Abstract

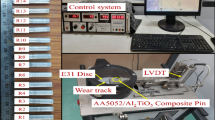

Strengthening, heat treating, or rolling these alloys with different reinforcement particles positively affects the physical, mechanical and tribological properties. In this study, materials were produced by squeeze casting method by adding B4C particle to Al7075 alloy matrix in 4 different reinforcement ratios (4%, 8%, 10%, 12%). The physical, mechanical, and tribological properties of B4C/Al7075 composites were compared to the Al7075 alloy. In addition, aging and rolling processes were applied to B4C reinforced composite and Al7075 alloy, where the best mechanical properties were obtained, and the effects of these processes on hardness, tensile and flexural strengths, and tribological properties were investigated. The fracture and wear surfaces of the samples were investigated by SEM. When the effect of reinforcement ratio was examined, the highest hardness value was seen at 12% reinforcement ratio. The highest tensile and flexural strength was obtained from 10% reinforcement. Tensile strength of 10% B4C/Al7075 composite material was determined as 249 MPa and flexural strength as 494 MPa. As in the hardness value, the best value in wear resistance was obtained from 12%. B4C reinforcement increased the wear resistance of the Al7075 alloy. When the effect of aging was examined, it was observed that the determined properties of the materials were considerably improved depending on the aging period, but they partially decreased after a certain aging period. The rolling process also improved the determined properties of the materials, but this effect was not as high as in the aging process.

Similar content being viewed by others

References

Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H.: Aluminium matrix hybrid composites: a review of reinforcement philosophies; Mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 4(4), 434–445 (2015). https://doi.org/10.1016/j.jmrt.2015.05.003

Kumar, R.; Dhiman, S.: A study of sliding wear behaviors of Al-7075 alloy and Al-7075 hybrid composite by response surface methodology analysis. Mater. Des. 50, 51–359 (2013). https://doi.org/10.1016/j.matdes.2013.02.038

Krishna, M.V.; Xavior, A.M.: An investigation on the mechanical properties of hybrid metal matrix composites. Procedia Eng. 97, 918–924 (2014). https://doi.org/10.1016/j.proeng.2014.12.367

Kumar, B.P.; Birru, A.K.: Microstructure and mechanical properties of aluminium metal matrix composites with addition of bamboo leaf ash by stir casting method. Trans. Nonferrous Met. Soc. China (English Ed.) 27(12), 2555–2572 (2017). https://doi.org/10.1016/S1003-6326(17)60284-X

Verma, N.; Vettivel, S.C.: Characterization and experimental analysis of boron carbide and rice husk ash reinforced AA7075 aluminium alloy hybrid composite. J. Alloys Compd. 741, 981–998 (2018). https://doi.org/10.1016/j.jallcom.2018.01.185

Saravanakumar, P.; Soundararajan, R.; Ps, D.; Parthasarathi, N.: A review on effect of reinforcement and squeeze casting process parameters on mechanical properties of aluminium matrix composites. Int. J. Innov. Res. Sci. Eng. Technol. 5(7), 58–63 (2016)

Pandi, G.; Muthusamy, S.: A review on machining and tribological behaviors of aluminium hybrid composites. Procedia Eng. 38, 1399–1408 (2012). https://doi.org/10.1016/j.proeng.2012.06.174

Kilic, M.; Imak, A.; Kirik, I.: Surface modification of AISI 304 stainless steel with NiBSi-SiC composite by TIG method. J. Mater. Eng. Perform. 30(2), 1411–1419 (2021). https://doi.org/10.1007/s11665-020-05378-5

Sonmez, F.: Combination of aging aluminum alloys by friction stir welding and examination of their mechanical properties after welding, Gazi University, Institute of Science, PhD., (2016)

Ipekoglu, M.; Nekouyan, A.; Albayrak, O.; Altintas, S.: Mechanical characterization of B4C reinforced aluminum matrix composites produced by squeeze casting. J. Mater. Res. 32(3), 599–605 (2017). https://doi.org/10.1557/jmr.2016.495

Reddy, S.S.K.; Sreedhar, C.; Suresh, S.: Investigations on Al 7075/nano-SiC/B4C hybrid reinforcements using liquid casting method. Mater. Today Proc. 46, 8540–8547 (2021). https://doi.org/10.1016/j.matpr.2021.03.536

Kamaraj, M.; Ramesh, A.: Effect of squeeze pressure on mechanical properties of LM6 aluminium alloy matrix hybrid composites. ARPN J. Eng. Appl. Sci. 10(14), 6051–6058 (2015)

