Abstract

Hydrocarbons exist in abundant quantity beneath the earth's surface. These hydrocarbons are generally classified as conventional and unconventional hydrocarbons depending upon their nature, geology, and exploitation procedure. Since the conventional hydrocarbons are under the depletion phase, the unconventional hydrocarbons have been a major candidate for current and future hydrocarbon production. Additionally, investment and research have increased significantly for its exploitation. Having the shift toward unconventional hydrocarbons, this study reviews in depth the technical aspects of unconventional hydrocarbons. This review brings together all the important aspects of unconventional reservoirs in single literature. This review at first highlights the worldwide unconventional hydrocarbon resources, their technical concept, distribution, and future supplies. A portion of this study also discusses the resources of progressive unconventional hydrocarbon candidates. Apart from this, this review also highlights the geological aspects of different unconventional hydrocarbon resources including tight, shale, and coalbed methane. The petrophysical behavior of such assists including the response to well logs and the discussion of improved correlation for petrophysical analysis is a significant part of this detailed study. The variation in geology and petrophysics of unconventional resources with conventional resources are also presented. In addition, the latest technologies for producing unconventional hydrocarbons ranging from fractured wells to different fluid injections are discussed in this study. In the end, the latest machine learning and optimization techniques have been discussed that aids in the optimized field development planning of unconventional reservoirs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Petroleum hydrocarbons are one of the major energy sources worldwide (Caineng et al. 2014). They can be highly categorized into conventional and unconventional hydrocarbons. These conventional and unconventional hydrocarbons exist in huge quantities around the world at a ratio of around 2:8, respectively, with a total of 5 × 1012 t in total (Caineng et al. 2014, 2013). Due to a large quantity of unconventional hydrocarbons and their resources, there is a paradigm shift in exploring and utilizing these resources for energy demands (Song et al. 2015). Moreover, the conventional resources are getting exhausted day by day and most of the oil and gas has already been produced with traditional methods. With the advancement of technology, unconventional petroleum resources are getting easier to produce which was in the early times considered as unproducible assets (Hamada 2016). This is the reason why currently the unconventional hydrocarbon resources are given major consideration in terms of their exploration and production.

The unconventional hydrocarbons can be defined as those which require unconventional technologies to recover them from subsurface as they cannot be produced with ordinary production well by simply pumping it in their natural state without being diluted or heated (Gordon 2012). The parameters which differentiate unconventional hydrocarbons from conventional hydrocarbons are the geologic nature of the reservoir (Song et al. 2015), the complex petrophysical system (Hamada 2016), and the techniques for hydrocarbons’ extraction (Heikal 2008a).

Conventional hydrocarbons deposits are highly porous and permeable with a closed trap. Moreover, they have a uniform pressure system and oil–water contact (Zou et al. 2013a). They can be produced easily with few wellbores, and it does not require any stimulation technique to recover the hidden fluids. Unconventional hydrocarbon deposits are, however, difficult to characterize and produce as they do not naturally flow through the rock (Hamada 2016). They have far less porosity and permeability. Also, they require stimulation and other conversion or extraction techniques such as enhanced oil recovery (EOR) for a feasible production (Zou et al. 2013a; Sprunger et al. 2021; Syed et al. 2021a; Kerr et al. 2020; Li et al. 2019a; Hawthorne et al. 2019; Jin et al. 2019). This makes them economically far more expensive than conventional methods. However, they have large total volumes in the world which makes them prospective candidates for future oil and gas production worldwide.

This paper provides a review of unconventional hydrocarbons and their resources. It includes the description of unconventional liquids and gases, geology of unconventional accumulation, characterization of these resources, petrophysical characteristics, and development techniques to produce those reservoirs. Moreover, this paper also introduces the description of different countries with unconventional hydrocarbon resources potential.

Unconventional liquids

Unconventional liquids are the type of fluids that require a non-traditional extraction method to recover more liquid. These liquids are much heavier than the lowest quality of conventional oil found. Moreover, they are sourer than typical conventional oil (Gordon 2012). Unconventional liquids can be categorized into the following groups depending on the density, viscosity, and hydrogen/carbon ratio in the oil. They are heavy and extra-heavy oil, bitumen, shale oil (Thakur and Rajput 2011). Some analysts also include gas to liquid (GTL), coal to liquid (CTL), and biofuels in the unconventional category (Gordon 2012).

Unconventional liquids constitute a higher percentage of oil than conventional under the subsurface (see Fig. 1). According to an estimate, about 45,000 billion barrels of unconventional oil is held by earth and approximately 1000 billion barrels can be produced (Thakur and Rajput 2011). As per recent estimates, technically recoverable reserves for these three unconventional oils are about 350 billion tons of oil. Many of them, approximately 60%, are distributed in the South and North Americas, whereas considerable amounts are distributed in Eurasian and the rest are evenly distributed around the world (Kapustin and Grushevenko 2018).

World Proven Oil Reserves (Thakur and Rajput 2011)

With the increase in the demand and consumption of liquid, the supply of unconventional liquids is surely going to increase. Moreover, the technological advancement will also lead to the production of more unconventional liquids which adds to the overall supply of liquid worldwide. The projection of liquid supply up to 2040 is shown in Fig. 2. Oil sands, tight oil, deep water, and NGLs are getting stronger gains. Up to 2040, the global liquids supply of tight oil and NGLs is forecasted to exceed 30 percent.

Liquid Supply Worldwide (MBDOE) (ExxonMobil 2018)

According to the EIA 2013 report, the total risked shale oil in place and the total technically recoverable risked shale oil resources of the world are estimated to be 5,799 billion barrels and 286.9 billion barrels (Kuuskraa et al. 2013). The distribution of this shale oil in place is shown in Table 1. Meanwhile, another recent report by World Energy Council 2016 presented the USA as the largest tight oil reserves in the world followed by China, Argentina, and Australia (World Energy Resources. 2020). This country-wise tight oil distribution is presented in Fig. 3.

Tight oil resources in the world (World Energy Resources. 2020)

Unconventional gas

Unconventional gas resources cannot be produced at an economical flow rate unless the well, either vertical or horizontal, is stimulated by large hydraulic fractures or a multilateral wellbore is drilled, or different other techniques to exploit much more from the resources. These resources are easier to locate as they are laterally extensive. The unconventional proven original gas in place of shale, tight, and coalbed methane in the world is 83,400 trillion cubic feet while the possible reserves are estimated to be 184,200 trillion cubic feet (Dong et al. 2011). Today, coalbed methane (CBM), tight gas, and shale gas contribute significantly to world gas production. Typically, the natural gas from tight and shale resources is considered in the general title of unconventional gas. Coalbed methane is found in coal seams, and when it is formed, different types of gases are produced which includes methane, that is why, it is called coalbed methane (CBM). It is produced by pumping the water in the coal seams to reduce the pressure that holds the gas. Coal bed methane (CBM) is generally found in shallow coal deposits. Tight gas is generally found in highly porous and very low permeable sandstones, whereas shale gas is associated with the source rock shale which has very low permeability (Mokhatab et al. 2019). Gas hydrates also come under the category of unconventional gas. Gas hydrates are ice-like solids that are formed at low temperature and high pressure with the amalgamation of water and hydrate forming methane gas. These are humongous reserves that are found in deep oceans in water sediments. The reserves in this resource are enormous; however, at present there is no such viable development scheme for the exploitation of this resource. With these resources, different other gases also come under the unconventional gas category. These include biogas, gas in the pressured zone, flue gas, landfill gas, and synthetic gas (Speight 2019).

The demand for natural gas is currently increasing (see Fig. 4). Globally the demand is forecasted to increase by 40% from 2016 to 2040. This requires the production of more unconventional gas to supply the need of the world. Currently, out of total recoverable resources of natural gas, a sum of less than 15% has been produced. Out of remaining natural gas resources, a value of around 45% can be produced from coalbed methane, tight gas, and shale gas (refer Fig. 5) (ExxonMobil 2018). The total distribution of tight, coal bed methane, and shale gas around the world is shown in Table 2.

Energy demand (%) forecast (ExxonMobil 2018)

Different countries unconventional hydrocarbons potential

USA

The USA contains vast unconventional resources spread from the East to West Coast. The unconventional resource contributor by region and their respective basins is presented in Table 3. The total unproved technical recoverable tight/shale oil reserves from those basins are estimated to be 174.0 billion bbls, whereas the gas recoverable gas quantities are estimated to be 1611.1 TCF. With this, the technical recoverable coalbed methane reserves of the USA are found to be 104.9 TCF as per a recently published report (EIA 2017).

