Abstract

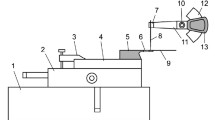

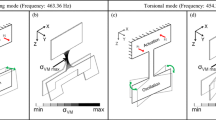

The conceptual design of a microfabricated load cell for mechanical testing of materials is presented that utilizes radiation pressure for the application of load. Using a laser as the source of radiation pressure cyclic and quasi-static materials testing is possible in force, spatial and temporal ranges not previously accessible. The overall design consists of 3 subsystems working in unison for the testing of micro-/nanostructured materials in tension, compression, and bending. One subsystem applies radiation pressure (load); a second subsystem measures displacement optically; and the third subsystem is the optomechanical load cell (OMLC) itself with which the other two subsystems interact. The OMLC translates in one dimension and contains a thermal dissipation structure. A detailed design of the OMLC is presented that takes into consideration optical, mechanical, and thermal considerations when a 1 W laser at 532 nm is utilized. With analytical and computational models, force, displacement, and temporal resolutions are demonstrated. Specifically, it is shown that the design is capable of forces from fN to mN, with 10 pm of displacement resolution and cyclic loads of up to 1 MHz.

Similar content being viewed by others

Abbreviations

- k :

-

Spring constant (N/m)

- F :

-

Force (N)

- x :

-

Displacement, position (m)

- P :

-

Pressure (Pa)

- I :

-

Irradiance (W/m2)

- c :

-

Speed of light (m/s)

- R o :

-

Reflectance (unitless)

- A o :

-

Absorptivity (unitless)

- T o :

-

Transmissivity (unitless)

- \(\overrightarrow{k}\) :

-

Wave vector (m−1)

- \(\overrightarrow{E}\) :

-

Electric field (V/m)

- \(\overrightarrow{B}\) :

-

Magnetic field (T)

- \(\overrightarrow{p}\) :

-

Momentum (kg m/s)

- t :

-

Time (s)

- u :

-

Energy density (J/m3)

- \(\overrightarrow{S}\) :

-

Poynting vector (W/m2)

- T :

-

Temperature (K)

- A :

-

Area (m2)

- k B :

-

Boltzmann’s constant (J/K)

- L :

-

Length of beam (m)

- M :

-

Moment (Nm)

- M o :

-

Moment at origin

- E :

-

Elastic modulus (Pa)

- I :

-

Second moment of inertia (m4)

- δ :

-

Maximum deflection (m)

- q :

-

Similarity parameter (unitless)

- Δ:

-

Change or difference

- θ :

-

Angle (°)

- v :

-

Per unit volume

- MEMS:

-

Microelectromechanical systems

- sample:

-

Sample

- rad:

-

Radiation

- in:

-

Into the object

- out:

-

Out of the object

- surf:

-

Surface

- photons:

-

Photons

- x:

-

X-direction

- y:

-

Y-direction

- cavity:

-

Optical cavity

- o:

-

Optical

- t:

-

Total

- OMLC:

-

Optomechanical load cell

- SFA:

-

Surface force apparatus

- AFM:

-

Atomic force microscope

- MEMS:

-

Microelectromechanical systems

- EM:

-

Electromagnetic

- PSD:

-

Position sensing detector

- FEM:

-

Finite element model

- SOI:

-

Silicon on insulator

- DOF:

-

Degree of freedom

References

Helm, C.A.; Knoll, W.; Israelachvili, J.N.: Measurement of ligand–receptor interactions. Proc. Natl. Acad. Sci. USA 88(18), 8169–8173 (1991)

Yang, S.; Saif, M.T.A.: MEMS based force sensors for the study of indentation response of single living cells, pp. 1–7 (2006). https://doi.org/10.1016/j.sna.2006.05.019

Saif, M.T.A., et al.: Functionalized biomicroeletromechanical systems sensors for force response study at local adhesion sites of living cells on substrates. Ann. Biomed. Eng. 31, 950–961 (2003)

