Abstract

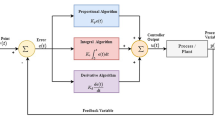

This paper exploits the design of a decentralized proportional integral derivative (PID) controller based on nonlinear optimization for a continuously stirred tank reactor system. The basic objective is to attain the design specifications by maintaining both the temperature and concentration. The continuously stirred tank reactor is modeled to a first-order plus dead time system by designing a decoupler. The proposed PID controller is designed on the basis of fundamentals of nonlinear optimization. Further, the overshoot is bounded with constraints on the maximum closed-loop amplitude ratio. The control algorithm is designed for decoupled systems to reduce the loop interactions and attain the servo response. The robust stability is analyzed by considering multiplicative input as well as output uncertainties, while stability is verified with the Kharitonov–Hurwitz theorem. A concise comparison is made between the proposed technique with existing methods. It is envisaged that the proposed control algorithm exhibits better servo and regulatory responses compared to the existing techniques. Furthermore, the efficacious nature of the proposed control scheme is validated by considering a wide range of closed-loop amplitude ratios.

Similar content being viewed by others

References

Wei, W.: Adaptive-like control methodologies for a CSTR system with dynamic actuator constraints. J. Process Control 13(6), 525–537 (2003)

Czeczot, J.: Balance-based adaptive control methodology and its application to the non-isothermal CSTR. Chem. Eng. Process. 45(5), 359–371 (2006)

Favache, A.; Dochain, D.: Thermodynamics and chemical systems stability: the CSTR case study revisited. J. Process Control 19(3), 371–379 (2009)

Chang, W.-D.: Nonlinear CSTR control system design using an artificial bee colony algorithm. Simul. Model. Pract. Theory 31, 1–9 (2013)

Seki, H.; Naka, Y.: Optimizing control of CSTR/distillation column processes with one material recycle. Ind. Eng. Chem. Res. 47(22), 8741–8753 (2008)

Li, D.-J.: Neural network control for a class of continuous stirred tank reactor process with dead-zone input. Neurocomputing 131, 453–459 (2014)

Ballesteros-Moncada, H.; Herrera-López, E.J.; Anzurez-Marín, J.: Fuzzy model-based observers for fault detection in CSTR. ISA Trans. 59, 325–333 (2015)

Estévez-Sánchez, K.H.; Sampieri-Croda, A.; García-Alvarado, M.A.; Ruiz-López, I.I.: Design of multiloop pi controllers based on quadratic optimal approach. ISA Trans. 70, 338–347 (2017)

Alshammari, O.; Mahyuddin, M.N.; Jerbi, H.D.: An advanced PID based control technique with adaptive parameter scheduling for a nonlinear CSTR plant. IEEE Access 7, 158085–158094 (2019)

Tavoosi, J.: An experimental study on inverse adaptive neural fuzzy control for nonlinear systems. Int. J. Knowl-based Intell. Eng. Syst. 24(2), 135–143 (2020)

Dombi, J.; Abrar, H.: A new approach to fuzzy control using the distending function. J. Process Control 86, 16–29 (2020)

Salahshour, E.; Malekzadeh, M.; Gordillo, F.; Ghasemi, J.: Quantum neural network-based intelligent controller design for CSTR using modified particle swarm optimization algorithm. Trans. Inst. Meas. Control. 41(2), 392–404 (2019)

Khanduja, N.; Bhushan, B.; Mishra, S.: Control of CSTR using firefly and hybrid firefly-biogeography based optimization (bbffo) algorithm. J. Inf. Optim. Sci. 41(6), 1443–1452 (2020)

Zerari, N.; Chemachema, M.: Robust adaptive neural network prescribed performance control for uncertain CSTR system with input nonlinearities and external disturbance. Neural Comput. Appl. 32(14), 10541–10554 (2020)

Zhou, W.; Yi, J.; Yao, L.; Chen, G.: Event-triggered optimal control for the continuous stirred tank reactor system. IEEE Trans. Artif. Intell. 3(2), 228–237 (2021)