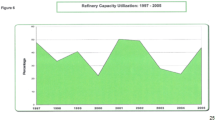

US shale gas proved reserves are estimated to be 342,135 billion cubic feet, all from the lower 48 states, with a majority of reserves contributing from Texas and Pennsylvania (refer Fig. 6). Meanwhile, the CBM proved reserves of around 11,878 BCF with again the contribution from the lower 48 states (refer Fig. 7) (U.S. EIA 2019).

US shale gas proved reserves (U.S. EIA 2019)

US CBM proved reserves (U.S. EIA 2019)

China

China consists of vast unconventional resources in major prospective basins including Songliao, Sichuan, Jianghan, Junggar, Subei, Tarim, Ordos, Bohai Bay, and the Yangtze Platform (Zhu 2019; U.S. Energy Information Administration. 2015a; Guoxin and Rukai 2020). The distribution statistics of China by major region is shown in Fig. 8.

China’s unconventional resources by basin (MMboe) (Zhu 2019)

China is estimated to have 650.44 × 1012 m3 of shale gas and 95.16 × 1012 m3 of tight gas. The recoverable shale gas and tight gas resources are 161.50 × 1012 m3 and 15.89 × 1012 m3, respectively. The tight gas reserves are majorly concentrated in Tarim, Ordos, Songliao, and Sichuan basins, whereas the shale gas is majorly found in Middle Lower Yangtze, Ordos Basin, and Sichuan Basin. Further details of China’s gas reserves are presented in Fig. 9 (Zheng et al. 2018).

China’s gas reserves (Zheng et al. 2018)

China’s tight and shale oil potential is vast; however, their estimates are unclear and vary based on the analysis and estimation of different institutions. As per the US EIA 2013 report, the shale oil recoverable reserves are estimated to be 32.2 billion bbls (approximately equal to 45 × 108 t) (U.S. Energy Information Administration. 2015a). In the recent literature, low and medium maturity shale oil recoverable resources are estimated between 700 and 900 × 108 t with an economically recoverable quantity between 150 and 200 × 108 t. Additionally, the medium and high maturity shale oil geological resources are found to be about 100 × 108 t. The geological resources of tight oil in China are found to be around 178.2 × 108 t with 17.65 × 108 t of technically recoverable (Guoxin and Rukai 2020).

Australia

The unconventional resources in Australia are very abundant. The unconventional hydrocarbon in Australia exists in the form of coal seam gas (CSG), tight gas/oil, and shale gas/oil. The development of CSG in Australia has been started way back in 1996, whereas tight and shale oil/gas exploration has taken its boom in the late 2000s (Hashimoto et al. 2012).

Australia has around 235 Tcf CSG underground with 33 Tcf as economic demonstrated resources (EDR) and subeconomic demonstrated resources (SDR) of around 60 Tcf, and this CSG contributes around 6% of the total world’s CSG resources (Geoscience Australia and BREE 2012). The majority of CSG deposits are distributed in the Surat and Bowen basins of Queensland, whereas the smaller amount contributes to the Sydney basin in New South Wales (NSW) (Ross et al. 2013). Figure 10 demonstrates the 2P reserves of CSG by different basins in Australia. Meanwhile, the gas resources of Australia are presented in Fig. 11.

Australia CSG 2P reserves (by basin) (Geoscience Australia and BREE 2012)

Australia Gas Resources (Geoscience Australia and BREE 2012)

The identified tight gas resource in Australia is mostly concentrated in Gippsland Basin (1.7 tcf), Cooper Basin (8 tcf), and Perth Basin (10 tcf) (Geoscience Australia and BREE 2012). Meanwhile, the shale gas reserves are mostly concentrated in the Cooper basin, Georgina basin, Maryborough basin, Beetaloo basin, Perth basin, and Canning basin. These basins are assessed by EIA; however, few unassessed basins may contain the potential of shale gas. These assessed basins contain a total of 2016 Tcf of risked shale gas with 437 Tcf being technically recoverable (U.S. Energy Information Administration. 2015b). The first shale gas operation in Australia begins in the Cooper basin in 2012 (Ross et al. 2013).

Except for these gas sources, the estimated risked shale oil-in-place reserves from the six assessed basins are found to be 403 billion bbls with an amount of 17.5 billion bbls as technically recoverable (U.S. Energy Information Administration. 2015b).

Pakistan

Pakistan has a large number of gas resources, however, its conventional resources are in a decline phase. Moreover, the gas demand in the country is also increasing. Pakistan consumes 100% of its natural gas production, and the remaining shortfall is managed through LNG import which requires high foreign exchange (Inam et al. 2018). Pakistan has a large volume of unconventional gas trapped in sand and shale reservoirs. As per the survey, Pakistan is estimated to have 24–40 TCF tight gas reserves in various horizons (Alam 2010). The approximate reserves of Pakistan are shown in Fig. 12.

Reserves in Pakistan (Jadoon 2011)

Moreover, the potential formations containing tight gas in Pakistan are Pirkoh Limestone, Sui Upper Limestone, Sember sands and siltstones, Habib Rahi Limestone, and Lower Goru Tight Sands. The approximate distribution of tight gas in Sulaiman Foldbelt, Indus Basin, and Kirthar Foldbets is shown in Fig. 13. Moreover, the above potential formations are largely distributed in Sulaiman Foldbelt, Indus Basin, and Kirthar Foldbets regions in Pakistan (see Fig. 14). Also, other resources are present in the Potwar region, Lower Indus Basin, and offshore areas near Karachi (see Fig. 15) (Alam 2010).

Distribution of Tight Gas in Pakistan (Ayaz et al. 2012)

Pakistan has also huge reserves of shale oil and shale gas. According to a survey (supported by US Agency for International Development—USAID), Pakistan has 10,159 Tcf of shale gas out of which 200 Tcf is technically recoverable reserves and 95 Tcf is risked technically recoverable reserves. Moreover, Pakistan has 2323 Billion barrels of shale oil out of which 58 Billion barrels are technically recoverable reserves and 14 Billion barrels are risked technically recoverable reserves. In addition to this, Pakistan stands 9th in the world in terms of technically recoverable shale oil resources (Bhutta 2015; Kiani 2015; Wang et al. 2016a). This amount is quite higher than the estimated reports of the United States Energy Information Administration (USEIA) published before. Table 4 shows the data of various resources on shale gas and oil resources of Pakistan.

Pakistan's prospective shale resources are largely concentrated in the Lower Indus Basin, predominantly in the Southern and Central Indus Basin (Zahid et al. 2016; Abbasi et al. 2014). The Northern Indus Basin and Balochistan Basin also show the potential of shale oil/gas (see Fig. 14) (Zahid et al. 2016). The prospective formations in the Lower Indus Basin include Sembar Formation, Lower Goru—shale members, Mughal Kot Formation, and Ghazij Formation. The Upper Indus Basin also has some prospective shale formations including Patala Formation, Sardhai Formation, and Hangu, Chichali, Datta formations (Ayaz et al. 2012).

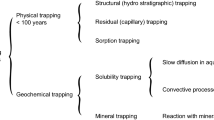

Geology of unconventional resources

Unconventional resources (referring to tight, shale, and coal) are stacked and continuous sedimentary layers that have comparatively low permeability and porosity and are generally associated with conventional reservoir rocks. The resources may be sandstone (most common), limestone, siltstone, dolomite, and sandy carbonates shale, etc. Numerous unconventional are naturally fractured and/or layered (Kumar and Shandilya 2013). They are also characterized as the resources continuously occupied in the core of basins without having usual traps (Zou et al. 2013b). These resources are also defined with the help of permeability-viscosity cross-plot curve which states them the resources that can be recovered at commercial production rate by altering their viscosity, reservoir rock properties, and changing permeability-viscosity ratio (refer Fig. 16) (Cander 2012).

Classification of Unconventional resources based on Viscosity and Natural Productivity (Zou et al. 2013b)

Unconventional resources are higher in volume but of lower grade and quality as compared to conventional reservoirs, as presented by Grey and Masters's concept of resource triangle. These resources have generally lower permeabilities with shale resources having the least permeability range (see Figs. 17 and 18). Also, they require high-cost technology to be commercially viable (Masters 1979; Holditch et al. 2007; Gomaa et al. 2014).

Resource triangle (Rahim et al. 2012)

There are two main geological factors (primary and secondary) that govern the development of such resources. The primary factors include mineralogy, grain size and sorting, lithification, provenance, depositional environment, and flow regime. The secondary factors include the development of fractures, tectonics, and diagenesis including compaction, cementation, and dissolution. Tectonics plays a critical part in the development of unconventional resources. Tectonics largely affects the pressure and thermal gradient (Kumar and Shandilya 2013; Speight 2017).