Ravi, B.; Naik, B.B.; Prakash, J.U.: Characterization of aluminium matrix composites (AA6061/B4C) fabricated by stir casting technique. Mater. Today Proc. 2(4–5), 2984–2990 (2015). https://doi.org/10.1016/j.matpr.2015.07.282

Rajesh, G.L.; Auradi, V.; Kori, S.A.: Mechanical behaviour and dry sliding wear properties of ceramic boron carbide particulate reinforced Al6061 matrix composites. Trans. Indian Ceram. Soc. 75(2), 112–119 (2016)

Wu, C., et al.: Influence of particle size and spatial distribution of B4C reinforcement on the microstructure and mechanical behavior of precipitation strengthened Al alloy matrix composites. Mater. Sci. Eng. A 675, 421–430 (2016). https://doi.org/10.1016/j.msea.2016.08.062

Chen, H.S.; Wang, W.; Nie, H.; Zhou, J.; Li, Y.; Zhang, P.: Microstructure and mechanical properties of B4C/6061Al laminar composites fabricated by power metallurgy. Vacuum 143, 363–370 (2017). https://doi.org/10.1016/j.vacuum.2017.06.009

Çelik, Y.H.; Kilickap, E.: Hardness and wear behaviours of Al matrix composites and hybrid composites reinforced with B4C and SiC. Powder Metall. Met. Ceram. 57(9–10), 613–622 (2019). https://doi.org/10.1007/s11106-019-00023-w

Xu, H.; Zhang, G.Z.; Cui, W.; Ren, S.B.; Wang, Q.J.; Qu, X.H.: Effect of Al2O3sf addition on the friction and wear properties of (SiC p + Al2O3sf)/Al2024 composites fabricated by pressure infiltration. Int. J. Miner. Metall. Mater. 25(3), 375–382 (2018). https://doi.org/10.1007/s12613-018-1581-z

Kalra, C.S.; Kumar, V.; Manna, A.: The wear behavior of Al/(Al2O3 + SiC + C) hybrid composites fabricated stir casting assisted squeeze. Part. Sci. Technol. 37(3), 303–313 (2019). https://doi.org/10.1080/02726351.2017.1369475

Kumar, A.; Kumar, V.; Kumar, A.; Nahak, B.; Singh, R.: Investigation of mechanical and tribological performance of marble dust 7075 aluminium alloy composites. Mater. Today Proc. 44, 4542–4547 (2020). https://doi.org/10.1016/j.matpr.2020.10.812

Sekar, K.: Mechanical and tribological properties of A7075/SiC/B4C hybrid composite fabricated by stir and squeeze casting method. Key Eng. Mater. 882, 77–88 (2021). https://doi.org/10.4028/www.scientific.net/KEM.882.77

Pang, X.; Xian, Y.; Wang, W.; Zhang, P.: Tensile properties and strengthening effects of 6061Al/12 wt%B4C composites reinforced with nano-Al2O3 particles. J. Alloys Compd. 768, 476–484 (2018). https://doi.org/10.1016/j.jallcom.2018.07.072

Kaushik, N.; Singhal, S.: Hybrid combination of Taguchi-GRA-PCA for optimization of wear behavior in AA6063/SiCp matrix composite. Prod. Manuf. Res. 6(1), 171–189 (2018). https://doi.org/10.1080/21693277.2018.1479666

Zhang, L.; Shi, J.; Shen, C.; Zhou, X.; Peng, S.; Long, X.: B4C-Al composites fabricated by the powder metallurgy process. Appl. Sci. 7(10), 1009 (2017). https://doi.org/10.3390/app7101009

Kayaroganam, P.; Krishnan, V.; Natarajan, E.; Natarajan, S.; Muthusamy, K.: Drilling parameters analysis on in-situ Al/B4C/mica hybrid composite and an integrated optimization approach using fuzzy model and non-dominated sorting genetic algorithm. Metals (Basel) 11(12), 2060 (2021). https://doi.org/10.3390/met11122060

Velavan, K.; Palanikumar, K.; Natarajan, E.; Lim, W.H.: Implications on the influence of mica on the mechanical properties of cast hybrid (Al + 10%B4C + Mica) metal matrix composite. J. Mater. Res. Technol. 10, 99–109 (2021). https://doi.org/10.1016/j.jmrt.2020.12.004

Sudhakar, I.; Madhusudhan Reddy, G.; Srinivasa Rao, K.: Ballistic behavior of boron carbide reinforced AA7075 aluminium alloy using friction stir processing: an experimental study and analytical approach. Def. Technol. 12(1), 25–31 (2016). https://doi.org/10.1016/j.dt.2015.04.005

