Abstract

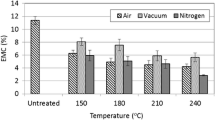

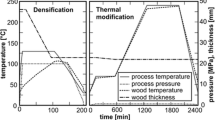

Plantation grown Hevea brasiliensis (rubberwood)—a tropical wood species of low natural durability was thermally processed at four temperatures in the range of 150–240 °C for different durations under vacuum. Effect of heat treatments on various important physical and mechanical properties such as weight loss, density, flexural strength (modulus of rupture—MOR), stiffness (modulus of elasticity—MOE), compressive strengths and surface hardness as well as decay resistance were evaluated and compared with untreated wood. The weight loss due to heat treatments was found to be in the range of 1.0–14.6%. Density and flexural MOR were found to decrease with increasing temperature (up to 210 °C), while flexural MOE, compressive strengths and hardness were not much affected. Higher treatment temperatures (210–240 °C) were observed to have deleterious effect on the mechanical strength of wood. Heat treated rubberwood showed excellent durability against brown rot (Polyporus meliae) and white rot (Coriolus versicolor) fungi as evidenced by lower amount of weight loss of exposed samples. The decay resistance was found to increase with severity of treatments. Based on improved durability and moderate variations in mechanical properties due to relatively mild heat treatments (180–210 °C), thermally modified rubberwood is found to be suitable for certain nonstructural applications. Moreover, heat-treated rubberwood may also be considered as an ecological alternative to chemically impregnated wood which offers many potential and attractive opportunities to the timber processing and product industry for commercial market.

Similar content being viewed by others

References

Akyildiz MH, Ates S, Ozdemir H (2009) Technological and chemical properties of heattreated Anatolian black pine wood. J Biotechnol 8(11):2565–2572

Anonymous (1986) IS:1708 Indian standard for ‘Methods of testing small clear specimens’. Bureau of Indian Standards, New Delhi

Anonymous (2003) ThermoWood handbook. Finnish Thermo-wood Association, Wood Focus Oy, PO Box 284 (Snellmaninkatu 13), FIN-00171 Helsinki, Finland

Anonymous (2008a) IS:4873 Indian standard specification for “methods of laboratory testing of wood preservatives against fungi and borers (powder post beetles): part 1 determination of threshold values of wood preservatives against fungi”. Bureau of Indian Standards, New Delhi

Anonymous (2008b) Promotion of rubberwood processing technology in the Asia-Pacific region. In: Zhao Y (ed) Proceedings of ITTO/CFC international rubberwood workshop, December 8–10, Haikou, China

Ayrilmis N, Jarusombuti S, Fueangvivat V, Bauchongkol P (2011) Effects of thermal treatment of rubberwood fibres on physical and mechanical properties of medium density fibreboard. J Trop For Sci 23(1):10–16

Bekhta P, Niemz P (2005) Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 57(5):539–546

Bilgin I, Beram A (2017) Effects of industrial heat treatment on some physical and mechanical properties of Iroko wood. Drvna Industrija 68(5):229–239

Bruno ME, Pereira HM (2009) Wood modification by heat treatment—a review. BioResources 4(1):370–404

Esteves B, Velez-Marques A, Domingos I, Pereira H (2008) Heat-induced colour changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 42(5):369–384

Gonzalez-Pena MM (2012) Improvement of the biological performance and dimensional stability of two tropical woods. Paper presented in 43rd IRG annual meeting, Kuala Lumpur, Malaysia, 6–10 May, IRG/WP 12-40605. The International Research Group on Wood Protection, Stockholm, Sweden

Gunduz G, Korkut S, Korkut DS (2008) The effects of heat treatment on physical and technological properties and surface roughness of Camiyani Black Pine (Pinus nigra Arn subsp pallasiana var pallasiana) wood. Biores Technol 99(7):2275–2280

Gunduz G, Korkut S, Aydemir D, Bekar I (2009) The density, compression strength and surface hardness of heat treated hornbeam (Carpinus betulus) wood. Maderas Ciencia T Tecnología 11(1):61–70

Guntekin E, Yilmaz AT, Uner B (2017) Physical, mechanical and bonding performance of Calabrian pine (Pinus brutia Ten.) as influenced by heat treatment. Drvna Industrija 68(2):99–108

Hill CAS (2006) Wood modification—chemical, thermal and other processes. Wiley, Chichester, p 239

Hodgin DA, Lee AWC (2002) Comparison of strength properties and failure characteristics between fire-retardant-treated and untreated roofing lumber after long-term exposure: a South Carolina case study. For Prod J 52(6):91–94