The pore throat structure of the various unconventional and conventional resources differentiates them from each other. The oil and gas accumulation of conventional resources has a pore throat diameter of 1 µm or more than it. The oil and gas accumulation and migration that occurs in this type of resource is by buoyancy factor. In contrast with these, the unconventional resources have a pore throat diameter lesser than 1 µm, and oil migration and accumulation occurs by different mechanisms including overpressure, buoyancy, stable temperature, and stable pressure (see Fig. 19) (Zou et al. 2013b).

Pore throat structure of conventional and Unconventional resources (Zou et al. 2013b)

Geologic features of Shale resources

The shale formation mainly consists of clay minerals that are firmed up so tightly that the rock becomes impermeable. In addition, these formations contain no trap or cap rock eventually having apparent or no boundary. They act both as a source and the reservoir rock, which implies that the kerogen is matured at the same place where it is deposited because of very low permeability values (Aadnøy and Looyeh 2019). Shale formations have far less permeability (often in the ranges of 0.001 to 0.0001 mD) than tight sandstone and carbonate (ranges between 0.1 and 0.001 millidarcy). The porosity in unconventional reservoirs is generally below 10% (Geology of Shale and Tight Resources 2016; Syed et al. 2021b). Shale reservoirs have nanoscale organic pores and pore throat volume, and these pores are the major source of gas accumulation in shale reservoirs. They have a pore diameter in the range of 50 mm – 400 mm. These nanopores in shale account for more than 90% of their total pores (Zou et al. 2017). Along with this, the total organic carbon, stress, pore structure, and adsorption/desorption phenomena widely contribute to the storage and transport mechanism of shale formation (Memon et al. 2020a). Besides, absorption is another important factor contributing to shale resource volume (Memon et al. 2020b, 2020c). Due to such complex characteristics including the low permeability, presence of micro-fractures, and sensitivity to contacting fluids, it is a difficult task to evaluate its geological nature in laboratory experiments (Gomaa et al. 2014).

Geologic features of Tight resources

A tight reservoir is generally a sandstone reservoir (tight sand) with low permeability. It may also consist of siltstone, silty sandstone, dolomites, and argillaceous limestones (Speight 2017). These formations are associated with high heterogeneities, have a complex pore structure system, and relatively low potential for a natural drive (Li et al. 2018). These complex pore structures are the combination of various small to very small pores resulting from several processes such as the fine-grained sediments deposition, post-depositional diagenesis altering the original structure of pores, and the presence of different clay and shale minerals in the pores (Rushing et al. 2008). Petrographically, tight formations are distinguished from the other formations by the loss of primary porosity during the process of diagenesis and the existence of most porosity in the dissolved pore spaces (Soeder and Chowdiah 1990). For the geological evaluation of tight gas formation, borehole images provide a plethora of information which include sedimentology evaluation, texture characterization, detection of calcite types of cement, and environment in which the deposition had occurred. It serves as the standard logging tool for tight geological evaluation (Shrivastva and Lawatia 2011). Most of the tight gas reservoirs are anisotropic and heterogeneous in nature (Abdelaziz Lafi Khlaifat 2011). Due to this reason, the production from the tight gas reservoir is generally lower than the conventional reservoirs (Stark et al. 2007).

Geologic features of Coalbed Methane resources

Coalbed methane just like the shale resources does not migrate at very long distance and is trapped on the bed of coal in the form of methane. Coalbed methane (CBM) reservoirs are the fast-growing unconventional reservoirs in which methane is adsorbed on the surface of micro-pores. Coal seams are identical to naturally fractured rock in which fluid flow can be described by the means of the dual-porosity model (Shi and Durucan 2005). In the CBM reservoirs, the coal matrix (micro-pores) is the main place in which methane gas is stored, and macro-pores (cleats) are the main track for the flow of gas, which are saturated with water at the start (Clarkson et al. 2010). To produce this methane gas from the surface of coal, these cleats need to be dewatered which results in the decrease in reservoir pressure, thereby creating pressure drawdown which leads to desorption of gas from the coalbed. This gas diffuses from the coal matrix to macro-pores and from the macro-pores to the wellbore (Darcy law) (Seidle 2011).

Geologic features of gas hydrate resources

The gas hydrate is a physical combination of water and natural gases. The natural gas, i.e., methane, is trapped in a very large amount in geological hydrate accumulations such as coarse-grained hydrate-bearing sediments (Abbasi et al. 2021). They are usually distributed in the Arctic and marine sediments (Lee and Holder 2001). The accumulation of gas hydrates is highly dependent on the fluid migration including both the water and gas into the gas hydrate stability zone (GHSZ). In addition, the gas hydrate accumulations can be categorized into stratigraphy, structural, and combination accumulations based on the gas hydrate concentrations within GHSZ and fluid migrations (Milkov and Sassen 2002). To produce such gas, the hydrates should be dissociated into water and gas. This is done by slurry mining, pressure reduction, and thermal injection (Lee and Holder 2001).

Petrophysical characterization of unconventional resources

Petrophysical parameters play a vital role in assisting the optimum exploration of unconventional resources. Porosity, permeability, lithology, and water saturation are some of the most important rock properties which are used for the petrophysical characterization of different unconventional reservoirs (Syed et al. 2020b). The well logging greatly assists in the petrophysical evaluation and identifying the scheme of deposition and the tightness of the reservoir. For the majority of a shale well, cased hole logging is used instead of open-hole logging due to economic constraints. If the well is drilled vertical, then open-hole logging is recommended for the petrophysical interpretation of unconventional reservoirs. After running the cased hole logging, cased sonic logs are run which determines the rock mechanical properties such as the brittleness, Poisson ratio, and young modulus (Strother and Valadares 2013).

The following logs are important for the evaluation of resources to exploit unconventional fluids:

-

Resistivity Logs

-

NMR Logs

-

Spectral Gamma Ray Logs

-

Borehole imaging logs

-

Density Logs

-

Porosity Logs

-

Acoustic logs

Due to the low porosity in unconventional, the resistivity log indicates high resistivity (approximately 70 Ωm). In tight shaly sands, the neutron porosities are affected by the thermal neutron absorbers which result in a very high neutron porosity. Because of this, the hydrocarbon zones in such formation can be miss-interpreted by neutron density logs. Shale content present in tight reservoirs does not affect the porosities from Nuclear Magnetic Resonance (NMR). Their signal amplitude provides comprehensive information about the porosity that is free from lithological effects. Relaxation time illustrates some other petrophysical parameters like distribution of sand and pore sizes, permeability, hydrocarbon identification, and capillary pressure (Shrivastva and Lawatia 2011). Borehole images usually carried out by formation image logs could interpret the structural features of unconventional, such as faults and fractures along with their orientation and morphology (refer Fig. 20) (Costin et al. 2019).

Fracture Development (Image log) (Shrivastva and Lawatia 2011)

By the study of rock physics, one can identify and comprehend the relations between the rock and fluid properties (gas vs. oil vs. water, fractures, rock-type, mineralogy stress, formation pressure & temperature, porosity) and seismic attributes (reflectivity and attenuation, velocity, AVO, impedance) (Asquith et al. 2004).

The role of core analysis is vital in the accurate determination of various properties. The study of cores, along with the thin sections, with the added support of tools like SEM, XRD, CT, and micro-CT scan is widely used to determine the exact nature of the matrix such as its microstructures and pore characteristics (Shrivastva and Lawatia 2011; Kazak et al. 2020; Gao et al. 2019; Sun et al. 2019; Chen et al. 2019a). The cores give the direct indication of various unconventional resources’ properties and it assists in the understanding of sand texture, nature of facies, reservoir morphology, depositional environment, orientation, sand distribution, diagenetic alteration, and structure. The thin section analysis of the rock deduces texture, detail mineralogy, matrix, sorting of grains, type of porosity, and cementing material (Kumar and Shandilya 2013; Speight 2017). With this, the digital rock physics implementation including the understanding of segmented images through pore network modeling and/or implementation of machine learning technology widely aided in understanding and calculating different core sample properties including the porosity, pore structures, and sizes, and permeability, etc. (Blunt et al. 2013; Wildenschild and Sheppard 2013; Armstrong et al. 2018; Chung et al. 2019; Yamanaka et al. 2019; Wang et al. 2020; Wan et al. 2020; Santos et al. 2020; Rabbani and Babaei 2019; Sudakov et al. 2019; Tembely et al. 2021; Alqahtani et al. 2020; Yun et al. 2020; Karimpouli and Tahmasebi 2019).

