Abstract

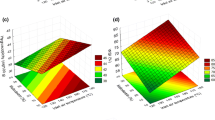

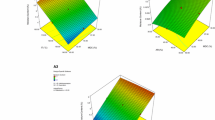

A completely randomized 23 factorial experimental design was used to optimize the process parameters for obtaining tucupi powder through spray drying. The effects of the process variables [inlet air temperature (IT), feed flow rate (FR), and maltodextrin concentration (MD)] on the product properties [moisture, water activity (aw), hygroscopicity, water absorption index (WAI), water solubility index (WSI), total color difference (ΔE*), and β-carotene content] were studied using the response surface methodology (RSM) and linear perturbation plot. In addition, scanning electron microscopy (SEM) images were obtained of the product. According to ANOVA and the regression coefficients (R2 > 0.90), the RSM models were significant and IT was the variable with the greatest impact on most of the responses. SEM shows that the powders obtained with higher IT and MD and lower FR were more uniform, with smooth and intact surfaces. The optimal conditions estimated for the process were IT at 214 °C, FR at 8.67 mL/min, and MD at 27%. Under those conditions, the product’s minimum values of moisture (9.56 g/100 g), aw (0.101), hygroscopicity (37.45% d.b.), and ΔE* (17.05) and maximum values of WAI (6.68 g/g d.b.), WSI (84.77%), and β-carotene (13.72 µg/g) were estimated.

Similar content being viewed by others

References

Adhikari B, Howes T, Bhandari BR, Troung V (2003) Characterization of the surface stickiness of fructose–maltodextrin solutions during drying. Dry Technol 21(1):17–34. doi:10.1081/DRT-120017281

Adhikari B, Howes T, Bhandari BR, Troung V (2004) Effect of addition of maltodextrin on drying kinetics and tackiness of sugar and acid-rich foods during convective drying: experiments and modelling. J Food Eng 62(1):53–68. doi:10.1016/S0260-8774(03)00171-7

Anderson RA, Conway HF, Pfeifer VF, Griffin EL Jr (1969) Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci Today 14(1):4–12

AOAC (1997) Official methods of analysis of the Association of Official Analytical Chemist. Washington

Augusto-Ruiz W, Bonato S, Arrieche L, Risso F (2003) Characterization of pregelatinized whole rice flour produced from broken rice grains. Rev Ciênc Exatas Eng 13(8):25–46

Balasubramani P, Viswanathan R, Vairamani M (2013) Response surface optimization of process variables for microencapsulation of garlic (Allium sativum L.) oleoresin by spray drying. Biosyst Eng 114(3):205–213. doi:10.1016/j.biosystemseng.2012.12.008

Barbosa-Cánovas GV, Juliano P (2005) Physical and chemical properties of food powders. In: Onwulata C (ed) Encapsulated and powdered foods. Taylor & Francis, New York, pp 39–71

Bas D, Boyaci IH (2007) Modeling and optimization I: usability of response surface methodology. J Food Eng 78(3):836–845. doi:10.1016/j.jfoodeng.2005.11.024

Bhandari BR, Hartel RW (2005) Phase transitions during food powder production and powder stability. In: Onwulata C (ed) Encapsulated and powdered foods. Taylor & Francis, New York, pp 261–292

Cai YZ, Corke H (2000) Production and properties of spray-dried Amaranthus betacyanin pigments. J Food Sci 65(7):1248–1252. doi:10.1111/j.1365-2621.2000.tb10273.x

Cassoni V, Cereda MP (2011) Cassava wastewater acetic fermentation process’ evaluation. Rev Energy Agric 26(4):101–113. doi:10.17224/EnergAgric.2011v26n4p101-113

Chegini RG, Ghobadian B (2005) Effect of spray-drying conditions on physical properties of orange juice powder. Dry Technol 23(3):657–668. doi:10.1081/DRT-200054161

Chen Q, Bi J, Zhou Y, Liu X, Wu X, Chen R (2014) Multi-objective optimization of spray drying of jujube (Zizyphus jujuba Miller) powder using response surface methodology. Food Bioprocess Technol 7(6):1807–1818. doi:10.1007/s11947-013-1171-z

Chisté RC, Cohen KO (2011) Total and free cyanide contents determination during the processing steps for preparing tucupi. Rev Inst Adolfo Lutz 70(1):41–46

Desai KGH, Park HJ (2005) Recent developments in microencapsulation of food ingredients. Dry Technol 23(7):1361–1394. doi:10.1081/DRT-200063478

Fennema OR (1996) Food chemistry. Marcel Dekker, New York

Goula AM, Adamopoulos KG (2010) A new technique for spray drying Orange juice concentrate. Innov Food Sci Emerg Technol 11(1):342–351. doi:10.1016/j.ifset.2009.12.001

