Abstract

In this work, we attempt a new approach for the study on photocatalytic ability of (ZnO/CeO2 ) improved by β-CD under UV light irradiation for the photodecolorization of RhB. The (ZnO/CeO2 ) composite was prepared by mixing ZnO with CeO2 in a weight ratio of 4:1. The surface interaction of (ZnO/CeO2 ) with β-CD was determined by characterizing their structural, morphological and optical properties. The formation of an inclusion complex between RhB dye and β-CD was confirmed by UV–visible spectral analyses. The photocatalytic activity of (ZnO/CeO2 )-β-CD system was evaluated by the decolorization of RhB dye in aqueous solution under UV light irradiation. The effects of operational parameters like the ratio of (ZnO/CeO2), initial concentration of dye, catalyst dose, irradiation time and pH have been analyzed. The photocatalytic decolorization of RhB follows pseudo-first order kinetics. The mineralization of RhB has been confirmed by COD measurements. A possible mechanism for the photocatalytic decolorization of RhB by (ZnO/CeO2 )-β-CD system under UV light irradiation was also discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Dyes, which belong to the class of synthetic organic compounds, are extensively used in textile, paper, plastics, leather, food, cosmetics, printing and pharmaceutical industries. Synthetic organic dyes are considered as one of the major environmental pollutants for water pollution because of their large-scale production, chemical stability, high aromaticity, low biodegradability, toxic and carcinogenic in nature (Liu et al. 2015; Zhang et al. 2015). During the dyeing processes, a significant amount of dyes is lost and discharged into the water sources (Kumar et al. 2013; Saraf et al. 2015; Liu et al. 2015). At very low concentrations, dyes give an unwanted color and hazardous to aquatic life, human health and also to the environment (Kumar et al. 2015). The conventional treatment methods like adsorption, coagulation and flocculation are used for wastewater treatment (Roy et al. 2015). These methods are nondestructive, transfer of organic pollutants from one phase to another and, thus, ineffective. Semiconductor photocatalysis is a promising and alternative to conventional methods and more attractive for the removal from waste water because of its effective, simple instrumental technique, easy controlled operation, non-selective oxidation, low expensive, complete mineralization and degradation of synthetic organic dyes (Zhang et al. 2015; Yuan et al. 2015). Many semiconductors like ZnO, TiO2, CeO2, WO3, CdS and ZnS are used as photocatalysts for environmental decontamination purposes (Montini et al. 2010). Among them, ZnO is a versatile n-type semiconductor with a wide band gap of 3.37 eV, large exciton binding energy of 60 meV at room temperature, high catalytic activity, low cost and environmental friendliness character. For these reasons, ZnO is used as a promising photocatalyst for the decomposition of a wide range of organic contaminants. Due to the efficient generation of hydroxyl radicals, high reaction and mineralization rates have been reported in ZnO photocatalysis. The biggest advantage of ZnO compared with TiO2 is that it absorbs over a larger fraction of the UV spectrum and absorbs more light quanta than TiO2 (Poongodi et al. 2015; Patil et al. 2014; Kuzhalosai et al. 2013). In some cases, ZnO shows better photocatalytic efficiency than TiO2, due to its generation, mobility and separation of photoinduced electron–hole pair. However, the rapid recombination of electron–hole pair reduces photocatalytic efficiency of ZnO (Poongodi et al. 2015). Among rare earth oxide series, Cerium Oxide (CeO2) is one of the important and most active catalysts and it has a wide band gap, high oxygen storage capacity and strong redox capability. CeO2 is considered as a promising and suitable candidate for the degradation of organic pollutants (Sherly et al. 2015; Chen et al. 2011). A number of effects have been made to extend the light absorption range and increase the lifetimes of photoexicited charge carriers, such as doping, structure improvement and coupling with other components. Combining of ZnO with other semiconductors can enhance light absorption from UV to visible region and enhances the redox reactions of the electrons and holes (Yin et al. 2014).

Cyclodextrins (CD) are cyclic oligosaccharides composed of 6(α-CD), 7(β-CD) or 8(γ-CD) residuals of α-D-glucopyranose molecules connected in macrocycles by α-D-1,4 glycosidic linkages. CDs have an inner hydrophobic cavity and outer hydrophilic surface which allow them to form host–guest inclusion complexes. These complexes increase the photodegradation of guest molecules (Salomatova et al. 2014). Among the three types of CDs (α-CD, β-CD and γ-CD), β-CD has an excellent capacity for the removal of phenol from water due to its optimal size matching and used as a potential adsorbent for treating the dye polluted waste water due to its ability to form inclusion complexes with various organic pollutants (Zhang et al.2014; Zhao et al.2015).

In continuation of our earlier research in β-CD modified semiconductor metal oxide on photodecolorization of organic pollutants, especially dye molecules (Rajalakshmi et al. 2014a, b; Pitchaimuthu et al. 2014a, b; Pitchaimuthu and Velusamy 2014; Velusamy et al. 2014), here we report, for the first in time, the photocatalytic activity of (ZnO/CeO2)-β-CD system for the photodecolorization of RhB dye in aqueous solution investigated under UV light irradiation and to study the interaction of β-CD on the binary semiconductor metal oxide. A plausible mechanism has also been proposed and explained in detail.

Experimental methods

Materials

In this work, Rhodamine B (RhB) (a cationic dye, C28H31ClN2O3, λ max = 544 nm, reddish violet in color) dye was used as a model organic pollutant purchased from Loba Chemie (India). ZnO and CeO2 used as the photocatalysts were obtained from Merck. β-Cyclodextrin (β-CD) was purchased from Hi Media Chemicals (P) Ltd. The physical properties and structure of RhB dye and β-CD are shown in Table 1. All other chemicals and reagents were of Analytical grade received from Merck. Double distilled water was used throughout the work.