Apart from these methods, different penetration fluid methods including mercury intrusion porosimetry (MIP), low-temperature nitrogen adsorption/desorption (LTNA), and nuclear magnetic resonance (NMR) are also used to evaluate micro-pore characteristics of unconventional reservoirs. The MIP and LTNA involve the injection of non-wetting fluid into the unconventional sample and recording the injection pressure and fluid volume. With these data available, different theoretical models are used to calculate the specific surface area and pore size distribution (Chen et al. 2018, 2019b; Clarkson et al. 2013; Okolo et al. 2015; Jijun et al. 2015). Both these techniques have different experimental environments; therefore, their detection ranges are different. The combination of both results allows the evaluation of nano- to micro-scale pore systems in unconventional reservoirs (Clarkson et al. 2013; Okolo et al. 2015). These methods, however, have restrictions as they reflect only interconnected pores (Chen et al. 2018). NMR technology reduces this limitation and allows the evaluation of pore volume and size in saturated liquid samples irrespective of the connectivity of the pores (Chen et al. 2019a; Jijun et al. 2015). Apart from this, Rock–Eval pyrolysis is highly used to determine the total organic content (TOC) of the samples (Hazra et al. 2017).

Petrophysical characterization of shale reservoirs

The lithology of unconventional shale reservoir rock is identified by the means of GR log and resistivity log. A good number of unconventional activities around the globe are concentrated mainly on clastic. Because of the occurrence of clay minerals, the GR log demonstrates high API readings that misrepresent the reservoir as a non-reservoir. This uncertainty is resolute by using the Spectral GR log which deduces the occurrence of radioactive minerals in the formation. The Spectral GR log is used to confirm the presence of unconventional oil and gas in the shale formations (Asquith et al. 2004). If the GR readings and resistivity readings are high, then running the Spectral GR log will tell the percentage of uranium, thorium, and potassium. If the oil and gas are present in the unconventional shale formations, then the readings of uranium, GR log, and resistivity will be higher, and the porosity log shows the high porosity. However, the readings of thorium and potassium will be lower because uranium is the only radioactive element that is present in the organic matter in the source rock. Due to this, every clay is not a shale, but every shale is clay. Thus, the shale formations that have a high amount of organic matter, carbon content, porosity, and show a high uranium signal compared to potassium and thorium are typically proved to be productive (Parker et al. 2009).

The water saturation of conventional formations can be predicted from the Archie equation; however, the presence of clay in the shale formation causes the resistivity of the formation to decrease which results in the overestimation of water saturation. Meanwhile, most shale formations show a high resistivity more than certain baseline resistivity of clay due to the presence of kerogen content, gas saturation, and total organic carbon (Parker et al. 2009). Thus, to calculate the water saturation involving shale formations, Simandoux modified the Archie equation by using the volume of clay/shale. The formula for calculating the water saturation is presented in Eq. 1 (Asquith et al. 2004). Other than this technique, the water saturation can also be calculated by Waxman–Smits, Dual water methods, Indonesia, and Schlumberger methods which seeks to use the electrical properties of clay present in the shale.

where Sw = water saturation, Rw = formation water resistivity, Rt = true resistivity, ϕ = porosity, Vshale = shale volume, and Rsh = shale resistivity.

For the calculation of the porosity of shale formations, three porosity logs data and core analysis are used. From all the porosity logs, density logs are used to determine the porosity of shale formations by incorporating TOC (total organic content) in the equation of density log. The equation for calculating the porosity of shale formation is given by Eq. 2 (Zhang et al. 2015; Xiuwen et al. 2011):

whereas

where \(\rho b\) = density log reading, \({\rho_{{\text{ma}}}}\) = matrix density, \({\rho_f}\) = fluid density,\({\rho_{{\text{TOC}}}}\) = organic matter density, \({V_{{\text{TOC}}}}\) = content of organic matter.

It is complicated sometimes to measure the porosity of shale formations because of the complex logging response and lithology of the formation. The porosity of shale formation can also be calculated with a model built by core calibration logs (Zhang et al. 2015). Some of the laboratory methods like imaging methods are used to determine the porosity and permeability of shale formation, but it depends upon the resolution of images and image processing methods due to which they have a high amount of ambivalence (Klaver et al. 2015).

The permeability of the shale formations is calculated by using Magnetic Resonance Logging (MRIL). The T1 (Polarization time interval) spectrum data method has made possible the applications of MRIL to the shale-gas volumetric calculations and reservoir properties. This new T1 allows to separate any gas signal and made an authentic calculation of clay-bound water, capillary bound water, and free-fluid porosity which can be used with the Coates Model to calculate the effective shale permeability (Parker et al. 2009). It is not possible to measure the permeability of shale formations by traditional techniques due to the low flow rate and time required to reach steady-state conditions. Therefore, unsteady methods such as GRI (Gas Research Institute) and pressure pulse decay helps in measuring the permeability of shale formation. GRI is a fast method for measuring the permeability of shale formations as low as 1 nano Darcy, but it results in inaccurate permeability under stress conditions. The pulse decay method under stress conditions measures the permeability, but its results are very sensitive to pore volume measurements. The laboratory tool Precision Petrophysical Analysis Laboratory (PPAL) measures the porosity and permeability of shale under in-situ conditions (Zamirian et al. 2015, 2016).

Petrophysical characterization of tight reservoirs

The lithology of tight formation is important for identifying the porosity of formations. Porosity logs require lithology or matrix constant before determining the porosity. The formation factor used in the Archie equation for determining the water saturation varies with the lithology. Thus, the porosity and water saturation calculations depend upon the lithology of the formations. The method for determining the lithology of tight formations is the same as that of conventional reservoirs, i.e., it is determined by the SP log and GR log. Water saturation of the tight formation can be determined from the resistivity log and by using the Archie equation. By knowing the porosity from logs, a, m, n, and Rt, water saturation in a clean formation can be determined from the Archie equation which is given as (Asquith et al. 2004; Archie 1942):

where a = tortuosity factor, m = cementation factor, n = Saturation factor.

The porosity of tight formation is measured by the means of the neutron, density, and sonic log. High hydrogen atoms and lower neutron counts in the neutron porosity log indicate the high porosity and vice versa, while the density log measures the number of electron density of the formation. It is also used for detecting the lithology of tight formations. The density log measures the bulk density of the formations. Using this bulk density from the density log, matrix density by knowing the lithology, and fluid density, density log can measure the density-porosity of tight formation. Neutron density crossover can also be used to identify the lithology and porosity of tight formation on conditions that the formation is free from clay and gas (Shrivastva and Lawatia 2011). The presence of tight gas in the formation causes the readings to be read too high in the density log and low in the neutron porosity log making the crossover of both logs. This crossover of neutron porosity log helps in the identification of gas zones in tight reservoirs. The porosity of the gas-bearing zone in tight formation is predicted by Eq. 5 given as:

where \({\phi_{{\text{NDgas}}}}\) = gas-bearing formation porosity, \({\phi_D}\) = density porosity, \({\phi_n}\) = neutron porosity.

The porosity of the formation can also be measured by the NMR tool which uses the strong electromagnetic field to align the hydrogen proton present in the formation by measuring their signals (Asquith et al. 2004).

The permeability of tight formation can be determined by using NMR logs and Kozeny correlation. The permeability of the reservoir is directly proportional to the amount of pore size and effective porosity. The larger the pore size, effective porosity, the greater will be permeability of the formation. By using NMR logs, two methods are used to determine the permeability of formations which are the Coates model and the SDR model. The Coates model or free-fluid method equation for permeability determination is given as:

where k = NMR-derived permeability, \({\phi_{{\text{NMR}}}}\) = NMR-derived effective porosity, FFI = proportion of movable fluid occupying effective porosity, BVI = proportion of capillary-bound fluids occupying effective porosity, c = constant.

This method does not apply to the formation where there is the presence of heavy fluids because it is not possible to distinguish high viscosity fluids from the bound fluids. The Kozeny correlation can be used to find the permeability of formation by using Eq. 7 (Asquith et al. 2004).

where \(\tau\) = tortuosity co-efficient, r = grain size radius.

Log-derived permeability of the tight formation can be determined by the three methods which are Wyllie and Rose Method, Timur Method, Coates, and Dumanoir (Asquith et al. 2004; Coates and Dumanoir 1973).