Anitha, P.; Shrinivas Balraj, U.: Dry sliding wear performance of Al/7075/Al2O3p/Grp hybrid metal matrix composites. Mater. Today Proc. 4(2), 3033–3042 (2017). https://doi.org/10.1016/j.matpr.2017.02.186

Bhaumik, M.; Maity, K.: Fabrication and characterization of the Al6063/5%ZrO2/5%Al2O3 composite. IOP Conf. Ser.: Mater. Sci. Eng. 178, 1–7 (2017). https://doi.org/10.1088/1757-899X/178/1/012011

Das, D.; Pattanaik, S.; Routara, B.C.; Mishra, P.C.; Samal, C.: Dry sliding wear behaviour of SiCp reinforced Zn-Mg-Cu based aluminium matrix composite. Mater. Today Proc. 4(2), 2965–2974 (2017). https://doi.org/10.1016/j.matpr.2017.02.178

Çelik, Y.H.; Demir, M.E.; Kilickap, E.; Kalkanli, A.: Investigation of wear behavior of aged and non-aged SiC-reinforced AlSi7Mg2 metal matrix composites in dry sliding conditions. J. Braz. Soc. Mech. Sci. Eng. 42(1), 1–9 (2020). https://doi.org/10.1007/s40430-019-2088-x

Singh, K.M.; Chauhan, A.K.: Effect of age hardening on sliding wear behaviour of Al7075/B4C nanocomposites. Mater. Today Proc. 47, 3865–3870 (2021). https://doi.org/10.1016/j.matpr.2021.03.440

Patle, H.; Mahendiran, P.; Ratna Sunil, B.; Dumpala, R.: Hardness and sliding wear characteristics of AA7075-T6 surface composites reinforced with B4C and MoS2 particles. Mater. Res. Express 6(8), 086589 (2019). https://doi.org/10.1088/2053-1591/ab1ff4

Gajakosh, A.K.; Keshavamurthy, R.; Ugrasen, G.; Adarsh, H.: Investigation on mechanical behavior of hot rolled Al7075-TiB2 in-situ metal matrix composite. Mater. Today Proc. 5(11), 25605–25614 (2018). https://doi.org/10.1016/j.matpr.2018.10.430

Raturi, A.; Mer, K.K.S.; Kumar Pant, P.: Synthesis and characterization of mechanical, tribological and micro structural behaviour of Al 7075 matrix reinforced with nano Al2O3 particles. Mater. Today Proc. 4(2), 2645–2658 (2017). https://doi.org/10.1016/j.matpr.2017.02.139

Kannan, C.; Ramanujam, R.: Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J. Adv. Res. 8(4), 309–319 (2017). https://doi.org/10.1016/j.jare.2017.02.005

Mazaheri, Y.; Meratian, M.; Emadi, R.; Najarian, A.R.: Comparison of microstructural and mechanical properties of Al-TiC, Al-B 4C and Al-TiC-B 4C composites prepared by casting techniques. Mater. Sci. Eng. A 560, 278–287 (2013). https://doi.org/10.1016/j.msea.2012.09.068

Ramkumar, K.R.; Sivasankaran, S.; Al-Mufadi, F.A.; Siddharth, S.; Raghu, R.: Investigations on microstructure, mechanical, and tribological behaviour of AA 7075–x wt.% TiC composites for aerospace applications. Arch. Civ. Mech. Eng. 19(2), 428–438 (2019). https://doi.org/10.1016/j.acme.2018.12.003

Topcu, I.; Gulsoy, H.O.; Kadioglu, N.; Gulluoglu, A.N.: Processing and mechanical properties of B4C reinforced Al matrix composites. J. Alloys Compd. 482(1–2), 516–521 (2009). https://doi.org/10.1016/j.jallcom.2009.04.065

Kalaiselvan, K.; Murugan, N.; Parameswaran, S.: Production and characterization of AA6061-B4C stir cast composite. Mater. Des. 32(7), 4004–4009 (2011). https://doi.org/10.1016/j.matdes.2011.03.018

Sharifi, E.M.; Karimzadeh, F.; Enayati, M.H.: Fabrication and evaluation of mechanical and tribological properties of boron carbide reinforced aluminum matrix nanocomposites. Mater. Des. 32(6), 3263–3271 (2011). https://doi.org/10.1016/j.matdes.2011.02.033

