Abstract

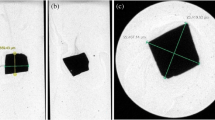

Previous laboratory tests conducted using rock-like samples with 2D through fractures are mostly high-level simplifications of real engineering conditions. Thus, the results from these 2D analyses cannot usually be successfully applied to 3D conditions and real engineering conditions. To study the mechanical properties and failure processes of samples that could highly represent the 3D conditions in the real world, brittle rock-like samples with designed internal open-type fractured structures are prepared for this study using the volume loss method and super absorbent polymer, and following studies included the uniaxial compression tests and discrete element numerical simulations. The results from real tests and simulations proved that the shape, position, and volume of internal open-type fractured structures had an obvious influence on the physical properties and spatial distributions of shear and tensile failures of specimens. Different from the results obtained by former 2D studies, failure surfaces in this work are not parallel with the preset structures, and the main failure faces develop along the diagonal directions of the internal structure. In addition, the tensile failure distribution is controlled by the shape and position of the internal structure, and the shear failure distribution is influenced by the height of the internal structure and the positions of the tensile failure surface. The findings are helpful for explaining the failure characteristics of specimens containing 3D fractured structures.

Similar content being viewed by others

Abbreviations

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional

- SAP:

-

Super absorbent polymer

- AE:

-

Acoustic emission

- CT:

-

Computed tomography

- PFC:

-

Particle Flow Code

- SRM:

-

Synthetic rock mass model

- BPM:

-

Bonded particle model (numerical model in PFC software)

- FJM:

-

Flat-joint model (numerical model in PFC software)

- FJC:

-

Flat-joint contact

- STL:

-

Stereolithography format of digital graph

- PS:

-

Peak-time uniaxial strain

- UCS:

-

Uniaxial compression strength

- TS:

-

Tensile strength

- EM:

-

Elastic modulus

References

Gao, W.; Dai, S.; Xiao, T.; He, T.Y.: Failure process of rock slopes with cracks based on the fracture mechanics method. Eng. Geol. 231, 190–199 (2017). https://doi.org/10.1016/j.enggeo.2017.10.020

Asadizadeh, M.; Hossaini, M.F.; Moosavi, M.; Masoumi, H.; Ranjithc, P.G.: Mechanical characterisation of jointed rock-like material with non-persistent rough joints subjected to uniaxial compression. Eng. Geol. 260, 105224 (2019). https://doi.org/10.1016/j.enggeo.2019.105224

Zhou, L.; Zhu, Z.M.; Dong, Y.Q.; Ying, P.; Wang, M.: Study of the fracture behavior of mode I and mixed mode I/II cracks in tunnel under impact loads. Tunn. Undergr. Space Technol. 84, 11–21 (2019). https://doi.org/10.1016/j.tust.2018.10.018

Chen, M.L.; Jing, H.W.; Ma, X.J.; Su, H.J.; Du, M.R.; Zhu, T.T.: Fracture evolution characteristics of sandstone containing double fissures and a single circular hole under uniaxial compression. Int. J. Min. Sci. Technol. 27(3), 499–505 (2017). https://doi.org/10.1016/j.ijmst.2017.03.027

Wu, T.H.; Zhou, Y.; Wang, L.; Sun, J.H.; Zhao, H.; Sun, Z.: Mesoscopic study of interaction mechanism between circular hole and fissures in rock under uniaxial compression. Rock Soil Mech. 39(s2), 463–472 (2018). https://doi.org/10.16285/j.rsm.2018.0957. (in Chinese)

Li, Y.P.; Chen, L.Z.; Wang, Y.H.: Experimental research on pre-cracked marble under compression. Int. J. Solids Struct. 42(9–10), 2505–2516 (2005). https://doi.org/10.1016/j.ijsolstr.2004.09.033

Li, X.B.; Zhou, T.; Li, D.Y.: Dynamic strength and fracturing behavior of single-flawed prismatic marble specimens under impact loading with a split-Hopkinson pressure bar. Rock Mech. Rock Eng. 50(1), 29–44 (2017). https://doi.org/10.1007/s00603-016-1093-y

Bobet, A.; Einstein, H.H.: Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 35(7), 863–888 (1998). https://doi.org/10.1016/S0148-9062(98)00005-9

Wong, R.H.C.; Chau, K.T.; Tang, C.A.; Lin, P.: Analysis of crack coalescence in rock-like materials containing three flaws—part I: experimental approach. Int. J. Rock Mech. Min. Sci. 38(7), 909–924 (2001). https://doi.org/10.1016/S1365-1609(01)00064-8

Zhuang, X.Y.; Chun, J.W.; Zhu, H.H.: A comparative study on unfilled and filled crack propagation for rock-like brittle material. Theor. Appl. Fract. Mech. 72, 110–120 (2014). https://doi.org/10.1016/j.tafmec.2014.04.004

Lee, H.; Jeon, S.: An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int. J. Solids Struct. 48(6), 979–999 (2011). https://doi.org/10.1016/j.ijsolstr.2010.12.001