Petrophysical characterization of coalbed methane

The petrophysical characterization of CBM reservoirs consists of porosity, permeability, and reservoir quality index (RQI). The economical production of coalbed methane reservoirs depends on the four characteristics of a coal seam which are: permeability, coal seam thickness, gas pressure, and gas content (McKee et al. 1988). The permeability of the coalbed is one of the important characteristics which are generated by natural fractures present in the coal. The coal formation may squeeze due to the emission of gas from coalbed and expand again on resorption (Shedid and Rahman 2009). During the primary production phase of methane gas from coalbed, two phenomena occur which makes the coal permeability decrease: first, the compaction of the reservoir results in an increment of horizontal stress. Second, gas desorption results in the shrinkage of the coal matrix and increases cleat permeability. Different models are used to describe the variation in the permeability of CBM reservoirs which include the Mckee et al. model (McKee et al. 1988), Shi-Durucan model (Shi and Durucan 2005), and Shedid. A. et al. correlation (Shedid and Rahman 2009). In addition, the characterization of the free and adsorbed gas is very important as they play a huge role in accurate reserve estimation. Generally, the adsorbed gas in coal is measured through partial pressure of methane or the evaluation of water bubble point pressure to estimate critical desorption pressure (CDP) (Pope et al. 2006; Carlson 2006). One important challenge to estimating adsorbed gas content is the uncertainty of heterogeneous coal thickness. In addition, the uncertainties in initial water saturation and natural fracture porosity also present difficulties inaccurate calculations (Kalam et al. 2015; Altowilib et al. 2020).

Exploitation techniques of unconventional resources

Considering such complex nature of unconventional hydrocarbon resources, they are generally be produced by following fundamental techniques:

-

(a)

Fractured vertical well

-

(b)

Horizontal well drilling with or without fractures

-

(c)

Multilateral well

-

(d)

Waterless fracturing

-

(e)

Miscible gas injection

-

(f)

Coalbed methane gas injection methods

Fractured vertical well

The fracturing of the vertical well occurs through hydraulic fracturing. Fracturing is a well stimulation operation in which the permeability of the reservoir rock is increased by creating multiple fractures into the reservoir (Ghosh et al. 2014). These fractures can have a breadth of about 5 to 35 mm and a length of more than 100 m. The purpose of fracturing is to enhance the flow capacity by increasing effective height (h) and permeability (k). The hydraulic fracturing job is done using fracturing fluid which is pumped from the surface at sufficiently high pressure to create the fractures. Firstly, the pad fluid is injected at a pressure greater than the formation breakdown pressure. Fracturing operations at the well site are carried out by heavy truck-mounted pumps and blenders, fluid tanks, and proppant tanks (Muther et al. 2020a; Economides et al. 1994).

As the fracture initiates, the fluid is continuously injected to extend the fractures further to the desired length. Afterward slurry fluid that contains proppants, is transported into the fracture. These proppants are used to keep the fracture open and provide a path for fluid to flow through fractures after the pressure is released from the surface. After the job is done, the remaining fracturing fluid in the reservoir is flushed out of the well (Muther et al. 2020b). This is used to exploit the shale, tight sand, and limestone formations successfully. A summary of the treatment schedule for a fracture treatment taken from the literature is shown in Table 5. A comparison of well productivity with and without fracture is presented in Fig. 21.

Well flow rates and cumulative production comparison (Holditch 2006)

For hydraulic fracturing optimization, the most important parameter which controls the majority of production is fracture half-length. Meanwhile, fracture permeability also plays a major share in the production (Muther et al. 2020b; Guo et al. 2007; McGuire and Sikora 1960). Hence, proper consideration should be given to these values for improving the fracturing and well performance from low permeable reservoirs. With this, the variation in fracture geometry also influences the production performance. A comparative variation in productivity under different geometry scenarios is given in Fig. 22.

Fracture Geometry Comparison (Muther et al. 2020a)

Horizontal well drilling with or without fractures

Horizontal well drilling is used to increase the contact area of the reservoir, thereby increasing the production, and enhancing the well deliverability of tight formations. Horizontal drilling has a lot of pros as it can enhance the well yield, oil and gas recovery, and minimize the well integrity problems (Memon et al. 2018). Horizontal drilling with fracturing has made enormous importance in the exploration and exploitation of unconventional resources (Gomaa et al. 2014). By carrying out fracturing with horizontal well, it has made the exploitation of competent tight and shale formations which were not possible to exploit using the vertical well fracturing. Figure 23 shows the development scheme in unconventional deposits.

Development scheme in unconventional deposits (Intermount Oil and Gas BMP Project. 2020)

The well recovery potential and the unconventional reservoir performance can be highly affected by the number of fracturing clusters in a horizontal well. With the fracture half-length and permeability controlling the majority of recovery potential in an unconventional reservoir, the fracture cluster, however, in a horizontal well can significantly improve the recovery. Meanwhile, the optimum clusters should be identified before their selection. A schematic representing fracture clusters is presented in Fig. 24. With this, the effect of several clusters in a horizontal is shown in Fig. 25 (Syed et al. 2020a).

Fracture clusters’ representation (Syed et al. 2020a)

Fracture clusters’ performance (Syed et al. 2020a)

The trend of using multi-fractured horizontal wells is increasing worldwide for the exploitation of unconventional reservoirs. In the USA, 69% of its all wells drilled for the development of hydrocarbon include multi-frac horizontal well technology and 83% of the total linear footage drilled (refer Fig. 26) (EIA 2018).

Well drilling footage (EIA 2018)

Multi-lateral well fracturing

Multi-lateral well fracturing is used to carry out the fracturing job from drilling a single well, and from that, the cluster of multi strings is used to reduce the cost of land occupation and maximize the production of wells. This is used to reduce the cost of surface pipelines and eventually maximize the recovery of unconventional shale and tight formations. The plug and perforating (PNP) and coil tubing activated completion system (CTACS) can be used in the multi-lateral well fracturing to carry out the fracturing in shale formations (Aaron Burton 2013). Increasing the number of stages and using these completion techniques can maximize the recovery factor of oil and gas production from the unconventional formation. However, increasing the number of stages increases the cost of fracturing. In the recent literature, a pilot well study suggests that it is highly possible to drill, stimulate, and successfully produce hydrocarbons through multi-lateral well completion (Wilcox et al. 2019). A schematic description of such a technology is shown in Fig. 27.

Multi-lateral well technology with hydraulic fractures in the laterals (Wilcox et al. 2019)

Waterless fracturing

Another technique that is used for the exploitation of unconventional shale and tight resources is waterless fracturing (Wang et al. 2016b), since hydraulic fracturing consumes a plethora amount of water and fracturing a well of shale formations in drought areas is difficult (Wang et al. 2016b). The major problem in the shale reservoirs is the reservoir heterogeneity and to overcome this obstacle needs an amount of 10 million gallons of water. There are various types of waterless fracturing, some of them are explosive, plasma pulsed power, gas gun, and extreme overbalance techniques (Unal et al. 2018), while other use CO2, LN2, and gaseous nitrogen (GN2) as base fracturing fluids (Wang et al. 2016b; Memon et al. 2020d; Li et al. 2019b).

The explosive technique involves the highest amount of pressure and the least amount of time to create the fractures in the formation followed by the plasma pulsed power technique and extreme overbalance (Unal et al. 2018). The explosive techniques use a negligible amount of water and use the explosive, propellant, dynamite, and stim gun to create a pressure of around 1 million psi to fracture the formations and create a channel for allowing the oil and gas to produce to the surface. The extreme overbalance technique uses the tubing conveyed perforating gun which is highly pressurized to high overbalance by using the nitrogen gas. This energy which is stored in tubing conveyed by gas is released during the perforation job, thereby creating fractures in shale and tight formations. The latest waterless fracturing technique which is widely used in the area of scarcity of water resources is pulsed plasma fracturing in which the fractures are created by using the high energy plasma pulsed. The pressure which is generated by the plasma shockwave is around 10,000–1,000,000 psi which creates the fractures in multiple directions. The fracture propagation can be monitored by electromagnetic waves which are created during this technique (Xiao et al. 2018).

In the recent literature, the application of cryogenic LN2 fracturing improves the porosity and permeability under various confining stress and treatment time of an unconventional shale sample (Memon et al. 2020d, 2021). The improvements are summarized in Table 6.

Miscible gas injection

The injection of gas to enhance hydrocarbon recovery has been widely used in many reservoirs (Syed 2012; Syed et al. 2012, 2019, 2020c). Specifically, enhancing the hydrocarbon recovery through gas injection such as CO2, N2, hydrocarbon gas in tight/shale reservoirs is getting a lot of attention nowadays owing to its high volatility, low viscosity, and easier flow in low-permeable media (Sorensen et al. 2015; Ren et al. 2016). Out of these gases, CO2 is a highly feasible option to recover hydrocarbon from unconventional reservoirs, which is proved through various laboratory measurements, field trials, and extensive numerical simulations. The main contributing factors causing the success of CO2 injection are viscosity reduction, oil swelling, wettability alteration, and molecular diffusion (Zhang et al. 2021a; Syed et al. 2011). Environmentally CO2 injection will result in a greenhouse effect through its trapping into the nano- tight pores of unconventional reservoirs (Ren et al. 2016; Al-Yaseri et al. 2022). The combination of a hydraulic fracturing network with CO2 capability results in an efficient enhanced hydrocarbon recovery from such a complex tight/shale system (Zhang et al. 2021b; Syed et al. 2022).