Preparation of (ZnO/CeO2)-β-CD composite mixture

The (ZnO/CeO2) composite mixture was prepared from a powdered mixture of the ZnO and CeO2 at the weight ratio of 4.5:0.5, 4:1, 3.5:1.5, 3:2, 2.5:2.5 and 2:3. From the above ratio of the mixtures, it is evidenced that the weight ratio of 4:1 is suitable for the present study. The mixture was then ground thoroughly in an agate mortar for 30 min. In order to improve the photocatalytic efficiency of two mixed oxides, this mixture was added into 0.01 mol/L of β-CD solution, magnetically stirred for 24 h, centrifuged and then the solid phase was collected. After being centrifuged, the solid phase of the suspension was carefully washed with double distilled water and dried at 50º C for 30 min. The prepared samples were used for SEM, XRD and UV-DRS analyses.

Exactly 10 × 10−6 M of RhB dye was prepared using deionised water and various concentrations of β-CD like 1.25, 2.50, 3.75, 5.00, 6.25 and 7.50 × 10−5 M were prepared in a 25 mL Standard Measuring Flask. These two solutions were mixed thoroughly with magnetic stirrer for 24 h. Then these samples were analyzed with UV–visible spectrophotometer.

Characterization

X-ray diffraction patterns of powder samples were recorded with a high resolution powder X-ray diffractometer model PAN analytical ‘X’PERT-PRO with Cu Kα radiation as the X-ray source (λ = 1.5418 × 10−10 m). The morphology of the sample was examined by Scanning Electron Microscope (FEG QUANTA-250). UV–vis diffuse reflectance spectra were recorded on Shimadzu 2401 UV–vis spectrophotometer with BaSO4 as the background between 200 and 700 nm. UV–visible spectrophotometer (Shimadzu UV-1700) and the scan range were from 400 to 700 nm.

Photocatalytic irradiation procedure

Photocatalytic activity of the catalysts was obtained by decolorization of RhB under UV light irradiation. Heber multilamp photoreactor (HML MB 88) with eight lamps was used as a UV light source. The lamp emits UV light radiation mainly at 365 nm with a power output of 30 W. The distance between the UV source and the sample holder is 5 cm. Glass tubes with 60 ml capacity were used as sample holders. Prior to irradiation, the suspension solutions of the catalysts were kept in dark for about 15 min to attain the adsorption–desorption equilibrium between RhB dye and catalytic surface systems. During irradiation, the reactant solutions were continuously stirred well with magnetic stirrer fitted at the bottom. The tubes were taken out at different intervals of time and the suspension solutions were centrifuged. The supernatant liquids of the solutions of different concentrations were collected for the determination of concentrations for the remaining dye by measuring its absorbance (at λ max = 544 nm) with visible spectrophotometer (ELICO-207). The pH values of RhB dye solutions were adjusted by adding a small amount of 0.1 N HCl or 0.1 N NaOH and monitored with digital pen pH meter (Hanna Instruments, Portugal). In all the cases, exactly 50 mL of the reactant solutions was irradiated with required amount of the catalyst. The pH of the RhB dye solutions was adjusted before irradiation process and it was not controlled during the course of the reaction. The experiments were carried out with the solution pH (at pH = 3.9) and the irradiation time was fixed at 120 min. By keeping the concentrations of RhB dye-β-CD as constant with the molar ratio of 1:1, the effects of all other experimental parameters on the percentage of photocatalytic decolorization of RhB dye solution were investigated.

Determination of chemical oxygen demand (COD)

Exactly, 50 mL of the sample was taken in a 500 mL round bottomed flask with 1 g of mercuric sulfate. Slowly, 5 mL of silver sulfate reagent (prepared from 5.5 g of silver sulfate per kg in concentrated sulfuric acid) was added to the solution. Cooling of the mixture is necessary to avoid possible loss of volatile matters if any, while stirring. Exactly 25 mL of 0.25 N potassium dichromate solutions were added to the mixture slowly. The flask was attached to the condenser and 70 mL of silver sulfate reagent were added and allowed to reflux for 2 h. After refluxing, the solution was cooled at room temperature. Five drops of Ferroin indicator was added and titrated against a standard solution of Ferrous Ammonium Sulfate (FAS) until the appearance of the first sharp color change from bluish green to reddish brown. The COD values can be calculated in terms of oxygen per liter in milligram (mg O2/l) using the following equation (Rajalakshmi et al. 2014b; Pitchaimuthu et al. 2014b)

where B is the volume of FAS consumed by K2Cr2O7 (mL), A is the volume of FAS consumed by K2Cr2O7 and RhB dye mixture (mL), N is the normality of FAS and S the volume of the RhB dye.

Results and discussion

Characterization of catalysts

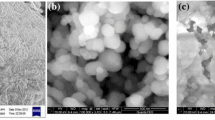

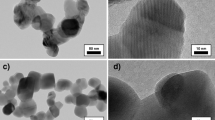

SEM images

Figure 1 depicts the SEM images of β-CD (a), (ZnO/CeO2) (b) and (ZnO/CeO2)-β-CD (c) respectively. β-CD shows amorphous surface (Fig. 1a). Figure 1b shows two kinds of the particles on the surfaces of (ZnO/CeO2), which are due to the ZnO and CeO2. This clearly shows that the two metal oxides are well dispersed with each other. The surface of (ZnO/CeO2)-β-CD system exhibits a similar morphology with (ZnO/CeO2) composite mixture which indicates that β-CD does not change the morphology of (ZnO/CeO2). All the above results indicate that β-CD molecules are adsorbed on the surfaces of the (ZnO/CeO2).

