Abstract

Rhodotorula kratochvilovae (syn, Rhodosporidium kratochvilovae) SY89, an oleaginous yeast, isolated from Ethiopian soil, was grown under nitrogen-limited media. The capacity this with respect to biomass production, lipid yield and lipid content was evaluated. The influence of inoculum size, carbon sources, variations in glucose concentration, nitrogen sources, C/N ratio, pH, temperature, agitation, and aeration rate and incubation period were investigated. Inoculum size of 10% v/v, glucose as a carbon source at 50 g/L glucose, 0.50 g/L yeast extract and 0.31 g/L (NH4)2SO4, C/N ratio of 120, pH 5.5, incubation temperature of 30 °C, 225 rpm, 0.2 as aeration ratio and 144 h of incubation were found to be optimum conditions for lipid production. Then the yeast was grown in a batch bioreactor by combining the different optimized parameters together. Under the optimized conditions, the yeast gave maximum biomass (15.34 ± 1.47 g/L), lipid yield (8.60 ± 0.81 g/L) and lipid content (56.06 ± 1.70%). The dominant fatty acids exhibited in order of their relative abundance (%w/w), were oleic, palmitic, linoleic, stearic, linolenic and palmitoleic acids. The concentration of saturated and monounsaturated fatty acids adds up 78.63 ± 2.19%. This suggests that this strain could be used as a good feedstock for biodiesel production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microorganisms that are capable of accumulating lipids above 20 up to 70% of their dry biomass are termed as oleaginous (Ratledge and Wynn 2002). The oil produced can be exploited as alternative sources of oils and fats for human consumption and can also be used as feedstocks for the production of biodiesel (Li et al. 2008) and components in paints and coatings, detergents, cleaning products, cosmetics, plastics, rubber, crop protection and intermediate products or synthons (Luque et al. 2010).

Compared to vegetable oils, the production of microbial oil has many advantages which include: high growth rate, short life cycle, less labor requirement, less affection by venue, season and climate, no arable land needed, easier to scale up (Li et al. 2008), and ability to use different carbon sources (Economou et al. 2011).

Basidiomycetous yeasts prevail among oleaginous yeasts. Many basidiomycetous yeasts including Rhodosporidium are now included in other existing or new genera (Wang et al. 2015). Accordingly, Rhodosporidium has been transferred to Rhodotorula and the oleaginous yeast Rhodosporidium kratochvilovae is renamed as Rhodotorula kratochvilovae (Wang et al. 2015).

Oil accumulation by oleaginous microorganisms depends highly on the culturing conditions such as inoculum size, the available carbon and nitrogen source in the growing medium, concentration of both carbon and nitrogen sources, C/N ratio, pH, temperature, culture time and agitation, and aeration rate (Li et al. 2008). Optimum initial C/N ratio of greater than 20 is needed for maximum production of lipids by oleaginous microorganisms (Papanikolaou and Aggelis 2011). C/N ratio depends on the nature of the microorganism, the medium composition in which the cultivation is undertaken, and types of carbon and nitrogen sources (Ykema et al. 1986). It is reported that lipid accumulation in oleaginous yeasts occurs when the growth medium is replete in carbon source with one limiting element that is usually nitrogen limitation (Wu et al. 2011).

Inoculum size or inoculation volume as a starter culture in the growing medium plays a key role on yeast single cell oil production. Optimum inoculum size is need for maximum biomass and hence higher lipid production. A low inoculum size could result in long lag phase (Kitcha 2012).

The influence of initial pH of the culture medium also plays a critical role on lipid synthesis by oleaginous microorganisms. Different optimum pH values for maximum production of lipids by different oleaginous yeasts were found in previous studies (Tao et al. 2008; Zhu et al. 2008; El-Fadaly et al. 2009; Kraisintu et al. 2010). The optimum pH for each oleaginous yeast for biomass production and hence single cell oil is also influenced by the different carbon sources available in the growth medium (Angerbauer et al. 2008). A decrease in lipid production was exhibited when the pH was below 4.0 and above 8.0 (Syed et al. 2006).

Temperature of the culture medium critically influences cellular lipid accumulation by an oleaginous microorganism. Too high or too low temperature affects the cell growth and lipid accumulation (Sha 2013). The composition of the lipid also varies at different temperatures (Saxena et al. 2009).

Culturing time (incubation period) also has an effect on lipid production. Usually lipid content reaches its highest value at stationary phase of microbial growth (Beopoulos et al. 2008). It is recommended that cells should be harvested at early stationary phase to prevent lipid degradation (Beopoulos et al. 2008).

In addition to the above factors, agitation and aeration rates play a significant role on the production of single cell oil by oleaginous microorganisms. These parameters play a pivotal role in aerobic fermentation process and in scaling up of aerobic biosynthesis systems (Bandaiphet and Prasertsan 2006).

It is clear from the previous studies that optimization of cultivation parameters can result in higher lipid production by oleaginous yeasts and fosters their potential for industrial application. Optimization is an essential step for each industrial process because it can result in higher production under economical cost (Enshaeieh et al. 2013).

