Abstract

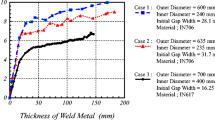

Welding residual stresses between 12Cr1MoV and P91 steel pipes were analyzed by experiment and finite element method (FEM). Both measured hoop and axial stresses are in general agree with the simulation results. Meanwhile, to examine the effect of start/stop welding position on residual stresses, a simulation model whose welding passes all started at the same location during multi-pass welding was compared with a model whose start/stop positions were uniformly distributed along circumferential direction of the dissimilar pipe. The results show that higher residual stresses occurred near the superimposed start/stop position than the steady region when calculated by the model whose welding passes all started at the same location. Whereas, start/stop welding positions which are distributed uniformly along the circumferential direction of the pipe can significantly relieve this effect, correspondingly leading to a more uniform residual stress distribution around the multi-pass welded dissimilar pipe.

Similar content being viewed by others

References

Banahan, B. D. (2008). “Application of secondary and residual stresses to the assessment of the structural integrity of nuclear power-generating plant.” Int. J. Press. Ves. Pip., 85 (3), pp. 191–197.

Bulletin, T. B., Noronha, P. J., Chapman, J. R., and Wert, J. J. (1973). “Residual stress measurement and analysis using ultrasonic techniques.” J. Test Eval. 1(3), pp. 209–214.

Chang, K. H., Lee, C. H., Park, K. T., and Um, T. H. (2011). “Experimental and numerical investigations on residual stresses in a multi-pass butt-welded high strength SM570-TMCP steel plate.” International Journal of Steel Structures, 11(3), pp. 315–324.

Chang, K. H., Lee, C. H., Park, K. T., You, Y. J., Joo, B. C., and Jang, G. H. (2010) “Analysis of residual stress in stainless steel pipe weld subject to mechanical axial tension loading.” International Journal of Steel Structures, 10(4), pp. 411–418.

Dalaei, K., Karlsson, B., and Svensson, L. E. (2011). “Stability of shot peening induced residual stresses and their influence on fatigue lifetime.” Mat. Sci. Eng., A 528(3), pp. 1008–1015.

Deng, D. and Murakawa, H. (2006). “Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements.” Comp. Mater. Sci., A 37, pp. 269–277.

Deng, D. and Kiyoshima, S. (2010). “Numerical simulation of residual stresses induced by laser beam welding in a SUS316 stainless steel pipe with considering initial residual stress influences.” Nucl. Eng. Des., 240, pp. 688–696.

Deng, D. and Kiyoshima, S. (2011). “FEM analysis of residual stress distribution near weld start/end location in thick plates.” Comp. Mater. Sci., 50 (8), pp. 2459–2469.

Dong, P. and Brust, F. W. (2000). “Welding residual stresses and effects on fracture in pressure vessel and piping components: a millennium and review and beyond.” ASME J. Pressure Vessel. Technol., 122 (3), pp. 329–338.

Dong, P. (2001). “Residual stress analyses of a multi-pass girth weld: 3-D special shell verse axisymmetric models.” ASME J. Pressure Vessel. Technol., 123 (2), pp. 207–213.

Fanous, I. F., Younan M. Y., and Wifi A. S. (2002). “3D finite element modeling of the welding process using element birth and element movement techniques.” Press. Vess. Piping Div. PVP, 442, pp. 165–172.

Fricke, S., Keim, E., and Schmidt, J. (2006). “Numerical weld modeling a method for calculating weld-induced residual stress.” Nucl. Eng. Des., 206, pp. 139–150.

Goldak, J., Bibby, M., Moore, J., House, J. R., and Patel, B. (1986). “Computer modeling of heat flow in welds.” Metall. Mater. Trans., B 17, pp. 587–600.

Karlsson, C. T. and Josefson, B. L. (1990). “Threedimensional finite element analysis of temperatures and stresses in a single-pass butt-welded pipe.” Trans. ASME, J. Pressure Vessel Technol., 112, pp. 76–84.

Lindgren, L. E. (2001). “Finite element modeling and simulation of welding. Part I: Increased complexity.” J. Therm. Stress, 24, pp. 141–192.

Pan, J. Z. (2000). Application manual for pressure vessel materials of carbon and low-alloy steel. Chemical Industry Press, Beijing, pp. 356–362.

Lu, H. M., Chen, Y. Y., and Zhu, S. D. (1995). Handbook of mechanical engineering material data. China Machine Press, Beijing, pp. 156–162.

Um, D. S. and Yoo, K. Y. (1997). “The experimental studies on residual stresses due to circumferential welds in thin steel cylinder.” J. Korean Weld. Soc., 15, pp. 149–156.

Venkitakrishnan, P. V., Philip, J., and Krishnamurthy, R. (2007). “An assessment of stresses in thin walled welded tubes through hole drilling and sectioning methods.” J. Mater. Process. Tech., 185 (1–3), pp. 228–232.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Y., Gong, J., Wang, Y. et al. Effect of start/stop position distribution on residual stresses in the multi-pass welded 12Cr1MoV/P91 dissimilar pipe. Int J Steel Struct 14, 539–546 (2014). https://doi.org/10.1007/s13296-014-3010-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-014-3010-0