In addition, the applicability of single-well-based huff-n-puff CO2 is found to be a productive option in unconventional reservoirs due to its underlying complexities such as dual-porosity, ultra-tight permeability, and no/minimal inter-well geological connectivity. A schematic representing the mechanism of CO2 huff-n-puff at pore scale is presented in Fig. 28. The huff-n-puff process works in three stages: (1) injection of CO2, (2) CO2 soaking and (3) flow back. The soaking period is an important stage where the CO2 diffuses into the oil resulting in the oil swelling and reduction in its viscosity (Syed et al. 2022; Wang et al. 2021a). In addition, the performance of the huff-n-puff is dependent on the efficient CO2 diffusion and miscibility of the (Zhang et al. 2021a).

Miscible CO2 injection mechanism in a shale oil reservoir (Syed et al. 2022)

CBM gas injection methods

Coalbed methane is produced by gas injection methods. Mostly CO2 is used for the production of methane from the coal seams. The swelling effect is created by injecting carbon dioxide gas which accelerates the methane desorption and diffusion process, thereby maintaining the reservoir pressure which keeps the macro-pores opens and results in maximizing the production of methane gas. However, nitrogen gas is also used for the desorption of methane from coal seams, but it results in the early breakthrough of injected gas. The combination of N2 and CH4 enhances the production of methane. Several techniques have been used for enhancing the recovery of methane gas from these unconventional reservoirs; one of them is injecting a mixture of both these gases N2 and CH4 with less carbon-dioxide concentrations and continues by raising its proportion results the better recovery of methane gas (Sayyafzadeh et al. 2015).

Recent advances in unconventional resources development optimization

As specified earlier that multiple techniques help in the development of unconventional resources. However, the optimization of these techniques is necessary to be considered for maximizing the production from such resources. Recent advances in computational power and machine learning technologies have paved the way to optimize such resources with a minimal computational expense.

The machine learning methods such as Artificial Neural Networks (ANN), Deep Neural Networks (DNN), Long-Short-Term Memory (LSTM), Support Vector Machines (SVM), Random Forest Regression (RF), Decision Tree (DT) have been used to predict future production performance and expected ultimate recovery (EUR) of unconventional reservoirs. Such networks are also utilized to estimate gas demand, determine the impact of reservoir and fracture parameters on production, design maximum reservoir contact (MRC), and predict petrophysical and geomechanical properties in an unconventional reservoir (Syed et al. 2021a, 2020b; Muther et al. 2021a; Lee et al. 2019; Asala et al. 2017; Alabboodi and Mohaghegh 2016; Alqahtani 2015; Kamari et al. 2017; Wang et al. 2021b; Liang and Zhao 2019; Pham et al. 2021a). In addition, applications of these machine learning techniques along with different optimization algorithms have been utilized to optimize hydrocarbon recovery specifically through CO2 injection (Syed et al. 2022; Esmaili and Mohaghegh 2016). In addition, closed-loop reservoir management (CLRM) techniques have also been implemented to find the optimal production strategies and avoid wrong decisions due to the presence of uncertainties in the reservoir (Bowie 2018).

Similarly, various machine learning and optimization techniques have been presented to optimize hydraulic fracture design to recover most hydrocarbons from unconventional reservoirs. ANN and DNN have been widely used by various researchers to optimize hydraulic fracture design. Different design parameters are included in the network to study their impacts on production and optimize the overall fracture design. The parameters include well log data; production history; fracture parameters including fracture length, width, height, permeability, conductivity, matrix-fracture permeability ratio, fracture tonnage, pump rate, stage count, injection volume, etc.; well completion parameters such as perforation design; etc. (Sprunger et al. 2021; Muther et al. 2021a; Thanh et al. 2020; Barros et al. 2020; Luo et al. 2018; Gu et al. 2016; Pham et al. 2021b, c). Moreover, different techniques such as Particle Swarm Optimization (PSO), Genetic Algorithm (GA), Cohort Intelligence (CI), Teaching–Learning Based Optimization (TLBO) have also been used for fracture design optimization (Muther et al. 2021b; Mohaghegh et al. 1999; Odedele and Ibrahim 2017).

In addition, well placement and control optimization is critical in unconventional reservoirs to maximize the production capabilities from the reservoir. Many computational methods have been adapted to solve such optimization problems. Depending upon the choice of optimization function and optimization algorithm, an efficient decision on well placement and control in such reservoirs containing geological uncertainties can be made. The gradient-based recovery optimization and derivative-free methods are usually adopted for such purposes. In general, the methods such as PSO, GA, Simultaneous Perturbation Stochastic Approximation (SPSA) algorithm, Stochastic Simplex Approximate Gradient (StoSAG), and Simulated Annealing (SA) have been used for vertical, horizontal, deviated well, and intelligent well placements. For incorporating geological uncertainties in the optimization problem, Probability Density Functions (PDF), different sampling methods, and Monte-Carlo simulation techniques are usually used; however, they require high computational loads because of the high number of realization for efficient optimization problems. Different researchers reduced this computational expense by solving optimization problems through a statistical proxy, retrospection optimization (RO), and reduced sampling strategy. Also, sequential iterative approaches on short- and long-term periods and surrogate treatments (ST) have also been proposed for such optimization. In addition, clustering has been usually adopted for determining the representative set of samples for realization. Also, the Net Present Value (NPV) is usually taken as an objective function (Jesmani et al. 2020; Salehian et al. 2021a, 2021b, 2020; Chen et al. 2012; Shirangi and Durlofsky 2016; Wang et al. 2012; Sefat et al. 2016; Moraes et al. 2019; Mohsin Siraj et al. 2017; Brito and Durlofsky 2021; Lu and Reynolds 2020; Fonseca et al. 2020).

Discussion

Unconventional liquids and gases are the two main resources of unconventional hydrocarbons. The factors which make them called unconventional liquids and gases are their density, viscosity, hydrogen/carbon ratio in the oil and most importantly the geological properties of the rock (resource) itself, which includes low to very low porosity and permeability (shale, tight and coalbed methane rocks). With the increasing demand for oil and gas, these unconventional hydrocarbon resources must be extracted and produced to their full potential to bridge the gap between the world's energy demand and supply which is expected to increase between 15 and 55% in various regions of the world. Again, their exploration and production are critical in terms of sustainable energy as these resources are spread at higher volumes all over the world as compared to conventional resources. These resources, however, present a variety of challenges in exploration and production that varies from one area to another depending on the technological advancements, project economics, and availability of the subject experts.

These unconventional resources have complex geology with developed heterogeneities and uncertainties. The geological development of such resources is bifurcated into two main factors including the primary and secondary. Mineralogy, grain size and sorting, lithification, provenance, depositional environment, and flow regime come under primary factors, whereas development of fractures, tectonics, and diagenesis, including compaction, cementation, and dissolution, lies under secondary geological factors. Due to such complex processes, the pores' throats and their connections are very small developing the low porosities and ultra-low permeabilities with underlying heterogeneities including the important natural fractures and adsorption phenomena.

Due to such complex structure and processes involved, their characterization is highly intricate but important to consider since these complex features highly impact the fluid flow from such resources. Different core analysis techniques including SEM, XRD, micro-CT, etc., and logging tools such as porosity logs, density logs, gamma-ray logs, borehole images, resistivity logs, etc. are highly used to characterize such resources effectively. Since these resources vary with conventional reservoirs in many aspects; hence, the conventional correlations and analysis are modified to include various geological and petrophysical complexities of unconventional resources. Currently, digital rock physics and the power of machine learning for lithology, and petrophysical features identification have paved the way for fast and accurate analysis.

Again, due to the ubiquitous nature of unconventionals, state-of-the-art technologies including the multistaged hydraulic fracturing in the vertical well; horizontal well; and multilateral well, waterless fracturing, gas injection, and enhanced oil recovery methods are utilized to recover hydrocarbon from such reservoirs with better economics. The execution of these methods is only finalized once the reservoir geological and petrophysical properties are determined.

Due to the advancement in computational technologies, machine learning methods and optimization algorithms have been widely used to understand the nature of unconventional reservoirs and deal with challenges they pose in terms of geological and petrophysical characterization, optimization of the production strategies, developing a field plan, and optimization of the economics of the project. This advancement resulted in making unconventional reservoir decisions with less computational cost and in a short time.

In a nutshell, there is a huge potential of trapped unconventional hydrocarbons that need to be extracted with advanced technology keeping in mind the economics, technical, and technological feasibility of the projects. It can be said without any doubt that the demand for fossil fuel in coming years will be swelling due to the growing number of industries around the world which will ultimately compel the exploration and production (E&P) companies to launch more research and development (R&D) projects and invest huge money on unconventional driven projects.