XRD patterns

XRD patterns of (ZnO/CeO2) composite and (ZnO/CeO2)-β-CD system are provided as Fig. 2. The diffraction peaks at 31.73°, 34.45°, 36.28°, 47.51° and 56.68° correspond to, respectively, (100), (002), (101), (102), and (110) planes of the Wurtzite structure of ZnO (JCPDS No. 36-1451) (Subhan et al. 2015). The diffraction peaks at 28.26°, 32.85°, 47.25°, 56.06° and 58.90° can be, respectively, indexed as (111), (200), (220), (311) and (222) planes of the cubic CeO2 (JCPDS No. 34-394) (Arul et al. 2015). Figure 2a (ZnO/CeO2) has both hexagonal structure of ZnO and cubic structure of CeO2. Figure 2b shows the deposition of β-CD on the surface of (ZnO/CeO2) does not change in the crystalline features of (ZnO/CeO2). After the addition of β-CD with (ZnO/CeO2), the main intensity peaks of (ZnO/CeO2)-β-CD system are slightly lower than (ZnO/CeO2). The XRD results indicate that there is a strong binding between (ZnO/CeO2) and β-CD (Rajalakshmi et al. 2014a).

UV-DRS spectra

The UV-DRS spectra of ZnO, CeO2, (ZnO/CeO2) and (ZnO/CeO2)-β-CD system are shown in Fig. 3. They show that all the samples exhibit an optical absorption near 350–400 nm. Incorporation of β-CD on (ZnO/CeO2) significantly affects the light absorption properties of (ZnO/CeO2). Further, (ZnO/CeO2) shows only a slight variation of band gap energy as compared to that of ZnO and CeO2. It is due to the effective blending of ZnO with CeO2. The light absorption of (ZnO/CeO2)-β-CD system in the visible light range is higher than that of (ZnO/CeO2), ZnO and CeO2. The optical band gap of all the samples can be calculated by extrapolating the straight linear portion of the plot between [F(R) hv]½ vs hv. The estimated energy band gap values are, respectively, 3.43, 3.31, 3.39 and 3.35 eV for ZnO, CeO2, (ZnO/CeO2) and (ZnO/CeO2)-β-CD system. The band gap energies of (ZnO/CeO2)-β-CD system is lower than that of (ZnO/CeO2), ZnO and CeO2. It indicates that (ZnO/CeO2)-β-CD has higher photocatalytic activity than other samples (Almeida et al. 2015; Li et al. 2014).

Dissociation constant measurement

From the UV–Visible absorption spectral studies, the dissociation constant (K D) is calculated using the Benesi–Hildebrand equation. The K D value for this study is calculated as 0.378 × 10−5 M. This clearly confirms that RhB dye molecules form a very strong inclusion complex with β-CD (Rajalakshmi et al. 2014a).

Effect of operational parameters

Effect of ratio of (ZnO/CeO2)

The photocatalytic activities of (ZnO/CeO2) and (ZnO/CeO2)-β-CD system with different ratio of ZnO and CeO2 were investigated by photocatalytic decolorization of RhB under UV light irradiation. The experiments were carried out by varying ratio of ZnO and CeO2 as 4.5:0.5, 4:1, 3.5:1.5, 3:2, 2.5:2.5 and 2:3. The obtained results are presented in Fig. 4. Bare ZnO shows 73.5% of decolorization of the dye. The photocatalytic activity of (ZnO/CeO2) decreases with the increase in CeO2 content. The observed results are explained on the basis of the influence of the space charge thickness. The optimum content of CeO2 makes the thickness of the space charge layer essentially equal to the light penetration depth. As the amount of CeO2 is increased, the surface barrier became higher and the space charge region became narrower. Then the electron–hole pairs within the region can be separated efficiently and helps to enhance the photocatalytic activity of the catalysts. If the content of CeO2 is increased, the space charge region became very narrow and, thus, the penetration depth of light into the catalyst exceeded the space charge layer. For this reason, the electron–hole pairs became easier, which reduces the photocatalytic activity of (ZnO/CeO2) and (ZnO/CeO2)-β-CD; (ii) The ceric ions (Ce4+) act as the recombination center for photogenerated electron–hole pair during photocatalytic reactions; (iii) At excess amount of CeO2 results in the agglomeration of CeO2 particles, which scatter the incident light, decreasing the quantum efficiency of the photocatalytic reaction (Sin et al.2015; Chen et al. 2009; Liu et al. 2011); (iv) Photocatalytic activity lowers by the progressive shielding of the ZnO surface by CeO2 particles; (v) The decrease of CeO2 content leads to increase in the photocatalytic activity of the catalyst because of the very low photocatalytic activity of CeO2 as compared to ZnO (Meksi et al. 2015; Rashad et al.2014; Karunakaran et al.2010); (vi) The OH plays a crucial role in photocatalytic process. When the content of ZnO increases the photocatalytic efficiency increases. It is due to the number of OH· radical generation is increased (Xu et al. 2010). Considering all the above facts, in this study, the optimum ratio of ZnO and CeO2 is fixed as 4:1.