Hofmann T, Retfalvi T, Albert L, Niemz P (2008) Investigation of the chemical changes in the structure of wood thermally modified within a nitrogen atmosphere autoclave. Wood Res 53(3):1–14

Jusoh I, Kamdem DP (2001) Laboratory evaluation of natural decay resistance and efficacy of CCA-treated rubberwood. Holzforschung 55:250–254

Kamdem DP, Pizzi A, Jermanaud A (2002) Durability of heat-treated wood. Holz Roh Werkstoff 60(1):1–6

Killmann W, Hong LT (2000) Rubberwood-t he success of an agricultural by-product. Unasylva 51(201):66–72

Kim GH, Yun KE, Kim JJ (1998) Effect of heat treatment on the decay resistance and the bending properties of radiata pine sapwood. Mater Org 32(2):101–108

Kocaefe D, Huang X, Kocaefe Y (2015) Dimensional stabilization of wood. Curr For Rep. https://doi.org/10.1007/s40725-015-0017-5

Kubojima Y, Okano T, Ohta M (2000) Bending strength and toughness of heat-treated wood. J Wood Sci 46(1):8–15

Metsa-Kortelainen S, Viitanen H (2010) Effect of fungal exposure on the strength of thermally modified Norway spruce and Scots pine. Wood Mater Sci Eng 1:13–23

Muhammed S, Musgrave OC, Petty JA (2009) Impregnation of rubberwood and other Malaysian timbers with copper naphthenate and trimethyl borate. J Trop For Sci 21(4):345–352

Naji HR, Sahri MH, Nobuchi T, Bakar ES (2011) The effect of growth rate on wood density and anatomical characteristics of Rubberwood (Hevea brasiliensis Muell Arg) in two different clonal trails. J Natl Prod Plant Resour 1(2):71–80

Niemz P, Hofmann T, Retfalvi T (2010) Investigation of chemical changes in the structure of thermally modified wood. Maderas-Ciencia Y Tecnologia 12(2):69–78

Pfriem A, Wagenführ A (2007) Influence of thermally modification of spruce to unsteady-state sorption processes and wood moisture-dependent elasticity. In: Proceedings third European conference on wood modification, 15–16th October, Cardiff, UK, pp 367–373

Ratnasingam J, Grohmann R (2015) Super heated steam application to optimize the kiln drying of rubberwood (Hevea brasiliensis). Eur J Wood Wood Prod 73(3):407–409

Rep G, Pohleven F (2001) Wood modification–a promising method for wood preservation. Drvna Industrija 52(2):71–76

Rowell RM, Banks WB (1985) Water repellency and dimensional stability of wood. Gen. Tech. Rep. FPL-50. Madison, WI, U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, p 24

Sandberg D, Kunter A (2016) Thermally modified timber- recent developments in Europe and North America. Wood Fiber Sci 48(1):1–12

Santos JA (2000) Mechanical behavior of Eucalyptus wood modified by heat. Wood Sci Technol 34(1):39–43

Schneid E, Cademartori PHG, Darci G (2014) The effect of thermal treatment on physical and mechanical properties of Lueheadivaricata hardwood. Maderas Ciencia Y Tecnologia 16(4):413–422

Severo ETD, Calonego FW, Sansígolo CA, Bond B (2016) Changes in the chemical composition and decay resistance of thermally-modified Hevea brasiliensis wood. PLoS ONE 11(3):e0151353. https://doi.org/10.1371/journalpone0151353

Shukla SR, Sharma SK (2014) Effect of high temperature processing under different environments on physical and surface properties of rubberwood (Hevea brasiliensis). J Ind Acad Wood Sci 11(2):182–189

Sundqvist B, Karlsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40(7):549–561

Winandy JE, Lebow PK (2001) Modelling strength loss in wood by chemical composition. Part I. An individual component model for southern pine. Wood Fiber Sci 33:39–254

Windeisen E, Wegener G (2008) Behaviour of lignin during thermal treatments of wood. Ind Crops Prod 27(2):157–162

Acknowledgements

The authors are thankful to the Director and the Group Coordinator (Research), Institute of Wood Science and Technology, Bangalore for their keen interest in the research work. Thanks are also to Mrs. G. Vijaylaksmi, Forest and Wood Protection Division of this Institute for her help in carrying out the fungus tests. Valuable technical support from the staff of WPEW Division, IWST in testing of wood samples is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, S.R., Sharma, S.K. Effect of high temperature treatment of Hevea brasiliensis on density, strength properties and resistance to fungal decay. J Indian Acad Wood Sci 15, 87–95 (2018). https://doi.org/10.1007/s13196-018-0213-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13196-018-0213-6