The objective of this study was to investigate the effect of different parameters on biomass production, lipid yield and lipid content of R. kratochvilovae SY89. The parameters tested, included growth on different carbon sources, combining inorganic and organic nitrogen sources, changes in C/N ratios and pH, agitation and aeration rates, different incubation temperatures and time of incubation.

Materials and methods

Sample collection and yeast isolation

About 200 samples were collected from soil, plant surfaces (leaves, fruits and flowers), dairy products (milk, yogurt and cheese) and traditional oil mill wastes in Ethiopia. Yeast isolation was performed according to the methods of Pan et al. (2009).

Screening for oleaginous yeast and determination of lipid content

The isolated yeast cultures were screened for their lipid producing abilities by qualitative analysis with the Sudan III staining technique (Thakur et al. 1988) and all yeasts positive for lipid production were further characterized and identified.

Yeast cells which were grown on nitrogen-limited media [70 g/L glucose, 0.3 g/L (NH4)2SO4, 0.3 g/L yeast extract, 2.0 g/L KH2PO4, 1.5 g/L MgSO4·7H2O, 0.25 g/L citric acid, 0.1 g/L CaCl2·2H2O,0.035 g/L FeSO4·7H2O, 0.011 g/L ZnSO4·7H2O, 0.007 g/L MnSO4·H2O, 0.002 g/L CoCl·6H2O, 0.0013 g/L Na2MoO4·2H2O, and 0.001 g/L CuSO4·5H2O] were harvested by centrifugation at 5000×g for 15 min. Biomass (pellet) was harvested and washed twice with distilled water, frozen at −80 °C and freeze dried over night to constant weight. The dry weight of oleaginous yeast was determined gravimetrically (Pan et al. 2009).

Lipid extraction was done following the protocol described by Folch et al. (1957), with some modifications. Freeze dried biomass was ground with a pestle in a mortar and 1 g of sample was extracted with 3.75 mL solvent mixture of chloroform and methanol (2:1) overnight. The solvent mixture was transferred into a clean separating funnel through Whatman No1 filter paper. Then 1.25 mL of the solvent mixture was added through filter paper into separating funnel. This was followed by washing with 0.75 mL of distilled water. The solvent/water mixture was left overnight to separate into two clear phases. The bottom phase was collected and the solvents evaporated under vacuum. Diethyl ether was used to transfer the extract into pre-weighed glass vials and the solvent evaporated. The dry lipids were weighed and lipid content was calculated using Eq. 1.

Identification of the yeast

Morphological and physiological tests

Various morphological and physiological tests were undertaken for identification purposes following the methods of Kurtzman et al. (2011). Morphological characteristics of the cultures such as colony color, size, shape, elevation, texture, and diameter were studied and characterized. Cell shape, dimension and budding features of the strains grown in a liquid Yeast extract-Malt extract (YM) medium (10 g/L glucose, 3 g/L yeast extract, 3 g/L malt extract and 5 g/L peptone) were observed using a microscope. The formation of pseudohyphae, ballistoconidia and ascospore were also tested. The physiological tests that were done include fermentation of carbon sources, assimilation of carbon and nitrogen sources using an auxonographic method, urea hydrolysis, Diazonium blue B color reaction, growth in media of high osmotic pressure, splitting of fat and formation of extracellular amyloid compounds.

Molecular identification of the yeast

Genomic DNA was extracted from cultures grown on 40 g/L glucose, 5 g/L peptone, 5 g/L yeast autolysate, and 20 g/L agar (GPYA) medium for 3 days using the FastDNA kit (BIO101, Carlsbad, CA, USA) with the “FastPrep” Instrument (Q-Biogene). Primers V9G (de Hoog and Gerrits van den Ende 1998) and LR5 (Vilgalys and Hester 1990) were used to amplify the region of the rRNA gene operon that includes the 3′ end of the small-subunit rRNA gene, the ITS regions (ITS 1, ITS 2 and the intervening 5.8S rRNA gene), and the D1/D2 domains of the 26S rRNA gene of the large subunit, as described by Knutsen et al. (2007).

The PCR products were separated by electrophoresis at 80 V for 40 min on a 0.8% (w/v) agarose gel containing 0.1 μg/mL ethidium bromide in 1 × TAE buffer (0.4 M Tris, 0.05 M NaAc, and 0.01 M EDTA, pH 7.85) and examined under UV-light. The amplicons were sequenced in both directions using the primers LR0R (Vilgalys and Hester 1990) and LR5 for the D1/D2 domain, while the primers V9G and ITS4 (White et al. 1990) were used for the ITS domain. The BigDye Terminator version 3.1 cycle sequencing kit (applied biosystems) was used according to the manufacturer’s recommendations and the products were analyzed on an ABI Prism 3730XL DNA Sequencer (Perkin-Elmer). A consensus sequence was computed from the forward and reverse sequences with SeqMan version 8 from the Lasergene package (DNASTAR). All sequences of the studied strains were blasted against sequences in GenBank (http://blast.ncbi.nlm.nih.gov/Blast.cgi) and the CBS yeast database (http://www.cbs.knaw.nl/Collections/) to identify the oleaginous yeasts. Sequences of the D1/D2 domain obtained during this study and related sequences from the GenBank (NCBI) database were aligned and phylogenetic analyses were done using MEGA 7 version (Kumar et al. 2016). The phylogenetic relationship of these yeast strains is displayed in a distance based neighbor-joining tree.

