Abstract

By discharging aerosols from a high-pressure vessel through a nozzle, an improved continuous aerosol dispersion system can disperse nanoparticle agglomerates to almost primary nanoparticle size. The system’s high-pressure dispersion was modelled and numerically simulated using the Taylor expansion method of moments. The strong turbulent shear near the nozzle could achieve the same level as the van der Waals force, which is the main mechanism for deagglomerating nanoparticle agglomerates. The change in nanoparticle size was determined to be proportional to the pressure drop between the nozzle inlet and outlet. Nanoparticle breakup was also observed to be affected by the fractional dimension and primary size of particles.

Similar content being viewed by others

References

Ammar Y, Dehbi A, Reeks MW (2012) Break-up of aerosol agglomerates in highly turbulent gas flow. Flow Turbul Combust 89:465–489

Arffman A, Marjamäki M, Keskinen J (2011) Simulation of low pressure impactor collection efficiency curves. J Aerosol Sci 42:329–340

Bałdyga J (2016) Mixing and fluid dynamics effects in particle precipitation processes KONA. Powder Part J 33:127–149

Bałdyga J, Orciuch W, Makowski Ł, Malski-Brodzicki M, Malik K (2007) Break up of nano-particle clusters in high-shear devices. Chem Eng Process 46:851–861

Bałdyga J, Makowski Ł, Orciuch W, Sauter C, Schuchmann HP (2009) Agglomerate dispersion in cavitating flows. Chem Eng Res Des 87:474–484

Barthelmes G, Pratsinis S, Buggisch H (2003) Particle size distributions and viscosity of suspensions undergoing shear-induced coagulation and fragmentation. Chem Eng Sci 58:2893–2902

Beinert S, Gothsch T, Kwade A (2012) Numerical evaluation of flow fields and stresses acting on agglomerates dispersed in high-pressure. Microsyst Chem Eng Technol 35:1922–1930

Beinert S, Gothsch T, Kwade A (2015) Numerical evaluation of stresses acting on particles in high-pressure microsystems using a Reynolds stress model. Chem Eng Sci 123:197–206

Bergström L (1997) Hamaker constants of inorganic materials. Adv Colloid Interface Sci 70:125–169

Biskos G, Vons V, Yurteri CU, Schmidt-Ott A (2008) Generation and sizing of particles for aerosol-based nanotechnology. KONA Powder Part J 26:13–35

Calvert G, Ghadiri M, Tweedie R (2009) Aerodynamic dispersion of cohesive powders: a review of understanding and technology. Adv Powder Technol 20:4–16

Calvert G, Hassanpour A, Ghadiri M (2011) Mechanistic analysis and computer simulation of the aerodynamic dispersion of loose aggregates. Chem Eng Res Des 89:519–525

Calvert G, Ghadiri M, Dyson M, Kippax P, McNeil-Watson F (2013a) The flowability and aerodynamic dispersion of cohesive powders. Powder Technol 240:88–94

Calvert G, Hassanpour A, Ghadiri M (2013b) Analysis of aerodynamic dispersion of cohesive clusters. Chem Eng Sci 86:146–150

Canepari S, Padella F, Astolfi ML, Marconi E, Perrino C (2013) Elemental concentration in atmospheric particulate matter: estimation of nanoparticle contribution. Aerosol Air Qual Res 13:1619–1629

Chan TL, Liu S, Yue Y (2018) Nanoparticle formation and growth in turbulent flows using the bimodal TEMOM. Powder Technol 323:507–517

De Bona J, Lanotte AS, Vanni M (2014) Internal stresses and breakup of rigid isostatic aggregates in homogeneous and isotropic turbulence. J Fluid Mech 755:365–396

Deng X, Davé RN (2017) Breakage of fractal agglomerates. Chem Eng Sci 161:117–126

Deng X, Huang Z, Wang W, Davé RN (2016) Investigation of nanoparticle agglomerates properties using Monte Carlo simulations. Adv Powder Technol 27:1971–1979

Endo Y, Hasebe S, Kousaka Y (1997) Dispersion of aggregates of fine powder by acceleration in an air stream and its application to the evaluation of adhesion between particles. Powder Technol 91:25–30

Friedlander SK (2000) Smoke, dust, and haze: fundamentals of aerosol dynamics. Oxford University Press, New York

Froeschke S, Kohler S, Weber AP, Kasper G (2003) Impact fragmentation of nanoparticle agglomerates. J Aerosol Sci 34:275–287

Glikin M, Glikina I, Kauffeldt E (2005) Investigations and applications of aerosol nano-catalysis in a vibrofluidized (vibrating) bed. Adsorpt Sci Technol 23:135–143

Kaminski H, Beyer M, Fissan H, Asbach C, Kuhlbusch TA (2015) Measurements of nanoscale TiO2 and Al2O3 in industrial workplace environments—methodology and results Aerosol. Air Qual Res 15:129–141

Lin X et al (2017) Mechanochemistry: a green, activation-free and top-down strategy to high-surface-area carbon materials. ACS Sustain Chem Eng 5:8535–8540

Lvov YM, Pattekari P, Zhang X, Torchilin V (2010) Converting poorly soluble materials into stable aqueous nanocolloids. Langmuir 27:1212–1217

Marchisio DL, Soos M, Sefcik J, Morbidelli M (2006) Role of turbulent shear rate distribution in aggregation and breakage processes. AICHE J 52:158–173