Marin, A.M.C.A.; Jimenez, J.A.; et al.: Tuning multivariable optimal PID controller for a continuous stirred tank reactor using an evolutionary algorithm. IEEE Lat. Am. Trans. 16(2), 422–427 (2018)

Zhou, W.; Liu, H.; He, H.; Yi, J.; Li, T.: Neuro-optimal tracking control for continuous stirred tank reactor with input constraints. IEEE Trans. Ind. Inf. 15(8), 4516–4524 (2018)

Wang, G.; Jia, Q.-S.; Qiao, J.; Bi, J.; Zhou, M.C.: Deep learning-based model predictive control for continuous stirred-tank reactor system. IEEE Trans. Neural Netw. Learn. Syst. 32(8), 3643–3652 (2020)

Begum, K.G.: Coot bird optimization algorithm for the temperature control of continuous stirred tank reactor process. Asia-Pacific J. Chem. Eng. 18, e2787 (2022)

Saini, P.; Thakur, P.: H-infinity based robust temperature controller design for a non-linear systems. Wireless Personal Commun. 126, 1–29 (2022)

Le, B.N.; Wang, Q.G.; Lee, T.H.: A graphical approach to computing loop gain margins for TITO systems. Trans. Inst. Meas. Control 36(5), 600–603 (2014)

Mutlu, A.; Yildirim, U.; Soylemez, M.T.: Achieving diagonal dominance for parameter uncertain TITO systems using static diagonal controllers. IFAC-PapersOnLine 48(14), 271–277 (2015)

Lengare, M.J.; Chile, R.H.; Waghmare, L.M.: Design of decentralized controllers for MIMO processes. Comput. Electric. Eng. 38(1), 140–147 (2012)

Besta, C.S.; Chidambaram, M.: Improved decentralized controllers for stable systems by IMC method. Indian Chem. Eng. 60(4), 418–437 (2018)

Lakshmanaprabu, S.K.; Elhoseny, M.; Shankar, K.: Optimal tuning of decentralized fractional order PID controllers for TITO process using equivalent transfer function. Cognit. Syst. Res. 58, 292–303 (2019)

Xu, J.; Wang, W.; Zhang, H.: Stabilization of discrete-time multiplicative-noise system under decentralized controllers. IEEE Trans. Autom. Control 67(10), 5448–55 (2021)

Briones, O.; Alarcon, R.; Rojas, A.J.; Sbarbaro, D.: Tuning generalized predictive PI controllers for process control applications. ISA Trans. 119, 184–195 (2022)

Anbu, S.; Jaya, N.: Design of gain scheduling adaptive control for continuous stirred tank reactor. Int. J. Autom. Control 8(2), 141–157 (2014)

Govind, K.A.; Mahapatra, S.: Design of decentralized PI/PID control algorithm for a benchmark continuously stirred tank reactor system using frequency domain specifications. International Journal of Modelling, Identification and Control, to be published, https://doi.org/10.1504/IJMIC.2023.10054671.

Tavakoli, S.; Griffin, I.; Fleming, P.J.: Tuning of decentralised PI (PID) controllers for TITO processes. Control Eng. Pract. 14(9), 1069–1080 (2006)

Edet, E.; Katebi, R.: On fractional-order PID controllers. IFAC-PapersOnLine 51(4), 739–744 (2018)

Vilanova, R.: IMC based robust PID design: tuning guidelines and automatic tuning. J. Process Control 18(1), 61–70 (2008)

Wang, Q.-G.; Huang, B.; Guo, X.: Auto-tuning of TITO decoupling controllers from step tests. ISA Trans. 39(4), 407–418 (2000)

Albertos, P.; Antonio, Sala: Multivariable control systems: an engineering approach. Springer Science & Business Media, USA (2006)

Bequette, B.W.: Process control: modelling, design and simulation. Prentice Hall Professional, Hoboken (2003)