Optimization of culture conditions for biomass production and lipid accumulation

The influence of inoculum size (5, 10, 15, 20 and 25% v/v) of the yeast, carbon sources (glucose, sucrose, maltose, galactose, xylose and glycerol), glucose concentration (10, 30, 50, 70 and 90 g/L), nitrogen sources [(NH4)2SO4 and yeast extract, NH4Cl and peptone, NH4Cl and yeast extract, (NH4)2SO4 and peptone, (NH4)2SO4 and urea, NH4Cl and urea], C/N ratio (40, 60, 80, 100, 120, 140, and 160), pH (4.0, 4.5, 5.0, 5.5, 6.0, 6.5, and 7.0), temperature (20, 25, 30, 35 and 40 °C), agitation speed (100, 125, 150, 175, 200 and 225 rpm), aeration ratio (0.1, 0.2, 0.3, 0.4 and 0.5) and incubation period (0, 24, 48, 72, 96, 120, 144 and 168 h) were tested in a nitrogen-limited media. One parameter was tested at a time. Dry biomass, lipid yield and lipid content were determined. Except for the experiments on aeration ratio, cultures were grown in 250 mL Erlenmeyer flasks containing 50 mL media. For determination of C/N ratio, total nitrogen content of yeast extract was determined using Kjeldahl apparatus according to the instructions published by Krishna and Ranjhan (1980).

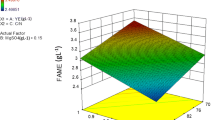

Bioreactor cultivation SY89 under the optimized conditions

Bioreactor fermentations were undertaken using glucose as a carbon source in nitrogen-limited medium [50 g/L glucose, 0.31 g/L (NH4)2SO4, 0.50 g/L yeast extract, 1.5 g/L MgSO4.7H2O, 0.1 g/L CaCl2·2H2O, 2.0 g/L KH2PO4, 0.035 g/L FeSO4·7H2O, 0.011 g/L ZnSO4·7H2O, 0.007 g/L MnSO4·H2O, 0.002 g/L CoCl·6H2O, 0.0013 g/L Na2MoO4·2H2O and 0.0001 g/L CuSO4·5H2O]. The fermentation medium was inoculated with 10% (v/v) of the liquid seed culture and then cultivated in a FerMac320, 0.8 L stirred-tank bioreactor. Fermentations were performed under the optimized conditions: work volume: 600 mL, stirring rate: 500 rpm, culture temperature, 30 °C, initial pH, 5.5, aeration rate: 1.25 vvm culture time, 144 h.

Analysis of fatty acids profiles using gas chromatography

To determine the fatty acid composition of the lipids, the extracted lipids were transferred to GC vials, dissolved in chloroform and methylated with trimethylsulphonium hydroxide (TMSOH) (Butte 1983). The vials were then sealed and vortexed for approximately 5 s. Fatty acid methyl esters were subsequently analyzed on a Shimadzu GC-2010 auto sampler gas chromatograph with a flame ionization detector. An injection volume of 0.5 µL of sample was added into a SGE-BPX-70 column (length of 50 m and inner diameter of 0.22 mm). The injection port had a temperature of 250 °C and a split ratio of 1:10. The column temperature was 200 °C. Hydrogen gas was used as a carrier gas at a flow rate of 40 mL/min. The total program time was 4.50 min per sample with a column flow rate of 1.37 mL/min. Peaks were identified by reference to authentic standards.

Statistical analysis

One-way ANOVA was performed to calculate significant differences in treatment means. SPSS version 20.0 software was used for interpretation of the data. Mean separations were performed by Tukey post hoc tests. A p value < 0.05 was considered significant. All experiments were done in triplicate.

Results and discussion

Screening potential oleaginous yeast

After screening using Sudan III stain and determination of oil content of 340 yeast strains isolated from the soil, plant surfaces (leaves, fruits and flowers), dairy products (milk, yogurt and cheese) and wastes from traditional oil milling houses, it was found that the yeast strain SY89, which was isolated from soil contained high oil content (39.33 ± 0.57% w/w). For details Jiru et al. (2016) can be referred. Therefore, the yeast strain SY89 was used in the subsequent analyses.

Identification of yeast strain

Based on colony and cell morphology of the yeast strain (Fig. 1), it was suggested that SY89 belongs to the genus Rhodosporidium (now Rhodotorula). Physiological tests supported this placement into this genus. The sequence of the D1/D2 domain and ITS region of the 26S rRNA gene was obtained and compared to sequences deposited in GenBank (NCBI) (http://blast.ncbi.nlm.nih.gov/Blast.cgi) and the CBS database (http://www.cbs.knaw.nl/Collections/). The sequence analysis results of SY89 (776 nucleotides, Genbank accession number KX525703) revealed that the amplified sequences were 100% identical to those corresponding to R. kratochvilovae CBS 7436 and R. kratochvilovae CECT 11956, while 99% similarity was exhibited by this yeast strain with R. kratochvilovae PYCC4778. So the SY89 was identified as R. kratochvilovae. The phylogenetic placement of this strain in relation to closely related species, based on the D1/D2 sequence is presented in Fig. 2. The tree obtained by analyzing ITS domain is not shown here since the same relationship among species was obtained.

