Abstract

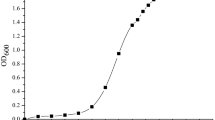

Sugarcane bagasse is one of the low-cost substrates used for bioethanol production. In order to solubilize sugars in hemicelluloses like xylan, a new thermotolerant isolate of Candida tropicalis HNMA-1 with xylan-hydrolyzing ability was identified and characterized. The strain showed relative tolerance to high temperature. Our results demonstrated 0.211 IU ml−1 xylanase activity at 40 °C compared to 0.236 IU ml−1 at 30 °C. The effect of high temperature on the growth and fermentation of xylose and sugarcane bagasse hydrolysate were also investigated. In both xylose or hydrolysate medium, increased growth was recorded at 40 °C. Meanwhile, the efficiency of ethanol fermentation was adversely affected by temperature since yields of 0.088 g g−1 and 0.076 g g−1 in the xylose medium, in addition to 0.090 g g−1 and 0.078 g g−1 in the hydrolysate medium were noticed at 30 °C and 40 °C, respectively. Inhibitory compounds in the hydrolysate medium demonstrated negative effects on fermentation and productivity, with maximum ethanol concentration attained after 48 h in the hydrolysate, as opposed to 24 h in the xylose medium. Our data show that the newly thermotolerant isolate, C. tropicalis HNMA-1, is able to efficiently ferment xylose and hydrolysate, and also has the capacity for application in ethanol production from hemicellulosic sources.

Similar content being viewed by others

References

Abdel-Banat BM, Hoshida H, Ano A, Nonklang S, Akada R (2010) High-temperature fermentation: how can processes for ethanol production at high temperatures become superior to the traditional process using mesophilic yeast? Appl Microbiol Biotechnol 85:861–867

Ahi M, Azin M, Shojaosadati SA, Vasheghani-Farahani E, Nosrati M (2013) Optimization of sugarcane bagasse hydrolysis by microwave-assisted pretreatment for bioethanol production. Chem Eng Technol 36:1997–2005

Alves A, Phillips AJ, Henriques I, Correia A (2005) Evaluation of amplified ribosomal DNA restriction analysis as a method for the identification of Botryosphaeria species. FEMS Microbiol Lett 245:221–229

Alves-Prado HF, Pavezzi FC, Leite RSR, De Oliveira VM, Sette LD, DaSilva R (2010) Screening and production study of microbial xylanase producers from Brazilian Cerrado. Appl Biochem Biotechnol 161:333–346

Antil PS, Gupta R, Kuhad RC (2015) Simultaneous saccharification and fermentation of pretreated sugarcane bagasse to ethanol using a new thermotolerant yeast. Ann Microbiol 65:423–429

Anwar Z, Gulfraz M, Irshad M (2014) Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: a brief review. J Radiat Res Appl Sci 7:163–173

Basaran P, Basaran N, Hang YD (2000) Isolation and characterization of Pichia stipitis mutants with enhanced xylanase activity. World J Microbiol Biotechnol 16:545–550

Basso LC, de Amorim HV, de Oliveira AJ, Lopes ML (2008) Yeast selection for fuel ethanol production in Brazil. FEMS Yeast Res 8:1155–1163

Bhadra B, Rao RS, Singh PK, Sarkar PK, Shivaji S (2008) Yeasts and yeast-like fungi associated with tree bark: diversity and identification of yeasts producing extracellular endoxylanases. Curr Microbiol 56:489–494

Brar KK, Kaur S, Chadha BS (2016) A novel staggered hybrid SSF approach for efficient conversion of cellulose/hemicellulosic fractions of corncob into ethanol. Renew Energy 98:16–22

Canilha L, Carvalho W, de Almeida Felipe MDG, e Silva JBDA, Giulietti M (2010) Ethanol production from sugarcane bagasse hydrolysate using Pichia stipitis. Appl Biochem Biotechnol 161:84–92

Canilha L, Chandel AK, dos Santos Milessi ST, Antunes, FAF, da Costa Freitas LW, das Graҫas Almeida FM, da Silva S (2012) Bioconversion of sugarcane biomass into ethanol: an overview about composition, pretreatment methods, detoxification of hydrolysates, enzymatic saccharification, and ethanol fermentation. Biomed Res Int 2012:989572

