shah N, Anthony EJ, Fennell PS (2016) An overview of advances in biomass gasification. Energy Environ Sci 9(10):2939–2977

Tuomi S, Kaisalo N, Simell P, Kurkela E (2015) Effect of pressure on tar decomposition activity of different bed materials in biomass gasification conditions. Fuel 158:293–305

de Oliveira CAS, Yepes Maya DM, Silva Lora EE, Lesme R, Martínez Reyes AM, Martínez González A, Vieira R, Martinez JD (2017) Experimental study on biomass (eucalyptus spp.) gasification in a two- stage downdraft reactor by using mixtures of air, saturated steam and oxygen as gasifying agents. Energy Convers Manag. 145:314–323. https://doi.org/10.1016/j.enconman.2017.04.101

Shen Y, Wang J, Ge X, Chen M (2016) By-products recycling for syngas cleanup in biomass pyrolysis – an overview. Renew Sustain Energy Rev 59:1246–1268

Couper JR, Penney WR, Fair JR, Walas SM (2012) Chemical process equipment – selection and design, 3rd ed. Butterworth-Heinemann, Elsevier, Walthmam (MA), p 752

Stoppiello G. Biomass gasification – process analysis and dimensioning aspects for downdraft units and gas cleaning lines. Ph.D. Thesis in Agricultural Engineering. Alma Mater Studiorum – University of Bologna. Bologna; 167 pp., 2010 [in English].

Protopapas G. Integrated biomass gasification – SOFC systems. Master Thesis. Faculty of Mechanical, Maritime and Materials Engineering. Delft University of Technology. Delft; 132 pp., 2006 [in English].

van Loon M. Design of a gas cleaning system for testing solid oxide fuel cells with biomass gasifiers. Master Thesis. Faculty of Mechanical, Maritime and Materials Engineering. Delft University of Technology. Delft; 147 pp., 2005 [in English].

Levenspiel O (1999) Chemical reaction engineering, 3rd edn. John Wiley & Sons Inc., New York, p 698

Rase HF (1990) Fixed-bed reactor design and diagnostics: gas phase reactions. Butterworth Publishers, Stoneham, Massachusetts, p 364

Green DW, Perry RH (2007) Perry’s chemical enginers’ handbook, 8th edn. McGraw-Hill Education, New York, p 2704

Bejan A, Kraus AD (2003) Heat transfer handbook. Wiley-Interscience Inc., New York, p 1496

Woolcock PJ, Brown RC (2013) A review of cleaning technologies for biomass-derived syngas. Biomass Bioenerg 52:54–84

Innocentini MDM, Coury JR, Fukushima M, Colombo P (2015) High-efficiency aerosol filters based on silicon carbide foams coated with ceramic nanowires. Sep Purif Technol 152:180–191

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48(2):89–94

Forchheimer P (1901) Wasserbewegung durch Boden. Zeitschrift des Vereines Deutscher Ingenieuer 45(50):1736–1741

Pathak BS, Kapatel DV, Bhoi PR, Sharma AM, Vyas DK (2007) Design and development of sand bed filter for upgrading producer gas to IC engine quality fuel. Int Energy J 8(1):15–20

Johnstone HF, Field RB, Tassler MC (1954) Gas absorption and aerosol collection in a venturi atomizer. Ind Eng Chem 46(8):1601–1608

Calvert S (1970) Venturi and other atomizing scrubbers efficiency and pressure drop. American Institute of Chemical Engineers Journal (AIChE J) 16(3):392–396

Calvert S, Lundgren D, Mehta DS (1972) Venturi scrubber performance. J Air Pollut Control Assoc 22(7):529–532

Ashtari AK, Majd AMS, Riskowski GL, Mukhtar S, Zhao L (2016) Removing ammonia from air with a constant pH, slightly acidic water spray wet scrubber using recycled scrubbing solution. Front Environ Sci Eng 10(6):1–10

Pye AM (1979) A review of asbestos substitute materials in industrial applications. J Hazard Mater 3(2):125–147

Xiao G, Wang X, Zhang J, Ni M, Gao X, Luo Z, Cen K (2013) Granular bed filter: a promising technology for hot gas clean–up. Powder Technol 244:93–99

Purchas DB, Sutherland K (2002) Handbook of filter media, 2nd ed. Elsevier Science & Technology, New York, p 526

Chiang B-C, Wey M-Y, Yang W-Y (2000) Control of incinerator organics by fluidized bed activated carbon adsorber. J Environ Eng 126(11):985–992

Galindo AL, Lora EES, Andrade RV, Giraldo SY, Jaén RL, Cobas VRM (2014) Biomass gasification in a downdraft gasifier with a two-stage air supply: effect of operating conditions on gas quality. Biomass Bioenerg 61:236–244

Neeft JPA. Rationale for setup of impinger train as used in the technical specification of sampling and analysis of tar and particles in the product gases of biomass gasification – technical background document. CEN BT/TF 143 Report – Organic contaminants (“tar”) in biomass producer gases. SenterNovem, Netherlands, 14 pp., 2005. Available at: <http://www.eeci.net/results/pdf/Rationale-for-setup-of-impinger-trains-v2_Jan05.pdf>

van de Kamp WL, de Wild PJ, Knoef HAM, Neeft JPA, Kiel JHA. Tar measurement in biomass gasification, standardisation and supporting R&D. EU–project ENK5–CT–2002–80648. SenterNovem project 2020–03–11–14–007. ECN–C––06–046, Netherlands, 168 pp., 2006. Available at: <https://www.ecn.nl/docs/library/report/2006/c06046.pdf> [Accessed 08.04.2017 (in English)].

