Abstract

Seawater desalination is a way ahead to produce tap water in the Iranian coastline of the Oman sea with arid climate. The Chabahar Maritime University (CMU) desalination plant which its prototype was launched in 1994, currently using the reverse osmosis (RO) membranes is producing fresh water with a capacity of 336 m3/day and TDS of 400. Here, it is attempting to draw the plant overall scheme and to produce the technical documents of its constituent parts. An experimental study was conducted to estimate the current working conditions of this RO desalination site, and a simple formulation method using by Microsoft Excel 2010 is developed to model and optimize the cost and processing parameters such as active surface area of the membrane in the RO desalination plant. The mode of site’s economic estimation provides a way to find the optimal working conditions including feed flow rate, recovery ratio and so on. The results indicate that with some small adjustments in the process, the cost of water can be dramatically reduced. For example, with an increase in the flow rate of the intake feed water from 840 to 5784 m3/day, cost of product water reduces from 2.2 $/m3 to 1.4 $/m3.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The current lifestyles require large quantities of fresh water to use in industrial activities, agricultural and domestic purposes. Now, the scarcity of fresh water resources has emerged as a global crisis and for overcoming it, desalination of seawater is a good solution and suitable choice (El-Emam and Dincer 2014). The main reasons of water scarcity are the global climate changes, earth warming, reducing rainfall and increasing consumption of freshwater (Mehdizadeh 2006).

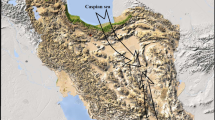

In some parts of the world, especially the Middle East countries and Iran, the problem of water scarcity has become more complicated due to lack of access to freshwater supplies (Marcovecchio et al. 2005; Farhoudi and Poll 1992). The central and southeast regions of Iran have a little rainfall and are considered as dry and semiarid climates (Daneshmand and Mahmoudi 2017). The rainfall rate in Sistan and Baluchistan of Iran is affected with the westerly winds and their consequent high and low waves. Monsoon system of summers is another effective system on the amount of rainfall of southern stations in the province, especially in mountainous areas of Makran (Rezaee et al. 2014).

In this area of Iran, problem of fresh water shortage could be solved by producing water from seawater using desalination methods. In the recent years, the desalination industry, especially seawater desalination, is expanding rapidly all over the world. The reliability and performance of freshwater production methods such as reverse osmosis (RO), multistage flash (MSF), multi-effect distillation (MED), and electro dialysis (ED) processes have led to a growing commercial use of them (Van der Bruggen and Vandecasteele 2002). It should be noted that in each of these methods, pretreatment and posttreatments are necessary to improve the quality of intake & product water, respectively (Brandt et al. 2017; Zahedi and Ghasemi 2017; Pourmortazavi et al. 2017). On the other hand, reducing the cost and utilizing a more environmentally friendly process have become the subject of many current researches (Sachit and Veenstra 2014).

In the reverse osmosis (RO) desalination system, ions and other chemicals remove from feed water using a semipermeable membrane (Wenten 2016). Today, RO has become a leading technology for seawater desalination, and its rapid growth is directly related to the development of membrane technology and its remarkable potential (Atab et al. 2016). Now, hundreds of RO seawater desalination plants have been made all over the world, due to its lower production cost and significant improvements in the membrane quality.

Controlling and optimizing the working process of the RO seawater desalination plant, play an important role in reducing overall costs and improve the quality of the producing water. The success of design, construction and operation of an RO system, needs its detailed analysis at the feasibility stage and evaluates the efficiency of the effective parameters in the operation period. In this regard, several modeling approaches are developed for optimizing of the RO design by membrane providers and manufacturers (Malek et al. 1996) which are used to evaluate the effects of various parameters on the cost of final freshwater. The results included the proper and optimized design conditions of a RO seawater desalination plants (Voutchkov 2018). In general, the attempt for numerical analysis and modeling of the desalination system process is a valuable and inexpensive way to evaluate which can improve and optimize the plant system (Lee et al. 2011; Wilf and Schierach 2001).

In this study, we select the Chabahar Maritime University desalination plant as a low capacity SWRO desalination plant for comprehensive process and economic analysis. The system is evaluated using model against monitored amounts, and RO plant efficiency is studied considering the effective working parameters such as feed water salinity and temperature, applied pressure, recovery ratio and so on. Finally, by offering some technical suggestion it has been tried to optimize the RO desalination system economically with quality. These types of investigation lead to better understanding of the advantages and disadvantages of the system and its components.