Zheng, R.; Hao, X.; Yuan, Y.; Wang, Z.; Ameyama, K.; Ma, C.: Effect of high volume fraction of B4C particles on the microstructure and mechanical properties of aluminum alloy based composites. J. Alloys Compd. 576, 291–298 (2013). https://doi.org/10.1016/j.jallcom.2013.04.141

Pul, M.: Effect of sintering on mechanical property of SiC/B4C reinforced aluminum. Mater. Res. Express 6(1), 016541 (2018)

Gao, M.; Kang, H.; Chen, Z.; Guo, E.; Peng, P.; Wang, T.: Effect of reinforcement content and aging treatment on microstructure and mechanical behavior of B4Cp/6061Al composites. Mater. Sci. Eng. A 744, 682–690 (2019). https://doi.org/10.1016/j.msea.2018.12.042

Salman, J.M.; Abbas, S.; Alsada, A.; Al-sultani, K.F.: Improvement properties of 7075–T6 aluminum alloy by quenching in 30% polyethylene glycol and addition 0.1% B. Resaerch J. Mater. Sci. 1(6), 12–17 (2013)

Chandra, B.T.; Sanjeevamurthy; Shivashankar, H.S.: Effect of heat treatment on hardness of Al7075-Albite particulate composites. Mater. Today Proc. 4(10), 10786–10791 (2017). https://doi.org/10.1016/j.matpr.2017.08.028

Gajakosh, A.K.; Keshavamurthy, R.; Jagadeesha, T.; Kumar, R.S.: Investigations on mechanical behavior of hot rolled Al7075/TiO2/Gr hybrid composites. Ceram. Int. 47(10), 14775–14789 (2021). https://doi.org/10.1016/j.ceramint.2020.10.236

Kumar, R.V.; Keshavamurthy, R.; Perugu, C.S.; Koppad, P.G.; Alipour, M.: Influence of hot rolling on microstructure and mechanical behaviour of Al6061-ZrB2 in-situ metal matrix composites. Mater. Sci. Eng. A 738, 344–352 (2018). https://doi.org/10.1016/j.msea.2018.09.104

Baradeswaran, A.; Perumal, A.E.: Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Compos. Part B Eng. 54(1), 146–152 (2013). https://doi.org/10.1016/j.compositesb.2013.05.012

Patil, S.; Haneef, M.; Narayanaswamy, K.S.: Effect of heat treatment on mechanical properties and wear behavior of Al7075 alloy reinforced with beryl and graphene hybrid metal matrix composites. Int. J. Aerosp. 13(6), 399–406 (2019)

Uthayakumar, M.; Aravindan, S.; Rajkumar, K.: Wear performance of Al-SiC-B4C hybrid composites under dry sliding conditions. Mater. Des. 47, 456–464 (2013). https://doi.org/10.1016/j.matdes.2012.11.059

Rao, R.N.; Das, S.: Effect of matrix alloy and influence of SiC particle on the sliding wear characteristics of aluminium alloy composites. Mater. Des. 31(3), 1200–1207 (2010). https://doi.org/10.1016/j.matdes.2009.09.032

Lakshmipathy, J.; Kulendran, B.: Reciprocating wear behavior of 7075Al/SiC in comparison with 6061Al/Al 2O3 composites. Int. J. Refract. Met. Hard Mater. 46, 137–144 (2014). https://doi.org/10.1016/j.ijrmhm.2014.06.007

Aherwar, A.; Patnaik, A.; Pruncu, C.I.: Effect of B4C and waste porcelain ceramic particulate reinforcements on mechanical and tribological characteristics of high strength AA7075 based hybrid composite. J. Mater. Res. Technol. 9(5), 9882–9894 (2020). https://doi.org/10.1016/j.jmrt.2020.07.003

Shorowordi, K.M.; Haseeb, A.S.M.A.; Celis, J.P.: Tribo-surface characteristics of Al-B4C and Al-SiC composites worn under different contact pressures. Wear 261(5–6), 634–641 (2006). https://doi.org/10.1016/j.wear.2006.01.023

Acknowledgements

This work was supported by Batman University Scientific Research Projects Unit (BTÜBAP). We would like to thank Batman University for their support for the works carried out within the scope of BTÜBAP-2020-01 project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demir, M.E., Çelik, Y.H. & Kalkanli, A. The Effect of Rolling and Aging on Mechanical and Tribological Properties in B4C Particle Reinforced Al7075 Matrix Composites. Arab J Sci Eng 47, 16187–16208 (2022). https://doi.org/10.1007/s13369-022-06891-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06891-6