Abstract

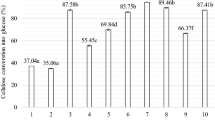

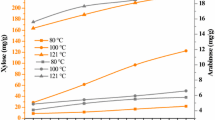

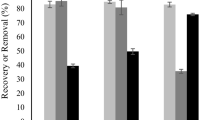

Lignocellulosic materials are complex, recalcitrant, and difficult to release fermentable carbohydrates, such as xylose. Xylose is the feedstock for the development of products with high added value, such as ethanol, butanol, xylitol, and furfural. A high xylose yield was obtained from epidermis-free stem and external fraction (containing epidermis) of sugarcane with minimal formation of degradation products using dilute acid pretreatment. The influences of variables such as sulfuric acid concentration (% m/m or % m/v), reaction time (min), and solid/liquid ratio (% m/v) on acid pretreatment were investigated through a central composite design. In study region 1, stem and external fraction had xylose yields of 58.69 and 55.33%, as well as 1.79 and 2.16% of furfural. The optimal condition to obtain high xylose yield was observed with the use of 50% m/m or 1% m/v of sulfuric acid. The highest xylose extraction was achieved in the epidermis-free stem, leading to a less recalcitrant fraction. Xylose has a key role in obtaining products with high added value. For this reason, this study obtained high xylose yield applying optimal conditions of dilute acid pretreatment, with minimum degradation products.

Similar content being viewed by others

References

Guo M, Song W, Buhain J (2015) Bioenergy and biofuels: history, status and perspective. Renew Sust Energ Rev 42:712–725

Binod P, Sindhu R, Singhania R, Vikram S, Devi L, Nagalakshmi S (2010) Bioethanol production from rice straw: an overview. Bioresour Technol 101:4767–4774

Sharma HK, Xu C, Qin W (2019) Biological pretreatment of lignocellulosic biomass for biofuels and bioproducts: an overview. Waste Biomass Valor 10:235–251

Freitas C, Carmona E, Brienzo M (2019) Xylooligosaccharides production process from lignocellulosic biomass and bioactive effects. Bioact Carbohydr Diet Fibre 18:100184

Zhou X, Xu Y (2019) Integrative process for sugarcane bagasse biorefinery to co-produce xylooligosaccharides and gluconic acid. Bioresour Technol 282:81–87

Guo J, Cao R, Huang K, Xu Y (2020) Comparison of selective acidolysis of xylan and enzymatic hydrolysability of cellulose in various lignocellulosic materials by a novel xylonic acid catalysis method. Bioresour Technol 304:122943

Naidu DS, Hlangothi SP, John MJ (2018) Bio-based products from xylan: a review. Carbohydr Polym 179:28–41

Lee TC, Xiong W, Paddock T, Carrieri D, Chang IF, Chiu HF, Ungerer J, Jou SHH, Maness PC, Yu J (2015) Engineered xylose utilization enhances bio-products productivity in the cyanobacterium Synechocystis sp. PCC 6803. Metab Eng 30:179–189

Jagtap SS, Rao CV (2018) Microbial conversion of xylose into useful bioproducts. Appl Microbiol Biotechnol 102:9015–9036

Matsushika A, Inoue H, Kodaki T, Sawayama S (2009) Ethanol production from xylose in engineered Saccharomyces cerevisiae strains: current state and perspectives. Appl Microbiol Biotechnol 84:37–53

Zheng J, Tashiro Y, Yoshida T, Gao M, Wang Q, Sonomoto K (2013) Continuous butanol fermentation from xylose with high cell density by cell recycling system. Bioresour Technol 129:360–365

Rao LV, Goli JK, Gentela J, Koti S (2016) Bioconversion of lignocellulosic biomass to xylitol: an overview. Bioresour Technol 213:299–310

Peleteiro S, Lopes AMC, Garrote G, Parajó JC, Lukasik RB (2013) Simple and efficient furfural production from xylose in media containing 1-butyl-3-methylimidazolium hydrogen sulfate. Ind Eng Chem Res 54:8368–8373

Fengel D, Wegener G (1989) Wood: chemistry, ultrastructure, reaction. Walter de Gruyter, Berlin, New York

Sant’Anna C, De SouzaW, Brienzo M (2014) The influence of the heterogeneity, physicochemical and structural properties on the recalcitrance and conversion of sugarcane bagasse. In: Sugarcane: production, consumption and agricultural management systems. Nova Science Publishers, Hauppauge, pp 1–34

Brienzo M, Fikizolo S, BenjaminY TL, Görgens J (2017) Influence of pretreatment severity on structural changes, lignin content and enzymatic hydrolysis of sugarcane bagasse samples. Renew Energy 104:271–280