Effect of initial concentration of dye

The effect of initial dye concentration is an important parameter in photocatalytic reactions from both application and mechanistic points of view (Amani-Ghadim et al. 2015). The effect of initial concentration of RhB dye on various catalysts in this study, say, ZnO, CeO2, (ZnO/CeO2) and (ZnO/CeO2)-β-CD system with a fixed amount of catalysts 2 g/L and irradiation time 120 min are provided in Fig. 5. The concentration of dye the solutions are varying from 0.4–2.5 × 10−5 M for ZnO, 0.2–1.2 × 10−5 M for CeO2, 1.0–6.3 × 10−5 M for (ZnO/CeO2) and 2.0–12.5 × 10−5 M for (ZnO/CeO2)-β-CD system at pH 3.9. The results show that increase in the concentration of RhB dye decreases the percentage removal of dye from 92.3–74.1% for ZnO, 82.5–56.2% for CeO2, 95.0–77.4% for (ZnO/CeO2) and 98.2–80.6% for (ZnO/CeO2)-β-CD system. The decrease in decolorization efficiency with increasing dye concentration is due to the following reasons: (i) Increase of dye concentration decrease the path length of photons entering into the dye solution. In addition, a significant amount of UV light may be absorbed by the dye molecules rather than by the catalysts which reduces the rate of decolorization; (ii) Some of the intermediates produced during the photocatalytic process may compete with organic molecules which limited the adsorption as well as the active sites on the surface of the catalyst; (iii) Large number of adsorbed dye molecules on the catalytic surface prevents the reaction between RhB molecules and hydroxyl radicals due to the lack of any direct contact between them.

Moreover, several investigations indicated that as the concentration of the target pollutant increases, more and more molecules of the compound are adsorbed on the surface of the photocatalyst. Therefore, the reactive species (·OH and ·O2 −) required for the degradation of the pollutant also increases. However, the formation of (·OH and ·O2 −) on the catalyst surface remains constant for a given light intensity, amount of the catalyst and irradiation time. Hence, the available OH· radicals are inadequate for the decolorization of RhB dye at higher concentrations. Consequently the rate of decolorization of RhB dye decreases as the concentration increases. In addition, increase in dye concentration leads to the generation of intermediates, which may adsorb on the surface of the catalyst. Slow diffusion of the generated intermediates from the catalyst surface can be resulted in the deactivation of active sites on the photocatalyst. This leads to decrease in the percentage removal of the dye. In contrast, at low concentrations, number of catalytic sites are not being the limiting factor and the rate of degradation will be proportional to the concentration of the dye (Thennarasu and Sivasamy 2013; Gupta et al.2011; Hu et al. 2015; Taleb 2014; Ahmed et al. 2011). The optimum concentration is fixed as 2.0 × 10−5 M for ZnO, 0.8 × 10−5 M for CeO2, 3.1 × 10−5 M for (ZnO/CeO2) and 6.2 × 10−5 M for (ZnO/CeO2)-β-CD system.

Effect of amount of catalysts

The effect of amount of catalysts is one of the important factors which too affect the photocatalytic processes. To avoid the use of excess catalysts, it is necessary to find out the optimum amount of the catalysts to reach an efficient removal of the dye. The effect of catalyst dose on the photocatalytic decolorization of RhB dye under UV light irradiation has been investigated by varying the dose of the catalysts from 1 to 6 g/L for all the catalysts used in this study. The results are presented in Fig. 6. The results clearly show that increase of the dose of the catalysts increases the percentage of decolorization. This may be due to (i) the increase in the number of dye molecules adsorbed on the catalysts; (ii) increase in the density of the catalysts in particle nature in the area of illumination; (iii) increase in the number of active sites on the surface of the catalysts; (iv) increase in the number of photogenerated electron–hole pairs which results in an increase in number of hydroxyl radicals (Rajamanickam and Shanthi 2012; Krishnakumar and Swaminathan 2011; Kaur and Singhal 2014). However, higher dose of the catalysts leads to decrease in the reaction rate which may be attributed to (i) the agglomeration of catalyst particles at higher dose of the catalyst leads to the fact that a part of the photocatalyst surface becoming unavailable for photon absorption and dye adsorption; (ii) deactivation of activated molecules by collision with the ground state molecules; (iii) turbidity of the reaction mixture increases which resulted in the screening effect that affects the penetration of UV light through the solution; (iv) increase in scattering of light and opacity of suspension (Sudrajat et al. 2016; Lin et al. 2011; Kaur and Singhal 2014; Pourahmed 2012). All the above reasons pointed out that increase of the amount of catalysts above a certain level does not execute any photocatalytic reactions. The optimum dose of the catalysts in all the cases is fixed as 2 g/L for further studies.

Effect of irradiation time

Successful applications of the photocatalytic decolorization process depend on the decolorization time and require the investigation of the photocatalytic decolorization rate (Mohammadi and Sabbaghi 2014). The effect of irradiation time for decolorization of RhB dye under UV light irradiation is evaluated by varying from 30 to 180 min. The decolorization efficiency increases with increase of irradiation time as shown in Fig. 7. It is attributed to the fact that there is enough time to produce more number of hydroxyl and superoxide radicals. It is observed that, at 180 min. the percentage decolorization of RhB is 98.0% for (ZnO/CeO2)-β-CD system.

Kinetics of photocatalytic decolorization

The pseudo-first order reaction kinetics can be used to describe the relationship between decolorization rates of RhB with respect to the irradiation time as shown in Fig. 8. The pseudo-first order model is expressed by the following equation,

where C 0 is the initial concentration of RhB, C t is the concentration of RhB at time t, and k is the rate constant. From Fig. 8, the linear relationship between ln (C 0/C t ) and irradiation time is observed, which indicates that the decolorization of RhB follows the follows pseudo-first order kinetics (Tamuly et al. 2014; Jin et al. 2015).