Phylogenetic tree of the D1/D2 domain of 26S rRNA gene sequences of oleaginous yeast strain SY89 with related yeast species in NCBI database. The tree was constructed using the Neighbor-Joining method of MEGA 7 software. The optimal tree with the sum of branch length = 0.99011017 is shown. Bootstrap values (1000 tree interactions) are indicated at the nodes

Effect of various parameters on biomass production and lipid yield

Effect of inoculum size

In the present study, the effect of inoculum size on biomass production, lipid yield and cellular lipid content by SY89 were tested using nitrogen-limited media. Maximum dry biomass (14.28 ± 0.73 g/L), lipid yield (5.32 ± 0.27 g/L) and cellular lipid content (37.25 ± 0.75%) were observed at inoculum size of 10% v/v, while lowest biomass (11.52 ± 0.50 g/L) was achieved at inoculum size of 5% v/v (Fig. 3). On the other hand, this yeast strain gave lowest lipid yield (3.32 ± 0.39 g/L) and lipid content (26.67 ± 0.85%) at inoculum size of 25% v/v. Based on this an inoculum size of 10% v/v was selected as the optimum inoculum size for SY89.

Size/volume of inoculum as a starter culture in the culture medium plays a crucial role on yeast single cell oil production. Inoculum size of 10% v/v was also the optimum for higher biomass and lipid yield as well as lipid content by Phenoliferia glacialis (syn, Rhodotorula glacialis) DBVPG4875 (Amaretti et al. 2010). Inoculum size of 5% v/v was the optimum value for maximum biomass and lipid production by Cutaneotrichosporon cutaneum (syn, Trichosporon cutaneum) grown on corncob acid hydrolysate (Chen et al. 2013).

Effect of carbon source

Mamatha (2009) discussed that the biomass production, lipid accumulation and fatty acid profiles of oleaginous microorganisms are affected by the carbon source available during fermentation. In the current study, the effect of various carbon sources (glucose, sucrose, maltose, lactose, galactose, xylose, and glycerol) on biomass production, lipid yield and lipid content by SY89 was tested using nitrogen-limited media. Although considerable lipid yield and lipid content were attained by this yeast strain when grown on sucrose and maltose, SY89 gave the maximum biomass (14.62 ± 0.65 g/L), lipid yield (6.53 ± 0.34 g/L) and lipid content (44.66 ± 0.95%) when glucose was used as a carbon source (Fig. 4). The lowest biomass (10.38 ± 2.14 g/L), lipid yield (2.70 ± 0.04 g/L) and lipid content (26.01 ± 2.11%) was attained by SY89 when grown in media containing xylose as carbon source. This results lead to selection of glucose as a carbon source for further studies. This confirms the results obtained by other researchers that glucose is the preferred carbon source for lipid production by oleaginous yeasts (Patel et al. 2014; Ahmad et al. 2015; Enshaeieh et al. 2015).

Effect of glucose concentration

To determine the optimum glucose concentration for maximum biomass production, lipid yield and lipid content of SY89, various concentrations of glucose were tested in a nitrogen-limited media. A medium containing 50 g/L of glucose was found to be optimum for maximum production of biomass (16.37 ± 1.57 g/L), lipid yield (6.95 ± 0.42 g/L) and lipid content (42.46 ± 2.31%) (Fig. 5). In contrast, the lowest biomass (10.79 ± 1.75 g/L), lipid yield (2.24 ± 0.25 g/L) and lipid content (20.76 ± 1.86%) were attained by this oleaginous yeast, when the medium contained 10 g/L glucose (Fig. 5). These results lead to the selection of 50 g/L glucose for further optimization.

Effect of nitrogen source

The effect of combined organic nitrogen (yeast extract, peptone and urea at 0.5 g/L) and inorganic nitrogen sources (NH4)2SO4 and NH4Cl at 0.30 g/L by SY89 was determined in the nitrogen-limited media composed of 50 g/L. Maximum biomass of circa 16 g/L was obtained when media containing combinations of (NH4)2SO4 with yeast extract or (NH4)2SO4 and peptone was used. In addition, this yeast provided the maximum lipid yield (7.27 ± 0.23 g/L) and lipid content (42.89 ± 2.05%) when (NH4)2SO4 and yeast extract were used as nitrogen sources in combinations. The lowest biomass (13.15 ± 0.12 g/L), lipid yield (3.78 ± 0.67 g/L) and lipid content (28.75 ± 0.75%) were obtained when NH4Cl and urea were used in combination (Fig. 6). According to other researchers different nitrogen sources support different oleaginous yeasts either in combination or alone. For example, Zhu et al. (2008) grew Geotrichum (syn, Trichosporon) fermentans by varying different nitrogen sources [(NH4)2SO4, NH4Cl, NH4NO3, peptone and urea)]. Among the nitrogen sources tested, urea supported maximum biomass. With respect to lipid content and lipid yield, peptone was the best nitrogen source. On the other hand, Kraisintu et al. (2010) reported that Rhodotorula (syn, Rhodosporidium) toruloidesDMKU3-TK16 produced the most biomass when the yeast was grown in medium containing yeast extract and (NH4)2SO4 as nitrogen sources.