Conclusion

This review paper focuses on the study of unconventional hydrocarbons including their nature, geology, and exploitation procedure. It further discusses the state-of-the-art technologies currently available to produce and characterize unconventional hydrocarbons. The very reason for focusing on unconventional methods is because of their huge existence around the world as compared to conventional ones. Considering the detailed discussion about the unconventional fluids and their resources, the following major points can be summarized:

-

It has been analyzed that there are a huge number of hydrocarbons trapped in unconventional resources with lower permeability reservoirs containing a higher amount of oil and gas.

-

The geology of unconventional reservoirs is highly ubiquitous. The tightness of the formation, the heterogeneous layers distribution, mineralogy, pore throat structure, sorption, and others are responsible for its ubiquitous nature. Such a nature restricts the hydrocarbon flow in the reservoirs.

-

The petrophysical distribution of unconventional reservoirs is completely different from conventional reservoirs. Some complex lithological responses present challenges in evaluating the exact porosities and permeabilities of the formation. Meanwhile, different conventional correlations have been updated and new correlations have been presented to accommodate various unconventional resource factors to accurately estimate water saturation, permeability, and porosity. Moreover, specialized equipment has also been designed for the above purpose.

-

Different geological and petrophysical parameters must also be identified with great certainty for the determination of unconventional hydrocarbons.

-

The development of unconventional hydrocarbons is highly dependent on the economics and availability of highly intense production techniques. The advanced techniques including horizontal and multilateral wells, different fracturing techniques, and gas injection can be used widely for the unconventionals’ exploitation. Meanwhile, the technical parameters of such techniques should be studied in depth for proper implementation and improvement in hydrocarbon production.

-

The developments in computational techniques such as machine learning and optimization methods have allowed the exploration, characterization, and development of unconventional reservoirs with less computational effort.

References

Aadnøy BS, Looyeh R (2019) Chapter 16—Shale oil, shale gas, and hydraulic fracturing. Petroleum rock mechanics (Second Edition). Gulf Professional Publishing, Houston, pp 357–389

Aaron Burton W (2013) Unconventional completions—An operational comparison. Soc Petrol Eng. https://doi.org/10.2118/167030-MS

Abbasi GR, Al-Yaseri A, Isah A, Keshavarz A, Iglauer S (2021) Influence of rock wettability on THF hydrate saturation and distribution in sandstones. J Phys Chem C 125(31):17323–17332

Abbasi AH, Mehmood F, Kamal M (2014) Shale oil and gas: lifeline for Pakistan. Sustainable Development Policy Institute

Khlaifat AL, Qutob H, Barakat N (2011) Tight gas sands development is critical to future world energy resources. Soc Petrol Eng. https://doi.org/10.2118/142049-MS,2011

Alabboodi MJ, Mohaghegh SD (2016) Conditioning the Estimating Ultimate Recovery of Shale Wells to Reservoir and Completion Parameters. In SPE Eastern Regional Meeting. OnePetro

Alam S (2010) Potential of Tight Gas in Pakistan: Productive, Economic and Policy Aspects. In Pakistan Association of Petroleum Geoscientists (PAPG), annual technical conference, Islamabad. Search and Discovery Article #80149

Alqahtani M (2015) Shale gas reservoirs development strategies via advanced well architectures. The Pennsylvania State University

Alqahtani N, Alzubaidi F, Armstrong RT, Swietojanski P, Mostaghimi P (2020) Machine learning for predicting properties of porous media from 2d X-ray images. J Petrol Sci Eng 184:106514

Altowilib A, AlSaihati A, Alhamood H, Alafnan S, Alarifi S (2020) Reserves estimation for coalbed methane reservoirs: a review. Sustainability 12(24):10621

Al-Yaseri A, Abbasi GR, Yekeen N, Al-Shajalee F, Giwelli A, Xie Q (2022) Effects of cleaning process using toluene and acetone on water-wet-quartz/CO2 and oil-wet-quartz/CO2 wettability. J Petrol Sci Eng 208:109555

Archie GE (1942) The electrical resistivity log as an aid in determining some reservoir characteristics. Trans AIME 146(01):54–62

Armstrong RT et al (2018) Porous media characterization using Minkowski functionals: theories, applications and future directions. Transp Porous Media 130(1):305–335

Asala HI, Chebeir J, Zhu W, Gupta I, Taleghani AD, Romagnoli J (2017) A machine learning approach to optimize shale gas supply chain networks. In SPE annual technical conference and exhibition. OnePetro

Asquith GB, Krygowski D, Gibson CR (2004) Basic well log analysis. American Association of Petroleum Geologists, Tulsa, OK

Ayaz SA, Haider BA, Ismail K, Smith PM (2012) Unconventional hydrocarbon resource plays in Pakistan: an overview Awakening a South East Asian Sleeping Giant-Technological Solutions to Unlock the Vast Unconventional Reserves of Pakistan. Search and Discovery Article, 80216

Barros EGD, Van den Hof PMJ, Jansen JD (2020) Informed production optimization in hydrocarbon reservoirs. Optim Eng 21(1):25–48

Bhutta Z (2015) Pakistan has 10,159 Tcf of shale gas deposits: USAID. The Express Tribune. https://tribune.com.pk/story/994883/hydrocarbon-presence-pakistan-has-10159-tcf-of-shale-gas-deposits-usaid/

Blunt MJ et al (2013) Pore-scale imaging and modelling. Adv Water Resour 51:197–216

Bowie B (2018) Machine learning applied to optimize Duvernay well performance. In SPE Canada unconventional resources conference. OnePetro

Caineng Z, Shizhen T, Lianhua H et al (2013) Unconventional hydrocarbon geology, 2nd edn. Geological Publishing House, Beijing

Caineng Z, Zhi Y, Zhang G, Lianhua H, Rukai Z, Shizhen T, Xuanjun Y, Yuman WANG, Qiulin GUO, Lan WANG, Haibin BI (2014) Conventional and unconventional petroleum “orderly accumulation”: concept and practical significance. Pet Explor Dev 41(1):14–30

Cander H (2012) What are unconventional resources? AAPG Annual Convention and Exhibition, Long Beach, California

Carlson FM (2006) Technical and economic evaluation of undersaturated coalbed methane reservoirs. In SPE Europec/EAGE annual conference and exhibition. Society of Petroleum Engineers

Chen C, Li G, Reynolds AC (2012) Robust constrained optimization of short-and long-term net present value for closed-loop reservoir management. SPE J 17(03):849–864

Chen F, Lu S, Ding X, He X, Xing H (2018) The splicing of backscattered scanning electron microscopy method used on evaluation of microscopic pore characteristics in shale sample and compared with results from other methods. J Petrol Sci Eng 160:207–218

Chen F, Lu S, Ding X, Zhao H, Ju Y (2019a) Total porosity measured for shale gas reservoir samples: a case from the lower Silurian Longmaxi Formation in southeast Chongqing. China Miner 9(1):5

Chen F, Zhao H, Lu S, Ding X, Ju Y (2019b) The effects of composition, laminar structure and burial depth on connected pore characteristics in a shale oil reservoir, the Raoyang Sag of the Bohai Bay Basin, China. Mar Pet Geol 101:290–302

Chung T, Wang Y, Armstrong R, Mostaghimi P (2019) Approximating permeability of microcomputed-tomography images using elliptic flow equations. SPE J. 24(3):1154–1163

Clarkson CR, Solano N, Bustin RM, Bustin AMM, Chalmers GR, He L, Melnichenko YB, Radliński AP, Blach TP (2013) Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 103:606–616

Clarkson CR, Pan Z, Palmer ID, Harpalani S (2010) Predicting sorption-induced strain and permeability increase with depletion for coalbed-methane reservoirs. Soc Petrol Eng. https://doi.org/10.2118/114778-PA

Coates G, Dumanoir JL (1973) A new approach to improve log-derived permeability: Society of Professional Well Log Analysts, 14th annual logging symposium, transactions, paper R

Costin S, Smith R, Yuan Y, Andjelkovic D, Garcia Rosas G (2019) In-Situ Stresses in Colorado Group, AB, Calculated from Open-Hole Mini-Fracs and FMI Logs. In SPE Annual Technical Conference and Exhibition. OnePetro

de Brito DU, Durlofsky LJ (2021) Field development optimization using a sequence of surrogate treatments. Comput Geosci 25(1):35–65

de Moraes RJ, Fonseca RM, Helici MA, Heemink AW, Jansen JD (2019) An efficient robust optimization workflow using multiscale simulation and stochastic gradients. J Petrol Sci Eng 172:247–258

Dong Z, Holditch SA, McVay DA, Ayers WB (2011) Global unconventional gas resource assessment. Soc Petrol Eng. https://doi.org/10.2118/148365-MS