System description and case study

Currently, the Chabahar Maritime University (CMU) reverse osmosis (RO) desalination plant (south of Sistan and Baluchistan state of Iran) is working to provide 336 m3/day of fresh water with average TDS of 400 ppm. Seawater sources with an average TDS of 31,400 mg/L are used as intake water of this plant. Overall schematic diagram of the system is shown in Fig. 1. At first, the saline water is pumped from two wells by the low-pressure pump (LPP). Applied pressure ratio to intake water line is 6 bar. Then, the feed water is directed to the relaxation pools, sand tanks and then cartridge filter as pretreatment process to get rid of any suspended particles. Next, in a mixer and during the initially treated saline water passing, certain chemicals are added to it that are required to prevent any damage to the RO elements. Like any conventional RO plant, the feed water pressure is raised to the RO operating pressure upper than osmotic pressure and then injected to two trains of RO membrane. The high-pressure pump (HPP) has adjusted the pressure to 45 bar, and the brine water is rejected from the pressure vessels at 43 bar. The permeate water leaves the modules to achieve the required TDS of the final product water. In this RO plant, there are not any pressure recovery system and feed bypass water. Here, in this RO system a DOW filmtec SW30HRLE 400 spiral wound membrane modules are used for SWRO desalination propose. Membrane specifications such as active area (37 m2), maximum operating pressure (83 bar), permeate flow rate (28 m3/day), minimum salt rejection (99.65%) are reported by Dow company. The 120 membranes of this type of membrane in two trains of five pressure vessels, work for the water desalination. In order to evaluate the output water quality, especially in terms of TDS, the product water by the RO plant was investigated during a period of 1 month for 78 sampling time and under normal operational conditions. The results of this study are illustrated in Fig. 2. It should be noted that the two parameters of chlorine and sodium ion are also evaluated during the same period, and the results of this test confirm the amount of TDS. Some of the average chemical parameters of feed, concentrate and product waters of RO system are shown in Table 1.

Model-based analysis and optimization

The present work is based on the theory and equations presented for estimating RO plant operation variables, including permeate flux (JW), solvent permeability coefficient (AW), osmotic pressure (Δπ), delta pressure (ΔP), etc., and as well as the equations required to estimate the total cost of final water production such as cost of the intake and pretreatment, annual cost of the energy of the intake pump, cost of chemical treatment in the pretreatment, capital cost of the RO membrane and so on. The related theories can be found extensively in the article of El-Emam and Dincer (2014) and Sachit and Veenstra (2014), etc. As is the case with equations (Table 2), operational variables such as feed flow rate (Qf), recovery ratio (rr), salinity of waters, pressure of high-pressure pump (P) and so on. are the effective parameters in determining the cost of product water. As we know (Barello et al. 2015; Ismail and Khulbe 2019), in the process of checking the optimal performance of a system, the cost price is a significant factor (Table 2). The cost is directly and indirectly related to the variables that are effective in setting the water production process, such as the flow rate and salinity of the feed water, the recovery ratio, the pump pressure, temperature and so on. In this research, it was initially tried to estimate the current cost of the water with formalization in the Microsoft Excel 2010 and to know about the current working conditions governing on the university’s seawater desalination plant. In the next step, by investigating the effective working variables in front of the cost and membrane active area, they tried to find the optimal working conditions of the plant. In this regard, the Solver tool in Excel can help us by selecting appropriate boundary range of input data. On the other hand, the membrane active area that reported by the manufacturer company (Dow) can help us to achieve these optimal conditions.