Based on the results in Fig. 6, lipid yield and lipid content percentage at different combinations of different nitrogen sources, it is evident that (NH4)2SO4 and yeast extract are the optimum nitrogen sources for SY89. Accordingly, (NH4)2SO4 and yeast extract were selected as the optimum nitrogen sources for SY89 for further optimization studies.

Effect of C/N ratio

The C/N ratio in the growth medium plays a pivotal role in achieving high lipid accumulation in oleaginous microorganisms. For the production of lipids by oleaginous microorganisms, there must be nutrient imbalance in the culture medium and specifically the C/N ratio has to be high (Beopoulos et al. 2009). According to Papanikolaou and Aggelis (2011) C/N ratio must be greater than 20. The optimal C/N value has to not only to be high (e.g., in the range between 80 and 350 mol/mol), but also strongly depends on the oleaginous species, the medium composition, the carbon and nitrogen sources used (Ykema et al. 1986). In a media having high C/N ratio, sufficient carbon will be left in the medium and be utilized for lipid accumulation during cell growth (Ratledge and Wynn 2002). To study the effect of C/N ratio on biomass production, lipid yield and lipid content of SY89, varying C/N ratios from 40 to 160 in nitrogen- limited media composed of 50 g/L of glucose, 0.5 g/L of yeast extract and various concentrations of (NH4)2SO4 and adjusted pH of 5.5, were used (Table 1). The approximate total nitrogen content of yeast extract was found to be 20% according to the Kjeldahl method, used.

The maximum biomass (12.89 ± 1.37 g/L), lipid yield (5.87 ± 0.53 g/L) and lipid content (42.54 ± 3.32%) were observed at C/N ratio of 120 (Fig. 7). At C/N ratio of 40, SY89 showed its minimum biomass, lipid yield and lipid content as 9.70 ± 0.88 g/L, lipid yield 1.96 ± 0.42 g/L and 20.21 ± 1.46%, respectively (Fig. 7). Based on the above result, C/N ratio of 120 was optimum and selected for further optimization studies. Other researchers also reported that C/N ratio is an important factor for maximum lipid production and found an optimum C/N ratio in which the yeasts they tested. For example, G. fermentans gave maximum lipid yield at C/N ratio of 163 (Zhu et al. 2008). Maximum lipid content was attained by R. toruloides DMAKU3-TK16 at C/N ratio of 140 (Kraisintu et al. 2010).

Effect of pH

pH is one of the significant physiological parameters affecting cell growth and lipid yield (Hong et al. 2006). To determine the optimum pH for maximum production of cell biomass, lipid yield and cellular lipid content in SY89, a nitrogen-limited media with pH ranging from 4.0 to 7.0 were evaluated (Fig. 8). Maximum biomass (16.32 ± 0.78 g/L) with cellular lipid yield of 6.28 ± 0.03 g/L and lipid content of 38.38 ± 0.67% were achieved at pH 5.5. At pH 7.0, the yeast showed its lowest biomass, lipid yield and lipid content. Accordingly, pH 5.5 was selected as the optimum pH for further optimization. This is similar to the results obtained for R. toruloides DMAKU3-TK16 (Kraisintu et al. 2010), Rhodotorula glutinis (Tao et al. 2008) and Cutaneotrichosporon curvatus (El-Fadaly et al. 2009).

Effect of temperature

Cellular lipid accumulation is critically affected by temperature of the culture medium. Temperature affects all living organisms and controls the growth rate, lipid synthesis and alters the composition of cellular fatty acids (Mamatha 2009). Biomass and lipid yield as well as intracellular lipid content of SY89 were tested by growing it at temperatures of 20, 25, 30, 35 and 40 °C in a culture with 10% v/v inoculum size in nitrogen-limited medium listed above. The pH was adjusted to 5.5. At a temperature of 30 °C, SY89 produced maximum biomass (15.06 ± 1.03 g/L), lipid yield (7.16 ± 0.02 g/L) and lipid content (47.54 ± 1.34%) (Fig. 9). These maximum values achieved at 30 °C are in agreement with results of other authors (Syed et al. 2006; Mamatha 2009). This temperature was selected for further experiments.

