Abstract

SMAW (Shielded Metal Arc Welding) and GMAW (Gas Metal Arc Welding) are two of the most prominent welding processes commonly utilized in almost all types of modern industries. Among various aspects of these processes, some of the important parameters that govern the quality of the final weld product are the skill level of welders, welding consumables, and the role of shielding gases (in GMAW). Currently, the role of these parameters in determining the quality of the welded product is examined by evaluating the final weld produced and not by investigating how these factors affect the welding process. This is an indirect way to evaluate such welding parameters, which are both time-consuming and expensive. During the actual welding process, random variations in arc signals (voltage and current) take place. These dynamic variations are so short and rapid that ordinary ammeters and voltmeters cannot monitor the rate of such variations. However, the reliable acquisition of such variations and its subsequent analysis can provide very useful information in determining the quality of the final weld product. In this study, arc voltage and current were acquired at 100,000 samples/sec, filtered and subsequently analyzed using Continuous Wavelet Transform based on Fast Fourier Transform (CWT-FFT) technique to evaluate welding skill, welding electrodes (in SMAW process), and the effect of shielding gases (in GMAW process). Results thus obtained clearly differentiated the skill level of different trainee welders and welding electrodes in the SMAW process and the effect of shielding gases and arc current in the GMAW process. Very good correlation among the obtained results, its weld bead and its weld pool images were observed. Hence, this research proposes a simple yet effective methodology to evaluate the arc welding process parameters using CWT-FFT analysis of the welding signals.

Similar content being viewed by others

Data availability

The authors declare that the data and the material included in the manuscript are included as electronic supplement material and are available within this article.

Code availability

Not applicable.

References

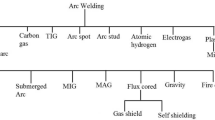

Ador welding limited (2008) Modern Arc Welding Technology. Oxford & MBH publishing Co. Pvt. Ltd., New Delhi, India

Bitharas I, McPherson NA, McGhie W et al (2018) Visualisation and optimisation of shielding gas coverage during gas metal arc welding. J Mater Process Technol 255:451–462. https://doi.org/10.1016/j.jmatprotec.2017.11.048

Caglar R (2012) Wavelet transform and current signature analysis for welding machine measurement. J Vibroengineering 14:805–812. https://www.jvejournals.com/article/10638.

Chen B, Chen S (2010) Multi-sensor information fusion in pulsed GTAW based on fuzzy measure and fuzzy integral. Assem Autom 30(3):276–285. https://doi.org/10.1108/01445151011061172

Chen SB, lv N, (2014) Research evolution on intelligentized technologies for arc welding process. J Manuf Process 16(1):109–122. https://doi.org/10.1016/j.jmapro.2013.07.002

Craig (1991) Gas metal arc and Flux cored welding parameters, A unique approach to parameters, Weld Quality and Weld Costs.

Das B, Pal S, Bag S (2016) A combined wavelet packet and Hilbert-Huang transform for defect detection and modelling of weld strength in friction stir welding process. J Manuf Process 22:260–268. https://doi.org/10.1016/j.jmapro.2016.04.002

Ebrahimnia M, Goodarzi M, Nouri M, Sheikhi M (2009) Study of the effect of shielding gas composition on the mechanical weld properties of steel ST 37–2 in gas metal arc welding. Mater Des 30(9):3891–3895. https://doi.org/10.1016/j.matdes.2009.03.031

He K, Zhou Z, Wang C, Li X (2016) Arc signal analysis of square wave alternating current submerged arc welding using local mean decomposition. J Adv Mech Des Syst Manuf. https://doi.org/10.1299/jamdsm.2016jamdsm0104

Kah P, Martikainen J (2013) Influence of shielding gases in the welding of metals. Int J Adv Manuf Technol 64:1411–1421. https://doi.org/10.1007/s00170-012-4111-6

Kapranov BI, Sutorikhin VA (2017) Remote acoustic emission monitoring of metal ware and welded joints. IOP Conf Ser: Mater Sci Eng 253:012005. https://doi.org/10.1088/1757-899X/253/1/012005

Komorowski D, Pietraszek S (2015) The use of continuous wavelet transform based on the fast Fourier transform in the analysis of multi-channel Electrogastrography recordings. J Med System 40(1):10. https://doi.org/10.1007/s10916-015-0358-4

Kumar V, Albert SK, Chandrasekhar N, Jayapandian J (2018a) Evaluation of welding skill using probability density distributions and neural network analysis. Measurement 116:114–121. https://doi.org/10.1016/j.measurement.2017.11.009

Kumar V, Albert SK, Chanderasekhar N, Jayapandian J (2018b) Performance evaluation of arc welding process using weld data analysis. Trans Indian Inst Met 71:3063–3075. https://doi.org/10.1007/s12666-018-1450-5

Kumar V, Albert SK, Chanderasekhar N (2020) Development of programmable system on chip-based weld monitoring system for quality analysis of arc welding process. Int J Comp Integr Manuf 33(9):925–935. https://doi.org/10.1080/0951192X.2020.1815847

Lanzoni M, Salomoni M, Riccò B (2010) Seam welding monitoring system based on real-time electrical signal analysis. Weld J (miami, Fla) 89:218S-223S

Lebar A, Selak L, Vrabič R, Butala P (2012) Online monitoring, analysis, and remote recording of welding parameters to the welding diary. StrojniskiVestnik-J Mech Eng 58(7–8):444–452. https://doi.org/10.5545/sv-jme.2012.341

Li ZY, Gao XD (2014) Study on regression model of measuring weld position. Appl Mech Mater 511–512:514–517. https://doi.org/10.4028/www.scientific.net/AMM.511-512.514

