Abstract

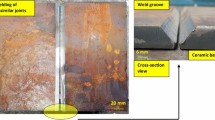

A total number of 44 fatigue tests were conducted under total stain control, 26 for G20Mn5QT cast steel and 18 for butt welds between G20Mn5QT cast steel and Q345B steel. Based on the test results, cyclic stress response, plastic strain energy, strainlife curves and Coffin-Manson equations were presented. Comparing with hot rolled steels widely used in steel construction, the fatigue behaviour of G20Mn5QT cast steel is poor, the reason for which was imputed to the defects caused by the casting process. The welds between G20Mn5QT cast steel and Q345B steel exhibited similar fatigue performance as G20Mn5QT cast steel. Fatigue crack tends to initiate in the heat affected zone (HAZ) at the cast steel. Microstructure observations using optical and scanning electron microscope showed that casting defects are the common fatigue source for both G20Mn5QT cast steel and the butt welds between G20Mn5QT cast steel and Q345B steel.

Similar content being viewed by others

References

Ahiale, G. K. and Oh, Y. J. (2014). “Microstructure and fatigue performance of butt-welded joints in advanced high-strength steels.” Materials Science and Engineering A, 597, pp.342–348.

BSISO 12108-2002 (2002). Metallic materials-Fatigue testing-Fatigue crack growth method. British Standards Institute, London, UK.

Callaghan, M. D., Humphries, S. R., Law, M., Ho, M., Bendeich, P., Li, H., and Yeung, W. Y. (2010). “Energybased approach for the evaluation of low cycle fatigue behaviour of 2.25Cr-1Mo steel at elevated temperature.” Materials Science and Engineering A, 527, pp.5619–5623.

CECS 235: 2008 (2008). Technical specification for application of connections of structural steel casting. Standards Press of China, Beijing, China (in Chinese).

Chen, H., Grondin, G. Y., and Driver, R. G. (2007). “Characterization of fatigue properties of ASTM A709 high performance steel.” Journal of Constructional Steel Research, 63, pp.838–848.

Chinese Welding Society (2008). Welding handbook (volume III). China Machine Press, Beijing, China (in Chinese).

de Jesus, A. M. P., Matos, R., Fontoura, B. F. C., Rebelo, C., Simões da Silva, L., and Veljkovic, M. (2012). “A comparison of the fatigue behavior between S355 and S690 steel grades.” Journal of Constructional Steel Research, 79, pp.140–150.

DINEN 10293 (2005). Steel castings for general engineering uses. European Committee for Standardization (CEN), Brussels, Belgium.

E606-92 (2000). Standard practice for strain-controlled fatigue testing. ASTM, West Conshohocken, USA.

E8M-04 (2004). Standard test methods for tension testing of metallic materials. ASTM, West Conshohocken, USA.

Fang, D., Liu, Y., Chen, Y., and Wang, Q. (2011). “Ultrahigh cycle fatigue behaviours of Q345 bridge steel welded joint.” Transactions of the China Welding Institution, 32(8), pp.77–80 (in Chinese).

GB/T 1591-2008 (2008). High strength low alloy structural steels. AQSIQ. Standards Press of China, Beijing, China (in Chinese).

GB 50017-2003 (2003). Code for design of steel structures. Standards Press of China, Beijing, China (in Chinese).

GB/T 15248-2008 (2008). The test method for axial loading constant-amplitude low-cycle fatigue of metallic materials. Standards Press of China, Beijing, China (in Chinese).

Kim, K., Lee, S., and Jung, K. (2009). “Evaluation of factors affecting the fatigue behavior of butt-welded joints using SM520C-TMC steel.” International Journal of Steel Structures, 9(3), pp.185–193.

Korean Society of Civil Engineers (2008). Korean design code and commentary for highway bridge. KiMoonDang., Inc., Seoul, Korea, pp.115–123.

Luo, Y., Wang, Q., Liu, Y., and Huang, C. (2012). “Low cycle fatigue properties of steel structure materials Q235 and Q345.” Journal of Sichuan University (Engineering Science Edition), 44(2), pp.169–175 (in Chinese).

Manson, S. S. (1965). “Fatigue: a complex subject-some simple approximations.” Experimental Mechanics, 5, pp.193–226.

Prasad, N. E., Vogt, D., Bidlingmaier, T., Wanner, A., and Arzt, E. (2000). “High temperature, low cycle fatigue behaviour ofan aluminium alloy (Al-12Si-CuMgNi.).” Materials Science and Engineering A, 276, pp.283–287.

Ye, D., Matsuoka, S., Nagashima, N., and Suzuki, N. (2006). “The low-cycle fatigue, deformation and final fracture behaviour of an austenitic stainless steel.” Materials Science and Engineering A, 415, pp.104–117.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, Q., Guo, Q., Yin, Y. et al. Fatigue behaviour of G20Mn5QT cast steel and butt welds with Q345B steel. Int J Steel Struct 16, 139–149 (2016). https://doi.org/10.1007/s13296-016-3020-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-016-3020-1