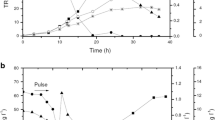

Effect of agitation rate and culture volume

It is suggested that oleaginous yeasts require substantial oxygen supply for energy and biosynthesis (Hong et al. 2006; Saad et al. 2014). One factor that influences the oxygen levels in medium is agitation rate. By increasing agitation rate, the dissolved oxygen in the medium increases, which enhances growth and lipid content (Enshaeieh et al. 2013). The effect of agitation rate on cell biomass production, lipid yield and lipid content by SY89 was determined under nitrogen-limited conditions by varying the agitation speed from 100 to 225 rpm. Maximum biomass of 14.25 ± 0.75 g/L was attained by SY89 when the agitation rate was held at 175 rpm (Fig. 10), while the highest lipid yield (6.24 ± 0.66 g/L) and lipid content (46.37 ± 2.36%) were obtained by this oleaginous yeast strain when the agitation speed was held at 225 rpm. Other researchers also investigated the optimum agitation rate for different oleaginous yeasts. For example, optimum agitation rate for production of single cell oil by R. glutinis was 180 rpm (Dai et al. 2007). El-Fadaly et al. (2009) investigated the effect of agitation speed on the SCO production by C. curvatus NRRLY-1511 and found that maximum cell dry cell mass and lipid yield were obtained at 200 rpm. Based on the above observation, all further experiments were carried out in nitrogen-limited media agitation at 225 rpm for SY89.

The culture volume also influences the oxygen level in the medium. In this study, the effect of culture volume on biomass production, lipid yield and cellular lipid content by SY89, the submerged cultures were performed by changing the ratio (R) of volume of the medium to the total volume of the flask (250 mL). The ratios used were 0.1, 0.2, 0.3, 0.4, and 0.5. The flasks were kept at 30 °C with agitation speed of 200 rpm for 144 h. In this investigation maximum biomass (15.22 ± 0.34 g/L), lipid yield (6.47 ± 0.08 g/L) and lipid content (42.51 ± 1.43%) were exhibited when the ratio of volume of media to the volume of the flask was held at 0.2. As shown in Fig. 11, there is a decrease in biomass, lipid yield and lipid content as the volume of the culture medium increased. This study confirms results obtained by Hong et al. (2006) and Mamatha (2009).

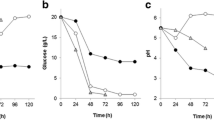

Effect of incubation period

Different oleaginous microorganisms require different incubation period for maximum biomass production and lipid accumulation. In this investigation, the effect of incubation period on biomass production, lipid yield and intracellular lipid content by SY89 was determined by growing the yeast 0, 24, 48, 72, 96, 120, 144 and 168 h in nitrogen-limited media. SY89 gave maximum biomass (16.08 ± 0.78 g/L) at the end of 168-h incubation. However, this yeast gave maximum lipid yield (7.65 ± 0.77 g/L) and lipid content (51.17 ± 1.72%) after growth period of 144-h (Fig. 12). A decrease in lipid yield and lipid content were exhibited by this oleaginous yeast after the 144-h growth. Based on the above observations, all such further experiments were carried out by incubating this oleaginous yeast for 144-h. Other researchers also reported different optimum incubation periods for maximum production of lipid by different oleaginous yeasts (Hong et al. 2006; Dai et al. 2007; El-Fadaly et al. 2009; Kraisintu et al. 2010).

Bioreactor cultivation SY89 under the optimized conditions

R. kratochvilovae SY89 was grown on nitrogen-limited medium using glucose as carbon source for 144 h. The fermentation was undertaken in a 0.8 L stirred-tank batch bioreactor. Set-up of the fermentation process is shown in Fig. 13. The results obtained in this study were considerable and showed high potential of biomass production, lipid yield and lipid content by R. kratochvilovae SY89. Under all the optimized conditions, the yeast gave maximum biomass (15.34 ± 1.47 g/L), lipid yield (8.60 ± 0.81 g/L) and lipid content (56.06 ± 1.70%).

Fatty acid composition

The type of species and growth conditions, i.e., temperature, pH, type of substrate, variation in C/N ratio and oxygen not only influence the efficiency of lipid accumulation, but also the fatty acid profiles of the cellular lipids (Jacob 1993). The fatty acid composition of lipids produced by SY89 is provided in Table 2. The total lipids of this yeast contained mostly oleic acid (C18:1) (53.82 ± 1.25%), followed by palmitic (C16:0) (18.63 ± 0.53%), linoleic (C18:2) (13.34 ± 1.15%), stearic (C18:0) (5.68 ± 0.32%), linolenic (C18:3) (5.47 ± 0.60%) and palmitoleic (C16:1) (0.50 ± 0.09%) acids. Similar results on major fatty acid profiles of different oleaginous yeasts were reported by other researchers (Ahmad et al. 2015). The fatty acid profiles that were exhibited by SY89 were not only similar to fatty acid profiles of other oleaginous yeasts, but also they are similar to the fatty acid profiles of different vegetable oils (Table 2). The cellular lipids contain circa 70% C16:0 and C18:1, suggesting that this strain could be used as feedstock for biodiesel production (Byreddy et al. 2015).

Conclusions

In this study it was observed that cultivation conditions had an influence on lipid accumulation of SY89. Comparing it to previous data it is clear that there are some differences across species and strains and it is, therefore, important to investigate the optimal parameters for each strain tested. Under the optimized conditions, SY89 yeast gave lipid content of 56.06 ± 1.70% of the biomass (15.34 ± 1.47 g/L). Such values suggest that SY89 could be considered as an attractive yeast for the production of lipid if cultivated under fed-batch or continuous bioreactor. Furthermore, the concentration of saturated and monounsaturated fatty acids of SY89 adds up 78.63 ± 2.19%. This suggests that this strain could be used as a feedstock for biodiesel production.

