Abstract

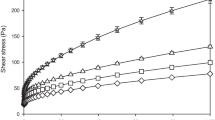

The effect of oil concentration (57.50, 58.75, 60.00 and 61.25 %) and temperature (5, 10 and 15 ºC) on steady shear rheological properties of O/W model system meat emulsions were investigated. The effect of temperature and oil concentration was modeled using power law and exponential type functions. The meat emulsions showed non-Newtonian flow behavior because flow behavior index was lower than unity. Consistency coefficient and flow behavior index values of O/W model system meat emulsions were calculated using Oswald de Waele model with higher coefficients of determination. Apparent viscosities of emulsions at a specified shear rate (50 s−1) were in the range of 0.652–0.941 Pa s. Increasing oil concentration provided an increase in apparent viscosity and increase in temperature levels resulted a decrease in consistency coefficient values. The exponential function performed better than the power-law function (R 2 > 0.922) in terms of describing the effect of oil concentration on the steady shear rheological properties of the model system meat emulsions. Higher coefficients of determination (R 2 = 0.979–0.999) were observed in exponential-type function compared to a power law function (R 2 = 0.880–0.946).

Similar content being viewed by others

Abbreviations

- a 1 :

-

constant [dimensionless] for concentration effect

- a 2 :

-

constant [(%)−1] for concentration effect

- A 1 :

-

constant for a fixed temperature [(%)−1]

- A 2 :

-

constant for a fixed temperature [kJ mol−1]

- B 1 :

-

constant for a fixed temperature [dimensionless]

- B 2 :

-

constant for a fixed temperature [(%)−1]

- C :

-

concentration [(%)−1]

- D 1 :

-

constant for combined effect [(%)−1]

- D 2 :

-

constant for combined effect [dimensionless]

- E a :

-

activation energy [kJ mol−1]

- EF :

-

modeling efficiency

- K :

-

consistency coefficient [Pa sn]

- n :

-

flow behavior index [dimensionless]

- η 50 :

-

apparent viscosity at 50 s−1 [Pa s]

- N:

-

number of data points

- nu :

-

number of model parameters

- η 0 :

-

constant for Arrhenius equation [Pa s]

- η 1 :

-

constant for concentration effect [Pa s]

- η 2 :

-

constant for concentration effect [Pa s]

- η 3 :

-

constant for combined effect [Pa s]

- η 4 :

-

constant for combined effect [Pa s]

- MBE :

-

mean bias error

- MPE :

-

mean percentage error

- R :

-

universal gas constant [kJ mol−1 K−1]

- R 2 :

-

coefficient of determination

- RMSE :

-

root mean square error

- T :

-

temperature (ºC)

- \( {x}_{{}_{\exp, \mathrm{i}}} \) :

-

experimental values

- \( {x}_{{}_{\exp, \mathrm{ave}}} \) :

-

average of experimental values

- \( {x}_{{}_{\mathrm{pre},\mathrm{i}}} \) :

-

predicted values

- χ 2 :

-

chi-square

- \( \dot{\gamma} \) :

-

shear rate [s−1]

- η :

-

apparent viscosity [Pa s]

- σ :

-

shear stress [Pa]

References

Arslan E, Yener M, Esin A (2005) Rheological characterization of tahin/pekmez (sesame paste/concentrated grape juice) blends. J Food Eng 69:167–172

Barnes HA (1994) Rheology of emulsions - A review. Colloids and Surfaces A. Physicochem Eng Asp 91:89–95

Carballo J, Barreto G, Colmenero FJ (1995) Starch and egg white lnfluence on properties of bologna sausage as related to fat content. J Food Sci 60:673–677

Constenla D, Lozano J, Crapiste G (1989) Thermophysical properties of clarified apple juice as a function of concentration and temperature. J Food Sci 54:663–668

Foegeding EA (1988) Gelation in meat batters. In: Reciprocal Meat Conference Proceedings, vol. 41. American Meat Science Association, 44–47

Gökalp HY, Yetim H, Selçuk N, Zorba Ö (1990) Et emülsiyonları ve bu emülsiyonların model sistemde çalıştırılması. Gida 15:21–27

Hassan B, Hobani A (1998) Flow properties of Roselle (Hibiscus sabdariffa L.) extract. J Food Eng 35:459–470

Hughes E, Cofrades S, Troy D (1997) Effects of fat level, oat fibre and carrageenan on frankfurters formulated with 5, 12 and 30 % fat. Meat Sci 45:273–281

Ibanoglu S (1998) Ibanoglu E (1998) Rheological characterization of some traditional Turkish soups. J Food Eng 35:251–256

Ibarz A, Vicente M, Graell J (1987) Rheological behaviour of apple juice and pear juice and their concentrates. J Food Eng 6:257–267