Results and discussion

The first and the most important parameter (Ismail and Khulbe 2019; Eshoul et al. 2017), whose variation has been studied on measuring the cost and effective area of the membrane, is the flow rate of seawater feed (Qf). At present, the feed water of RO plant is supplied through two deep wells drilled in the university with a distance of 400 meters from the beach. The total flow rate of water reached the relaxing pools is 35 m3/min, and the total solid solvent content is 31,400 mg/L. Water salinity suggests that the main source of this feed is the leakage seawater of the sea and the use of the well reduces the total suspended solids content. The results of the modeling feed water flow rate variations on the amount of water cost and the active area of the membrane are shown in Fig. 3 when all other variables make constant. The calculation of the membrane active area is based on Eq. (7) in which the relevant variables are defined in the nomenclature section and this parameter has a good fit with the amount of Jw. As it is seen, feed flow rates have an important impact on the cost of producing potable water and as the feed flow rate increases, the membrane’s active area increases and the total cost of water production decreases. If we target the reported active area (37 m2), the optimum flow rate should be 5758 m3/day which leads to 70 % reduction per cubic meter of product water and this parameter has a significant effect on overall cost and optimum working condition such as active area of membrane.

Determining the recovery ratio correctively is another important factor affecting the quality and operations of the reverse osmosis membrane, and on the RO desalination process. This factor plays an important role in the equations used to calculate process variables and also cost of product water. The choice of the low recovery ratio results in a prolonged membrane lifetime, reducing the effects of fouling and TDS of product water. Apparently, if you set it at high ratios, we will have an increase in production. But working with an optimal amount of the recovery ratio is essential, which currently in the university RO plant is 0.4. The recovery ratio variable influences the concentration values of the formulas given in Table 2 and eventually changes the values of the active surface area of the membrane and the final cost of water production. According to the model described in the previous section, by evaluating the effect of the recovery ratio (in range of 0.2–0.55) on the cost and active surface area of the membrane in the conditions governing the unit, the results of Fig. 4 are obtained. As you can see, by increasing the recovery ratio, the active cross section of the membrane increases sharply and the cost of water production drops significantly and changing the recovery ratio has a huge impact on the cost and, at the same time, the active area of the membrane. These results suggest the use of a value of 0.55, which also causes a more theoretical involvement of the membrane area to about 36 m2. Also, the results show significant reduction in the cost of water from $ 4 in the ratio of 0.2–1.8 dollars to the ratio of 0.55. It should be noted that in higher recovery ratios, we need to focus on the effective pretreatment of feed water ahead of fouling subsequent effects.

In the current operating conditions of the desalinating plant, the change of the applied pressure in the range of 38–60 bar has been investigated versus the cost and active surface of the membrane. The results of this study are presented in Fig. 5. It should be noted that the maximum pressure which could be applied by the high-pressure pump in the RO site is 60 bar. As can be seen, this parameter has an adverse effect on the cost and active surface of the membrane, and variation in the active surface area of the membrane is much more than cost variation. It seems that a large decrease in the active area of the membrane is due to the change in the value of variable Bs. This is the opposite of practical and theoretical prediction, which implies an increase in the permeate flux (Jw) with increasing P or ΔP.

The next parameter that is used to model and optimize the desalination process is the temperature. The selected temperature range is the maximum and the minimum reported temperature for the Chabahar and are provided from the Iranian Meteorological Organization. The results of the study of temperature changes versus water cost and active area of the membrane are presented in Fig. 6. As you can see, temperature changes affect the cost and active area of membrane, but its effect is less important than other parameters such as feed flow rate and recovery ratio. According to this figure, both the cost and active surface of the membrane increase with increasing the temperature. But because these two parameters also behave in the opposite direction, finding the optimal value should be done according to the site’s priority. It seems that the effect of temperature on cost and active area of membrane is based on its effect on the reduction in solute rejection.

The next parameter to be considered is the amount of salinity of the feed water. The results of the modeling in the working conditions of the site and the recovery ratio 0.4 are shown Fig. 7. The results indicate the high effect of salinity on active area and apparently its low impact on water costs. It should be noted that in adjusting the working conditions of the feed in terms of salinity, not only salinity but also the amount of recovery ratio has a significant effect, and by reducing the salinity of the feed water its cost decreases with increasing the recovery ratio. Apparently, the output of the model indicates the high effect of salinity on the active surface of the membrane. It seems that the low variation in the cost of water produced is due to the low cost of unit power cost, in Iran, which has led to abnormal behavior in this section.

As we have seen, the process used in the site’s economic estimation provides a way to find the optimal conditions of desalination work, including optimal feed flow rate, recovery ratio, and so on. Some of the current work parameters, as well as the optimal conditions reported, and the result of modeling process for optimal condition can be found in Table 3. The results indicate that with a few small adjustments in the process, the cost of water can be dramatically reduced. For example, with an increase in the flow rate of inputs feed water from 840 to 5784 m3/day, cost of product water reduces from 2.2 $/m3 to 1.4 $/m3.