Cardona C, Quintero J, Paz I (2010) Production of bioethanol from sugarcane bagasse: status and perspectives. Bioresour Technol 101:4754–4766

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

De Souza CJ, Costa DA, Rodrigues MQ, dos Santos AF, Lopes MR, Abrantes AB, dos Santos CP, Silveira WB, Passos FM, Fietto LG (2012) The influence of presaccharification, fermentation temperature and yeast strain on ethanol production from sugarcane bagasse. Bioresour Technol 109:63–69

Den Haan R, Van Zyl W (2003) Enhanced xylan degradation and utilisation by Pichia stipitis overproducing fungal xylanolytic enzymes. Enzyme Microb Technol 33:620–628

Dias MO, Ensinas AV, Nebra SA, Maciel Filho R, Rossell CE, Maciel MRW (2009) Production of bioethanol and other bio-based materials from sugarcane bagasse: integration to conventional bioethanol production process. Chem Eng Res Des J 87:1206–1216

Edgardo A, Carolina P, Manuel R, Juanita F, Baeza J (2008) Selection of thermotolerant yeast strains Saccharomyces cerevisiae for bioethanol production. Enzyme Microb Technol 43:120–123

Eijsink VG, Vaaje-Kolstad G, Vårum KM, Horn SJ (2008) Towards new enzymes for biofuels: lessons from chitinase research. Trends Biotechnol 26:228–235

Fan G, Yang S, Yan Q, Guo Y, Li Y, Jiang Z (2014) Characterization of a highly thermostable glycoside hydrolase family 10 xylanase from Malbranchea cinnamomea. Int J Biol Macromol 70:482–489

Hahn-Hägerdal B, Karhumaa K, Fonseca C, Spencer-Martins I, Gorwa-Grauslund MF (2007) Towards industrial pentose-fermenting yeast strains. Appl Microbiol Biotechnol 74:937–953

Hande A, Mahajan S, Prabhune A (2013) Evaluation of ethanol production by a new isolate of yeast during fermentation in synthetic medium and sugarcane bagasse hemicellulosic hydrolysate. Ann Microbiol 63:63–70

Hendriks A, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100:10–18

Herbert D, Phipps P, Strange R (1971) Chemical analysis of microbial cells. Methods Microbiol 5:209–344

Jeffries TW, Kurtzman CP (1994) Strain selection, taxonomy, and genetics of xylose-fermenting yeasts. Enzym Microb Technol 16:922–932

Kádár Z, Szengyel Z, Réczey K (2004) Simultaneous saccharification and fermentation (SSF) of industrial wastes for the production of ethanol. Ind Crop Prod 20:103–110

Kim Y, Ximenes E, Mosier NS, Ladisch MR (2011) Soluble inhibitors/deactivators of cellulase enzymes from lignocellulosic biomass. Enzym Microb Technol 48:408–415

Kuhad RC, Gupta R, Khasa YP, Singh A (2010) Bioethanol production from lantanacamara (red sage): pretreatment, saccharification and fermentation. Bioresour Technol 101:8348–8354

Kulkarni N, Shendye A, Rao M (1999) Molecular and biotechnological aspects of xylanases. FEMS Microbiol Rev 23:411–456

Kumar S, Tamura K, Jakobsen IB, Nei M (2001) MEGA2: molecular evolutionary genetics analysis software. Bioinformatics 17:1244–1245

Kurtzman C, Fell JW, Boekhout T (2011) The yeasts: a taxonomic study. Elsevier, Amsterdam

Kwon YJ, Ma AZ, Li Q, Wang F, Zhuang GQ, Liu CZ (2011) Effect of lignocellulosic inhibitory compounds on growth and ethanol fermentation of newly-isolated thermotolerant Issatchenkiaorientalis. Bioresour Technol 102:8099–8104

Lee H, Biely P, Latta RK, Barbosa MF, Schneider H (1986) Utilization of xylan by yeasts and its conversion to ethanol by Pichia stipitis strains. Appl Environ Microbiol 52:320–324

