Abstract

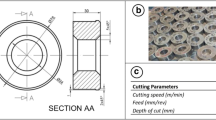

Particle damping is a derivative of impact damping, which can be used to achieve structural damping. Real-time applications of particle damping are scarce in literature. For this study, a boring bar, filled with various metal particles, was used for internal turning operation, and the impacts on the surface roughness were studied. The influences of particle parameters on the surface roughness of machined surface are investigated in this study. In spite of the simplicity of the experiments conducted, the results provide us with a fundamental understanding of the parameters influencing particle damping.

Similar content being viewed by others

References

Xu, Z.; Wang, M.Y.; Chen, T.: Particle damping for passive vibration suppression: numerical modeling and experimental verification. Proceedings of DETC’03, Illinois, USA, 2–6 Sept (2003)

Panossian, H.V.: An overview of non-obstructive particle damping: a new passive damping technique. Shock Vib. Technol. Rev. 1(6), 4–10 (1991)

Mao, K.; Wang, M.Y.; Xu, Z.; Chen, T.: Simulation and characterization of particle damping in transient vibrations. ASME J. Vib. Acoust. 126, 202–211 (2004)

Friend, R.D.; Kinra, V.K.: Particle impact damping. J. Sound Vib. 233(1), 93–118 (2000)

Ekwaro-Osire, S.; Desen, I.C.: Experimental study on an impact vibration absorber. J. Vib. Control 7, 475–493 (2001)

Chen, T.; Mao, K.; Huang, X.; Wang, M.Y.: Dissipation mechanisms of non obstructive particle damping using discrete element method. Proceedings of SPIE International Symposium on Smart Structures and Materials, vol. 4331, pp.294–301. Damping and Isolation, Newport Beach, CA, March (2001)

Xu, Z.; Wang, M.Y.; Chen, T.; An experimental study of particle damping for beams and plates. ASME J. Vib. Acoust. 126, 141–148 (2004)

Mei, C.: Active regenerative suppression during boring manufacturing process. J. Robot. Comput. Integr. Manuf. 21, 153–158 (2005)

Sathishkumar, B.; Mohana Sundaram, K.M.; Senthil Kumar, M.: Experimental studies on impact of particle damping on surface roughness of machined components in boring operation. Eur. J. Sci. Res. 71(3), 327–337 (2012)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sathishkumar, B., Mohanasundaram, K.M. & Kumar, M.S. Impact of Particle Damping Parameters on Surface Roughness of Bored Surface. Arab J Sci Eng 39, 7327–7334 (2014). https://doi.org/10.1007/s13369-014-1209-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-014-1209-1