Conclusions

In this paper, an experimental and numerical study was conducted to estimate and optimize the working conditions of the RO desalination site of the Chabahar Marine University. The plant is set for water production with TDS of 400, but there is a fluctuation in the quality of water produced. Although this fluctuation is not beyond the Iranian national standard for drinking water, it shows the change in the function of the equipment, the quality of the feed and the operators. Here, a simple formulation in Excel is used to model and optimize the cost and process of a small reverse osmosis plant. The modeling results suggest a low input water feed flow rate, which should be eliminated by new well drilling. At present, the cost of water ($/m3) is $ 2.2, although it is acceptable compared to existing reports, but according to numerical calculations it can be reduced to less than $1.4. According to the results presented in the previous section (membrane active area of 9.36 m2), it can be said that the current operating conditions are not such that the entire membrane active area (37 m2) is involved in the desalinating process.

Abbreviations

- A:

-

Area (m2)

- Aw :

-

Permeability coefficient (m/s-Pa)

- Bs :

-

Solute transport parameter (m/s)

- C:

-

Average salinity through the membrane element (mol/m3)

- Cch :

-

Cost of chemical treatment ($/m3)

- CDm :

-

Membrane cost ($)

- Ce :

-

Unit power cost ($/kWh)

- Cf :

-

Concentration of feed water (mol/m3)

- Cm :

-

Solute concentration in the membrane (mol/m3)

- CRO :

-

Mass fraction of salt in permeate (%)

- Cp :

-

Solute concentration at permeate (mol/m3)

- Cr :

-

Concentration in the concentrate (mol/m3)

- Cw :

-

Water concentration in the membrane (mol/m3)

- f1 :

-

Plant load factor (%)

- ieff :

-

Effective discount rate relation between the future value and present value

- Js :

-

Solute transport (m/s)

- JW:

-

Permeate flux (m/s)

- N:

-

Number of membrane elements

- PCm :

-

Cost per membrane ($)

- Pf :

-

Feed water pressure (Pa)

- PIP :

-

Pressure after the intake pump (bar)

- Pm :

-

Annual membrane replacement factor (%)

- Pp :

-

Permeate pressure (Pa)

- ΔP:

-

Transmembrane pressure difference (Pa)

- Qf :

-

Feed flow rate (v)

- \(\dot{Q}_{f}\) :

-

Daily feed flow rate after extracting the bypass ratio (m3/day)

- Qp :

-

Permeate flow rate (m3/day)

- \(\dot{Q}_{P.a}\) :

-

Annual volume flow rate of product water (m3)

- Qp, el :

-

Permeate flow rate per membrane element (m3/s)

- \(\dot{Q}_{P}\) :

-

Mass flow rate of permeate in one element (kg/s)

- Qr :

-

Rejected flow rate (m3/day)

- R:

-

Gas constant (J/mol-k)

- rn :

-

Nominal escalation rate which effects of resource depletion, increased demand and inflation (%)

- rr :

-

Recovery ratio

- Rs :

-

Salt rejection (%)

- T:

-

Temperature (K)

- TCF:

-

Temperature correction factor at T (%)

- Vw :

-

Water molar volume (m3)

- η:

-

Efficiency (%)

- Δπ:

-

Osmotic pressure difference (Pa)

- E:

-

Energy

- f:

-

Feed water

- IP:

-

Intake pump

- m:

-

Membrane

References

Atab MS, Smallbone AJ, Roskilly AP (2016) An operational and economic study of a reverse osmosis desalination system for potable water and land irrigation. Desalination 397:174–184. https://doi.org/10.1016/j.desal.2016.06.020

Barello M, Manca D, Patel R, Mujtaba IM (2015) Operation and modeling of RO desalination process in batch mode. Comput Chem Eng 83:139–156. https://doi.org/10.1016/j.compchemeng.2015.05.022

Brandt MJ, Johnson KM, Elphinston AJ, Ratnayaka DD (2017) Specialized and advanced water treatment processes. https://doi.org/10.1016/b978-0-08-100025-0.00010-7