Granato D, Calado VMA (2014) The use and importance of design of experiments (DOE) in process modelling in food science and technology. In: Granato D, Calado VMA (eds) Mathematical and statistical methods in food science and technology, 1st edn. Wiley, Blackwell, New York, pp 1–18

Homma AKO, Santos JC, Sena ALS, Menezes AJEA (2014) Smallholder production in the Amazon: conflicts and opportunities, which ways? Amaz Ciênc Desenvolv 9(18):137–154

Jaya S, Das H (2004) Effect of maltodextrin, glycerol monostearate and tricalcium phosphate on vacuum dried mango powders properties. J Food Eng 63(2):125–134. doi:10.1016/S0260-8774(03)00135-3

Jaya S, Das H (2009) Glass transition and tacky point temperature and stability/mobility diagram of fruits powder. Food Bioprocess Technol 2(1):1–7. doi:10.1007/s11947-007-0047-5

Kha TC, Nguyen MH, Roach PD (2010) Effect of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J Food Eng 98(3):385–392. doi:10.1016/j.jfoodeng.2010.01.016

Kudra T (2003) Tacky region in drying—definition and identification. Dry Technol 21(8):1457–1469. doi:10.1081/DRT-120024678

Kurozawa LE, Morassi AG, Vanzo AA, Park KJ, Hubinger MD (2009) Influence of spray drying conditions on physicochemical properties of chicken meat powder. Dry Technol 27(11):1248–1257. doi:10.1080/07373930903267187

León K, Mery D, Pedreschi F, León J (2006) Color measurement in L* a* b* units from RGB digital images. Food Res Int 39(10):1084–1091. doi:10.1016/j.foodres.2006.03.006

Marques GR, Borges SV, Botrel DA, Costa JMG, Silva EK, Corrêa JLG (2014a) Spray drying of green corn pulp. Dry Technol 32(7):861–868. doi:10.1080/07373937.2013.873452

Marques GR, Borges SV, Mendonça KS, Fernandes RVB, Menezes EGT (2014b) Application of maltodextrin in green corn extract powder production. Powder Technol 263:89–95. doi:10.1016/j.powtec.2014.05.001

Montgomery DC (2001) Desing and analysis of experiments. Wiley, New York

Myers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments. Wiley, New York

Nelson DL, Cox MM (2012) Lehninger—principles of biochemistry. Freeman, New York

Noordin MY, Venkatesh VV, Sharif S, Elting S, Abdullah A (2004) Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J Mater Process Technol 145(1):46–58. doi:10.1016/S0924-0136(03)00861-6

Obon JM, Castellar MR, Alacid M, Fernández-López JA (2009) Production of a red–purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. J Food Eng 90(4):471–479. doi:10.1016/j.jfoodeng.2008.07.013

Quek SY, Chok NK, Swedlund P (2007) The physicochemical properties of spray-dried watermelon powders. Chem Eng Process 46(5):386–392. doi:10.1016/j.cep.2006.06.020

Rascón MP, Beristain C, Garcia H, Salgado M (2011) Carotenoid retention and storage stability of spray-dried encapsulated paprika oleoresin using gum Arabic and Soy protein isolate as wall materials. Food Sci Technol 44(2):549–557. doi:10.1016/j.lwt.2010.08.021

Ré M (1998) Microencapsulation by spray drying. Dry Technol 16(6):1195–1236. doi:10.1080/07373939808917460

Rodriguez-Amaya DB, Kimura M (2004) Harvestplus handbook for carotenoid analysis. Washington

Rodríguez-Jimenes GC, Páramo-Calderón DE, Wall-Martínez HA, Robles-Olvera VJ, Valerio-Alfaro G, García-Alvarado MA (2014) Effect of process variables on spray-dried garlic juice quality evaluated by multivariate statistic. Food Bioprocess Technol 7(8):2434–2442. doi:10.1007/s11947-014-1311-0

Sagar VR, Suresh Kumar P (2010) Recent advances in drying and dehydration of fruits and vegetables: a a review. J Food Sci Technol 47(1):15–26. doi:10.1007/s13197-010-0010-8

Tonon RV, Brabet C, Hubinger MD (2009) Influence of drying air temperature and carrier agent concentration on the physicochemical properties of açai juice powder. Ciênc Technol Aliment 29(2):444–450. doi:10.1590/S0101-20612009000200034

Yousefi S, Emam-Djomeh Z, Mousavi MS (2011) Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica Granatum L.). J Food Sci Technol 48(6):677–684. doi:10.1007/s13197-010-0195-x

Acknowledgements

The authors would like to thank CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico) for financial support (473898/2012-8).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pires, F.C.S., da Silva Pena, R. Optimization of spray drying process parameters for tucupi powder using the response surface methodology. J Food Sci Technol 54, 3459–3472 (2017). https://doi.org/10.1007/s13197-017-2803-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2803-5