References

Ahmad FB, Zhang Z, Doherty WOS, O’Hara IM (2015) A multi-criteria analysis approach for ranking and selection of microorganisms for the production of oils for biodiesel production. Bioresour Technol 190:264–273

Amaretti A, Raimondi S, Sala M, Roncaglia L, Lucia MD, Leonardi A, Rossi M (2010) Single cell oils of the cold adapted oleaginous yeast Rhodotorula glacialis DBVPG4875. Microb Cell Fact 9:73

Angerbauer C, Siebenhofer M, Mittelbach M, Guebitz GM (2008) Conversion of sewage sludge into lipids by Lipomyces starkeyi for biodiesel production. Bioresour Technol 99:3051–3056

Bandaiphet C, Prasertsan P (2006) Effect of aeration and agitation rates and scale-up on oxygen transfer coefficient, kLa in exopolysaccharide production from Enterobacter cloacae WD7. Carbohyd Polym 66:216–228

Beopoulos A, Mrozova Z, Thevenieau F, Dall MT, Hapala I, Papanikolaou S, Chardot T, Nicaud JM (2008) Control of lipid accumulation in the yeast Yarrowia lipolytica. Appl Environ Microbiol 74:7779–7789

Beopoulos A, Chardot T, Nicaud JM (2009) Yarrowia lipolytica: a model and a tool to understand the mechanisms implicated in lipid accumulation. Biochimie 91:692–696

Butte W (1983) Rapid method for the determination of fatty acid profiles from fats and oils using trimethylsulphonium hydroxide for transesterification. J Chromatogr A 261:142–145

Byreddy AR, Gupta A, Barrow CJ, Puri M (2015) Comparison of cell disruption methods for improving lipid extraction from Thraustochytrid strains. Mar Drugs 13:5111–5127

Chen XF, Huang C, Yang XY, Xiong L, Chen XD, Ma LL (2013) Evaluating the effect of medium composition and fermentation condition on the microbial oil production by Trichosporon cutaneum on corncob acid hydrolysate. Bioresour Technol 143:18–24

Dai C, Tao J, Xie F, Dai Y, Zhao M (2007) Biodiesel generation from oleaginous yeast Rhodotorula glutinis with xylose assimilating capacity. Afr J Biotechnol 6:2130–2134

de Hoog GS, Gerrits van den Ende AHG (1998) Molecular diagnostics of clinical strains of filamentous basidiomycetes. Mycoses 41:183–189

Economou CN, Aggelis G, Pavlou S, Vayenas DV (2011) Modeling of single cell oil production under nitrogen-limited and substrate inhibition condition. Biotechnol Bioeng 108:1049–1055

El-Fadaly HA, El-Naggar NA, Marwan SM (2009) Single cell oil production by an oleaginous yeast strain in a low cultivation medium. Res J Microbiol 4:301–313

Enshaeieh M, Abdoli A, Nahvi I (2013) Medium optimization for biotechnological production of single cell oil using Yarrowia lipolytica M7 and Candida sp. J Cell Mol Res 5:17–23

Enshaeieh M, Abdoli A, Madani M (2015) Single cell oil (SCO) production by Rhodotorula mucilaginosa and its environmental benefits. J Agr Sci Tech 17:387–400

Folch J, Lees M, Sloane-Stanley GH (1957) A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226:497–509

Hong LY, Bo L, Bao ZZ, Wu BF (2006) Optimization of culture conditions for lipid production by Rhodosporidium toruloides. Chin J Biotech 22:650–656

Jacob Z (1993) Yeast lipid biotechnology. Adv Appl Microbiol 39:185–212

Jiru TM, Abate D, Kiggundu N, Pohl C, Groenewald M (2016) Oleaginous yeasts from Ethiopia. AMB Exp 6:78

Kitcha S (2012) Screening of oleaginous yeasts and optimization for lipid production using crude glycerol as a carbon source, thesis submitted to the Prince of Songkla University for the award of degree of doctor of philosophy in biotechnology, pp 1–162

Knutsen AK, Robert V, Poot GA, Figge M, Epping W, Holst-Jensen A, Skaar I, Smith MT (2007) Polyphasic re-examination of Yarrowia lipolytica strains and the description of three novel Candida species: Candida osloensis sp.nov, Candida alimentaria sp nov and Candida hollandica sp nov. Int J Syst Evol Microbiol 57:2426–2435

Kraisintu P, Yongmanitchai W, Limtong S (2010) Selection and optimization for lipid production of a newly isolated oleaginous yeast, Rhodosporidium toruloides DMKU3-TK16. Kasetsart J (Nat Sci) 44:436–445

Krishna G, Ranjhan SK (1980) Laboratory manual for nutrition research. Vicas Publishing House, New Delhi, pp 1–134

Kumar S, Stecher G, Tamura K (2016) MEGA7: molecular evolutionary genetics analysis version 7.0 for bigger datasets. Mol Biol Evol 33:1870–1874

