Abstract

To decrease the coke yield while increase the conversion of FCC feedstock is of great significance as the crude oil becoming heavier and poorer in quality. In this work, the modified mesoporous alumina with rich Brönsted acidic sites (BAS) and reduced Lewis acidic sites (LAS) have been prepared by a sol-gel method. The modified γ-Al2O3 was characterized by X-ray diffraction, N2 sorption and FT-IR analysis and then used as the binder in FCC catalyst for catalytic activity tests. The results showed that the modified γ-Al2O3 (M-2) possessed a high BAS/LAS pyridine-IR band ratio of 0.75. The new catalysts with modified γ-Al2O3 (New-2) showed a good performance in increasing conversion of FCC feedstock by 8.55 % but reduced the coke yield by 3.25 % compared with catalyst of commercial alumina sol binder (C-AS). Besides, the New-2 increased the gasoline yield and diesel yield by 7.02 and 3.02 %.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fluid catalytic cracking (FCC) is one of the most important conversion technologies to produce transportation fuels and petrochemicals. It has been widely adopted to transform high-boiling, high-molecular weight petroleum hydrocarbons into valuable distillates such as olefins, gasoline, and diesel in the last decades. Modern FCC catalysts consist of two main components: (1) zeolites which provide the main active sites for the oil conversion and gasoline fraction, and (2) the matrix which offer the physical characteristics of the catalysts and extra acidic sites for pre-cracking heavier fractions [1, 2]. γ-Al2O3 has been extensively used as one of the most important binder as well as the matrix materials in FCC catalysts due to its good adhesive properties, physical performances, and acidity for pre-cracking of hydrocarbon macromolecules [3]. However, traditional γ-Al2O3 possesses only Lewis acidity which causes excessive hydrogen transfer reactions and results in severe coke formation [2, 4]. So an innovative idea is to reduce Lewis acidity and/or generate more Brönsted acidic sites which are more conducive to cracking by surface modification of γ-Al2O3 in order to reduce the coke formation.

Hetero atoms such as silicon and phosphorus were commonly added to the surface alumina to adjust the acidity of γ-Al2O3 [5, 6]. Fluorine modified γ-Al2O3 was found to have low content of Brönsted acidic sites and fluorine modification has been widely studied [7–10]. Rodriguez and Moreno [8, 9] prepared partially fluorinated alumina catalysts by incipient wetness impregnation with NH4F and observed that active Brönsted sites were formed by doping lower fluorine content. Dambournet and Zheng [11, 12] also observed the occurrence of weak Brönsted acid sites and suggested that the acid sites were associated with the dissociation of surface water molecules by the strongly under-coordinated species. In other research, no Brönsted acid sites have been observed on fluorine modified alumina [10, 13, 14]. Besides, the amount of Lewis acid sites increased with fluorine content at lower F doping amount which is unfavorable to be used as FCC catalyst components [3, 15, 16]. In contrast, it was reported that the introduction of boron into γ-Al2O3 increased its surface area as well as the concentrations of acid sites [15, 17]. However, the acid type was not mentioned and the acid sites were thermal instable. Whereas, few reports about alumina modification by NH4BF4 have been published. Therefore, it is interesting to synthesize γ-Al2O3 with improved Brönsted acid sites and to characterize these materials for their application as a matrix in FCC catalysts.

With this aim, a sol-gel method was adopted to modify the surface acidity of γ-Al2O3 using NH4BF4 as modifier. The modified γ-Al2O3 was then characterized by XRD, N2 sorption and FT-IR to investigate the crystalline structures, porosity and the surface acidity. The catalytic activities of FCC catalysts were also tested using the modified γ-Al2O3 as the binder.

Experimental section

Preparation

Pseudo-boehmite (Al2O3 content is 71.90 wt% on a dry basis), Kaolin clays and zeolite USY were purchased from Hua Xin powder Co. Ltd. Ammonium hydroxide (28.00 wt%) and nitric acid (HNO3, AR) were purchased from Sinopharm Chemical Reagent Co. Ltd. Ammonium fluoroborate (NH4BF4 97.00 wt%) was purchased from Shanghai SSS Reagent Co. Ltd.

The modified γ-Al2O3 was prepared by a modified sol-gel route [18]. The samples were prepared as follows. Pseudo-boehmite was dispersed in 40 ml of distilled water and then 35 ml of NH4BF4 aqueous solution was added at 85 ºC under vigorous stirring. Nitric acid was added into the solution until pH = 3. The whole suspension was then stirred vigorously for 6 h. Thereafter, aqueous ammonia was added into the solution to adjust to a pH of 11. The quiescent suspension was aged at 75 ºC for 24 h. The resulting gel was subsequently washed with distillated water and dried at 85 ºC for 24 h. The sample was finally obtained by heating the dried material under air at 550 ºC for 4 h. Two modified γ-Al2O3 samples, marked as M-1 and M-2, were prepared at selected F/Al atomic ratios of 0.20, 0.40.