Martinez A, Rodriguez ME, York SW, Preston JF, Ingram LO (2000) Use of UV absorbance to monitor furans in dilute acid hydrolysates of biomass. Biotechnol Prog 16:637–641

Meethit P, Ratanaprasit P, Sakdaronnarong C (2016) Candida shehatae and Saccharomyces Cerevisiae work synergistically to improve ethanol fermentation from sugarcane bagasse and rice straw hydrolysate in immobilized cell bioreactor. Eng Life Sci 16:706–719

Menon V, Prakash G, Prabhune A, Rao M (2010) Biocatalytic approach for the utilization of hemicellulose for ethanol production from agricultural residue using thermostable xylanase and thermotolerant yeast. Bioresour Technol 10:5366–5373

Milessi TS, Antunes FA, Chandel AK, Silva SS (2013) Rice bran extract: an inexpensive nitrogen source for the production of 2G ethanol from sugarcane bagasse hydrolysate. 3 Biotech 3:373–379

Miller G (1959) Modified DNS method for reducing sugars. Anal Chem 31:426–428

Morais CG, Cadete RM, Uetanabaro AP, Rosa LH, Lachance MA, Rosa CA (2013) D-xylose-fermenting and xylanase-producing yeast species from rotting wood of two Atlantic rainforest habitats in Brazil. Fungal Genet Biol 60:19–28

Olofsson K, Bertilsson M, Lidén G (2008) A short review on SSF—an interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol Biofuels 1:1–14

Pilone GJ (1984) Determination of ethanol in wine by titrimetric and spectrophotometric dichromate methods: collaborative study. J Assoc Off Anal Chem 68:188–190

Polizeli M, Rizzatti A, Monti R, Terenzi H, Jorge J, Amorim D (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Reis AL, Damilano ED, Menezes RS, de Morais MA Jr (2016) Second-generation ethanol from sugarcane and sweet sorghum bagasses using the yeast Dekkera bruxellensis. Ind Crop Prod 92:255–262

Saitou N, Nei M (1987) The neighbor-joining method: a new method for reconstructing phylogenetic trees. Mol Biol Evol 4:406–425

de Souza Moreira LR, de Carvalho CM, de Siqueira PH, Silva LP, Ricart CA, Martins PA, Queiroz RM, Ferreira Filho EX (2013) Two β-xylanases from Aspergillus terreus: characterization and influence of phenolic compounds on xylanase activity. Fungal Genet Biol 60:46–52

Sree NK, Sridhar M, Suresh K, Banat I, Rao LV (2000) Isolation of thermotolerant, osmotolerant, flocculating Saccharomyces cerevisiae for ethanol production. Bioresour Technol 72:43–46

Standing C, Fredrickson A, Tsuchiya H (1972) Batch-and continuous-culture transients for two substrate systems. Appl Microbiol 23:354–359

Sun JX, Sun XF, Zhao H, Sun RC (2004) Isolation and characterization of cellulose from sugarcane bagasse. Polym Degrad Stab 84:331–339

Talamantes D, Biabini N, Dang H, Abdoun K, Berlemont R (2016) Natural diversity of cellulases, xylanases, and chitinases in bacteria. Biotechnol Biofuels 9:133

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. PCR protocols: a guide to methods and applications 18:315–322

Wrolstad RE (2001) Current protocols in food analytical chemistry. Wiley, New York

Zabed H, Sahu JN, Boyce AN, Faruq G (2016) Fuel ethanol production from lignocellulosic biomass: an overview on feedstocks and technological approaches. Renew Sust Energ Rev 66:751–774

Acknowledgments

The authors thank the Iranian Research Organization for Science and Technology for financial support for accomplishing the present research. They also are grateful to Farzaneh Ahadzadeh and Sepideh Shokri for their technical assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Rights and permissions

About this article

Cite this article

Nouri, H., Azin, M. & Mousavi, M.L. Xylan-hydrolyzing thermotolerant Candida tropicalis HNMA-1 for bioethanol production from sugarcane bagasse hydrolysate. Ann Microbiol 67, 633–641 (2017). https://doi.org/10.1007/s13213-017-1292-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13213-017-1292-0