Daneshmand Hojatollah, Mahmoudi Peyman (2017) Estimation and assessment of temporal stability of periodicities of droughts in Iran. Water Resour Manage 31:3413–3426. https://doi.org/10.1007/s11269-017-1676-8

El-Emam RS, Dincer I (2014) Thermodynamic and thermoeconomic analyses of seawater reverse osmosis desalination plant with energy recovery. Energy 64:154–163. https://doi.org/10.1016/j.energy.2013.11.037

Eshoul Nuri M, Agnew Brian, Anderson Alexander, Atab Mohanad S (2017) Exergetic and economic analysis of two-pass RO desalination proposed plant for domestic water and irrigation. Energy 122:319–328. https://doi.org/10.1016/j.energy.2017.01.095

Farhoudi Godratollah, Poll Kurt (1992) A morphotectonic study of environmental impact on ground water in Southern Iran and under the Persian Gulf. Geol Rundsch 81:581–587

Ismail AF, Khulbe KC (2019) Takeshi matsuura. RO Econ. https://doi.org/10.1016/b978-0-12-811468-1.00007-4

Lee KP, Arnot TC, Mattia D (2011) A review of reverse osmosis membrane materials for desalination—development to date and future potential. J Membr Sci 370:1–22. https://doi.org/10.1016/j.memsci.2010.12.036

Malek A, Hawlader MNA, Ho JC (1996) Design and economics of RO seawater desalination. Desalination 105:245–261. https://doi.org/10.1016/j.desal.2016.06.020

Marcovecchio Marian G, Aguirre Pío A, Scenna Nicolaś J (2005) Global optimal design of reverse osmosis networks for seawater desalination: modeling and algorithm. Desalination 184:259–271. https://doi.org/10.1016/j.desal.2005.03.056

Mehdizadeh H (2006) Membrane desalination plants from an energy–exergy viewpoint. Desalination 191:200–209. https://doi.org/10.1016/j.desal.2005.06.037

Pourmortazavi SM, Taghdiri M, Ahmadi R, Zahedi MM (2017) Procedure optimization for removal of 2,4-dichlorophenoxyacetic acid from water by surfactant-modified magnetic nanoparticles. Desalination Water Treat 70:261–268. https://doi.org/10.5004/dwt.2017.20472

Rezaee Mohsen, Khaksefidi Samaneh, Bostani Mohsen, Ghasemi Mohamad (2014) Flood management via zoning extreme rainfalls in sistan and baluchistan. Bulletin of Environment, Pharmacology and Life Sciences 3:210–214

Sachit DE, Veenstra JN (2014) Analysis of reverse osmosis membrane performance during desalination of simulated brackish surface waters. J Membr Sci 453:136–154. https://doi.org/10.1016/j.memsci.2013.10.051

Van der Bruggen B, Vandecasteele C (2002) Distillation versus membrane filtration: overview of process evolutions in seawater desalination. Desalination 143:207–218. https://doi.org/10.1016/s0011-9164(02)00259-x

Voutchkov Nikolay (2018) Energy use for membrane seawater desalination – current status and trends. Desalination 431:2–14. https://doi.org/10.1016/j.desal.2017.10.033

Wenten IG (2016) Reverse osmosis applications: prospect and challenges. Desalination 391:112–1251. https://doi.org/10.1016/j.desal.2015.12.011

Wilf Mark, Schierach Manfred K (2001) Improved performance and cost reduction of RO seawater systems using UF pretreatment. Desalination 135:61–68. https://doi.org/10.1016/S0011-9164(01)00139-4

Zahedi MM, Ghasemi SM (2017) Separation study of Mg+2 from seawater and RO brine through a facilitated bulk liquid membrane transport using 18-Crown-6. J Water Reuse Desalination 7:468–475. https://doi.org/10.2166/wrd.2016.103

Acknowledgements

The authors are grateful to Mr. Abed Lalbakhsh for his kind help. The research described in the present paper was financially supported by Chabahar Maritime University (CMU), and the authors declare that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Emamjome, A., Zahedi, M.M. & Ziyaadini, M. Economic analysis for process optimization of Chabahar Maritime University reverse osmosis desalination plant: a case study. Appl Water Sci 9, 114 (2019). https://doi.org/10.1007/s13201-019-0995-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-019-0995-8