Martínez JD, Mahkamov K, Andrade RV, Lora EES (2012) Syngas production in downdraft biomass gasifiers and its application using internal combustion engines. Renewable Energy 38(1):1–9

Lee U, Balu E, Chung JN (2013) An experimental evaluation of an integrated biomass gasification and power generation system for distributed power applications. Appl Energy 101:699–708

Kuramochi H, Wu W, Kawamoto K (2005) Prediction of the behaviors of H2S and HCl during gasification of selected residual biomass fuels by equilibrium calculation. Fuel 84(4):377–387

Zhao Y, Tian S, Gong Y et al (2019) Efficient removal of lead from water using stabilized iron sulfide nanoparticles: effectiveness and effects of stabilizer. Water Air Soil Pollut 230:115. https://doi.org/10.1007/s11270-019-4157-2

Hyeondeok Jeong, Michael Geis, Christian Lenser, Sandra Lobe, Stephan Herrmann, Sebastian Fendt, Norbert H. Menzler, Olivier Guillon, Coupling SOFCs to biomass gasification – the influence of phenol on cell degradation in simulated bio-syngas. Part II – Post-test analysis, International Journal of Hydrogen Energy, 2018; (43), 20911–20920, https://doi.org/10.1016/j.ijhydene.2018.09.006.

Cavalli A, Aravind PV (2021) Effect of selected representative biomass gasification tar compounds on Ni-GDC solid oxide fuel cells. Int J Hydro Energy 46(40):21124–21135. https://doi.org/10.1016/j.ijhydene.2021.03.188

Din Zia Ud, Zainal ZA (2017) The fate of SOFC anodes under biomass producer gas contaminants. Renew Sustain Energy Rev 72:1050–1066. https://doi.org/10.1016/j.rser.2016.10.012

Hofmann Ph, Panopoulos KD, Fryda LE, Schweiger A, Ouweltjes JP, Karl J (2008) Integrating biomass gasification with solid oxide fuel cells: effect of real product has tars, fluctuations and particulates on Ni–GDC anode. Int J Hydrogen Energy 33(11):2834–2844

Jeong Hyeondeok, Geis Michael, Lenser Christian, Lobe Sandra, Herrmann Stephan, Fendt Sebastian, Menzler Norbert H, Guillon Olivier (2018) Coupling SOFCs to biomass gasification – the influence of phenol on cell degradation in simulated bio-syngas. Part II – Post-test analysis. Int J Hydr Energy 43:45

Zia Ud Din, Z.A. Zainal,The fate of SOFC anodes under biomass producer gas contaminants, Renewable and Sustainable Energy Reviews, 2017; (72); 1050-1066

Bocci E, Di Carlo A, McPhail SJ, Gallucci K, Foscolo PU, Moneti M, Villarini M, Carlini M (2014) Biomass to fuel cells state of the art: a review of the most innovative technology solutions. Int J Hydrogen Energy 39(36):21876–21895

Lanzini A, Ferrero D, Papurello D, Santarelli M (2017) Reporting degradation from different fuel contaminants in Ni-anode SOFCs. Fuel Cells 17:423–433. https://doi.org/10.1002/fuce.201600184

Aravind PV, Ouweltjes JP, Woudstra N, Rietveld G (2008) Impact of biomass-derived contaminants on SOFCs with Ni/Gadolinia–Doped ceria anodes. Electrochem Solid-State Lett 11(2):B24–B28

Xu C, Gong M, Zondlo JW, Liu X, Finklea HO (2010) The effect of HCl in syngas on Ni–YSZ anode–supported solid oxide fuel cells. J Power Sources 195(8):2149–2158

Cavalli A, Aravind PV (2021) Effect of selected representative biomass gasification tar compounds on Ni-GDC solid oxide fuel cells. Int J Hydrogen Energy 46:21124–21135

Papurello D, Lanzini A, Drago D, Leone P, Santarelli M (2016) Limiting factors for planar solid oxide fuel cells under different trace compound concentrations. Energy 95:67–78

Zhijian Wan, Youkun Tao, Jing Shao, Yinghui Zhang, Hengzhi You, Ammonia as an effective hydrogen carrier and a clean fuel for solid oxide fuel cells, Energy Conversion and Management, 2021;(228) 113729,

Rocha MH, Capaz RS, Lora EES, Nogueira LAH, Leme MMV, Renó MLG, Almazán OO (2014) Life cycle assessment (LCA) for biofuels in Brazilian conditions: a meta-analysis. Renew Sustain Energy Rev 37:435–459

Centeno FO, Mahkamov K, Lora EES, Andrade RV (2012) Theoretical and experimental investigations of a downdraft biomass gasifier-spark ignition engine power system. Renewable Energy 37(1):97–108

Acknowledgements

The authors would like to extend their gratitude to CEMIG, the power company of Minas Gerais, for their financial support through the Research and Development project (R&D) ANEEL/CEMIG N° 237 “Theoretical and experimental evaluation of biomass gasification in the conduction of Solid Oxide Fuel Cells (SOFCs).” We wish to thank the National Council for Scientific and Technological Development (CNPq) and the Minas Gerais State Agency of Research and Development (FAPEMIG) for funding our R&D projects and grants. We also express our special thanks to the Coordination for the Improvement of Higher Education Personnel (CAPES) and the Netherlands Organisation for International Cooperation in Higher Education (NUFFIC) for their support in allowing the graduate students Sandra Restrepo and Mateus Rocha to complete the research projects whose results are included in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Restrepo, S.Y.G., Rocha, M.H., Lora, E.E.S. et al. Design and operation of a gas cleaning system for biomass gasification in a two-stage air-blown downdraft gasifier to meet quality requirements of solid oxide fuel cells. Biomass Conv. Bioref. 13, 8239–8265 (2023). https://doi.org/10.1007/s13399-021-01796-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01796-0