Rajagopalan, J.; Han, J.H.; Saif, M.T.A.: Plastic deformation recovery in freestanding nanocrystalline aluminum and gold thin films. Science (80-. ) 315, 1831–1834 (2007)

Saif, M.T.; Zhang, S.; Haque, A.; Hsia, K.J.: Effect of native Al2O3 on the elastic response of nanoscale Al films. Acta Mater. 50, 2779–2786 (2002)

Kumar, S.; Alam, M.T.; Connell, Z.; Haque, M.A.: Electromigration stress induced deformation mechanisms in free-standing platinum thin films. Scr. Mater. 65(4), 277–280 (2011). https://doi.org/10.1016/j.scriptamat.2011.04.030

Israelachvili, J.: Intermolecular and Surface Forces, 2nd edn. Academic Press, New York (1998)

Israelachvili, J.N.; Adams, G.E.: Direct measurement of long range forces between two mica surfaces in aqueous KNO3 solutions. Nature 262, 774–776 (1976)

Asay, D.B.; Kim, S.H.: Direct force balance method for atomic force microscopy lateral force calibration. Rev. Sci. Instrum. 77, 043903 (2006)

Bowen, W.R.; Hilal, N.; Lovitt, R.W.; Wright, C.J.: Direct measurement of the force of adhesion of a single biological cell using an atomic force microscope. Colloids Surf. A 136, 231–234 (1998)

Pratt, J.R.; Kramar, J.A.; Newell, D.B.; Smith, D.T.: Review of SI traceable force metrology for instrumented indentation and atomic force microscopy. Meas. Sci. Technol. 16, 2129–2137 (2005)

Chung, K.-H.; Shaw, G.A.; Pratt, J.R.: Accurate noncontact calibration of colloidal probe sensitivities in atomic force microscopy. Rev. Sci. Instrum. 80, 065107 (2009)

Cuenot, S., et al.: Measurement of elastic modulus of nanotubes by resonant contact atomic force microscopy. J. Appl. Phys. 93, 5650–5655 (2003)

Dietzel, D.; Faucher, M.; Iaia, A., et al.: Analysis of mechanical properties of single wall carbon nanotubes fixed at a tip apex by atomic force microscopy. Nanotechnology 16, S73 (2005)

Dulinska, I., et al.: Stiffness of normal and pathological erythrocytes studied by means of atomic force microscopy. J. Biochem. Biophys. methods 66, 1–11 (2006)

Green, C.P.; Lioe, H.; Cleveland, J.P.; Proksch, R.; Mulvaney, P.: Normal and torsional spring constants of atomic force microscope cantilevers. Rev. Sci. Instrum. 75, 1988–1996 (2004)

E. D. Langlois, G. A. Shaw, J. A. Kramar, J. R. Pratt, and D. C. Hurley, “Spring constant calibration of atomic force microscopy cantilevers with a piezosensor transfer method,” Rev. Sci. Instrum., vol. 78, 2007. 093705.

Matei, G.A.; Thoreson, E.J.; Pratt, J.R.; Newell, D.B.; Burnham, N.A.: Precision and accuracy of thermal calibration of atomic force microscopy cantilevers. Rev. Sci. Instrum. 77, 083703 (2006)

Ogletree, D.F.; Carpick, R.W.; Salmeron, M.: Calibration of frictional forces in atomic force microscopy. Rev. Sci. Instrum. 67(9), 3298–3306 (1996)

Saif, M.T.A.; MacDonald, N.C.: Measurement of forces and spring constants of microinstruments. Rev. Sci. Instrum. 69(3), 1410–1422 (1998)

Haque, M.A.: Length-scale effects on nano-scale materials behaviour. University of Illinois Urbana-Champaign (2002)

Zhu, Y.; Espinosa, H.D.: An electromechanical material testing system for in situ electron microscopy and applications. Proc. Natl. Acad. Sci. 102(41), 14503–14508 (2005)