Masuda H (2009) Dry dispersion of fine particles in gaseous phase. Adv Powder Technol 20:113–122

Menter FR (1994) Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J 32:1598–1605

Noël A et al (2012) Effects of inhaled nano-TiO2 aerosols showing two distinct agglomeration states on rat lungs. Toxicol Lett 214:109–119

Park KS, Heister SD (2013a) Modeling particle collision processes in high Reynolds number flow. J Aerosol Sci 66:123–138

Park KS, Heister SD (2013b) Numerical simulation of particle breakup/coalescence processes in shock waves. In: Paper presented at the 49th AIAA/ASME/SAE/ASEE joint propulsion conference & Exhibit

Park KS, Xia G, Heister SD (2010) Modeling two-phase flow with stochastic coalescence/breakage model. In: Paper presented at the 46th AIAA/ASME/SAE/ASEE joint propulsion conference & exhibit, Nashville

Pope SB (2000) Turbulent flows. Cambridge University Press, Cambridge

Qin C, Yang N (2016) Population balance modeling of breakage and coalescence of dispersed bubbles or droplets. Multiph Syst Prog Chem 28:1207–1223

Rumpf H (1962) The strength of granules and agglomerate. In: Knepper WA (ed) Agglomeration. John Wiley, New York, pp 379–413

Sullivan RC et al (2010) Impact of particle generation method on the apparent hygroscopicity of insoluble mineral particles. Aerosol Sci Technol 44:830–846

Tang P, Fletcher D, Chan H-K, Raper JA (2008) Simple and cost-effective powder disperser for aerosol particle size measurement. Powder Technol 187:27–36

Taylor GI (1932) The viscosity of a fluid containing small drops of another fluid. Proc R Soc Lond Ser A 138:41–48

Taylor G (1934) The formation of emulsions in definable fields of flow. Proc R Soc Lond Ser A 146:501–523

Tiwari AJ, Fields CG, Marr LC (2013) A cost-effective method of aerosolizing dry powdered nanoparticles. Aerosol Sci Technol 47:1267–1275

To D, Dave R, Yin X, Sundaresan S (2009) Deagglomeration of nanoparticle aggregates via rapid expansion of supercritical or high-pressure suspensions. AICHE J 55:2807–2826

Tsai C-J, Lin G-Y, Liu C-N, He C-E, Chen C-W (2012) Characteristic of nanoparticles generated from different nano-powders by using different dispersion methods. J Nanopart Res 14:777

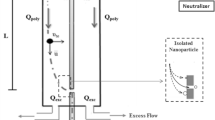

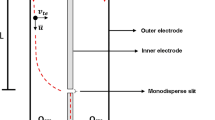

Tu C, Lin J, Yin Z, Bao F, Du P (2017a) Powder disperser for the continuous aerosolizing of dry powdered nanoparticles. Adv Powder Technol 28:2848–2858

Tu C, Yin Z, Lin J, Bao F (2017b) A review of experimental techniques for measuring micro-to nano-particle-laden gas. Flows Appl Sci 7:120

Weiler C, Wolkenhauer M, Trunk M, Langguth P (2010) New model describing the total dispersion of dry powder agglomerates. Powder Technol 203:248–253

Wengeler R, Nirschl H (2007) Turbulent hydrodynamic stress induced dispersion and fragmentation of nanoscale agglomerates. J Colloid Interface Sci 306:262–273

Wengeler R, Teleki A, Vetter M, Pratsinis SE, Nirschl H (2006) High-pressure liquid dispersion and fragmentation of flame-made silica agglomerates. Langmuir 22:4928–4935

Wong W, Fletcher DF, Traini D, Chan H-K, Crapper J, Young PM (2010) Particle aerosolisation and break-up in dry powder inhalers 1: evaluation and modelling of venturi effects for agglomerated systems. Pharm Res 27:1367–1376

Xu G, Wang J (2017) CFD modeling of particle dispersion and deposition coupled with particle dynamical models in a ventilated room. Atmos Environ 166:300–314

Yin Z-Q, Li X-F, Bao F-B, Tu C-X, Gao X-Y (2018) Thermophoresis and Brownian motion effects on nanoparticle deposition inside a 90 square bend tube. Aerosol Air Qual Res 18:1746–1755

Yu M, Lin J, Chen L, Chan T (2006) Large eddy simulation of a planar jet flow with nanoparticle coagulation. Acta Mech Sin 22:293–300

Yu M, Lin J, Chan T (2008) A new moment method for solving the coagulation equation for particles in Brownian motion. Aerosol Sci Technol 42:705–713

Zhang N, Zheng Z, Maghirang R (2008) Numerical simulation of smoke clearing with nanoparticle aggregates. Int J Numer Methods Eng 74:601–618

Zhang N, Zheng ZC, Glasgow L, Braley B (2010) Simulation of particle deposition at the bottom surface in a room-scale chamber with particle injection. Adv Powder Technol 21:256–267

Acknowledgements

This work was supported by the National Natural Science Foundation of China (no. 11802105) and the Fundamental Research Funds for the Central Universities (JUSRP51634B) and Jiangsu Key Laboratory of Advanced Food Manufacturing Equipment & Technology (FMZ201808).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, F., Tu, C., Yu, J. et al. High-pressure dispersion of nanoparticle agglomerates through a continuous aerosol disperser. Appl Nanosci 9, 1857–1868 (2019). https://doi.org/10.1007/s13204-019-00991-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-019-00991-w