Economides MJ, Hill AD, Ehlig-Economides C (1994) Petroleum production systems. PTR Prentice Hall, Englewood Cliffs, NJ

Energy Information Administration (EIA). World Shale Resource Assessments. 2017. Available online: https://www.eia.gov/outlooks/aeo/assumptions/pdf/oilgas.pdf

Energy Information Administration (EIA). Hydraulically fractured horizontal wells account for most new oil and natural gas wells. Available online: https://www.eia.gov/todayinenergy/detail.php?id=34732

Esmaili S, Mohaghegh SD (2016) Full field reservoir modeling of shale assets using advanced data-driven analytics. Geosci Front 7(1):11–20

ExxonMobil, (2018) 2018 Outlook for Energy: A View to 2040

ExxonMobil, (2019) 2019 Outlook for Energy: A Perspective to 2040

Fonseca RM, Della Rossa E, Emerick AA, Hanea RG, Jansen JD (2020) Introduction to the special issue: Overview of OLYMPUS Optimization Benchmark Challenge

Gao Y, Raeini AQ, Blunt MJ, Bijeljic B (2019) Pore occupancy, relative permeability and flow intermittency measurements using X-ray micro-tomography in a complex carbonate. Adv Water Resour 129:56–69

Geology of Shale and Tight Resources (2016) https://www.nrcan.gc.ca/our-natural-resources/energy-sources-distribution/clean-fossil-fuels/natural-gas/shale-tight-resources-canada/geology-shale-and-tight-resources/17675

Geoscience Australia and BREE (2012) Australian Gas Resource Assessment 2012, Canberra

Ghosh S, Rai CS, Sondergeld CH et al. (2014) Experimental Investigation of Proppant Diagenesis. Presented at the SPE/CSUR unconventional resources conference–Canada, Calgary, 30 September–2 October. SPE-171604-MS. https://doi.org/10.2118/171604-MS

Gomaa AM, Qu Q, Maharidge R, Nelson S, Reed T (2014) “New Insights into Hydraulic Fracturing of Shale Formations. International petroleum technology conference”, https://doi.org/10.2523/IPTC-17594-MS

Gordon D (2012) Understanding Unconventional Oil. Energy and Climate. Carnegie Endowment for International Peace. https://carnegieendowment.org/2012/05/03/understanding-unconventional-oil-pub-48007

Gu M, Gokaraju D, Chen D, Quirein J (2016) Shale fracturing characterization and optimization by using anisotropic acoustic interpretation, 3D fracture modeling, and supervised machine learning. Petrophys- SPWLA J Format Eval Reserv Descr 57(06):573–587

Guo B, Lyons WC, Ghalambor A (2007) Hydraulic fracturing. In: Guo B, Lyons WC, Ghalambor A (eds) Petroleum production engineering, A computer assisted approach, Chap. 17. Gulf Professional Publishing, Houston, pp 251–265

Guoxin L, Rukai Z (2020) Progress, challenges and key issues in the unconventional oil and gas development of CNPC[J]. China Petrol Explor 25(2):1–13

Hamada GM (2016) Comprehensive Evaluation and Development of Unconventional Hydrocarbon Reserves as Energy Resource. Petro and Envi Biotech, APEB-102. https://doi.org/10.29011/2574-7614.100102

Hashimoto T, Stacey A, Bernecker T (2012) Assessing the Unconventional Hydrocarbon Resource Potential of Eastern Australian Basins

Hawthorne SB, Sorensen JA, Miller DJ, Gorecki CD, Harju JA, Pospisil G (2019) Laboratory studies of rich gas interactions with Bakken crude oil to support enhanced oil recovery. In unconventional resources technology conference, Denver, Colorado, 22–24 July 2019 (pp 3480–3487). Unconventional resources technology conference (URTeC); Society of Exploration Geophysicists

Hazra B, Dutta S, Kumar S (2017) TOC calculation of organic matter rich sediments using Rock-Eval pyrolysis: critical consideration and insights. Int J Coal Geol 169:106–115

Heikal S (2008) Scope of Tight Gas Reservoir in Pakistan. Pakistan Petroleum Exploration & Production Companies Association (PPEPCA), Islamabad, Pakistan

Heikal S (2008) Scope of Tight Gas Reservoir in Pakistan. Pakistan Petroleum Exploration & Production Companies Association (PPEPCA), Islamabad, Pakistan. 3–4 November 2008. http://www.ppepca.com/pdfs/presentations/Scope_of_Tight_Gas_Reservoir.pdf

Holditch SA (2006) Tight gas sands. JPT 58:84–86

Holditch SA, Perry K, Lee J (2007) Unconventional Gas Reservoirs–Tight Gas, Coal Seams, and Shales. Working Document of the National Petroleum Council on Global Oil and Gas Study, 52

IEA (2009) World energy outlook 2009. IEA, Washington D C

Inam S, Shaukat CB, Haider SA, Latif MK, Ali A, Abbas A (2018) Development of indigenous resources to optimize hydraulic fracturing job cost to exploit shale and tight reservoirs. Soc Petrol Eng. https://doi.org/10.2118/195658-MS41

Intermount Oil and Gas BMP Project. Hydraulic Fracturing. Available online: http://www.oilandgasbmps.org/resources/fracing.php. Assessed on 19–12–2020

Jadoon MSK (2011) Development of Unconventional Reservoirs in Pakistan. Presentation at Serena Hotel, Islamabad. Viewed 23 May 2020. https://www.slideserve.com/jana/development-of-unconventional-reservoirs-in-pakistan-by-dr-m-saeed-khan-jadoon-ogdcl-islamabad-april-11-2011-ser

Jesmani M, Jafarpour B, Bellout MC, Foss B (2020) A reduced random sampling strategy for fast robust well placement optimization. J Petrol Sci Eng 184:106414

Jijun L, Weiming W, Qun C, Yinglin S, Xintong Y, Shansi T (2015) Impact of hydrocarbon expulsion efficiency of continental shale upon shale oil accumulations in eastern China. Mar Pet Geol 59:467–479

Jin XJ, Pavia M, Samuel M, Shah S, Zhang R, Thompson J (2019) Field Pilots of Unconventional Shale EOR in the Permian Basin. In unconventional resources technology conference, Denver, Colorado, 22–24 July 2019 (pp 3540–3560). Unconventional resources technology conference (URTeC); Society of Exploration Geophysicists

Kalam S, Khan RA, Baig MT, Al-Hashim HS (2015) A review of recent developments and challenges in igip estimation of coal bed methane reservoirs. In SPE Saudi Arabia section annual technical symposium and exhibition. OnePetro

Kamari A, Mohammadi AH, Lee M, Bahadori A (2017) Decline curve based models for predicting natural gas well performance. Petroleum 3(2):242–248

Kapustin NO, Grushevenko DA (2018) Global prospects of unconventional oil in the turbulent market: a long term outlook to 2040. Oil Gas Sci Technol-Revue d’IFP Energ Nouvelles 73:67

Karimpouli S, Tahmasebi P (2019) Image-based velocity estimation of rock using convolutional neural networks. Neural Netw 111:89–97

Kazak A, Simonov K, Kulikov V (2020) Machine-Learning-Assisted Segmentation of FIB-SEM Images with Artifacts for Improved of Pore Space Characterization of Tight Reservoir Rocks. In unconventional resources technology conference, 20–22 July 2020 (pp 3169–3188). Unconventional Resources Technology Conference (URTEC)

Kerr E, Venepalli KK, Patel K, Ambrose R, Erdle J (2020) Use of reservoir simulation to forecast field EOR response—An eagle ford gas injection Huff-N-Puff application. Soc Petrol Eng. https://doi.org/10.2118/199722-MS

Kiani K (2015) Shale gas, oil reserves outweigh conventional stock, study reveals. Dawn. https://www.dawn.com/news/1220955

Klaver J, Desbois G, Littke R, Urai JL (2015) BIB-SEM characterization of pore space morphology and distribution in postmature to overmature samples from Haynesville and Bossier shales. Mar Pet Geol 59:451–466

Kumar T, Shandilya A (2013) Tight Reservoirs: An overview in Indian context. In 10th Biennial international conference and exposition

Kuuskraa V, Stevens S, Van Leeuwen T, Moodhe K (2011) World Shale Gas Resources: An Intital Assessment of 14 Regions Outside the United States. Prepared for: United States Energy Information Administration

Kuuskraa AV, Stevens SH, Moodhe KD (2013) World shale gas and shale oil resource assessment. Prepared for: United States Energy Information Administration

Lee SY, Holder GD (2001) Methane hydrates potential as a future energy source. Fuel Process Technol 71(1–3):181–186