Four types of binders, commercial alumina sol, commercial silica sol, M-1 and M-2, were selected to compare their catalytic activity. The catalysts, named them in turn C-AS, C-SS, New-1 and New-2, were prepared with the USY, kaolin and binder at a dry basis mass ratio of 30: 40: 30. All catalysts were hydrothermally treated in 100 % water steam at 800 ºC for 4 h before catalytic activity tests.

Characterization

XRD patterns were recorded on a Bruker Axs diffractometer (Germany) using Cu-Kα radiation generated at 40 kV and 40 mA. A scanning range from 5º to 75º was used at a speed of 0.01º/s. N2 isothermal sorption measurements at −196 ºC were carried out in a Micrometrics TRISTAR 3000 analyzer. The samples were first outgassed at 300 ºC with a vacuum degree of 10−2 torr for 4 h prior to N2 sorption measurement. Specific surface area was calculated by the Brunauer-Emmett-Teller (BET) method using experimental points at a relative pressure (P/P0) = 0.05–0.25 and total pore volume using a single point adsorption at (P/P0) = 0.99. The pore size distribution was derived from the desorption branch, using the Barrett–Joyner–Halenda (BJH) method [19]. Fourier transform infrared (FT-IR) spectra were recorded on a Nicolet 6700 spectrometer equipped with a MCT liquid nitrogen cooled detector and a KBr beam splitter. The spectra of the samples were recorded by accumulating 64 scans at 4 cm−1 resolution [20]. The transmission electron microscopy (TEM) images were acquired on a JEOL JEM 2100 electron microscope operated at an accelerating voltage of 200 kV.

Catalytic evaluation

Catalytic activity tests of catalysts were performed in an automated bench-scale micro-activity test (MAT) unit. The catalytic reactions occurred at 500 ºC for 75 s, using 3.00 g of catalyst in a tubular stainless steel reactor with inner diameter of 13 mm and length of 180 mm and 1.00 g feed. Vacuum gas oil (VGO) as heavy hydrocarbon feedstock. VGO was purchased from Fushun Petrochemical Co. (Table 1 as provided by vendor). The resulting cracking gas was collected and analyzed by a Varian 3800 gas chromatograph (GC) equipped with two thermal conductivity detectors (TCD) and a flame ionization detector (FID). The liquid products were weighed and analyzed by simulated distillation on a Varian 3800 GC according to the ASTM D2887 method. So, the mass percentage of gasoline (IBP-204 ºC), diesel (204–350 ºC), and slurry (>350 ºC) were quantified. The Elemental Analyzer (Elementar Vario EL III) was used for measuring the weight of coke deposited on the catalyst by analyzing the CO2 and CO quantities after combustion.

Results and discussion

The XRD patterns in Fig. 1 showed that the pseudo-boehmite raw material had two crystalline phases of boehmite and bayerite. It was transformed into the γ-Al2O3 phase after a simple heating at high temperature via dehydroxylation and reconstruction reactions. Similarly, the NH4BF4 modified alumina, M-1 and M-2, possessed only γ-Al2O3 crystalline phases. However, the elemental analysis demonstrated that the fluorine contents on them were above 4 % (not shown here). It indicated that the modification process did not change the long range order composition of γ-Al2O3 phase.

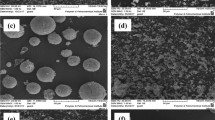

The further investigation of textural properties of samples, however, showed that after modification, M-1 and M-2 had lower specific surface areas but increased pore volumes compared with γ-Al2O3 (Table 2). Simultaneously, the pore width of modified alumina increased from 5.7 nm to about 7.0 nm. It is probably because that γ-Al2O3 partially reacted with fluorine to form the hydroxyl fluoride phase although it was undetected by XRD analysis, however, this framework was of a dense packed stacking and lower surface area [13]. The TEM images of M-2 showed that the modified alumina was the aggregation of nanostructure particles with sizes ca. 20 nm and M-2 showed an open channel structures (Fig. 2).

The acidities of alumina before and after modification were determined by pyridine FT-IR spectra (Fig. 3). The band at 1490 cm−1 was generally ascribed to the combined Brönsted and Lewis acidic sites. In pyridine IR spectra of all additives, there were four bands for γ-Al2O3 at about 1,444, 1,577, 1,593 and 1,614 cm−1 which could be attributed to the Lewis acidic sites [20]. After modification, another three bands at 1,543 and 1,643 cm−1 appeared for M-1 and M-2. It was attributed to Brönsted acidic sites. In addition, the associated shoulder band at 1,453 and 1,597 cm−1 was assigned to strong Lewis acidic sites [21, 22]. Therefore, the modification of γ-Al2O3 using NH4BF4 led to the creation of Brönsted acidic sites.