Karakaya M (1990) Farkli Tur Organ Etlerinin Bitkisel ve Degisik Hayvansal Yaglar ile Olusturdukları Emulsiyonlarin Cesitli Ozelliklerinin Model Sistemde Arastirilmasi. In Graduate School of Natural and Applied Sciences. Ataturk Univeristy, Erzurum, p 60

Karakaya M, Gökalp HY (1991) Farklı tür etlerin bitkisel ve değişik hayvansal yağlar ile oluşturdukları emülsiyonların çeşitli özelliklerinin model sistemde araştırılması. II. International Food Symposium, Bursa, pp 383–397

Karaman S, Yilmaz MT, Dogan M, Yetim H, Kayacier A (2011) Dynamic oscillatory shear properties of O/W model system meat emulsions: Linear viscoelastic analysis for effect of temperature and oil concentration on protein network formation. J Food Eng 107:241–252

Lorenzo G, Zaritzky N, Califano A (2008) Modeling rheological properties of low-in-fat O/W emulsions stabilized with xanthan/guar mixtures. Food Res Int 41:487–494

Partal P, Guerrero A, Berjano M, Gallegos C (1997) Influence of concentration and temperature on the flow behavior of oil-in-water emulsions stabilized by sucrose palmitate. J Am Oil Chem Soc 74:1203–1212

Pietrasik Z, Duda Z (2000) Effect of fat content and soy protein/carrageenan mix on the quality characteristics of comminuted, scalded sausages. Meat Sci 56:181–188

Quintana J, Lorenzo G, Zaritzky N, Califano A, Lupano C (2007) Hydrocolloids as O/W emulsion stabilizers: effect of the structural features during storage. In: Lupano CE (ed) Functional Properties of Food Components. Research Signpost, Kerala, pp 1–22

Rao M, Cooley H, Vitali A (1984) Flow properties of concentrated juices at low temperatures. Food Technol 38:113–119

Rao M, Tattiyakul J (1999) Granule size and rheological behavior of heated tapioca starch dispersions. Carbohyd Polym 38:123–132

Rezler R, Poliszko S, Dolata W, Piotrowska E (2003) Dynamic-mechanical and thermal analysis of the hydro-colloidal phase in model meat emulsions with the addition of pea cellulose. Acta Agrophisic 2:417–424

Rezler R, Piotrowska E, Dolata W, Wojciechowski M (2007) Effect of the substitution of meat by a protein preparation on the rheological properties of finely-comminuted sausage force meats. Acta Agrophisic 9:221–231

Saravacos G (1970) Effect of temperature on viscosity of fruit juices and purees. J Food Sci 3:122–125

Saricoban C, Özalp B, Yilmaz MT, Özen G, Karakaya M, Akbulut M (2008) Characteristics of meat emulsion systems as influenced by different levels of lemon albedo. Meat Sci 80:599–606

Saricoban C, Yilmaz MT, Karakaya M, Tiske SS (2010) The effect of different levels of sunflower head pith addition on the properties of model system emulsions prepared from fresh and frozen beef. Meat Sci 84:186–195

Smith D (1988) Meat proteins: Functional properties in comminuted meat products. Food Technol 42:116–121

Togrul H, Arslan N (2004) Mathematical model for prediction of apparent viscosity of molasses. J Food Eng 62:281–289

Tuncturk Y, Zorba O (2006) The effects of enzymatic hydrolysis of casein on apparent yield stress and some emulsion properties. Food Hydrocolloid 20:475–482

Yilmaz MT, Karaman S, Dogan M, Yetim H, Kayacier A (2012) Characterization of O/W model system meat emulsions using shear creep and creep recovery tests based on mechanical simulation models and their correlation with texture profile analysis (TPA) parameters. J Food Eng 108:327–336

Yoo SS, Kook SH, Park SY, Shim JH, Chin KB (2007) Physicochemical characteristics, textural properties and volatile compounds in comminuted sausages as affected by various fat levels and fat replacers. Int J Food Sci Technol 42:1114–1122

Zorba O (2006) The effects of the amount of emulsified oil on the emulsion stability and viscosity of myofibrillar proteins. Food Hydrocolloid 20:698–702

Zorba O, Kurt S, Genccelep H (2005) The effects of different levels of skim milk powder and whey powder on apparent yield stress and density of different meat emulsions. Food Hydrocolloid 19:149–155

Zorba O, Kurt S (2006) Optimization of emulsion characteristics of beef, chicken and turkey meat mixtures in model system using mixture design. Meat Sci 73:611–618

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karaman, S., Yilmaz, M.T., Kayacier, A. et al. Steady shear rheological characteristics of model system meat emulsions: Power law and exponential type models to describe effect of corn oil concentration. J Food Sci Technol 52, 3851–3858 (2015). https://doi.org/10.1007/s13197-014-1434-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-014-1434-3