Effect of pH

The photocatalytic activities of the catalysts are strongly affected by the surface charge property, the nature of the dye molecule and the population of the available hydroxyl radicals. As all these properties are pH dependent, pH plays a vital role in the wastewater treatment which influences on the decolorization of dyes to a greater extent. The effect of pH on the photocatalytic decolorization of RhB is investigated by varying pH from 2 to 12 and the results are provided in Fig. 9. It is designated that as pH of the dye solution increases the percentage of decolorization of RhB is increasing from 77.0–93.5% for ZnO, 54.3–72.5% for CeO2, 82.2–97.0% for (ZnO/CeO2) and 85.0–99.5% for (ZnO/CeO2)-β-CD system. Both adsorption and dye removal are favored at pH around the point of zero charge (pzc). It is evidently reported that the point zero charges of ZnO and CeO2 are 9.0 and 6.8, respectively (Peng et al. 2013; Pitchaimuthu and Velusamy 2014). At a pH lower than pzc the surface of photocatalyst is positively charged, whereas at pH higher than pzc it becomes negatively charged. Since RhB is a cationic dye, the pH higher than that of the pzc favors the adsorption of RhB dye molecule on the catalyst surface which results in increases the removal of RhB dye under neutral and basic conditions (Hadjltaief et al. 2016). Moreover, pH of the solution affects the formation of hydroxyl radicals by the reaction between hydroxide ions and photoinduced holes on the surface of the photocatalysts. The positive holes and hydroxyl radicals are considered as the predominant species at low and higher pH, respectively. At higher pH, formation of OH· is higher which due to the presence of more number of available hydroxyl ions on the surface of the catalysts. Thus, the decolorization efficiency is higher at basic pH. A low pH is associated with a positively charged surface which cannot be provided the hydroxyl groups which are needed for hydroxyl radical formation. Furthermore, at low pH there is a columbic repulsion between the dye cation and positively charged catalytic surface observed and thus, the adsorption of dye on the surface of the photocatalysts decreases (Ahmed et al. 2011; Rajamanickam and Shanthi 2012; Velusamy et al. 2015). Hence the percentage removal of dye is less in acidic pH.

Mechanism for photocatalytic performance of (ZnO/CeO2)-β-CD system

The photocatalytic decolorization of RhB dye in the presence of (ZnO/CeO2)-β-CD system is explained with the mechanism as shown in Fig. 10. RhB dye molecules are entered into the cavity of β-CD which is bonded on the (ZnO/CeO2) surface at the equilibrium stage. Since CDs have higher affinity on the surface of (ZnO/CeO2) than RhB, β-CD molecules could be adsorbed on the surface of (ZnO/CeO2) and can occupy the reaction sites. β-CD could capture the holes on the active surface of (ZnO/CeO2) resulting in the formation of stable β-CD-(ZnO/CeO2)-β-CD system. The inclusion complex reaction of β-CD with RhB dye molecules is the key step in photocatalytic decolorization in suspension containing β-CD (Zhang et al. 2009; Rajalakshmi et al. 2014b; Pitchaimuthu et al. 2014b; Velusamy et al.2014). The complex RhB-β-CD-(ZnO/CeO2)-β-CD-RhB is formed. Then the dye molecules absorb UV radiation followed by excitation. At the time of excitation, the photogenerated electrons are transferred from the conduction band (CB) of CeO2 to the conduction band of ZnO (Sherly et al. 2015). Further, an electron is rapidly injected from the excited dyes to CB of ZnO and CB of CeO2. Superoxide anion radicals are formed in the presence of oxygen. The dye and dye cation radical then undergo degradation.

The enhanced of photocatalytic activity of (ZnO/CeO2)-β-CD for the decolorization of RhB is mainly due to the following reasons (a) photogenerated electron transfer from CeO2 to ZnO; (b) enhanced adsorption of RhB on (ZnO/CeO2); (c) moderate inclusion depth of RhB in the β-CD cavity; (d) β-CD capture photogenerated holes (Wang et al. 2006a).

In this work, β-CD acts as a bridge or channel between the RhB and both the metal oxides, as β-CD can include the dye molecule into its cavity and adsorbed onto the surfaces of both the metal oxides and accumulate at higher concentrations, which makes the decolorization of RhB more easy and effective in the presence of hydroxyl radicals produced during photocatalytic decolorization processes (Wang et al. 2006b). Therefore, the photocatalytic activity of (ZnO/CeO2)-β-CD is enhanced by decreasing the recombination of electron–hole pairs which results in the increasing the lifetime of charge carriers and formation of more number of hydroxide and superoxide radicals.

RhB + ZnO + hv | → | CO2 + H2O + mineralization products | (i) |

RhB + CeO2 + hv | → | CO2 + H2O + mineralization products | (ii) |

RhB + (ZnO/CeO2) + hv | → | CO2 + H2O + mineralization products | (iii) |

(ZnO/CeO2) + β-CD | → | (ZnO/CeO2)-β-CD | (iv) |

β-CD + (ZnO/CeO2)-β-CD | → | β-CD-(ZnO/CeO2)-β-CD | (v) |

RhB + β-CD | → | β-CD–RhB | (vi) |

RhB + β-CD- (ZnO/CeO2)-β-CD | → | RhB-β-CD-(ZnO/CeO2)-β-CD | (vii) |

RhB + RhB -β-CD-(ZnO/CeO2)-β-CD | → | RhB-β-CD-(ZnO/CeO2)-β-CD-RhB | (viii) |

RhB-β-CD-(ZnO/CeO2)-β-CD-RhB + hv | → | RhB*-(β-CD-(ZnO/CeO2)-β-CD)·1-RhB* + RhB*-(β-CD-(ZnO/CeO2)-β-CD)·3-RhB* | (ix) |

(RhB-β-CD-(ZnO/CeO2)-β-CD-RhB)* | → | RhB-β-CD-(e−)(ZnO/CeO2)-β-CD- RhB | (x) |

(RhB-β-CD-(ZnO/CeO2)-β-CD- RhB)* | → | RhB+·-β-CD-(e−)(ZnO/CeO2)(e−)-β-CD-RhB+· | (xi) |

