Abstract

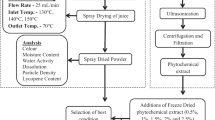

Hog plum juice powder was obtained from its juice under optimized condition by spray drying with juice: maltodextrin ratio at 2:1, 4:1 and 6:1 (v/w) basis. The inlet temperature and feed rate were varied between 120 to 175 °C and 8 to 14 mL/min. The effect of variables i.e. maltodextrin level, temperature and feed rate on the physicochemical properties and total phenolic content were studied. Moisture content, hygroscopicity, bulk density, water activity and total phenolic content of the powder were significantly affected by inlet temperature and maltodextrin level. However feed rate showed no any significant effect on the bulk density of the powder. An increase in inlet temperature and maltodextrin level reduced the total phenolic content in the spray dried powder. Morphological study showed that at high inlet temperature the spray dried powder were of smooth surfaces however, at low inlet temperature majority of the particles were of shrivelled surfaces. Spray dried hog plum juice powder made with 3.9:1 juice: maltodextrin, processed at 171 °C inlet temperature and at 8 mL/min feed rate had less hygroscopicity, water activity, moisture content and potent TPC content. Storage temperature significantly affected the TPC and DPPH free radical scavenging activity of the powder. Refrigeration temperature was found to be more effective to reduce the losses of TPC and DPPH free radical scavenging activity during storage. Colour acceptability of the refrigerated sample was comparatively more than to the sample stored at room temperature.

Similar content being viewed by others

References

Adewuyi A, Prasad SKB, Rao V, Oderinde AR (2010) Oil composition, mineral nutrient and fatty acid distribution in the lipid classes of underutilized oils of Trilepisium madagascariense and Antiaris Africana from Nigeria. Food Res Int 43(3):665–670

Allamila-Beltran L, Chanona-Perez LL, Jimenez-Aparicio AR, Gutierrez-Lopez GF (2005) Description of morphological changes of particles along spray drying. J Food Eng 67:179–184

Ames BN, Shigenaga MK, Hagen TM (1993) Oxidants, antioxidants and the degenerative diseases of aging. Proc Natl Acad Sci 90(8):7915–7922

Bas D, Boyaci IH (2007) Modelling and optimization I: Usability of response surface methodology. J Food Engg 78(3):836–845

Cai YZ, Corke H (2000) Production and properties of spray dried Amaranthus betacyanin pigments. J Food Sci 65(6):1248–1252

Dib-Taxi CM, Menezes HC, Santos AB, Grosso CR (2003) Study of the microencapsulation of camu-camu (Myrciaria) juice. J Microencapsul 20(4):443–448

Duangmal K, Saicheau B, Sueeprasan S (2008) Colour evaluation of freeze dried roselle extract as natural food colorants in model system of a drink. LWT-Food Sci Technol 41(8):1437–1445

Gil-Izquierdo A, Riquelme MT, PorrasI Ferreres F (2004) Effect of rootstock and interstock grafted in lemon tree (Citrus limon (L) Burm) on the flavonoid content of lemon juice. J Agric Food Chem 52:324–331

Gonzalez-Molina E, Moreno DA, Garcia-Viguera C (2008) Aronia-enriched lemon juice: a new highly antioxidant beverage. J Agric Food Chem 56:1242–1246

Goula AM, Adamopoulous KG (2005) Stability of lycopene during spray drying of Roselle extracts (Hibiscus sabdariffa L.). Plant Foods Human Nutr 64(1):62–67

Goula AM, Adamopoulous KG (2008) Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. Powder properties. Dry Technol 26(6):725–737

Grabowski JA, Truong VD, Daubert CR (2006) Spray drying of amylase hydrolyzed sweet potato puree and physiochemical properties of powder. J Food Sci 71(5):E209–E217

Kha CT, Nguyen HM, Roach DP (2010) Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordicacochinchinensis) fruit aril powder. J Food Eng 98:385–392

Kim EHJ, Chen D (2009) Pearce surface composition of industrial spray-dried milk powders 2. Effects of spray drying conditions on the surface composition. J Food Eng 94(2):169–181

Kritikar KR, Basu BD (1975) Indian medicinal plants, M/S Bishen Singh, Mahendra Pal Singh. In: International book distributors, vol I, pp 672–675. Dehradun

Kwapinska M, Zbicinski I (2005) Prediction of final product properties after concurrent spray drying. Dry Technol 23:1653–1665

Luo W, Zhao M, Yang B, Ren J, Shen G, Rao G (2012) Antioxidant and antiproliferative capacities of phenolics purified from Phyllanthus emblica L. fruit. Food Chem 126:277–282

Mahanta RK, Rout SD, Sahu HK (2006) Ethnomedicinal plant resources of Similipal Biosphere Reserve, Orissa, India. Zoo’s Print J 21(8):2372–2374

Mishra P, Mishra S, Mahanta CL (2014) Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod Process 92(3):252–258

Mishra P, Rai GK, Mahanta CL (2015) Process standardization for development od spray dried lemon juice powder and optimization of amla lemon based RTS (ready to serve drink) using response surface methodology. J Food Process Preserv 39:1216–1228

Murakamia A, Jiwajindab S, Koshimizuc K, Ohigashia H (1995) Screening for in vitro anti-tumor promoting activities of edible plants from Thailand. Cancer Lett 95:139–146

Nijdam JJ, Langrish TAJ (2006) The effect of surface composition on the functional properties of milk powders. J Food Eng 77(4):919–925

Quek SY, Chok NK, Swedland P (2007) The physicochemical properties of spray dried watermelon powders. Chem Eng Process 46(5):386–392

Ranganna S (1986) Handbook of analysis and quality control for fruits and vegetable products, 2nd edn. Tata McGraw Hill Publ Co., New Delhi

Righetto AM, Netto FM (2005) Effect of encapsulating materials on water sorption glass transition and stability of juice from immature acerola. Int J Food Prop 8(2):337–346

Rodriguez-Hernandez GR, Gonzalez-Garcia R, Grazales-Lagunes A, Ruiz-Cabrera MA, Abud-Archila M (2005) Spray drying of cactus pear juice (Opuntia streptacantha): effect on the physicochemical properties of the powder and reconstituted product. Dry Technol 23(4):955–973

Sagar VR, Kumar PS (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–26

Solvol KM, Sundarajan S, Alfaro L, Sathivel S (2012) Development of cantaloupe (Cucumismelo) juice powder using spray drying technology. LWT-Food Sci Technol 46:287–293

Thimmmaiah SR (2012) Standard methods of biochemical analysis. Kalyani Publishers, New Delhi

Tonon RV, Brabet C, Hubinger MD (2008) Influence of process conditions on the physicochemical properties of açai (Euterpeoleraceae Mart.) powder produced by spray drying. J Food Eng 88(3):411–418

Walton DE (2000) The morphology of spray-dried particles. A qualitative view. Dry Technol 18:1943–1986

Yousefi S, Emam-Djomeh Z, Mousavi SM (2011) Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica Granatum L.). J Food Sci Technol 48(6):677–684

Acknowledgements

Author is very thankful to Dr. S.K., Chauhan, Centre of Food Technology University of Allahabad, India, for his valuable guidance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mishra, P., Brahma, A. & Seth, D. Physicochemical, functionality and storage stability of hog plum (Spondia pinnata) juice powder produced by spray drying. J Food Sci Technol 54, 1052–1061 (2017). https://doi.org/10.1007/s13197-017-2531-x

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2531-x