Zhao, Y.L.; Zhang, L.Y.; Wang, W.J.; Pu, C.Z.; Wan, W.; Tang, J.Z.: Cracking and stress-strain behavior of rock-like material containing two flaws under uniaxial compression. Rock Mech. Rock Eng. 49(7), 2665–2687 (2016). https://doi.org/10.1007/s00603-016-0932-1

Yang, S.Q.; Yang, D.S.; Jing, H.W.; Li, Y.H.; Wang, S.Y.: An experimental study of the fracture coalescence behavior of brittle sandstone specimens containing three fissures. Rock Mech. Rock Eng. 45, 563–582 (2012). https://doi.org/10.1007/s00603-011-0206-x

Wong, R.H.C.; Chau, K.T.: Crack coalescence in a rock-like material containing two cracks. Int. J. Rock Mech. Min. Sci. 35(2), 147–164 (1998). https://doi.org/10.1016/S0148-9062(97)00303-3

Sagong, M.; Bobet, A.: Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int. J. Rock Mech. Min. Sci. 39(2), 229–241 (2002). https://doi.org/10.1016/S1365-1609(02)00027-8

Zhu, J.B.; Zhou, T.; Liao, Z.Y.; Sun, L.; Li, X.B.; Chen, R.: Replication of internal defects and investigation of mechanical and fracture behavior of rock using 3D printing and 3D numerical methods in combination with X-ray computerized tomography. Int. J. Rock Mech. Min. Sci. 106, 198–212 (2018). https://doi.org/10.1016/j.ijrmms.2018.04.022

Ju, Y.; Ren, Z.Y.; Zheng, J.T.; Gao, F.; Mao, L.T.; Chiang, F.P.; Xie, H.P.: Quantitative visualization methods for continuous evolution of three-dimensional discontinuous structures and stress field in subsurface rock mass induced by excavation and construction—an overview. Eng. Geol. 265, 105443 (2020). https://doi.org/10.1016/j.enggeo.2019.105443

Fu, J.W.; Chen, K.; Zhu, W.S.; Zhang, X.Z.; Li, X.J.: Progressive failure of new modelling material with a single internal crack under biaxial compression and the 3-D numerical simulation. Eng. Fract. Mech. 165, 140–152 (2016). https://doi.org/10.1016/j.engfracmech.2016.08.002

Ju, Y.; Xie, H.P.; Zheng, Z.M.; Lu, J.B.; Mao, L.T.; Gao, F.; Peng, R.D.: Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin. Sci. Bull. 59, 5354–5365 (2014). https://doi.org/10.1007/s11434-014-0579-9

Zhou, T.; Zhu, J.B.; Ju, Y.; Xie, H.P.: Volumetric fracturing behavior of 3D printed artificial rocks containing single and double 3D internal flaws under static uniaxial compression. Eng. Fract. Mech. 205, 190–204 (2019). https://doi.org/10.1016/j.engfracmech.2018.11.030

Jiang, C.; Zhao, G.F.; Zhu, J.B.; Zhao, Y.X.; Shen, L.M.: Investigation of dynamic crack coalescence using a gypsum-like 3D printing material. Rock Mech. Rock Eng. 49, 3983–3998 (2016). https://doi.org/10.1007/s00603-016-0967-3

Zhang, R.; Ai, T.; Li, H.G.; Zhang, Z.T.; Liu, J.F.: 3D reconstruction method and connectivity rules of fractured networks generated under different mining layouts. Int. J. Min. Sci. Technol. 23(6), 863–871 (2013). https://doi.org/10.1016/j.ijmst.2013.10.013

Wong, L.N.Y.; Li, H.Q.: Numerical study on coalescence of two pre-existing coplanar flaws in rock. Int. J. Solids Struct. 50(22–23), 3685–3706 (2013). https://doi.org/10.1016/j.ijsolstr.2013.07.010

Zhao, C.; Zhou, Y.M.; Zhao, C.F.; Bao, C.: Cracking processes and coalescence modes in rock-like specimens with two parallel pre-existing cracks. Rock Mech. Rock Eng. 51, 3377–3393 (2018). https://doi.org/10.1007/s00603-018-1525-y

Lei, Q.H.; Latham, J.P.; Tsang, C.F.: The use of discrete fracture networks for modelling coupled geomechanical and hydrological behaviour of fractured rocks. Comput. Geotech. 85, 151–176 (2017). https://doi.org/10.1016/j.compgeo.2016.12.024

Sagong, M.; Park, D.; Yoo, J.; Lee, J.S.: Experimental and numerical analyses of an opening in a jointed rock mass under biaxial compression. Int. J. Rock Mech. Min. Sci. 48(7), 1055–1067 (2011). https://doi.org/10.1016/j.ijrmms.2011.09.001

Bahaaddini, M.; Sharrock, G.; Hebblewhite, B.K.: Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput. Geotech. 49, 206–225 (2013). https://doi.org/10.1016/j.compgeo.2012.10.012

Zhang, X.P.; Zhang, Q.; Wu, S.C.: Acoustic emission characteristics of the rock-like material containing a single flaw under different compressive loading rates. Comput. Geotech. 83, 83–97 (2017). https://doi.org/10.1016/j.compgeo.2016.11.003