(RhB-β-CD-(ZnO/CeO2)-β-CD-RhB)* + O2 | → | RhB-β-CD-(ZnO/CeO2)-β-CD-RhB + 1O2 | (xii) |

(e−) β-CD-(ZnO/CeO2)-β-CD + O2 | → | β-CD-(ZnO/CeO2)-β-CD + O · −2 | (xiii) |

RhB·+ | → | Mineralized products | (xiv) |

RhB + 1O2 | → | Mineralized products | (xv) |

RhB + O ·−2 | → | Mineralized products | (xvi) |

Mineralization

The COD is one of the widely used effective techniques for measuring the organic strength present in textile wastewater and it is also used to confirm the mineralization of dyes. This test allows the measurement of total quantity of oxygen required for the complete oxidation of organic pollutant to carbon dioxide and water. During the photocatalytic oxidation processes, dye solution contains some intermediates which on continued treatment resulted in the formation of CO2 and H2O, which can be established as a complete mineralization (Thennarasu and Sivasamy 2013; Dalbhanjan et al. 2015). The reduction of COD measurements of RhB dye on ZnO, CeO2, (ZnO/CeO2) and (ZnO/CeO2)-β-CD at different pH form 2 to 12 under UV light irradiation are present in Fig. 11. It is observed form the results that the COD value decreases with increase in the pH value of the solution. Among all the catalysts, COD values are significantly reduced with (ZnO/CeO2)-β-CD system which indicates that (ZnO/CeO2)-β-CD system is an efficient photocatalyst than all other catalysts analyzed in this study.

Conclusion

In this study, the photocatalytic behavior of (ZnO/CeO2)-β-CD system under UV light irradiation for the decolorization of RhB dye was investigated. The catalysts employed in this study were characterized by SEM, XRD and UV-DRS analyses. UV–visible study confirms the formation of inclusion complex. The effect of operational parameters such as ratio of (ZnO/CeO2), initial dye concentration, amount of catalysts, irradiation time and pH were discussed. The photodecolorization efficiency is high in basic pH. The kinetics of photocatalytic decolorization of RhB dyes showed pseudo-first order reaction kinetics. (ZnO/CeO2)-β-CD system exhibits higher photocatalytic activity than (ZnO/CeO2), ZnO and CeO2. This is due to the formation of inclusion complex and synergistic effect of ZnO and CeO2. From this study, (ZnO/CeO2)-β-CD system is found to be a potential photocatalyst for the application of waste water treatment.

References

Ahmed S, Rasul MG, Brownb R, Hashib MA (2011) Influence of parameters on the heterogeneous photocatalytic degradation of pesticides and phenolic contaminants in wastewater: a short review. J Environ Manage 92:311–330

Almeida MFD, Bellato CR, Mounteer AH, Ferreira SO, Milagres JL, Miranda LDL (2015) Enhanced photocatalytic activity of TiO2-impregnated with MgZnAl mixed oxides obtained from layered double hydroxides for phenol degradation. Appl Surf Sci 357:1765–1775

Amani-Ghadim AR, Alizadeh S, Khodam F, Rezvani Z (2015) Synthesis of rod-like α-FeOOH nanoparticles and its photocatalytic activity in degradation of an azo dye: empirical kinetic model development. J Mol Catal A Chem 408:60–68

Arul NS, Mangalaraj D, Kim TW (2015) Photocatalytic degradation mechanisms of CeO2/Tb2O3 nanotubes. Appl Surf Sci 349:459–464

Chen Q, Jiang D, Shi W, Wu D, Xu Y (2009) Visible-light-activated Ce–Si co-doped TiO2 photocatalyst. Appl Surf Sci 255:7918–7924

Chen F, Cao Y, Jia D (2011) Preparation and photocatalytic property of CeO2 lamellar. Appl Surf Sci 257:9226–9231

Dalbhanjan RR, Pande NS, Banerjee BS, Hinge SP, Mohod AV, Gogate PR (2015) Degradation of patent blue V dye using modified photocatalytic reactor based on solar and UV irradiations. Desalin Water Treat. doi:10.1080/19443994.2015.1090922

Gupta VK, Jain R, Agarwal S, Shrivastava M (2011) Kinetics of photo-catalytic degradation of hazardous dye Tropaeoline 000 using UV/TiO2 in a UV reactor. Colloids Surf A Physicochem Eng Asp 378:22–26

Hadjltaief HB, Zina MB, Galvez ME, Costa PD (2016) Photocatalytic degradation of methyl green dye in aqueous solution over natural clay-supported ZnO–TiO2 catalysts. J Photochem Photobiol A Chem 315:25–33

Hu L, Yuan H, Zou L, Chen F, Hu X (2015) Adsorption and visible light-driven photocatalytic degradation of Rhodamine B in aqueous solutions by Ag@AgBr/SBA-15. Appl Surf Sci 355:706–715

Jin Z, Duan W, Liu B, Chen X, Yang F, Guo J (2015) Fabrication of efficient visible light activated Cu–P25–graphene ternary composite for photocatalytic degradation of methyl blue. Appl Surf Sci 356:707–718

Karunakaran C, Gomathisankar P, Manikandan G (2010) Preparation and characterization of antimicrobial Ce-doped ZnO nanoparticles for photocatalytic detoxification of cyanide. Mater Chem Phys 123:585–594

Kaur J, Singhal S (2014) Heterogeneous photocatalytic degradation of rose bengal: effect of operational parameters. Phys B 450:49–53

Krishnakumar B, Swaminathan M (2011) Influence of operational parameters on photocatalytic degradation of a genotoxic azo dye Acid Violet 7 in aqueous ZnO suspensions. Spectrochim. Acta Part A Mol Biomol Spectrosc 81:739–744