Brienzo M, Ferreira S, Vicentim MP, Souza W, Sant’anna C (2014) Comparison study on the biomass recalcitrance of different tissue fractions of sugarcane culm. Bioenerg Res 7:1454–1465

Brienzo M, Abud Y, Ferreira S, Corrales RCNR, Ferreira-Leitão VS, Souza W, Sant’anna C (2016) Characterization of anatomy, lignin distribution, and response to pretreatments of sugarcane culm node and internode. Ind Crop Prod 84:305–313

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318

Melati RB, Shimizu FL, Oliveira G, Pagnocca FC, Souza W, Sant’Anna C, Brienzo M (2019) Key factors affecting the recalcitrance and conversion process of biomass. Bioenerg Res 12:1–20

Candido JP, Claro EMT, Paula CBC, Shimizu FL, Leite DANO, Brienzo M, Angelis DF (2020) Detoxification of sugarcane bagasse hydrolysate with different adsorbents to improve the fermentative process. World J Microbiol Biotechnol 36:43

Kumar AK, Sharma S (2017) Recent updates on different methods of pretreatment of lignocellulosic feedstocks: a review. Bioresour Bioprocess 4:7

Melati RB, Schmatz AA, Pagnocca FC, Contiero J, Brienzo M (2017) Sugarcane bagasse: production, composition, properties, and feedstock potential. In: Murphy R (ed) Sugarcane: production systems, uses and economic importance, 1st edn. Nova Publishers, Hauppauge

Castro AM, Pereira N (2010) Production, properties and application of cellulases in the hydrolysis of agroindustrial residues. Quím Nova 33:181–188

Rocha GJM, Nascimento VM, Gonçalves AR, Silva VFN, Martín C (2015) Influence of mixed sugarcane bagasse samples evaluated by elemental and physical-chemical composition. Ind Crop Prod 64:52–58

Shimizu FL, Zamora HDZ, Schmatz AA, Melati RB, Bueno D, Brienzo M (2020) Biofuel generation based on technical process and biomass quality. In: Biofuel production technologies: critical analysis for sustainability. Springer Nature, Berlin, pp 37–64

Liu ZL, Lan TQ, Li H, Gao X, Zhang H (2017) Effect of bisulfite treatment on composition, structure, enzymatic hydrolysis and cellulase adsorption profiles of sugarcane bagasse. Bioresour Technol 223:27–33

Szczerbowski D, Pitarelo AP, Zandoná FA, Ramos LP (2014) Sugarcane biomass for biorefineries: comparative composition of carbohydrate and non-carbohydrate components of bagasse and straw. Carbohydr Polym 114:95–101

Neureiter M, Danner H, Thomasser C, Saidi B, Braun R (2002) Dilute-acid hydrolysis of sugarcane bagasse at varying conditions. Appl Biochem Biotechnol 98:49–58

Lavarack BP, Griffin GJ, Rodman D (2002) The acid hydrolysis of sugarcane bagasse hemicellulose to produce xylose, arabinose, glucose and other products. Biomass Bioenergy 23:367–380

Schmatz AA, Tyhoda L, Brienzo M (2020) Sugarcane biomass conversion influenced by lignin. Biofuels Bioprod Biorefin 14:469–480

Lorencini P, Siqueira MR, Maniglia BC, Tapia DR, Maintinguer SI, Reginatto V (2016) Biohydrogen production from liquid and solid fractions of sugarcane bagasse after optimized pretreatment with hydrochloric acid. Waste Biomass Valor 7:1017–1029

Canilha L, Santos VTO, Rocha GJM, Silva JBS, Giulietti M, Silva SS, Felipe MGA, Ferraz A, Milagres AMF, Carvalho W (2011) A study on the pretreatment on sugarcane bagasse sample with dilute sulfuric acid. J Ind Microbiol Biotechnol 38:1467–1475

Alvira P, Pejó ET, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Maanzor A, Khokhar ZU, Hussain A, Uzma, Ahmad SA, Syed QU, Baig S (2012) Dilute sulfuric acid: a cheap acid for optimization of bagasse pretreatment. Sci Int 24:41–45

Funding

This study was financially supported by the Coordination of Superior Level Staff Improvement (CAPES).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 26.6 kb).

Rights and permissions

About this article

Cite this article

Santos, C., Bueno, D., Sant’Anna, C. et al. High xylose yield from stem and external fraction of sugarcane biomass by diluted acid pretreatment. Biomass Conv. Bioref. 12, 5835–5843 (2022). https://doi.org/10.1007/s13399-020-01088-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01088-z