The band areas of Brönsted acidic sites and Lewis acidic sites were calculated to compare the changes of acid amounts because of the unknown absorption coefficient (Table 2). It was obvious that the total acidity amount decreased by ca. 18.77 % for both modified alumina. In contrast, the Lewis acidity, respectively, decreased by 47.45 and 53.73 % for M-1 and M-2 while the generated Brönsted acidic sites were, respectively, up to 1.897 and 2.308. The more modifier was used, the higher BAS and lower LAS were obtained in our experimental conditions. M-2 had a high BAS/LAS pyridine-adsorbed band ratio up to 0.75.

It is universally recognized that both Brönsted and Lewis acidic sites on FCC catalysts can initiate the hydrocarbon reactions by forming carbonium/carbenium ions [23, 24]. It involves C–C bond breakup in parallel-series reactions via β-scission and hydrogen transfer, which convert high molecule hydrocarbons into light distillates, gases and coke [25]. In particular, LAS can give rise to much higher coke formation since their reactions are initiated by dehydrogenation or hydrogen transfer reactions of hydrocarbons [2, 4]. In this work, four FCC catalysts have been prepared to examine the effects of acidity on cracking abilities and coke formation, using four types of binders of the conventional alumina sol which had the LAS alone, silica sol with low acidity, modified alumina M-1 and M-2 with the varied BAS and LAS.

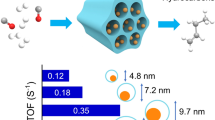

The results in Table 3 showed that C-AS, C-SS, New-1 and New-2 had the orderly increased conversions and light oil yields, indicating their increased cracking abilities of hydrocarbons. The similar trends occurred on the yields of gasoline and diesel. On contrary, the yields of dry gas and coke decreased orderly for them.

The advantages of the introduction of Brönsted acidic sites were better illustrated by the comparison of the yields of gasoline, diesel and coke taken C-AS as a reference (Fig. 4). The results demonstrated that New-2 had the best performance in improving the gasoline yield by 7.02 % and diesel yield by 3.02 %, simultaneously, decreasing the coke formation by 3.25 %. The better performances of New-2 catalyst than New-1 catalyst coincided with the results of the increased BAS and reduced LAS of M-2 compared with M-1 in Table 2. The lower coke yield of C-SS was probably ascribed to its lower acidic sites compared with C-AS since it is known that matrix derived from silica sol by heating has very few acidic sites. Therefore, it was reasonable to draw the conclusion that the Lewis acidic sites were responsible for the coke formation while Brönsted acidic sites were favourable to the decrease of coke formation. On the other hand, the combined effects of Brönsted and Lewis acidic sites increased the conversion of hydrocarbons to produce more gasoline and diesel.

Conclusion

By the modification of alumina with NH4BF4, the alumina with rich Brönsted acidic sites and reduced Lewis acidic sites were prepared. The modified alumina showed pure γ-Al2O3 crystalline phase and without obvious changes of pore structures. As the binder in FCC catalysts, the new catalysts with modified γ-Al2O3 had a good performance in hydrocarbon conversion which remarkably reduced the coke formation and increased the yields of gasoline and diesel.

References

Holland BT, Subramani V, Gangwal SK (2007) Utilizing colloidal silica and aluminum-doped colloidal silica as a binder in FCC catalysts: effects on porosity, acidity, and microactivity. Ind Eng Chem Res 46:4486–4496

Wang G, Li Z-K, Liu Y-D, Gao J-S, Xu C-M, Lan X-Y, Ning G-Q, Liang Y-M (2012) FCC-catalyst coking: sources and estimation of their contribution during coker gas oil cracking process. Ind Eng Chem Res 51:2247–2256

Van Borm R, Aerts A, Reyniers M-F, Martens JA, Marin GB (2010) Catalytic cracking of 2,2,4-trimethylpentane on FAU, MFI, and bimodal porous materials: influence of acid properties and pore topology. Ind Eng Chem Res 49:6815–6823

Qian K, Tomczak DC, Rakiewicz EF, Harding RH, Yaluris G, Cheng, Zhao X, a Peters W (1997) Coke formation in the fluid catalytic cracking process by combined analytical techniques. Energ Fuel 11:596–601

Góra-Marek K, Derewiński M, Sarv P, Datka J (2005) IR and NMR studies of mesoporous alumina and related aluminosilicates. Catal Today 101:131–138