Kumar P, Govindaraju M, Senthamilselvi S, Premkumar K (2013) Photocatalytic degradation of methyl orange dye using silver (Ag) nanoparticles synthesized from Ulva lactuca. Coll Surf B Biointerfaces 103:658–661

Kumar R, Rashid J, Barakat MA (2015) Zero valent Ag deposited TiO2 for the efficient photocatalysis of methylene blue under UV-C light irradiation. Coll Interface Sci Commun 5:1–4

Kuzhalosai V, Subash B, Senthilraja A, Dhatshanamurthi P, Shanthi M (2013) Synthesis, characterization and photocatalytic properties of SnO2–ZnO composite under UV-A light. Spectrochim Acta Part A Mol Biomol Spectrosc 115:876–882

Li L, Zhang X, Zhang W, Wang L, Chen X, Gao Y (2014) Microwave-assisted synthesis of nanocomposite Ag/ZnO–TiO2 and photocatalytic degradation Rhodamine B with different modes. Coll Surf A Physicochem Eng Asp 457:134–141

Lin S-H, Chiou C-H, Chang C-K, Juang R-S (2011) Photocatalytic degradation of phenol on different phases of TiO2 particles in aqueous suspensions under UV irradiation. J Environ Manage 92:3098–3104

Liu H, Wang M, Wang Y, Liang Y, Cao W, Su Y (2011) Ionic liquid-templated synthesis of mesoporous CeO2–TiO2 nanoparticles and their enhanced photocatalytic activities under UV or visible light. J Photochem Photobiol A Chem 223:157–164

Liu X, Chen K, Shim J-J, Huang J (2015) Facile synthesis of porous Fe2O3 nanorods and their photocatalytic properties. J Saudi Chem Soc 19:479–484

Meksi M, Kochkar H, Berhault G, Guillard C (2015) Effect of cerium content and post-thermal treatment on doped anisotropic TiO2 nanomaterials and kinetic study of the photodegradation of formic acid. J Mol Catal A Chem 409:162–170

Mohammadi M, Sabbaghi S (2014) Photo-catalytic degradation of 2,4-DCP wastewater using MWCNT/TiO2 nano-composite activated by UV and solar light. Environ Nanotechnol Monit Manage 1–2:24–29

Montini T, Gombac V, Hameed A, Felisari L, Adami G, Fornasiero P (2010) Synthesis, characterization and photocatalytic performance of transition metal tungstates. Chem Phys Lett 498:113–119

Patil RS, Kokate MR, Shinde DV, Kolekar SS, Han SH (2014) Synthesis and enhancement of photocatalytic activities of ZnO by silver nanoparticles. Spectrochim Acta Part A Mol Biomol Spectrosc 122:113–117

Peng Y, Ji J, Zhao X, Wan H, Chen D (2013) Preparation of ZnO nanopowder by a novel ultrasound assisted non-hydrolytic sol–gel process and its application in photocatalytic degradation of C.I. Acid Red 249. Powder Technol 233:325–330

Pitchaimuthu S, Velusamy P (2014) Enhanced photocatalytic activity of CeO2 using β-cyclodextrin on visible light assisted decolorizationof methylene blue. Water Sci Technol 69(1):114–119

Pitchaimuthu S, Rajalakshmi S, Kannan N, Velusamy P (2014a) Enhancement of zinc oxide-mediated solar light decolorizationof acid yellow 99 dye by addition of β-CD. Appl Water Sci 5(2):201–208

Pitchaimuthu S, Velusamy P, Rajalakshmi S, Kannan N (2014b) Enhanced photocatalytic activity of titanium dioxide by β-cyclodextrin in decolorization of acid yellow 99 dye. Desalin Water Treat 52(16–18):3392–3402

Poongodi G, Anandan P, Kumar RM, Jayavel R (2015) Studies on visible light photocatalytic and antibacterial activities of nanostructured cobalt doped ZnO thin films prepared by sol–gel spin coating method. Spectrochim Acta Part A Mol Biomol Spectrosc 148:237–243

Pourahmad A (2012) Ag2S nanoparticle encapsulated in mesoporous material nanoparticles and its application for photocatalytic degradation of dye in aqueous solution. Superlattices Microstruct 52:276–287

Rajalakshmi S, Pitchaimuthu S, Velusamy P, Kannan N (2014a) Enhanced photocatalytic activity of metal oxides/β-cyclodextrin nanocomposites for decolorizationof Rhodamine B dye under solar light irradiation. Water Sci, Appl. doi:10.1007/s13201-014-0223-5

Rajalakshmi S, Pitchaimuthu S, Velusamy P, Kannan N (2014b) Photocatalytic effect of β-cyclodextrin on semiconductors for the removal of Acid Violet dye under UV light irradiation. Desalin Water Treat 52(16–18):3432–3444

Rajamanickam D, Shanthi M (2012) Photocatalytic degradation of an organic pollutant by zinc oxide—solar process. Arab J Chem. doi:10.1016/j.arabjc.2012.05.006

Rashad MM, Ismail AA, Osama I, Ibrahim IA, Kandil A-HT (2014) Photocatalytic decomposition of dyes using ZnO doped SnO2 nanoparticles prepared by solvothermal method. Arab J Chem 7:71–77

Roy K, Sarkar CK, Ghosh CK (2015) Photocatalytic activity of biogenic silver nanoparticles synthesized using potato (Solanum tuberosum) infusion. Spectrochim Acta Part A Mol Biomol Spectrosc 146:286–291

Salomatova VA, Pozdnyakov IP, Yanshole VV, Wu F, Grivin VP, Bazhin NM, Plyusnin VF (2014) Photodegradation of 4,4-Bis(4-hydroxyphenyl)valeric acid and its inclusion complex with β-cyclodextrin in aqueous solution. J Photochem Photobiol A Chem 274:27–32