Li X, Simpson S (2009) Parametric approach to positional fault detection in short arc welding. Sci Technol Weld Join 14(2):146–151. https://doi.org/10.1179/136217108X370272

Luksa K, Rymarski Z (2006) Collection of arc welding process data. J Achiev Mater Manuf Eng 17:377–379

Lv N, Xu Y, Zhang Z et al (2013) Audio sensing and modeling of arc dynamic characteristic during pulsed Al alloy GTAW process. Sensor Rev 33(2):141–156. https://doi.org/10.1108/02602281311299680

Martínez RT, Alfaro SCA (2020) Data analysis and modeling techniques of welding processes: the state-of-the-art. Intech Open Welding-Modern topics pp 1–25

Mirapeix J, Cobo A, Fuentes J et al (2009) Use of the plasma spectrum RMS signal for arc-welding diagnostics. Sensors 9(7):5263–5276. https://doi.org/10.3390/s90705263

O’Brien, welding hand book (1991) 8th Edition volume 2, welding process, American Welding Society.

Pal S, Pal SK, Samantaray, (2010) Determination of optimal pulse metal inert gas welding parameters with a neuro- GA technique. Mater Manuf Process 25:606–615. https://doi.org/10.1080/10426910903179963

Rioul O, Vetterli M (1991) Wavelets and signal processing. IEEE Signal Process Mag 8:14–38. https://doi.org/10.1109/79.91217

Shin S, Jin C, Yu J, Rhee S (2020) Real-time detection of weld defects for automated welding process base on deep neural network. Metals 10(3):389. https://doi.org/10.3390/met10030389

Siewert T, Samardžić I, Klaric S (2002) Application of an on-line weld monitoring system. Proc 1st DAAAM Int Conf Adva Tech Dev Countries 227–232. https://www.bib.irb.hr/76583?rad=76583.

Song H, Zhang Y (2007) Three-dimensional reconstruction of specular surface for a gas tungsten arc weld pool. Meas Sci Technol 18:3751–3767. https://doi.org/10.1088/0957-0233/18/12/010

Torrence C, Compo GP (1998) A practical guide to wavelet analysis. Bull Am Meteorol Soc 79:61–78. https://doi.org/10.1175/1520-0477(1998)079%3c0061:APGTWA%3e2.0.CO;2

Yang L, Jiang H (2020) Weld defect classification in radiographic images using unified deep neural network with multi- level features. J Intell Manuf 32(2):459–469

Yu W, Dalu G, Mingfu L (2005) A better method for detecting friction welding defect. J Northwestern Polytech Univ 23(4):496–499

Zhang Z, Chen H, Xu Y et al (2015) Multisensor-based real-time quality monitoring by means of feature extraction, selection and modeling for Al alloy in arc welding. Mech Syst Signal Process 60:151–165. https://doi.org/10.1016/j.ymssp.2014.12.021

Zhang S, Hu S, Wang Z (2016) Weld penetration sensing in pulsed gas tungsten arc welding based on arc voltage. J Mater Process Technol C 229:520–527. https://doi.org/10.1016/j.jmatprotec.2015.09.034

Zhang B, Shi Y, Gu S (2018) Narrow-seam identification and deviation detection in keyhole deep-penetration tig welding. Int J Adv Manuf Technol 101:2051–2064. https://doi.org/10.1007/s00170-018-3089-0

Zhang L, Basantes A, Ozevin D, Indacochea E (2019) Real-time monitoring of welding process using air-coupled ultrasonics and acoustic emission. Int J Adv Manuf Technol 101(5):1623–1634. https://doi.org/10.1007/s00170-018-3042-2

Zhou W, Li Q, Zhou Z (2001) Power quality detection using wavelet-Multiresolution signal decomposition. Trans China Electrotech Soc 16(6):81–84. https://doi.org/10.1080/00051144.2019.1565337

Acknowledgements

The authors would like to thank Dr A. K. Bhaduri, Director, Indira Gandhi Centre for Atomic Research (IGCAR, Kalpakkam) and Central Workshop Division of IGCAR for their support and encouragement. The authors would also like to thank the Dean, School of Electronics Engineering (SOEE), Kalinga Institute of Industrial Technology (KIIT), Deemed to be University and our colleagues at KIIT for extending their genuine support to carry out this study.

Funding

The authors received no financial support for this research.

Author information

Authors and Affiliations

Contributions

Conceptualization: VK and SKA; methodology: VK and MK; software: VK and SG; validation: VK and SKA; formal analysis: SG, VK and MKP; investigation: VK, SG and SKA; data curation: VK and SG; writing—original draft preparation: VK and SG; writing—review and editing: SKA and MKP; visualization and supervision: VK and SKA; project administration: SKA. All authors have read and agreed to the drafted version of the current manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interest associated with this work.

Ethics approval

One section of this study involves welder’s skill classification, for this, the authors confirm that necessary permission from the institution (Indira Gandhi Centre for Atomic Research, Kalpakkam) was taken.

Consent to participate

The authors declare that the consent from all the participating welders (involved in this study) were taken.

Consent for publication

The authors (along with all the co-authors and whole team) approve the submission of this manuscript to be considered for publication to IJAMT. The authors have also agreed to online copy right transfer statement of the IJAMT (Springer).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, V., Ghosh, S., Parida, M.K. et al. Application of continuous wavelet transform based on Fast Fourier transform for the quality analysis of arc welding process. Int J Syst Assur Eng Manag 15, 917–930 (2024). https://doi.org/10.1007/s13198-023-02178-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-023-02178-7