Hensen E J M, Poduval D G, Degirmenci V, Ligthart D a J M, Chen W, Maugé F, Rigutto M S, and Veen J a R V (2013) Acidity characterization of amorphous silica-alumina. J Phys Chem C 116:21416-21429

Zhang W, Sun M, Prins R (2002) Multinuclear MAS NMR identification of fluorine species on the surface of fluorinated γ-alumina. J Phys Chem B 106:11805–11809

Moreno M, Rosas A, Alcaraz J, Hernández M, Toppi S, Da Costa P (2003) Identification of the active acid sites of fluorinated alumina catalysts dedicated to n-butene/isobutane alkylation. Appl Catal A-Gen 251:369–383

Rodriguez LM, Alcaraz J, Hernandez M, Dufaux M, Taârit YB, Vrinat M (1999) Fluorinated alumina: characterization of acid sites and relationship between acidity and activity in benzene alkylation. Appl Catal A-Gen 189:53–61

Chupas PJ, Grey CP (2004) Surface modification of fluorinated aluminas: application of solid state NMR spectroscopy to the study of acidity and surface structure. J Catal 224:69–79

Zheng C, Sun X (2012) Low cost and non-surfactant synthesis of fluorinated alumina modified with magnesium for condensation of aniline to diphenylamine. J Fluorine Chem 135:373–378

Dambournet D, Demourgues A, Martineau C, Majimel J, Feist M, Legein C, Buzaré J-Y, Fayon F, Tressaud A (2008) Nanostructured Al-based fluoride-oxide materials with a core-shell morphology. J Phys Chem C 112:12374–12380

Dambournet D, Demourgues A, Martineau C, Pechev S, Lhoste J, Majimel J, Vimont A, Lavalley J-C, Legein C, Buzaré J-Y, Fayon F, Tressaud A (2008) Nanostructured aluminium hydroxyfluorides derived from β-AlF3. Chem Mater 20:1459–1469

Boese O, Unger WES, Kemnitz E, Schroeder SLM (2002) Active sites on an oxide catalyst for F/Cl-exchange reactions: x-ray spectroscopy of fluorinated [gamma]-Al2O3. Phys Chem Chem Phys 4:2824–2832

Dumeignil F, Rigole M, Guelton M, Grimblot J (2005) Characterization of boria-alumina mixed oxides prepared by a sol-gel method. Part 2: charaterization of the calcined xerogels. Chem Mater 17:2369–2377

Dumeignil F, Rigole M, Guelton M, Grimblot J (2005) Characterization of boria-alumina mixed oxides prepared by a sol-gel method. 1. NMR characterization of the xerogels. Chem Mater 17:2361–2368

El-Hakam SA, El-Sharkawy EA (1998) Structural characterization and catalytic properties of aluminum borates-alumina catalysts. Mater Lett 36:167–173

Feng R, Liu S, Bai P, Qiao K, Wang Y, Al-Megren HA, Rood MJ, Yan Z (2014) Preparation and characterization of γ-Al2O3 with rich Brönsted acid sites and its application in the fluid catalytic cracking process. J Phys Chem C 118:6226–6234

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Emeis CA (1993) Determination of Integrated Molar Extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalysts. J Catal 141:347–354

Tamura M, Shimizu K-I, Satsuma A (2012) Comprehensive IR study on acid/base properties of metal oxides. Appl Catal A-Gen 433–434:135–145

Matsunaga Y, Yamazaki H, Yokoi T, Tatsumi T, Kondo JN (2013) IR characterization of homogeneously mixed silica-alumina samples and dealuminated Y zeolites by using pyridine, CO, and propene probe molecules. J Phys Chem C 117:14043–14050

Wojciechowski BW, Corma A (1986) Catalytic cracking: catalysts, chemistry, and kinetics. AIChE J 33:1581

Occelli ML, O’connor P (1994) Fluid catalytic cracking III: materials and processes. American Chemical Society, California

Meisel SL (1987) Catalytic cracking: catalysis, chemistry, and kinetics. Wojciechowski, B. W. and Corma, A. Marcel Dekker, 1986, 236 pp. AIChE J 33:1581

Acknowledgments

This work was financially supported by Funds of Development of Science and Technology of China National Petroleum Corporation (No. 2013A-2,106), the Joint Funds of the National Natural Science Foundation of China and China National Petroleum Corporation (Grant No. U1362202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Feng, R., Bai, P., Liu, S. et al. The application of mesoporous alumina with rich Brönsted acidic sites in FCC catalysts. Appl Petrochem Res 4, 367–372 (2014). https://doi.org/10.1007/s13203-014-0073-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-014-0073-y