Abstract

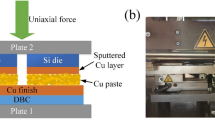

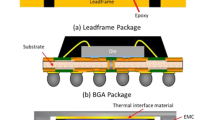

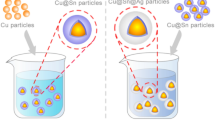

This framework assesses the mechanical behavior of some potential thin/thick metallization systems in use as either ohmic contacts for diamond semi-conductors or for metallization on copper double bounded ceramic substrates present in the next-generation power electronics packaging. The interesting and unique characteristic of this packaging is the use of diamond as a semi-conductor material instead of silicon to increase the lifetime of embedded power converters for use in aeronautical applications. Theoretically, such packaging is able to withstand temperatures of up to 300 °C without breaking the semi-conductor, provided that the constitutive materials of the packaging are compatible. Metallization is very important to protect the chips and substrates. Therefore, we address this issue in the present work. The tested metallization systems are Ni/Au, Ni/Cr/Au and Ni/Cr. These specific systems were studied since they can be used in conjunction with existing bonding technologies, including AuGe soldering, Ag–In Transient liquid Phase Bonding and silver nanoparticle sintering. The metallization is achieved via electrodeposition, and a mechanical test, consisting of a microtension technique, is carried out at room temperature inside a scanning electron microscopy chamber. The technique permits observations the cracks initiation and growth in the metallization to locate the deformation zones and identify the fracture mechanisms. Different failure mechanisms were shown to occur depending on the metallic layers deposited on top of the copper substrate. The density of these cracks depends on the imposed load and the involved metallization. These observations will help choose the metallization that is compatible with the particular bonding material, and manage mechanical stress due to thermal cycling so that they can be used as a constitutive component for high-temperature power electronics packaging.

Graphical Abstract

Similar content being viewed by others

References

Brown, W., Beera, R., Naseem, H., Malshe, A.: State-of-the-art synthesis and post-deposition processing of large area CVD diamond substrates for thermal management. Surf. Coat. Technol. 86–87, 698 (1996)

Msolli, S., Alexis, J., Kim, H.S., Dalverny, O., Karama, M.: Assessment of candidate metallization systems deposited on diamond using nano-indentation and nano-scratching tests. Thin Solid Films 619, 53 (2016)

Koné, S., Schneider, H., Isoird, K., Thion, F., Achard, J., Issaoui, R., Msolli, S., Alexis, J.: An assessment of contact metallization for high power and high temperature diamond Schottky devices. Diam. Relat. Mater. 27–28, 23 (2012)

Johnson, R.W., Williams, J.: Power Device Packaging Technologies for Extreme Environments. In: IEEE aerospace conference, pp. 1–6 (2005)

Lang, F., Tanimoto, S., Ohashi, H., Yamaguchi, H.: Long-term joint reliability of SiC power devices at 330°C. In: European conference on microelectronics and packaging, pp. 1–5 (2009)

So, W., Choe, S., Chuang, R., Lee, C.: A barrier metallization technique on copper substrates for soldering applications. In: Electronic components and technology conference, pp. 855–860 (2000)

Mustain, H.A., Brown, W., Ang, S.: Tungsten carbide as a diffusion barrier on silicon nitride active- metal-brazed substrates for silicon carbide power devices. J. Electron. Packag. 131, 1 (2009)

Lindfeldt, E., Ekh, M., Cvetskovski, K., Schilke, M.: Using DIC to identify microscale strain fields from in-situ SEM images of a pearlitic steel. Exp. Mech. 54, 1503 (2014)

Engqvist, J., Hall, S., Wallin, M., Ristinmaa, M., Plivelic, T.: Multi-scale measurement of (amorphous) polymer deformation: simultaneous x-ray scattering, digital image correlation and in-situ loading. Exp. Mech. 54, 1373 (2014)

Agrawal, D., Raj, R.: Measurement of the ultimate shear strength of a metal-ceramic interface. Acta Metall. 37, 1265 (1989)

Chen, B., Hwang, J., Chen, I., Yu, G., Huang, J.-H.: A tensile-film-cracking model for evaluating interfacial shear strength of elastic film on ductile substrate. Surf. Coat. Technol. 126, 91 (2000)

Beghini, M., Benamati, G., Bertini, L., Frendo, F.: Measurement of coatings' elastic properties by mechanical methods: Part 2. Application to thermal barrier coatings. Exp. Mech. 41, 305 (2001)

Yang, Y., Ruan, H., Lu, J., Yao, N., Shan, W., Soboyejo, W.: Development of a micro-beam method to investigate the fatigue crack growth mechanisms of submicron-scale cracks. Exp. Mech. 49, 731 (2009)

Kammers, A., Daly, S.: Digital image correlation under scanning electron microscopy: methodology and validation. Exp. Mech. 53, 1743 (2013)

Alaca, B.E., Saif, M., Sehitoglu, H.: On the interface debond at the edge of a thin film on a thick substrate. Acta Mater. 50, 1197 (2002)

Jin, H., Lu, W.-Y., Cordill, M., Schmidegg, K.: In situ study of cracking and buckling of chromium films on PET substrates. Exp. Mech. 51, 219 (2011)

Acknowledgements

This work was supported by the French DGE Project DIAMONIX, No. 08 2 90 6066. This work was also supported by the Technology Innovation Program (10048305, Launching Plug-in Digital Analysis Framework for Modular system Design) funded by the Ministry of Trade, Industry & Energy (MI, Korea). We do thanks to Prof. Alexis for his precious remarks.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Msolli, S., Kim, H.S. Study of the Fracture Mechanisms of Electroplated Metallization Systems Using In Situ Microtension Test. Electron. Mater. Lett. 14, 517–525 (2018). https://doi.org/10.1007/s13391-018-0052-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-018-0052-z