Liptak, B.G.; Lipták, B.G.: Process measurement and analysis, vol. 20. CRC Press Boca Raton, USA (2003)

Achu Govind, K.R.; Mahapatra, S.; Mahapatro, S.R.: A comparative analysis of various decoupling techniques using frequency domain specifications. In 2023 3rd International conference on Artificial Intelligence and Signal Processing (AISP), pp. 1–6. IEEE, (2023)

Achu Govind, K.R.; Mahapatra, S.: Design of PI/PID control algorithm for a benchmark heat exchanger system using frequency domain specifications. In 2022 IEEE International Power and Renewable Energy Conference (IPRECON), pp. 1–5. IEEE, (2022)

Wuhua, H.; Xiao, G.; Li, X.: An analytical method for PID controller tuning with specified gain and phase margins for integral plus time delay processes. ISA Trans. 50(2), 268–276 (2011)

Achu Govind, K.R.; Mahapatra, S.: Frequency domain specifications based robust decentralized PI/PID control algorithm for benchmark variable-area coupled tank systems. Sensors 22(23), 9165 (2022)

Nath, U.M.; Datta, S.; Dey, C.: Centralized auto-tuned IMC-PI controllers for industrial coupled tank process with stability analysis. In 2015 IEEE 2nd International Conference on Recent Trends in Information Systems (ReTIS), pp 296–301. IEEE, (2015)

Krishnamurthy, V.; Seshadri, V.: Model reduction using the routh stability criterion. IEEE Trans. Autom. Control 23(4), 729–731 (1978)

Author information

Authors and Affiliations

Contributions

The authors contributed equally to the work.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest in this work.

Appendices

Appendix A

The open-loop transfer function is given by Eq. (23)

As solving a third-order system is quite complicated, the model is reduced by the Routh stability criterion model reduction method. The transfer function of the reduced-order model can be obtained from the Routh array as reported in [42] and is given as

where

where

As Eq. (82) is of the form \(s^2+2\zeta \omega _n s+\omega _n ^2\), it can be simplified as

The model specified in Eq. (81) can be approximated as second-order model. Hence, closed-loop resonant frequency, maximum overshoot, resonant peak and bandwidth are given by

The relation between damping ratio and phase margin is given as

The frequency domain specifications of the second-order system is shown in Fig. 29.

Appendix B: Stability Analysis

1.1 Lower Region

The FOPDT model of the plant

The designed PID controller is

Hence, as per Eq. (45), the open-loop transfer function can be obtained as

where the time delays can be expressed by neglecting the higher order terms as \(e^{-0.6412s}=1-0.641269s\) and \( e^{-2.357s} = 1-2.357s\). Further, Eqs. (81) and (83) can be rearranged as

As described in Eq. (46),

On substituting, Equations (85) into (86), the characteristics Equation can be obtained as

The four Kharitonov polynomials are derived from Eqs. (505152)–(53) as

The Hurwitz matrix and the row reduced Hurwitz matrices for the Kharitonov polynomials described in Eqs. (888990)–(91) are given by Table 6. The elements in the matrix is positive, and there is no sign change. The positive values of the diagonal elements are verified, and the proposed controller is robust stable.

1.1.1 Middle Region

Similarly, Table 7 presents the Hurwitz matrix and the row reduced Hurwitz matrix for the Kharitonov polynomials for middle region. The positive values of the diagonal elements are verified, and the proposed controller is robust stable.

1.1.2 Higher Region

Subsequently, the Hurwitz matrix and the row reduced Hurwitz matrix for the Kharitonov polynomials for higher region is presented in Table 8. The positive values of the diagonal elements are verified and the proposed controller is robust stable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Achu Govind, K.R., Mahapatra, S. & Mahapatro, S.R. Nonlinear Constraint Optimization Based Robust Decentralized PID Controller for a Benchmark CSTR System Using Kharitonov–Hurwitz Stability Analysis. Arab J Sci Eng 48, 15377–15402 (2023). https://doi.org/10.1007/s13369-023-08076-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08076-1