Abbas, K., et al.: Nanoscale size effects on the mechanical properties of platinum thin films and cross-sectional grain morphology. J. Micromech. Microeng. 26(1), 015007 (2015). https://doi.org/10.1088/0960-1317/26/1/015007

Li, C.; Cheng, G.; Wang, H.; Zhu, Y.: Microelectromechanical systems for nanomechanical testing: displacement- and force-controlled tensile testing with feedback control. Exp. Mech. 60(7), 1005–1015 (2020). https://doi.org/10.1007/s11340-020-00619-z

Mousavi, B.K.; Mousavi, A.K.; Hieber, T.J.; Chen, J.; Leseman, Z.C.: Mode II adhesion energy analysis of stiction-failed poly-Si μ cantilevers using a MEMS load cell. J. Micromech. Microeng. 29(7), 075013 (2019). https://doi.org/10.1088/1361-6439/ab173e

Li, C.; Zhang, D.; Cheng, G.; Zhu, Y.: Microelectromechanical systems for nanomechanical testing: electrostatic actuation and capacitive sensing for high-strain-rate testing. Exp. Mech. 60(3), 329–343 (2020). https://doi.org/10.1007/s11340-019-00565-5

Taylor, P.; Molloy, J.E.; Padgett, M.J.: Lights, action: optical tweezers. Contemp. Phys. (2012). https://doi.org/10.1080/0010751011011605

Hart’Anský, R., et al.: Novel method of contactless sensing of mechanical quantities. Meas. Sci. Rev. 20(3), 150–156 (2020). https://doi.org/10.2478/msr-2020-0018

Bell, D.J.; Lu, T.J.; Fleck, N.A.; Spearing, S.M.: MEMS actuators and sensors: observations on their performance and selection for purpose. J. Micromech. Microeng. (2005). https://doi.org/10.1088/0960-1317/15/7/022

Zhang, X.; Ma, L.; Zhang, Y.: High-resolution optical tweezers for single- molecule manipulation. Yale J. Biol. Med. 86(3), 367–383 (2013)

Sattler, K.D. (ed.): Handbook of Nanophysics: Principles and Methods. CRC Press, Boca Raton (2010)

Panwar, A.S.; Singh, A.; Sehgal, S.: Material characterization techniques in engineering applications: a review. Mater. Today Proc. 28, 1932–1937 (2020). https://doi.org/10.1016/j.matpr.2020.05.337

Gheith, M.H., et al.: Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J. Mater. Res. Technol. 8(1), 853–860 (2019). https://doi.org/10.1016/j.jmrt.2018.06.013

Dror, R.O.; Jensen, M.; Borhani, D.W.; Shaw, D.E.: Perspectives on: Molecular dynamics and computational methods Exploring atomic resolution physiology on a femtosecond to millisecond timescale using molecular dynamics simulations. J. Gen. Physiol. 135(6), 555–562 (2010). https://doi.org/10.1085/jgp.200910373

Robertson, I.M., et al.: Towards an integrated materials characterization toolbox. J. Mater. Res. 26(11), 1341–1383 (2011). https://doi.org/10.1557/jmr.2011.41

Nichols, E.F.; Hull, G.F.: The pressure due to radiation author (s): Nichols, E.F.; Hull, G.F. Hull reviewed work (s): Source: Proceedings of the American Academy of Arts and Sciences, Vol. 38, No. 20 (April, Published by: American Academy of Arts & Sciences Stable URL). Proc. Am. Acad. Arts Sci. 38(20), 559 (1903)

Gordon, J.P.; Zeiger, H.J.; Townes, C.H.: The maser-new type of microwave amplifier, frequency standard, and spectrometer. Phys. Rev. 99(4), 1264–1274 (1955). https://doi.org/10.1103/PhysRev.99.1264

Maiman, T.H.: Stimulated optical radiation in ruby. Nature 187(4736), 493–494 (1960). https://doi.org/10.1038/187493a0