Kurtzman CP, Fell JW, Boekhout T, Robert V (2011) Methods for isolation, phenotypic characterization and maintenance of yeasts. In: Kurtzman CP, Fell JW, Boekhout T (eds) The yeasts: a taxonomic study, 5th edn. Elsevier Science, Amsterdam, pp 87–110

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80:749–756

Li M, Liu GM, Chi Z, Chi ZM (2010) Single cell oil production from hydrolysate of cassava starch by marine—derived yeast Rhodotorula mucilaginosa TJY15a. Biomass Bioenerg 34:101–107

Luque R, Lovett JC, Datta B, Clancy J, Campelo JM, Romero AA (2010) Biodiesel as feasible petrol fuel replacement: a multidisciplinary overview. Energ Enivron Sci 3:1706–1721

Ma F, Hanna MA (1999) Biodiesel production: a review. Bioresour Technol 70:1–15

Mamatha SS (2009) Polyunsaturated fatty acids of Mucor sp. with special reference to gamma linolenic acid, thesis submitted to the University of Mysore for the award of degree of doctor of philosophy in microbiology, pp 123–169

Pan LX, Yang DF, Shao L, Chen WGG, Liang ZQ (2009) Isolation of the oleaginous yeasts from the soil and studies of their lipid producing capacities. Food Technol Biotechnol 47:215–220

Papanikolaou S, Aggelis G (2011) Lipids of oleaginous yeasts. Part II: technology and potential applications: a review. Eur J Lipid Sci Technol 113:1052–1073

Patel A, Pravez M, Deeba F, Pruthi V, Singh RP, Pruthi PA (2014) Boosting accumulation of neutral lipids in Rhodosporidium kratochvilovae HIMPA1 grown on hemp (Cannabis sativa Linn) seed aqueous extract as feedstock for biodiesel production. Bioresour Technol 165:214–222

Ratledge C, Wynn JP (2002) The biochemistry and molecular biology of lipid accumulation in oleaginous microorganisms. Adv Appl Microbiol 51:1–51

Saad N, Abdeshahian P, Kalil MS, Yusoff WMW, Hamid AA (2014) Optimization of aeration and agitation rate for lipid and gamma linolenic acid production by Cunninghamella bainieri 2a1 in submerged fermentation using response surface methodology. Sci World J 2014:12. doi:10.1155/2014/280146

Saxena RK, Anand P, Saran S, Isar J (2009) Microbial production of 1,3-propanediol: recent developments and emerging opportunities. Biotechnol Adv 27:895–913

Sha Q (2013) A comparative study on four oleaginous yeasts on their lipid accumulating capacity. Swedish University of Agricultural Sciences, Department of Microbiology, Master’s thesis, pp 1–29

Syed MA, Singh SK, Pandey A, Kanjilal S, Prasad RBN (2006) Effects of various process parameters on the production of α-Linolenic acid in submerged fermentation. Food Technol Biotechnol 44:282–287

Tao J, Dai C, Li R, Chen J, Zhang B (2008) The changes of microdiesel composition with the culture conditions by fallen leaves of Populus euramevicana cv. Int J Sustain Energ 27:73–79

Thakur MS, Prapulla SG, Karanth NG (1988) Microscopic observation of Sudan Black B staining to monitor lipid production by microbes. J Chem Technol Biotechnol 42:129–134

Vilgalys R, Hester M (1990) Rapid genetic identification and mapping of enzymatically amplified ribosomal DNA from several Cryptococcus species. J Bacteriol 172:4238–4246

Wang QM, Yurkov AM, Göker M, Lumbsch HT, Leavitt SD, Groenewald M, Theelen B, Liu XZ, Boekhout T, Bai FY (2015) Phylogenetic classification of yeasts and related taxa within Pucciniomycotina. Stud Mycol 81:149–189

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In: Innis N, Gelfand D, Sninsky J, White T (eds) PCR protocols: a guide to methods and applications. Academic Press, New York, pp 315–332

Wu S, Zhao X, Shen H, Wang Q, Zhao ZK (2011) Microbial lipid production by Rhodosporidium toruloides under sulfate-limited conditions. Bioresour Technol 102:1803–1807

Ykema A, Verbree EC, Verseveld HW, Smit H (1986) Mathematical modeling lipid production by oleaginous yeasts in continuous cultures. Antonie Van Leeuwenhoek 52:491–506

Zhu LY, Zong MH, Wu H (2008) Efficient lipid production with Trichosporon fermentans and its use for biodiesel preparation. Bioresour Technol 99:7881–7885

Acknowledgements

Tamene is thankful to Ethiopian Ministry of Science and Technology for their financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interests

The authors declare that they have no conflicts of interests.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jiru, T.M., Groenewald, M., Pohl, C. et al. Optimization of cultivation conditions for biotechnological production of lipid by Rhodotorula kratochvilovae (syn, Rhodosporidium kratochvilovae) SY89 for biodiesel preparation. 3 Biotech 7, 145 (2017). https://doi.org/10.1007/s13205-017-0769-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0769-7