Yang, S.Q.; Tian, W.L.; Huang, Y.H.; Ranjith, P.G.; Ju, Y.: An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression. Rock Mech. Rock Eng. 49(4), 1497–1515 (2016). https://doi.org/10.1007/s00603-015-0838-3

Ma, S.K.; Shao, Y.; Liu, Y.; Jiang, J.; Fan, X.L.: Responses of pipeline to side-by-side twin tunnelling at different depths: 3D centrifuge tests and numerical modelling. Tunn. Undergr. Space Technol. 66, 157–173 (2017). https://doi.org/10.1016/j.tust.2017.04.006

Charles, W.W.N.: The state-of-the-art centrifuge modelling of geotechnical problems at HKUST. J. Zhejiang Univ. Sci. A (Appl. Phys. Eng.) 15, 1–21 (2014). https://doi.org/10.1631/jzus.A1300217

Song, X.F.; Wei, J.F.; He, T.S.H.: A method to repair concrete leakage through cracks by synthesizing super-absorbent resin in situ. Constr. Build. Mater. 23, 386–391 (2009). https://doi.org/10.1016/j.conbuildmat.2007.11.009

Zhu, H.; Wang, Z.J.; Xu, J.; Han, Q.H.: Microporous structures and compressive strength of high-performance rubber concrete with internal curing agent. Constr. Build. Mater. 215, 128–134 (2019). https://doi.org/10.1016/j.conbuildmat.2019.04.184

Shen, D.J.; Liu, C.; Li, C.C.; Zhao, X.G.; Jiang, G.Q.: Influence of Barchip fiber length on early-age behavior and cracking resistance of concrete internally cured with super absorbent polymers. Constr. Build. Mater. 214, 219–231 (2019). https://doi.org/10.1016/j.conbuildmat.2019.03.209

Riyazi, S.; Kevern, J.T.; Mulheron, M.: Super absorbent polymers (SAPs) as physical air entrainment in cement mortars. Constr. Build. Mater. 147, 669–676 (2017). https://doi.org/10.1016/j.conbuildmat.2017.05.001

Baloch, H.; Usman, M.; Rizwan, S.A.; Hanif, A.: Properties enhancement of super absorbent polymer (SAP) incorporated self-compacting cement pastes modified by nano silica (NS) addition. Constr. Build. Mater. 203, 18–26 (2019). https://doi.org/10.1016/j.conbuildmat.2019.01.096

Xu, X.L.; Wu, S.C.; Gao, Y.T.; Xu, M.F.: Effects of micro-structure and micro-parameters on Brazilian tensile strength using Flat-Joint model. Rock Mech. Rock Eng. 49, 3575–3595 (2016). https://doi.org/10.1007/s00603-016-1021-1

Wu, S.C.; Xu, X.L.: A study of three intrinsic problems of the classic discrete element method using Flat-Joint model. Rock Mech. Rock Eng. 49, 1813–1830 (2016). https://doi.org/10.1007/s00603-015-0890-z

Huang, D.; Gu, D.M.; Yang, C.; Huang, R.Q.; Fu, G.Y.: Investigation on mechanical behaviors of sandstone with two preexisting flaws under triaxial compression. Rock Mech. Rock Eng. 49(2), 375–399 (2016). https://doi.org/10.1007/s00603-015-0757-3

Aker, E.; Kühn, D.; Vavryčuk, V.; Soldal, M.; Oye, V.: Experimental investigation of acoustic emissions and their moment tensors in rock during failure. Int. J. Rock Mech. Min. Sci. 70, 286–295 (2014). https://doi.org/10.1016/j.ijrmms.2014.05.003

Cao, R.H.; Cao, P.; Lin, H.; Ma, G.W.; Fan, X.; Xiong, X.G.: Mechanical behavior of an opening in a jointed rock-like specimen under uniaxial loading: experimental studies and particle mechanics approach. Arch. Civ. Mech. Eng. 18(1), 198–214 (2018). https://doi.org/10.1016/j.acme.2017.06.010

Wu, T.H.; Gao, Y.T.; Zhou, Y.; Li, J.W.: Experimental and numerical study on the interaction between holes and fissures in rock-like materials under uniaxial compression. Theor. Appl. Fract. Mech. 106, 102488 (2020). https://doi.org/10.1016/j.tafmec.2020.102488

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant Numbers 51774020 and 51934003], the Program for Yunnan thousand talents plan high-level innovation and entrepreneurship team, and the Program for innovative research team (in Science and Technology) in University of Yunnan Province. Thanks for the guidance from Prof. Zach Agioutantis in the University of Kentucky, and thanks Ph.D. Congcong Chen for her assistance in laboratory tests, Ph.D. Long Chen and Ph.D. Liangfeng Xiong for their helps in PFC3D simulations. Finally, we declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhao, Y., Gao, Y. & Wu, S. Experimental and Numerical Studies of Brittle Rock-Like Samples with Internal Open Fractures and Cavities Under Uniaxial Compression. Arab J Sci Eng 45, 8349–8368 (2020). https://doi.org/10.1007/s13369-020-04712-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04712-2