Ashkin, A.: Acceleration and trapping of particles by radiation pressure. Phys. Rev. Lett. 24(4), 156–159 (1970). https://doi.org/10.1103/PhysRevLett.24.156

Ashkin, A.; Dziedzic, J.M.; Bjorkholm, J.E.; Chu, S.: Observation of a single-beam gradient force optical trap for dielectric particles. Opt. Angular Momentum 11(5), 196–198 (2016). https://doi.org/10.1364/ol.11.000288

Hecht, E.: Optics, 4th edn. Addison Wesley, San Francisco (2002)

Mahrle, A.; Beyer, E.: Theoretical evaluation of radiation pressure magnitudes and effects in laser material processing. Phys. Scr. (2019). https://doi.org/10.1088/1402-4896/ab04c3

MacLeod, H.A.: Thin Film Optical Filters. IOP Publishing, Bristol (2003)

Yang, M.; Gatto, A.; Kaiser, N.: Optical thin films with high reflectance, low thickness and low stress for the spectral range from vacuum UV to near IR. J. Opt. A Pure Appl. Opt. 8, 327–332 (2006)

Wagner, R.; Guzman, F.; Chijioke, A.; Gulati, G.K.; Keller, M.; Shaw, G.: Direct measurement of radiation pressure and circulating power inside a passive optical cavity. Opt. Express 26(18), 23492 (2018). https://doi.org/10.1364/oe.26.023492

Ando, T.: High-speed AFM imaging. Curr. Opin. Struct. Biol. 28(1), 63–68 (2014). https://doi.org/10.1016/j.sbi.2014.07.011

Chary, K.V.R.; Srivastava, A.K.: Encyclopedia of Biophysics (2013)

Braunsmann, C.; Prucker, V.: Optical knife-edge displacement sensor for high-speed atomic force microscopy. Appl. Phys. Lett. 104(10), 1–5 (2014). https://doi.org/10.1063/1.4868043

Frisch-Fay, R.: Flexible Bars. Butterworths, New York (1962)

Pulavarthy, R.A.; Alam, M.T.; Haque, M.A.: Effect of heated zone size on micro and nanoscale convective heat transfer ☆. Int. Commun. Heat Mass Transf. 52, 56–60 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2014.01.016

Alaie, S.; Goettler, D.F.; Su, M.; Leseman, Z.C.; Reinke, C.M.; El-Kady, I.: Thermal transport in phononic crystals and the observation of coherent phonon scattering at room temperature. Nat. Commun. 6, 7228 (2015). https://doi.org/10.1038/ncomms8228

Alaie, Z.C.L.S.; Goettler, D.; Abbas, K.; El-Kadi, I.: Measurement of in-plane thermal conductivity using suspended SiNX Islands. IMECE2012. ASME, Houston, Texas, vol. 9, pp. 611–616 (2012)

Abbas, K.; Alaie, S.; Leseman, Z.C.: Design and characterization of a low temperature gradient and large displacement thermal actuators for in situ mechanical testing of nanoscale materials. J. Micromech. Microeng. (2012). https://doi.org/10.1088/0960-1317/22/12/125027

Pantano, M.F.; Calusi, B.; Mazzolai, B.; Espinosa, H.D.; Pugno, N.M.: Load sensor instability and optimization of MEMS-based tensile testing devices. Front. Mater. 6(July), 1–8 (2019). https://doi.org/10.3389/fmats.2019.00161

Acknowledgements

ZCL acknowledges support provided by the Deanship of Scientific Research at King Fahd University of Petroleum & Minerals for funding this work through Project SR191001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Leseman, Z.C. Design of a Microscale Optomechanical Load Cell for Micro-/Nanostructured Materials Testing Applications. Arab J Sci Eng 47, 1053–1067 (2022). https://doi.org/10.1007/s13369-021-06019-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-06019-2