Saraf R, Shivakumara C, Behera S, Nagabhushana H, Dhananjaya N (2015) Facile synthesis of PbWO4: applications in photoluminescence and photocatalytic degradation of organic dyes under visible light. Spectrochim Acta Part A Mol Biomol Spectrosc 136:348–355

Sherly ED, Vijaya JJ, Kennedy LJ (2015) Effect of CeO2 coupling on the structural, optical and photocatalytic properties of ZnO nanoparticles. J Mol Struct 1099:114–125

Sin J-C, Lam S-M, Lee K-T, Mohamed AR (2015) Preparation of cerium-doped ZnO hierarchical micro/nanospheres with enhanced photocatalytic performance for phenol degradation under visible light. J Mol Catal A Chem 409:1–10

Subhan MA, Uddin N, Sarker P, Nakata H, Makioka R (2015) Synthesis, characterization, low temperature solid state PL and photocatalytic activities of Ag2O·CeO2·ZnO nanocomposite. Spectrochim Acta Part A Mol Biomol Spectrosc 151:56–63

Sudrajat H, Babel S, Sakai H, Takizawa S (2016) Rapid enhanced photocatalytic degradation of dyes using novel N-doped ZrO2. J Environ Manage 165:224–234

Taleb MFA (2014) Adsorption and photocatalytic degradation of 2-CP in waste water onto CS/CoFe2O4 nanocomposite synthesized using gamma radiation. Carbohydr Polym 114:65–72

Tamuly C, Hazarika M, Bordoloi M, Bhattacharyya PK, Kar R (2014) Biosynthesis of Ag nanoparticles using pedicellamide and its photocatalytic activity: an eco-friendly approach. Spectrochim Acta Part A Mol Biomol Spectrosc 132:687–691

Thennarasu G, Sivasamy A (2013) Metal ion doped semiconductor metal oxide nanosphere particles prepared by soft chemical method and its visible light photocatalytic activity in degradation of phenol. Powder Technol 250:1–12

Velusamy P, Pitchaimuthu S, Rajalakshmi S, Kannan N (2014) Enhanced photocatalytic activity of titanium dioxide by β-cyclodextrin in decolorizationof Acid Yellow 99 dye. J Adv Res 5(1):19–25

Velusamy P, Lakshmi G, Pitchaimuthu S, Rajalakshmi S (2015) Investigation of Photocatalytic activity of (ZnO/TiO2) modified by β-Cyclodextrin in photodecolorizationof Rhodamine B under visible light irradiation. J Environ Sci Poll Res 1(1):1–5

Wang G, Wu F, Zhang X, Luo M, Deng N (2006a) Enhanced TiO2 photocatalytic degradation of bisphenol A by β-cyclodextrin in suspended solutions. J Photochem Photobiol A Chem 179:49–56

Wang G, Wu F, Zhang X, Luo M, Deng N (2006b) Enhanced TiO2 photocatalytic degradation of bisphenol E by β-cyclodextrin in suspended solutions. J Hazard Mater B133:85–91

Xu WG, Liu SF, Lu SX, Kang SY, Zhou Y, Zhang HF (2010) Photocatalytic degradation in aqueous solution using quantum-sized ZnO particles supported on sepiolite. J Coll Interface Sci 351:210–216

Yin H, Yu K, Song C, Huang R, Zhu Z (2014) Synthesis of Au-decorated V2O5@ZnO hetero nanostructures and enhanced plasmonic photocatalytic activity. ACS Appl Mater Interfaces 6:14851–14860

Yuan X, Yang B, Hu X, Dong X, Wei Y, Zhu J (2015) Room-temperature synthesis and solar photocatalytic performance of MoO3·0.5H2O nanorods. Appl Surf Sci 357:968–974

Zhang X, Wu F, Wang Z, Guo Y, Deng N (2009) Photocatalytic degradation of 4,4′-biphenol in TiO2 suspension in the presence of Cyclodextrins: a trinity integrated mechanism. J Mol Catal A Chem 301:134–139

Zhang X, Wang Y, Yang S (2014) Simultaneous removal of Co(II) and 1-naphthol by core–shell structured Fe3O4@cyclodextrin magnetic nanoparticles. Carbohydr Polym 114:521–529

Zhang DE, Ren LZ, Hao XY, Pan BB, Wang MY, Ma JJ, Li F, Li SA, Tong ZW (2015) Synthesis and photocatalytic property of multilayered Co3O4. Appl Surf Sci 355:547–552

Zhao R, Wang Y, Li X, Sun B, Jiang Z, Wang C (2015) Water-insoluble sericin/β-Cyclodextrin/PVA composite electrospun nanofibers as effective adsorbents towards methylene blue. Colloids Surf B Biointerfaces 136:375–382

Acknowledgement

The authors acknowledge the Management and the Principal of Ayya Nadar Janaki Ammal College, Sivakasi, India for providing the necessary facilities. Authors also acknowledged Department of Industrial Chemistry and Department of Physics, Alagappa University, Karaikudi for recoding SEM, UV-DRS analyses and Powder XRD patterns, respectively. PV dedicates this work to one of the co-workers of his research group, Late Dr. N. Kannan (Former Head of the Department of Chemistry, Ayya Nadar Janaki Ammal College, Sivakasi) who initiated and motivated to continue his research in the field of photocatalysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Velusamy, P., Lakshmi, G. Enhanced photocatalytic performance of (ZnO/CeO2)-β-CD system for the effective decolorization of Rhodamine B under UV light irradiation. Appl Water Sci 7, 4025–4036 (2017). https://doi.org/10.1007/s13201-017-0554-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-017-0554-0